Patents

Literature

148results about How to "Uniform conductivity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Cathode material of lithium ion battery, preparation method of cathode, and lithium ion battery

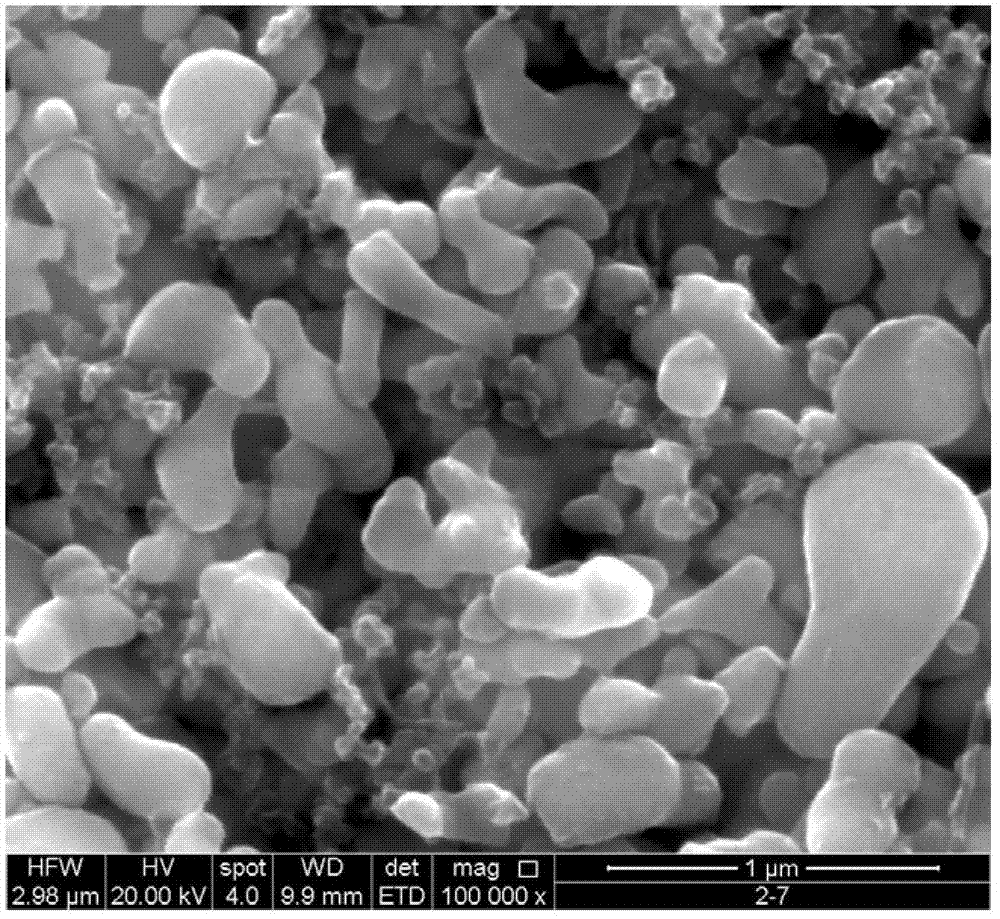

ActiveCN103199258APromote accumulationEvenly dispersedCell electrodesSecondary cellsSodium-ion batteryNano carbon

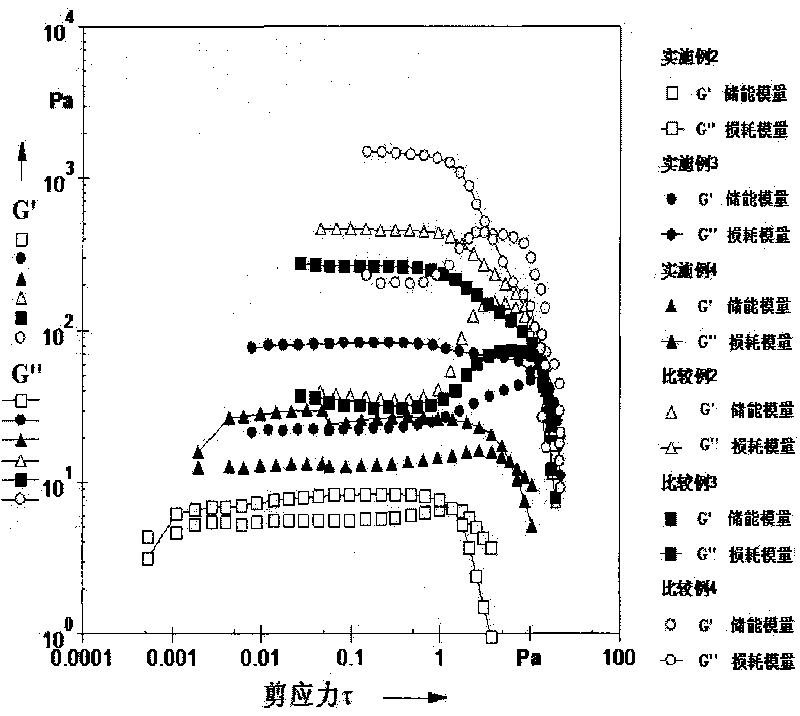

The invention discloses a cathode material of a lithium ion battery, a preparation method of the cathode, and the lithium ion battery using the cathode material, belonging to the technical field of energy material. According to the invention, a chemical dispersant is added into the cathode of an aqueous lithium-ion battery, thereby solving problems of uniform dispersion for active materials of positive electrode and a nano-carbon mixed conductive agent; and a mechanical dispersion method is combined, preferably with a revolution speed of the mechanical dispersion being 15-35 HZ and a rotation speed being 10-30 HZ, thereby realizing uniform dispersion of the nano-active substances in a relatively short time. The cathode material of a lithium ion battery and the preparation method provide technical approach for solving uniform dispersion of the aqueous nano-active substances, and are high in production efficiency and low in cost; the prepared battery is high in discharge capacity, and is significantly improved in low temperature, multiplying power and cycling performances; and a new approach is provided for a large scale application of the nanometer lithium batteries which are limited to a high cost and a high-polluting oil system in the field.

