Method for controlling temperature of steelmaking melting pool of converter by blowing CO2 gas

A converter steelmaking, CO2-O2 technology, applied in the manufacture of converters and other directions, can solve the problems of difficult control, decreased dephosphorization rate, unstable dephosphorization, etc., to achieve diversification, improve dephosphorization efficiency, and flexibly control smelting Effect of Steel Cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

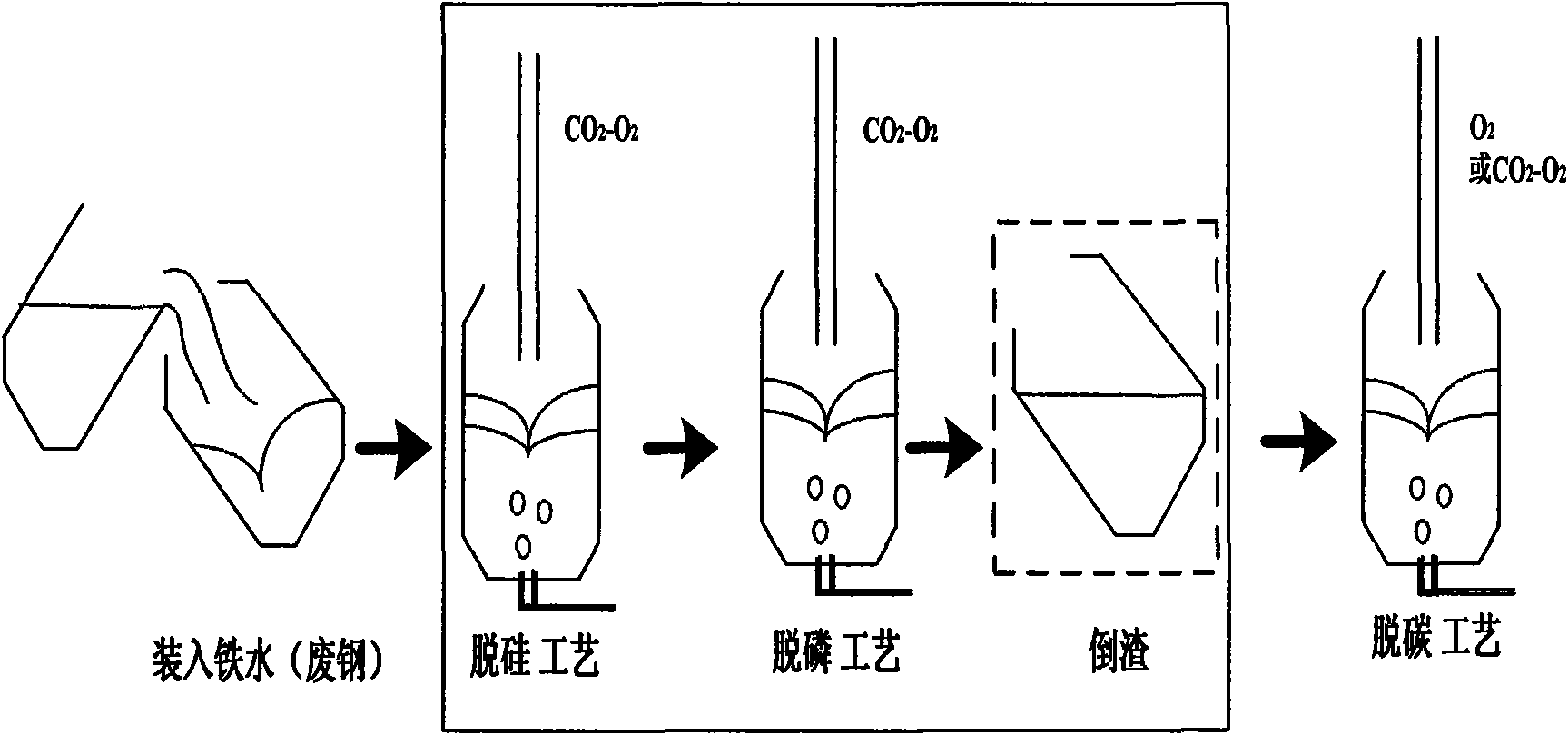

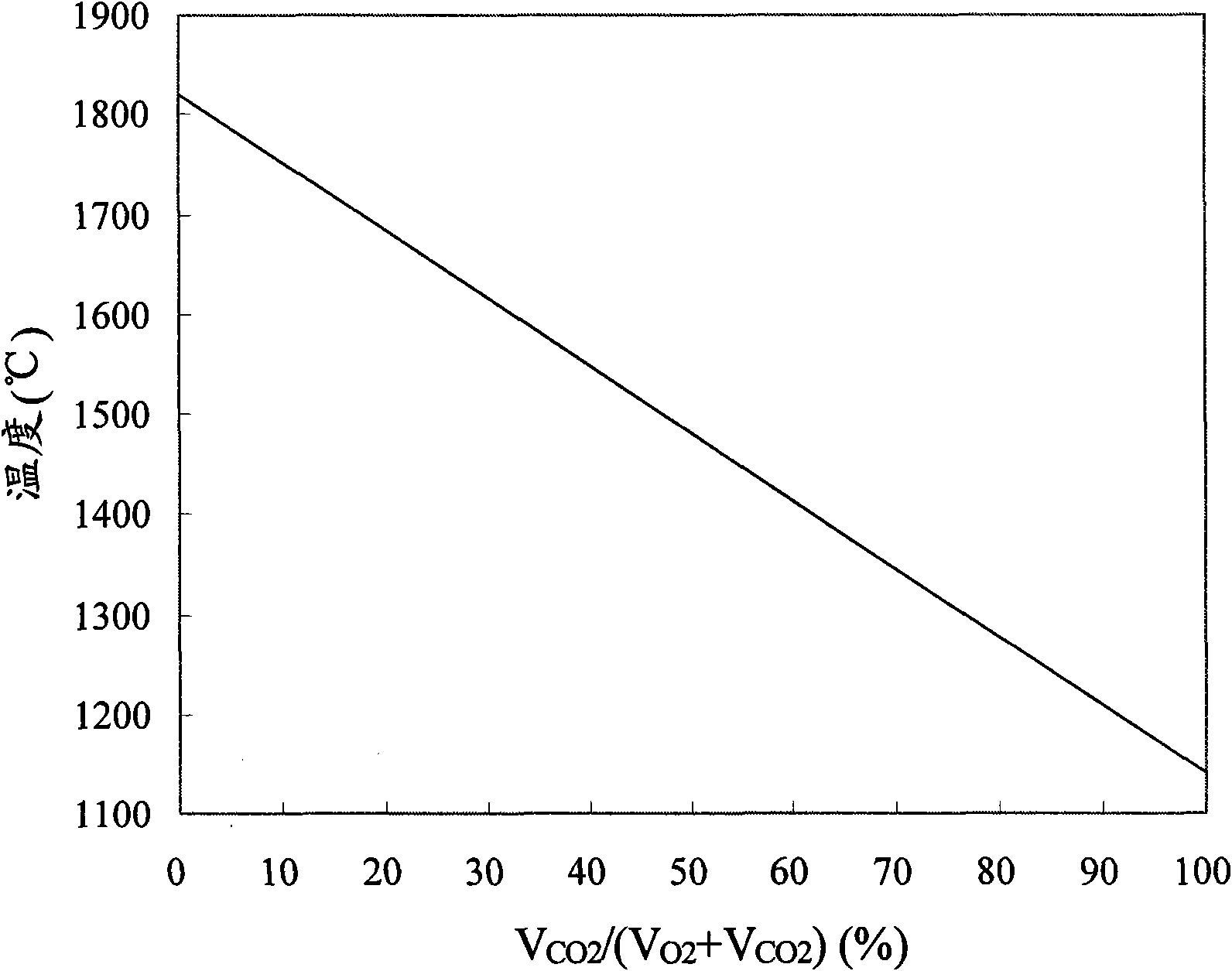

[0017] (1) Pour 28 tons of molten iron and 5 tons of steel scrap into the converter, the temperature of the molten iron is 1300°C, adjust V in the spray gun according to the composition of the molten pool (C, Si, Mn, P) CO2 / (V O2 +V CO2 ) ratio, the ratio range is 20% to 50%, and the gas flow rate is 6000 to 9000Nm 3 / h. After about 5 minutes of spraying, the desiliconization and dephosphorization are completed, and the decarburization period is entered;

[0018] (2) After entering the decarburization period, adjust V CO2 / (V O2 +V CO2 ) ratio, the gas flow rate is 7500~10000Nm 3 / h. Then take samples and measure temperature to prepare for tapping.

[0019] Table 133 ton converter smelting parameter comparison table

[0020] process

Embodiment 2

