Transparent conductive film, preparation method thereof, application and photoelectric device containing transparent conductive film

A technology of transparent conductive film and optoelectronic devices, which is applied in the manufacture of conductive/semiconductive layer equipment, electrical components, cable/conductor manufacturing, etc., and can solve problems such as difficult current flow, difficulty in applying optoelectronic products, and opaque conductive film

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

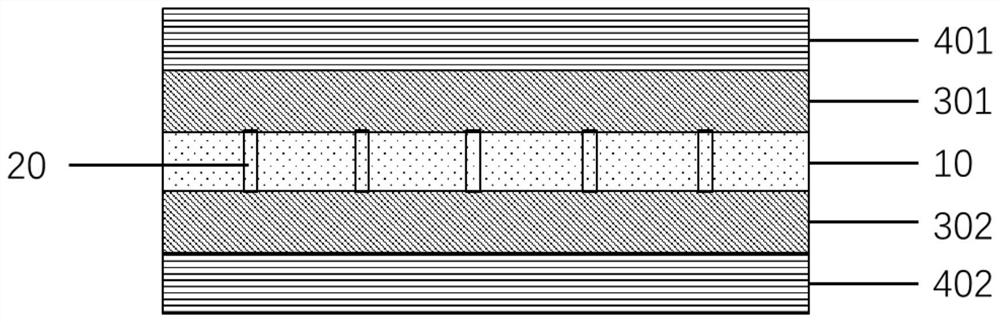

[0092] figure 1 It is a schematic cross-sectional structure diagram of the transparent conductive film of Example 1. The transparent conductive film successively includes: a first hardened layer 401, a first conductive film layer 301, a transparent substrate layer 10, a second conductive film layer 302, and a second hardened layer 401 stacked on each other, the transparent substrate layer Through holes 20 are distributed on 10 .

[0093] The preparation method of transparent conductive film is as follows:

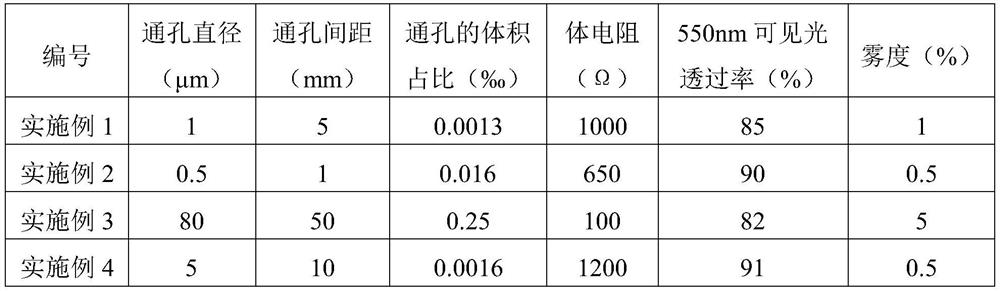

[0094] (1) First, the silver metal is embossed on the surface of the transparent PVC film 10, and the PVC film is pressed through to form a silver metal conductive channel 20 with a diameter of 1 μm, and the distance between the center points of two adjacent silver metal conductive channels is controlled to be 5mm. The volume ratio of the conductive channel to the transparent PVC film is 0.0013‰;

[0095] (2) Then, both sides of the PVC film are coated with silver nanowi...

Embodiment 2

[0098] The preparation method of transparent conductive film is as follows:

[0099] (1) First, use a laser puncher to prepare a through hole with a pore diameter of 0.5 μm on the surface of the transparent PC film, and control the distance between two adjacent holes and the center point of the hole to be 1mm, and the volume ratio of the through hole to the transparent PC film 0.016‰;

[0100] (2) then fill polypyrrole in hole;

[0101] (3) Finally, AZO was magnetron sputtered on both sides of the transparent PC film to prepare a transparent conductive layer.

Embodiment 3

[0103] The preparation method of transparent conductive film is as follows:

[0104] (1) First, copper metal is embossed on the surface of the transparent PI film, and the PI film is pressed through to form a copper metal conductive channel with a diameter of 80 μm. The distance between the center points of two adjacent copper metal conductive channels is controlled to be 50 mm, and the copper metal conductive channel The volume ratio of the transparent PI film is 0.25‰;

[0105] (2) Coating copper nanowires on one side of the PI film to prepare a transparent conductive layer, and magnetron sputtering AZO on the other side of the PI film to prepare a transparent conductive layer;

[0106] (3) Finally, a hardened layer of polyurethane is coated on the surface of the copper nanowires to prevent the copper nanowires from being stripped or oxidized.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| electrical resistance | aaaaa | aaaaa |

| haze | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com