Owner:中创新航科技(江苏)有限公司

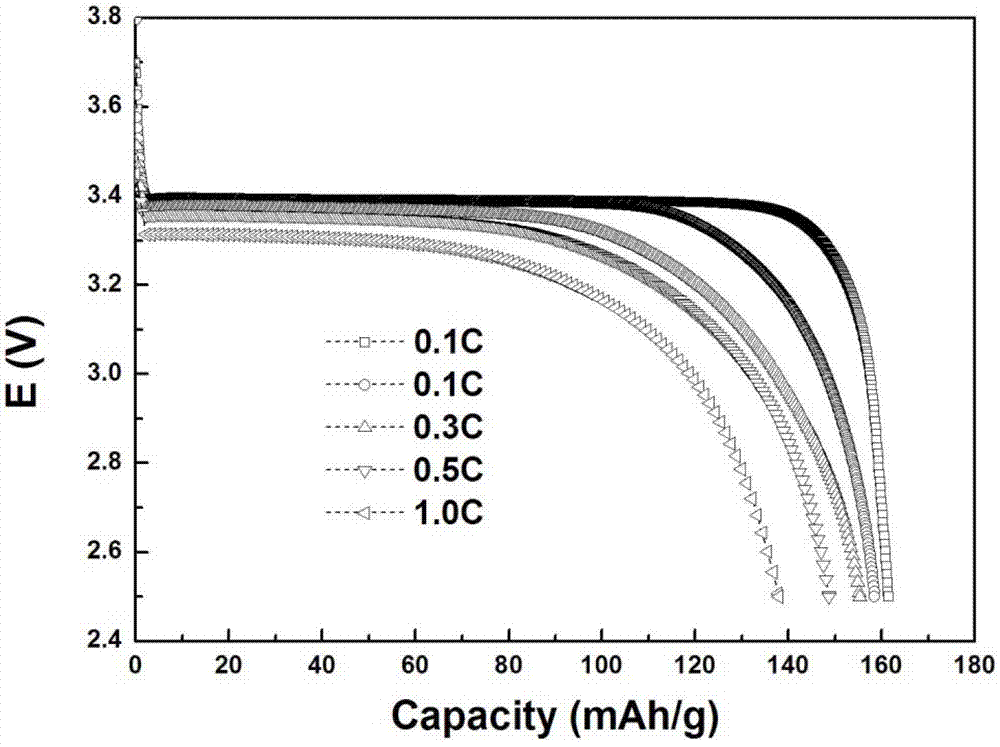

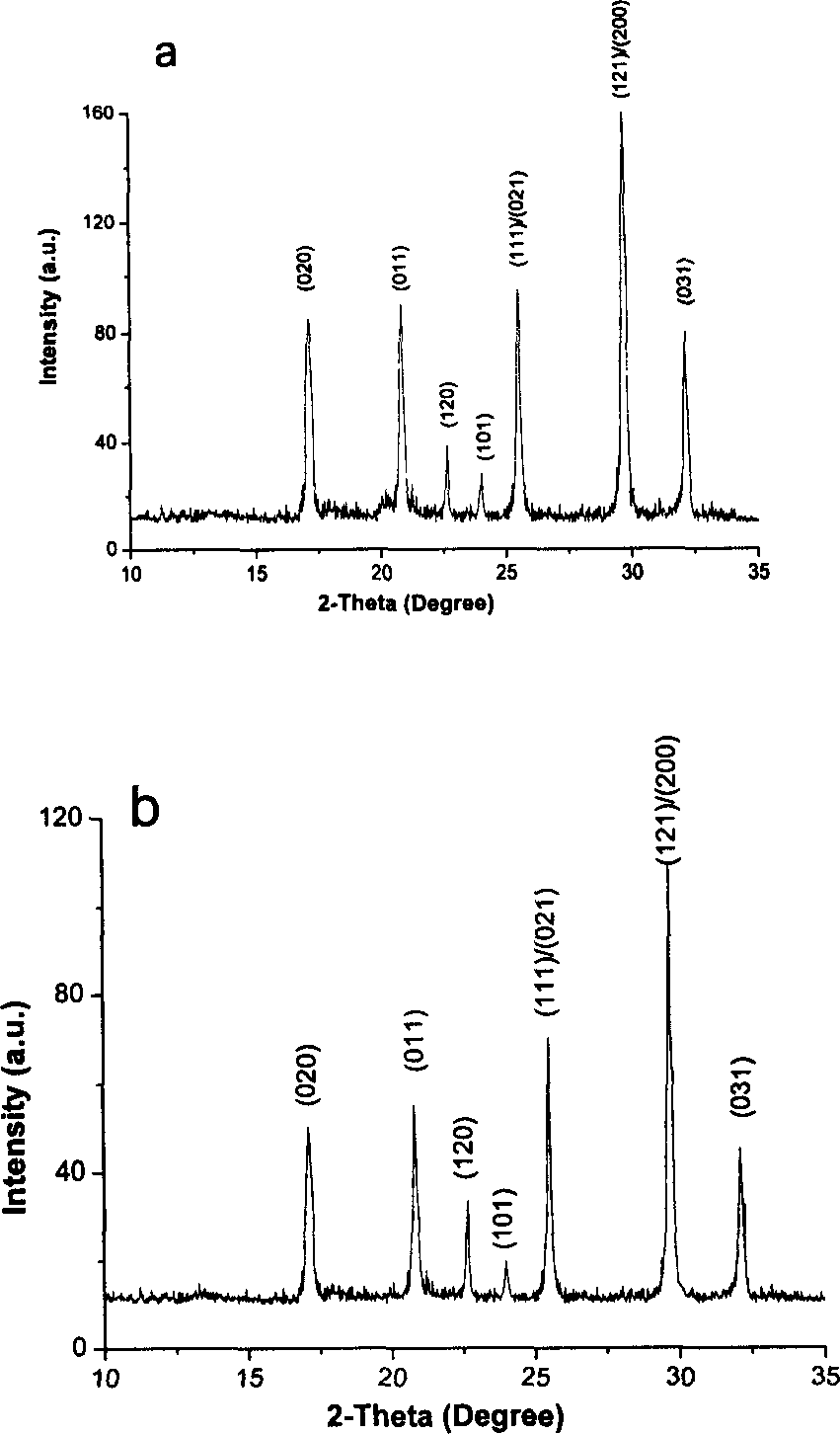

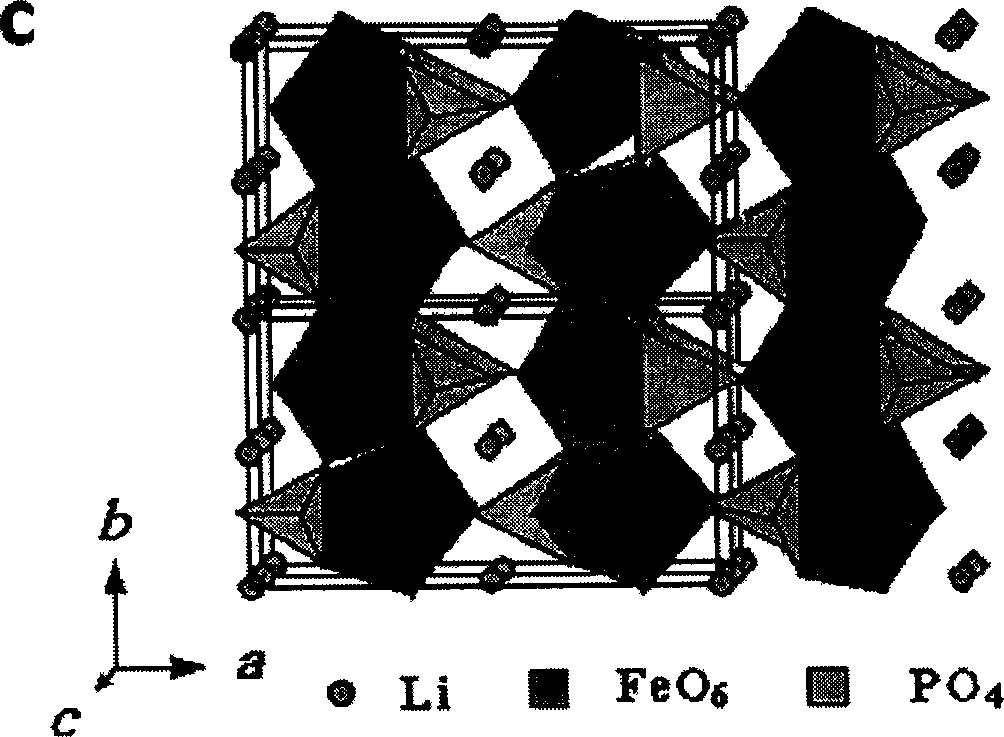

Ferrolithium phosphate and its compound metal phosphide electrode material and producing method thereof

InactiveCN1773754AProlong the fall timePromote growthCell electrodesPhosphorus compoundsLithium iron phosphateHigh density

An electrode material of Fe¿CLi phosphate and its composite metal phosphate is electrode material of LiFePO4 and LiFePO4 / MxP in high density spherical shape with diameter of 2micro m. The electrode material of LiFePO4 and LiFePO4 / MxP can be prepared by low ¿C temperature controllable one ¿C stage atomizing process in short flow.

