Ultra-high strength thermoplastic elastomer and preparation method thereof

A thermoplastic elastomer and ultra-high-strength technology, applied in the field of biomass-based polymer materials, can solve the problems of poor mechanical properties of elastomers and unsatisfactory mechanical properties, and achieve excellent performance, excellent mechanical strength, and complete crystal orientation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Example 1 Preparation of Biomass-Based Functional Polyamide 1

[0037] The functional polyamide monomer 1 was prepared as follows: 100 g of methyl undecylenate and 1 g of 1,3-diamino-propanol were added to 4 ml of tetrahydrofuran. After passing argon for half an hour, place it in a 40°C oil bath, add 10ml of sodium methoxide, react at 40°C for 20 hours, and then recrystallize to obtain a white powdery solid, which is the hydroxyl amido monomer.

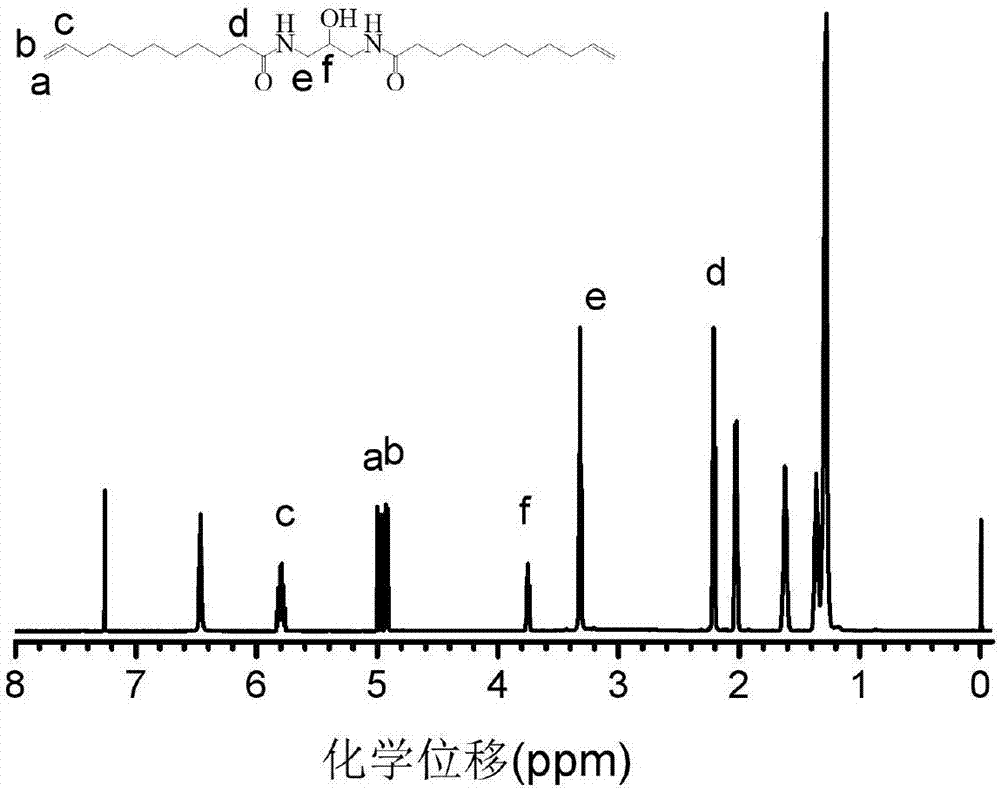

[0038] The 1HNMR spectrum of the functional polyamide monomer 1 is as follows figure 1 As shown, from the e peak at 3.38ppm and the f peak at 3.8 in the figure, it can be seen that the monomer contains amide groups and hydroxyl groups; at 4.85ppm, 5.0ppm and 5.8ppm, the three peaks a, b, and c show single The monomer contains a double bond, proving the successful preparation of functional polyamide monomer 1.

[0039] The structural formula of the functional polyamide monomer 1 is as follows:

[0040] where R 1 It is -OH ...