[0022] (1) Pour 135 tons of molten iron and 25 tons of steel scrap into the converter, the temperature of the molten iron is 1320°C, adjust V in the spray gun according to the composition of the molten pool (C, Si, Mn, P) CO2 / (V O2 +V CO2 ) ratio, the ratio range is 10% to 50%, and the gas flow rate is 24000 to 36000Nm 3 / h. After about 5 minutes of spraying, the slag is dumped, new slag is made, and the decarburization period is entered;

[0023] (2) After entering the decarburization period, adjust V CO2 / (V O2 +V CO2 ) ratio, the gas flow rate is 26000~36000Nm 3 / h, then sampling and temperature measurement, ready to tap.

[0024] Table 2160 ton converter smelting parameter comparison table

[0025] process

Embodiment 3

[0027] (1) Pour 110 tons of molten iron into the converter for full iron smelting. The temperature of the molten iron is 1290°C. Adjust the V in the spray gun according to the composition of the molten pool (C, Si, Mn, P). CO2 / (V O2 +V CO2 ) ratio, the ratio range is 15% to 60%, and the gas flow rate is 18000 to 28000Nm 3 / h. After about 5 minutes of spraying, the slag is dumped, new slag is made, and the decarburization period is entered;

[0028] (2) After entering the decarburization period, adjust V CO2 / (V O2 +V CO2 ) ratio, the gas flow rate is 21000~28000Nm 3 / h, then sampling and temperature measurement, ready to tap.

[0029] Table 3 Comparison table of smelting parameters of full molten iron converter

[0030] process

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com