Owner:NANKAI UNIV

Conductive agent dispersion liquid, electrode slurry, electrode, battery, and preparation methods thereof

InactiveCN101752548AEvenly dispersedSmall diameterElectrode manufacturing processesActive material electrodesSolubilityCapacitance

The invention discloses a conductive agent dispersion liquid and a preparation method thereof. The conductive agent dispersion liquid contains a conductive agent, a solvent and a dispersion agent, wherein the dispersion agent contains aromatic rings and can be bound with the surface of the conductive agent by Van der Waals force among molecules and pi-pi action force between planes; and the solubility in the first solvent at the temperature of 25 DEG C is not smaller than 10wt%. The invention also discloses an electrode slurry and a preparation method thereof, and a battery electrode prepared from the electrode slurry and a battery. As using the matter which contains the aromatic rings and can be bound with the surface of the conductive agent by Van der Waals force among molecules and pi-pi action force between planes as the dispersion agent of the conductive agent, the battery capacitance, the charging and discharging capacitance and the rate discharge property are effectively enhanced.

Owner:BYD CO LTD

Copper chromium zirconium alloy and preparing method thereof

A copper chromium zirconium alloy comprises, by weight, 0.7% to 2.0% of chromium, 0.05% to 0.3% of zirconium, 0.01% to 0.08% of magnesium, 0.01% to 0.1% of yttrium and the balance copper. The invention further provides a preparing method of the copper chromium zirconium alloy. The preparing method sequentially comprises the following steps that firstly, the copper, the chromium, the zirconium, the magnesium and the yttrium are prepared according to the proportion and are subject to vacuum purified smelting and flow dividing type casting, and a casting blank is prepared; secondly, the casting blank is subject to homogenization treatment and hot extrusion, and a sheared billet is prepared; thirdly, the sheared billet is subject to solid-solution treatment; fourthly, the sheared billet obtained after the solid-solution treatment is subject to cold deformation machining; and fifthly, a material obtained after cold deformation machining is subject to aging treatment, and the needed copper chromium zirconium alloy is obtained. The copper chromium zirconium alloy has the good comprehensive performance, the room temperature tensile strength of the copper chromium zirconium alloy is larger than 520 MPa, the room temperature elongation of the copper chromium zirconium alloy is larger than or equal to 22%, the room temperature electric conductivity of the copper chromium zirconium alloy is larger than or equal to 90%IACS, and the 350 DEG C high-temperature tensile strength of the copper chromium zirconium alloy is larger than 390 MPa.

