Variable emissivity and variable reflectivity electrochromic intelligent thermal control coating and preparation method

An electrochromic and thermal control coating technology, applied in chemical instruments and methods, layered products, synthetic resin layered products, etc., can solve the problems of less research on changes in reflectivity and emissivity of intelligent thermal control coatings, etc. Achieve the effect of meeting the needs of intelligent thermal control, degrading the potential barrier, and short response time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

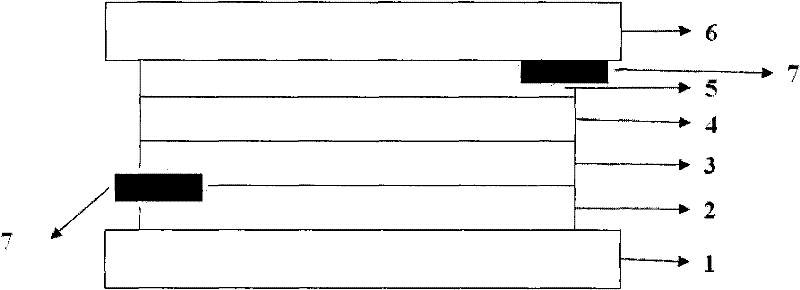

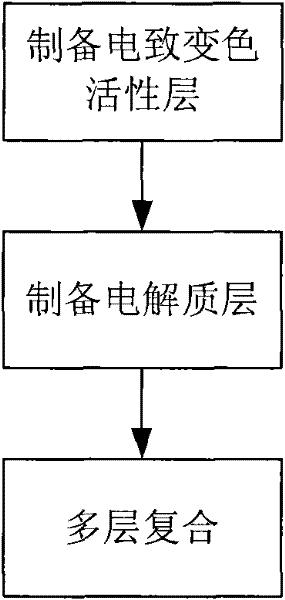

Method used

Image

Examples

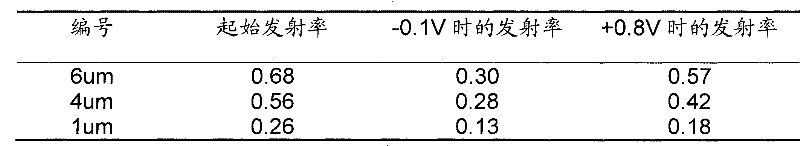

Embodiment 1

[0052] Prepare 50ml of sulfuric acid mixed solution of aniline and diphenylamine (20:80 in molar ratio) with a concentration of 0.5M, add 100ml of 0.1M potassium salt of polytoluenesulfonate, and gold-plate the polyolefin porous battery diaphragm (4cm×4cm) as the substrate, Pt as the counter electrode, saturated Ag / AgCl - As a reference electrode, a constant voltage of 0.8v was deposited for 40 minutes to prepare an electrochromic layer of about 6um. Dissolve 10g of polyacrylonitrile and 10g of lithium trifluoromethanesulfonate in a mixed solution of dimethyl carbonate and acetone, prepare a 0.1M mixed solution, and spray it on a glass substrate coated with a gold electrode 2 to obtain an electrolyte layer 3. The electrochromic coating of glass / gold / lithium trifluoromethanesulfonate (polyacrylonitrile) / polyolefin support layer / polyaniline / gold auxiliary electrode / polyester is prepared by multilayer composite method. Applying a positive voltage of 2v, the coating changes from...

Embodiment 2

[0054] Dissolve polyaniline, a soluble conductive polymer solution, in solvents such as m-cresol and methylpyrrolidone, and prepare a 0.1M solution, add 0.01M camphorsulfonic acid, grind and disperse evenly, and spray a 2.8um electrodeposited film on the porous gold support layer. Color-changing active layer; mix 10g polyvinylidene fluoride, 20g perchloric acid, 5g [emim]BF 4 Dissolve in a mixed solution of dimethyl carbonate and tetrahydrofuran, prepare a 0.2M mixed solution, spray on the surface of the gold-plated polyimide film, and solidify to obtain the electrolyte layer 3 . The electrochromic coating of polyimide / gold / perchloric acid (polyvinylidene fluoride) / porous gold film / polyaniline / gold auxiliary electrode / polyethylene is prepared by multilayer composite method. Apply 1.2v, -0.8v voltage, the device changes from dark green to golden, and then dark green. At the same time, the emissivity changes from 0.46 to 0.07, and then to 0.4. Solar Spectral Reflectance change...

Embodiment 3

[0056] Add 100ml of 0.2M lithium perchlorate to 50ml of sulfuric acid mixed solution with a concentration of 0.1M 3,4-ethylenedioxythiophene, use gold-plated aluminum oxide porous membrane as substrate, Pt as counter electrode, saturated Ag / AgCl - As a reference electrode, a constant voltage of 0.8v was deposited for 120min to prepare a 5um electrochromic layer. 10 g of polyvinylidene fluoride and 10 g of lithium perchlorate were dissolved in a mixed solution of dimethyl carbonate and acetone to prepare a 0.1 M mixed solution, which was sprayed on the surface of gold-plated polyimide and cured to obtain an electrolyte layer 3 . Polyimide / gold / lithium perchlorate (polyvinylidene fluoride) / aluminum oxide support layer / poly(ethylenedioxythiophene) / gold auxiliary electrode / polyethylene electrode was prepared by multilayer composite method. Photochromic coating. Applying a positive voltage of 1.8v, the coating changes from dark blue to light blue, the emissivity changes from 0.46 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical conductivity | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com