Embodiment 2

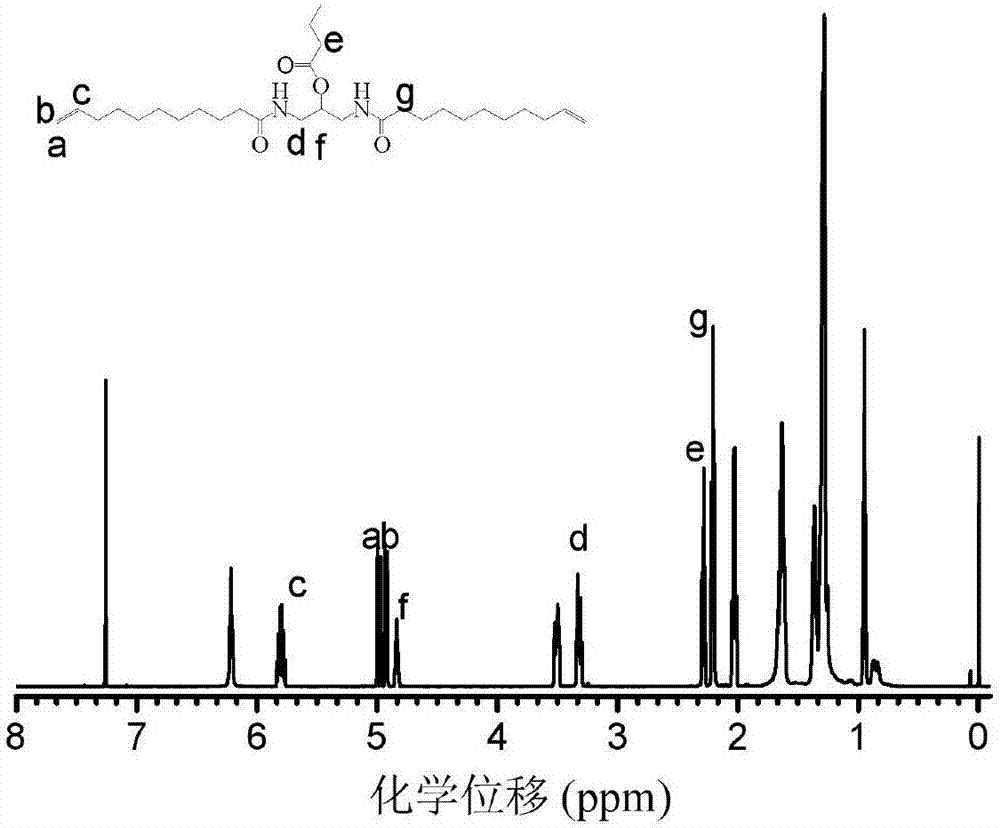

[0050] Example 2 Preparation of Biomass-Based Functional Polyamide 2

[0051] Biomass-based functional polyamide 2 was prepared as follows: the preparation method was the same as in Example 1, except that 1200 mg of functional polyamide monomer 2 and 300 mg of functional polyamide monomer 1 were added to obtain functional polyamide 2.

Embodiment 3

[0052] Example 3 Preparation of Biomass-Based Functional Polyamide 3

[0053] Biomass-based functional polyamide 3 was prepared as follows: the preparation method was the same as in Example 1, except that functional polyamide monomer 2 was added with a mass of 750 mg and functional polyamide monomer 1 with a weight of 750 mg to obtain functional polyamide 3.

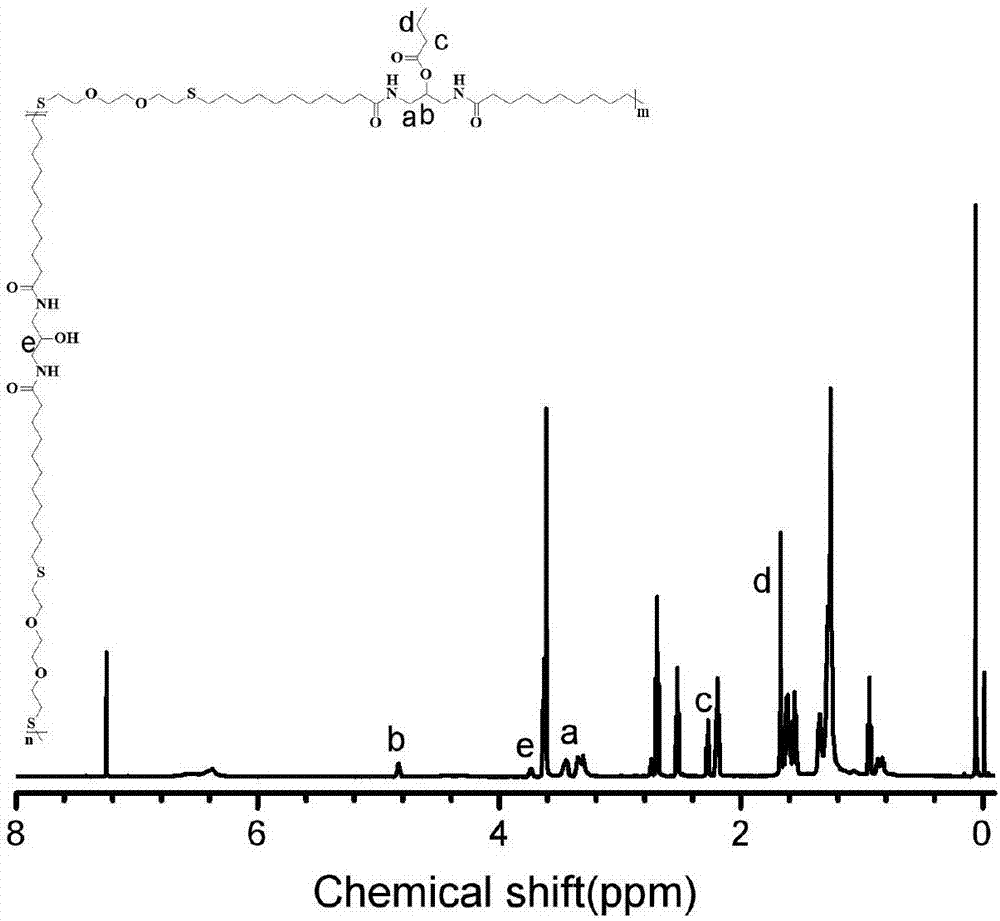

[0054] The H NMR spectrum of functional polyamide 3 is as image 3 shown, compared figure 1 , figure 2 , The peaks at 1.7ppm, 2.3ppm, 3.8ppm and 4.8ppm indicate that the copolymer of Example 3 has functional polyamide monomer 1 and functional polyamide monomer 2 at the same time. It shows that functional polyamide monomer 1 and functional polyamide monomer 2 can be copolymerized into functional polyamide by this method.

[0055] Figure 4 It is the atomic force microscope observation of functional polyamide 3, as can be seen from the figure that functional polyamide 3 contains a large amount of nanoscale crystals, i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elastic modulus | aaaaa | aaaaa |

| breaking strength | aaaaa | aaaaa |

| mechanical strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com