Owner:SHANTOU HUAXING (RAOPING) COPPER IND CO LTD +1

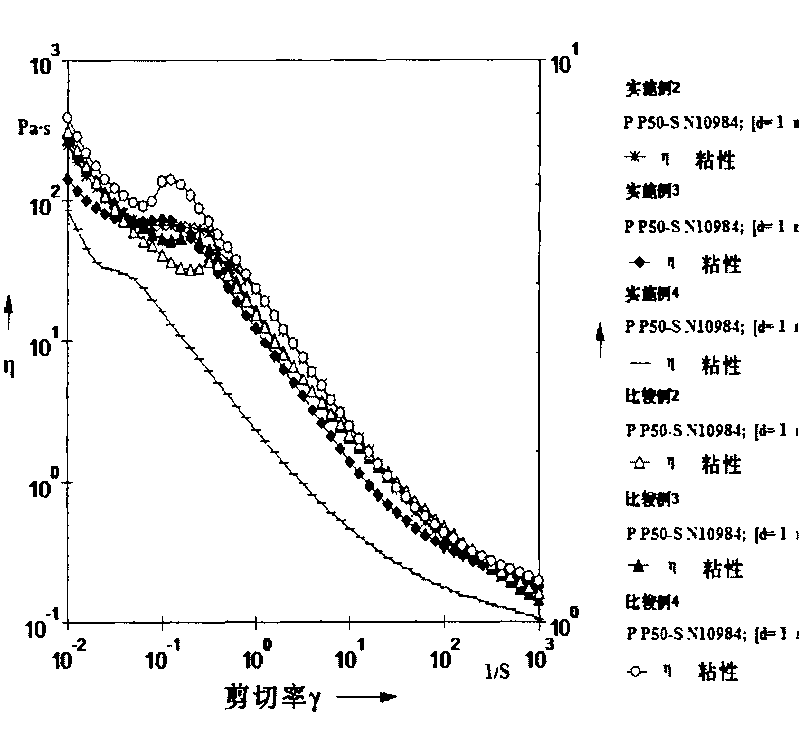

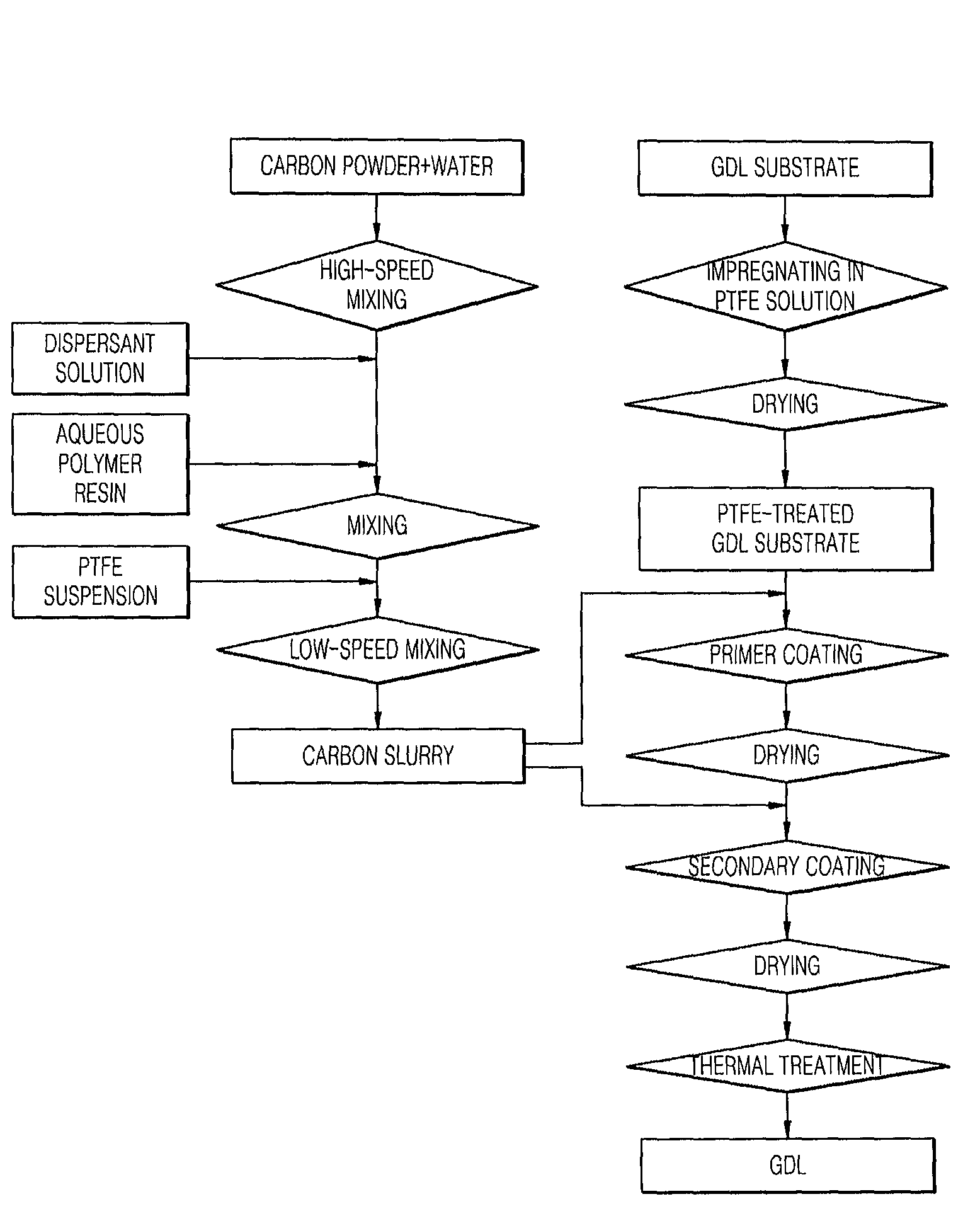

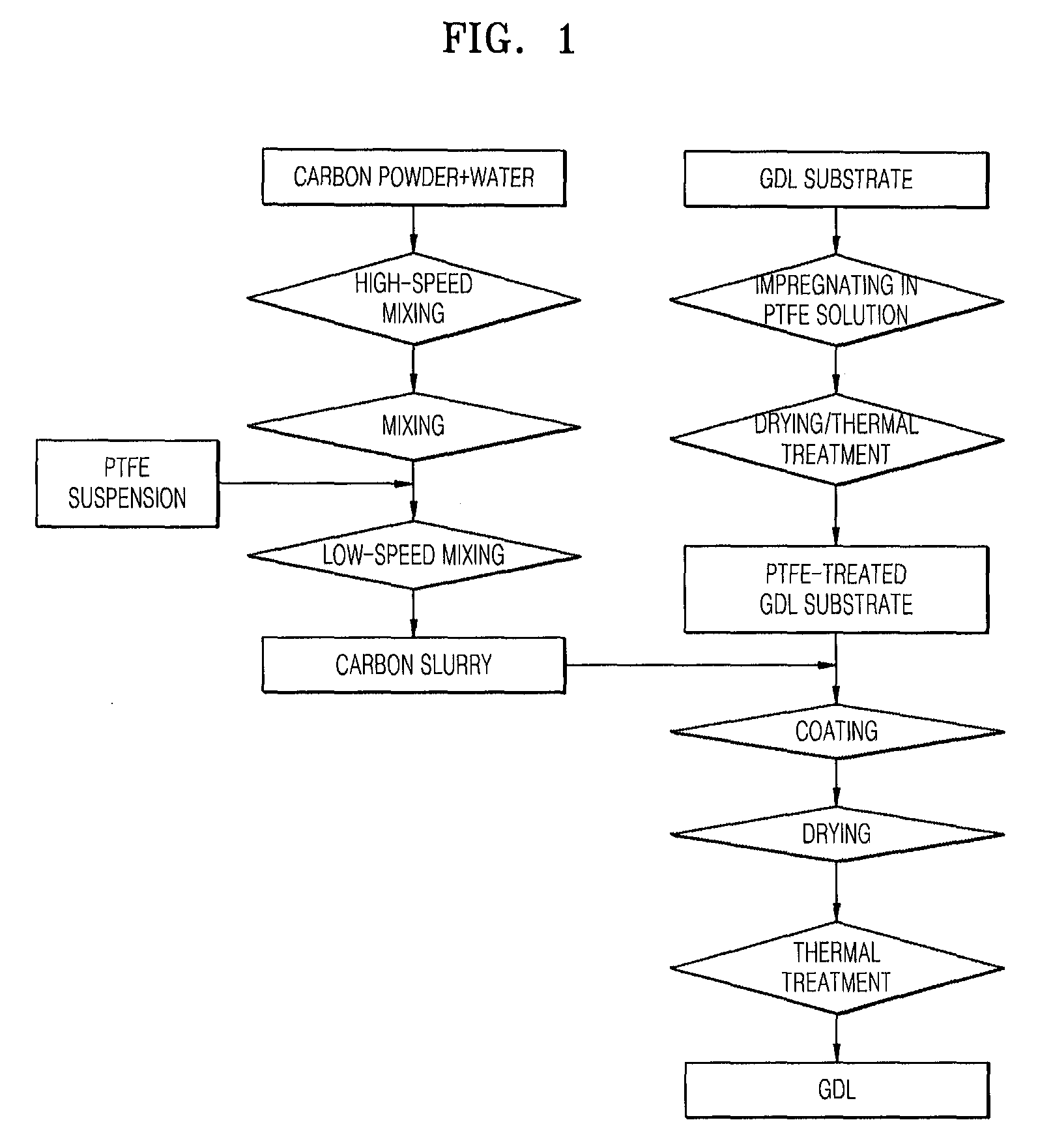

Preparation of Gas Diffusion Layer for Fuel Cell

InactiveUS20090011308A1Uniform electronic conductivityEffectively electrically connecting and electricallyApparel holdersElectrode manufacturing processesPorosityFuel cells

A common method of preparing a gas diffusion layer for a fuel cell has problems in that a microporous layer is impregnated into a substrate, thereby lowering the porosity of the substrate, and cracks are created on a surface of a gas diffusion layer prepared using the method. Provided is a method of reproducibly preparing a gas diffusion layer with a uniform thickness and no cracks based on the principle of a primer coating method, wherein a first microporous layer is hardly impregnated into a substrate and uniformly covers a surface of the substrate, and at least one microporous layer is further coated on the first microporous layer. Provided is also a fuel cell showing improved performance by enhancing utilization of a catalyst layer and guaranteeing a uniform diffusion of fuel and an efficient discharge of a product.

Owner:LEE EUN SOOK +7

Physical grounding resistance reducing agent

InactiveCN1472750AWill not pollutePhysical health hazardConductive materialElectrical resistance and conductanceSoil resistivity

The agent mainly consists of electrode graphite and cement, which is an ideal conduction material for earthing and has low resistivity for durative action and stability service. It can satisfy earthing protective requirements for various electric or microelectronic equipment with in quite long period under the various environmental conditions.

Owner:成都圣威电气有限公司

Preparation method of fibroin/graphene conductive fiber

ActiveCN104674362ANot easy to reuniteEasy to manufactureMonocomponent protein artificial filamentElectroconductive/antistatic filament manufactureFiberElectrospinning

The invention discloses a preparation method of fibroin / graphene conductive fiber. The preparation method comprises the following steps: mixing a graphene oxide solution and a fibroin solution, pouring a mixture into a polytetrafluoroethylene mould, drying to obtain a graphene oxide / fibroin compound membrane, putting the graphene oxide / fibroin compound membrane into a solvent, stirring till the graphene oxide / fibroin compound membrane is completely dissolved, performing ultrasonic treatment to obtain a spinning solution, putting the spinning solution into a container of electrostatic spinning equipment, performing high-voltage electric spinning to obtain composite fiber, and performing steam treatment to obtain the fibroin / graphene conductive fiber. The concentrations of fibroin and graphene in the fibroin / graphene conductive fiber prepared by the preparation method are high, so that the fibroin / graphene conductive fiber has good conductivity besides excellent wearability.

Owner:苏州欧尔迪威地暖科技有限公司

Reinforced electrolyte membrane for fuel cell, fuel cell membrane-electrode assembly, and solid polymer electrolyte fuel cell comprising the fuel cell membrane-electrode assembly

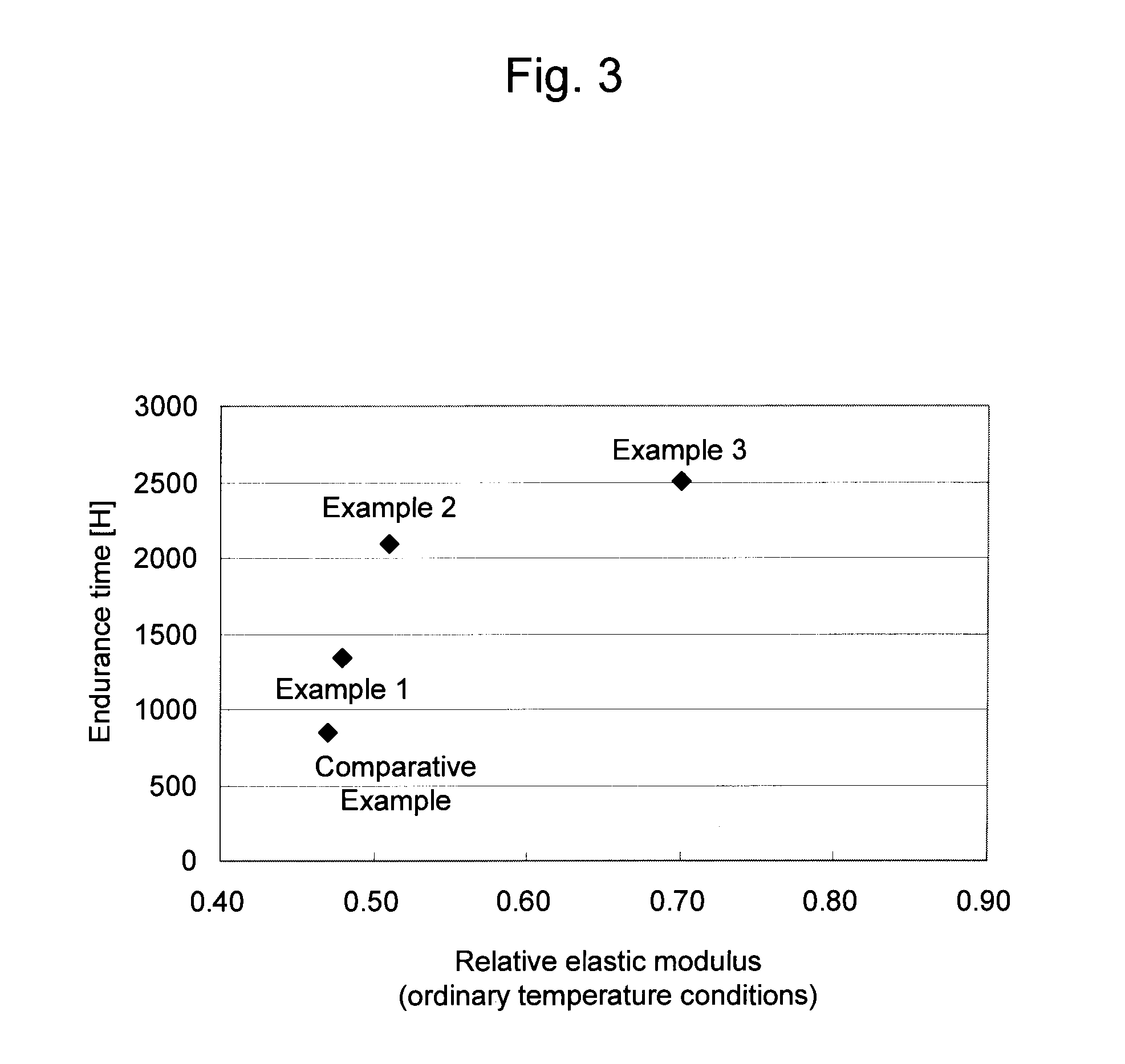

ActiveUS20110008708A1Increased durabilityReduced elution amountFinal product manufactureConductive materialPorous substratePolyelectrolyte

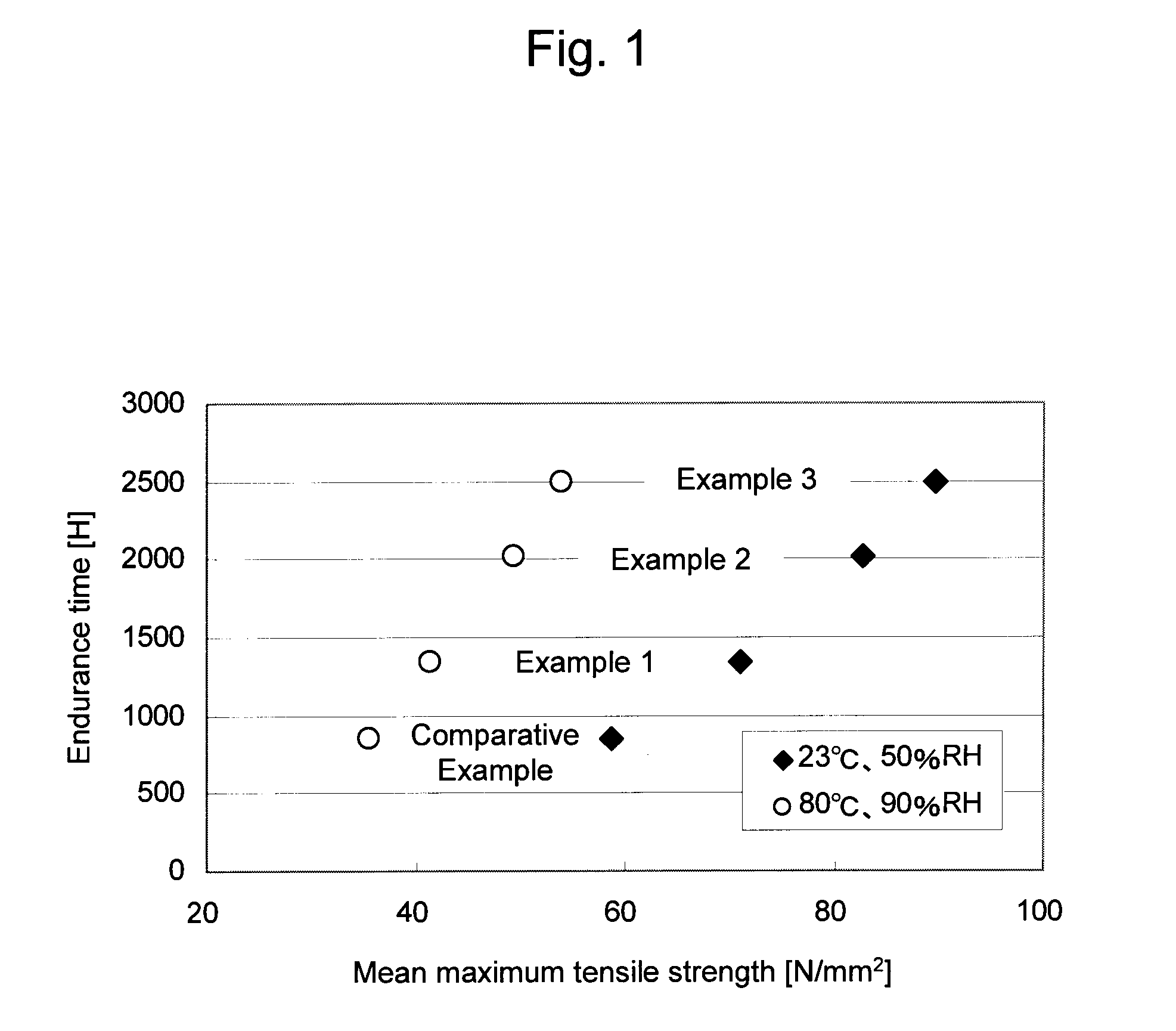

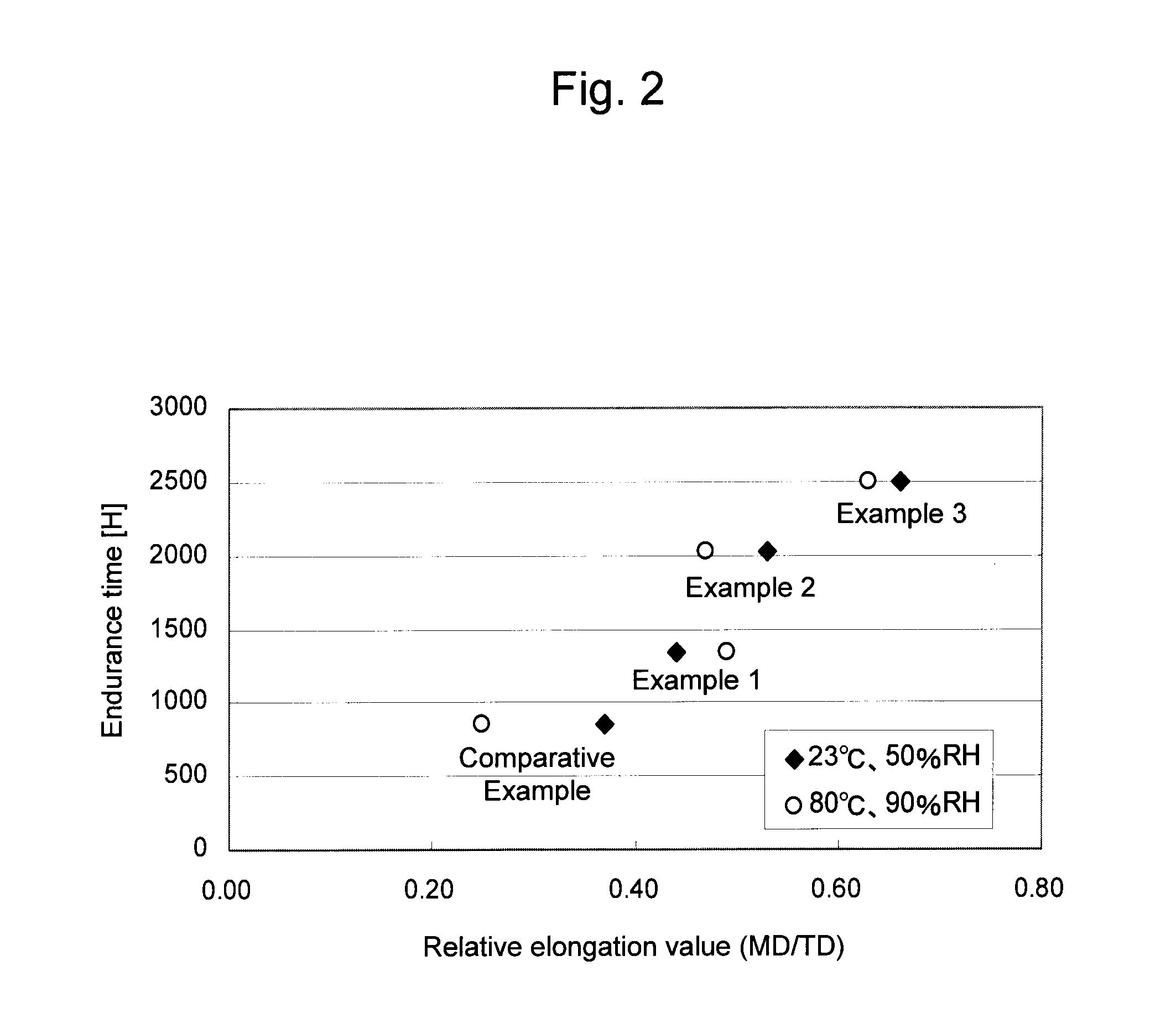

The present invention provides a reinforced electrolyte membrane for fuel cell comprising a porous substrate impregnated with a polyelectrolyte liquid dispersion, wherein either the maximum tensile strength in the machine direction (for sheet processing) (MD) or the maximum tensile strength in the transverse direction (TD; vertical to the MD direction) for the electrolyte membrane is 70 N / mm2 or more at 23° C. at a relative humidity of 50% or 40 N / mm2 or more at 80° C. at a relative humidity of 90%. This reinforced electrolyte membrane for fuel cell, in which the amount of fluorine ions eluted as a result of deterioration of electrolyte membrane components in particular is reduced, has excellent durability.

Owner:TOYOTA JIDOSHA KK +1

Making method for charcoal electrode of liquid flow type electroadsorption desalinization device

InactiveCN1544116AImprove conductivityHigh strengthIon-exchange process apparatusIon-exchanger regenerationFiberPorosity

The invention relates to a method of making carbon electrode of fluid electric-absorption desalter. It mainly mixes high specific surface area electrode carbon, nano carbon tube absorption material, carbon fiber, and nano carbon tube conductive material as well as adhesive polytetrafluoroethylene in a certain proportion and in a certain mode to make cold press molding and makes them into a double-faced electrode with a collector interlaid; the carbon electrode has good electric conductivity, small resistance, large electric capacity and low energy consumption; in addition, the modified carbon electrode has larger specific surface area and mesoporous porosity, therefore able to increase the absorption quantity of electrode to salt ions. The carbon electrode is especially applied to the fluid electric-absorption desalter and has higher desalting efficiency.

Owner:上海维安新材料研究中心有限公司 +1

Method for preparing metal/polyaniline/plastic composite film through electrochemical in-situ polymerization

ActiveCN102876037ASolve the difficulty of processingSolve defects such as low conductivityElectrolytic organic material coatingComposite filmConductive polymer

The invention discloses a method for preparing a metal / polyaniline / plastic composite film through electrochemical in-situ polymerization. The method comprises the following steps of: 1) preparing a polyaniline / plastic conductive composite film, namely performing electrooxidation polymerization of polyaniline in an aniline-acid solution by taking a plastic microporous film as a base film to obtain the polyaniline / plastic conductive composite plastic film, wherein the electric conductivity of the polyaniline / plastic conductive composite plastic film is 1 to 59.5S.cm<-1>; and 2) preparing a polyaniline / plastic / metal conductive composite film, namely electrodepositing silver on the surface of the polyaniline / plastic conductive composite film to obtain the polyaniline / plastic / metal conductive plastic composite film, wherein the electric conductivity of the polyaniline / plastic / metal conductive plastic composite film is 10<2> to 10<4>S.cm<-1>. The conductive plastic composite film prepared by the method has high electric conductivity and thermal stability and excellent mechanical properties, is high in performance price ratio and light in mass, realizes the organic combination of conductive polymers and metal particles, overcomes the unworkability of the polyaniline, and expands the application range of the conductive polymers. The method is simple and easy; and the obtained composite film can be used as a photoelectronic device, and is used for various fields such as detection and sensing, and electromagnetic shielding.

Owner:CENT SOUTH UNIV

Process for forming metal layers

InactiveUS7416763B2High level of smoothnessUniform conductivityLine/current collector detailsInsulating substrate metal adhesion improvementPlastic filmElectroplating

A process in which a base metal film is formed on the surface of a plastic film using a dry plating process, and a liquid containing an organic monomer is then brought in contact with the base metal film, thereby selectively forming a conductive organic polymer coating within any pinhole defects, and effectively filling the defects. A metal film is then formed on top of the base metal film using an electroplating process, thus forming a metal wet plating layer.

Owner:MITSUBISHI SHINDOH CO LTD +1

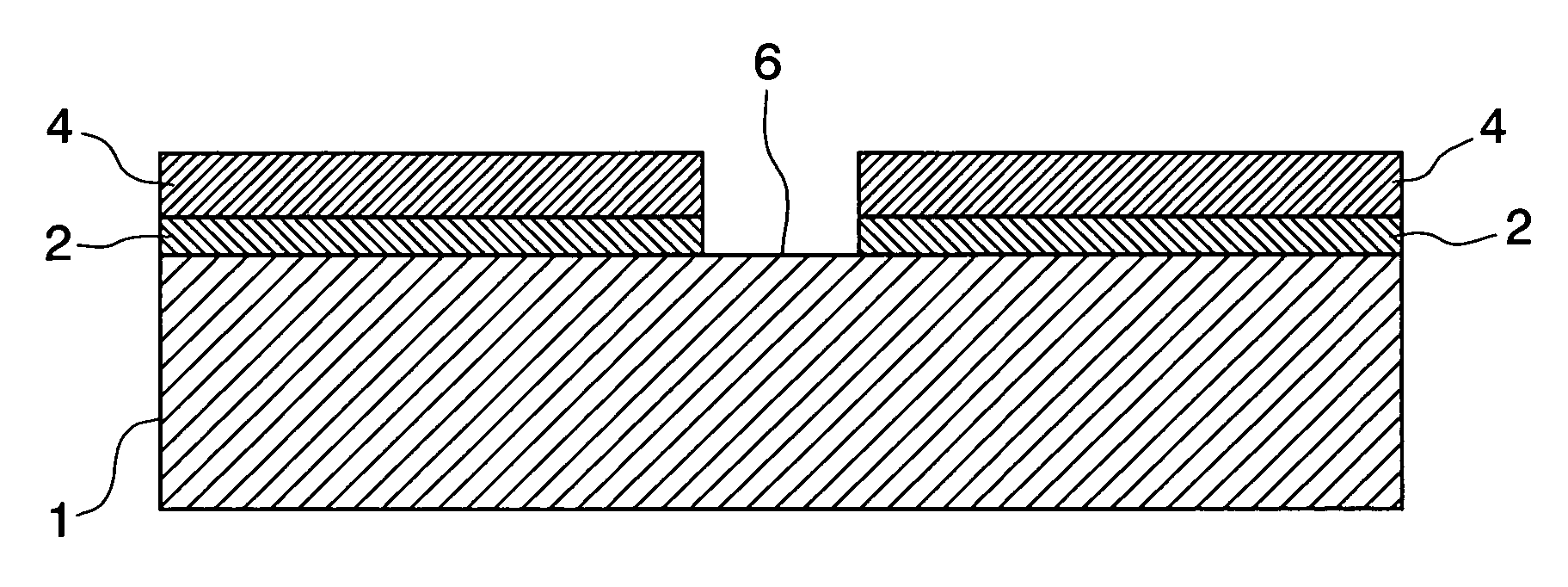

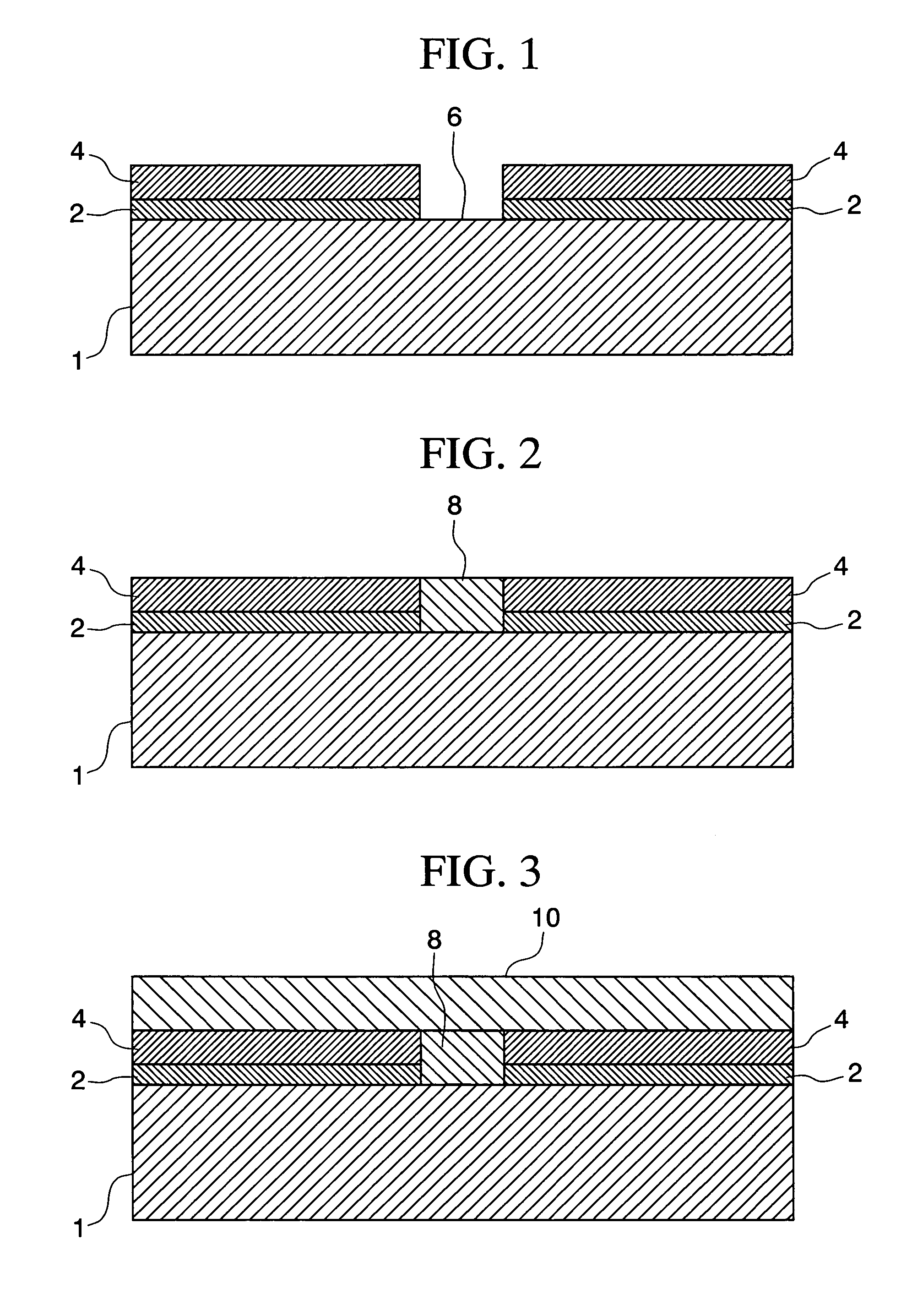

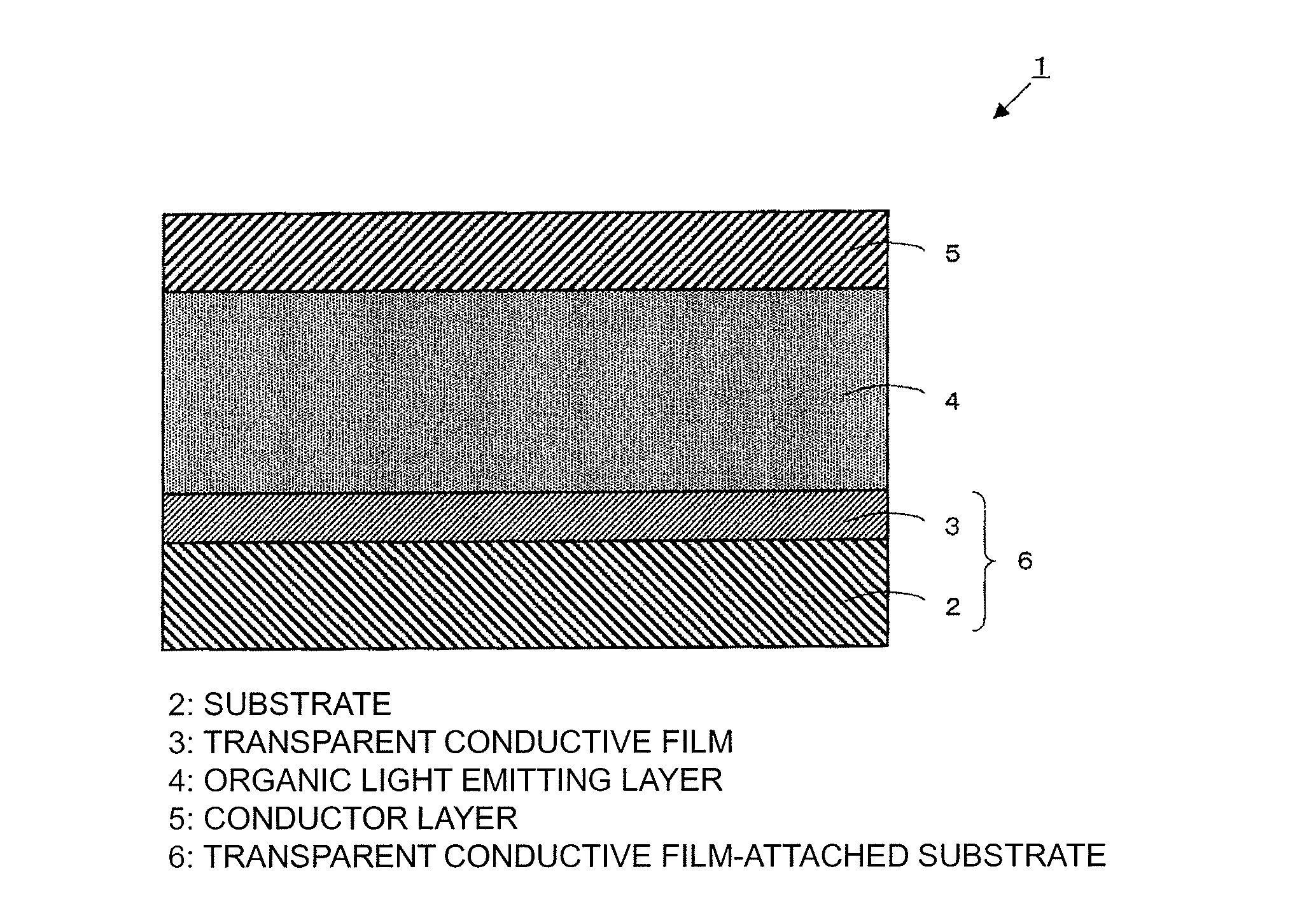

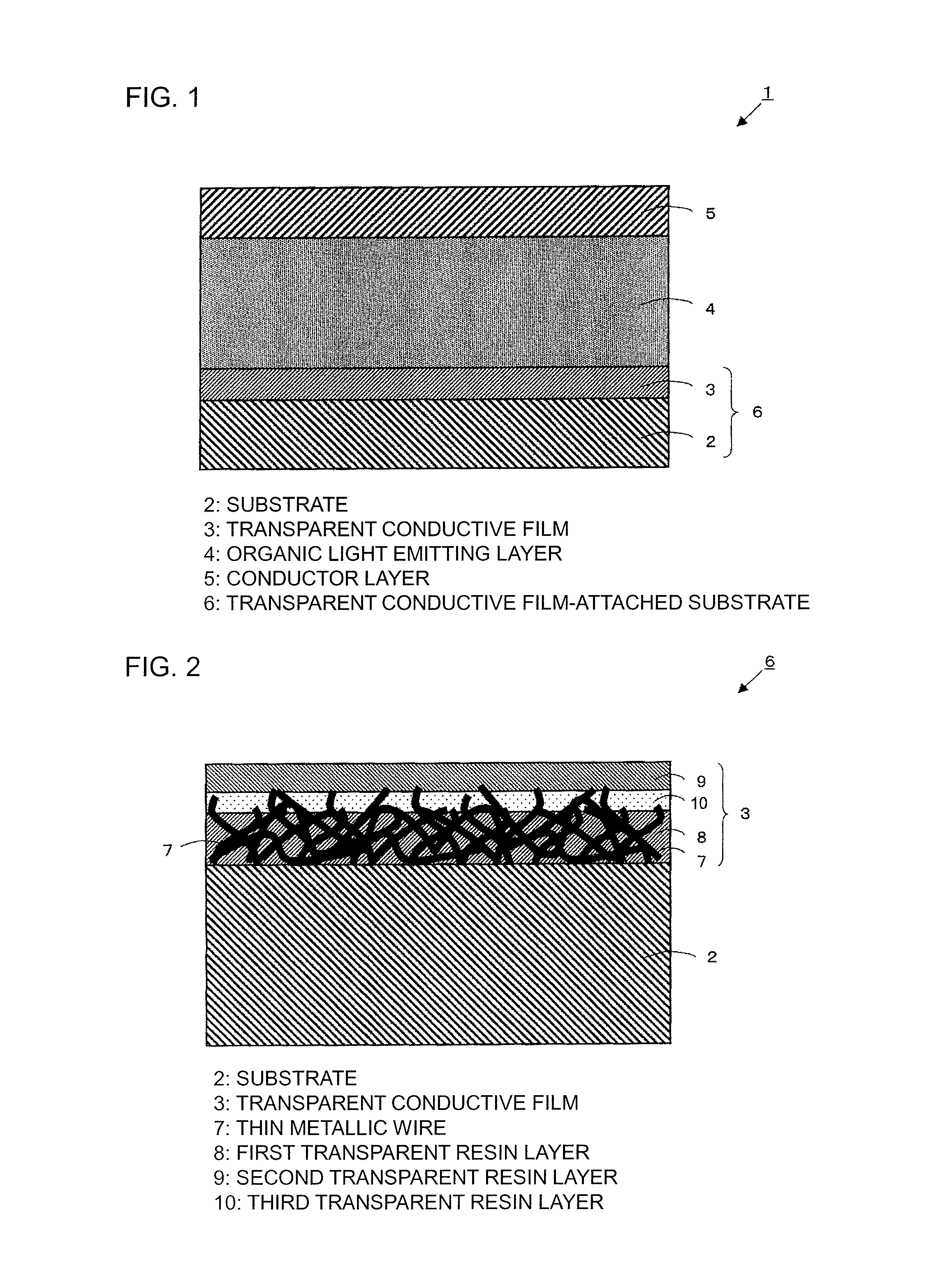

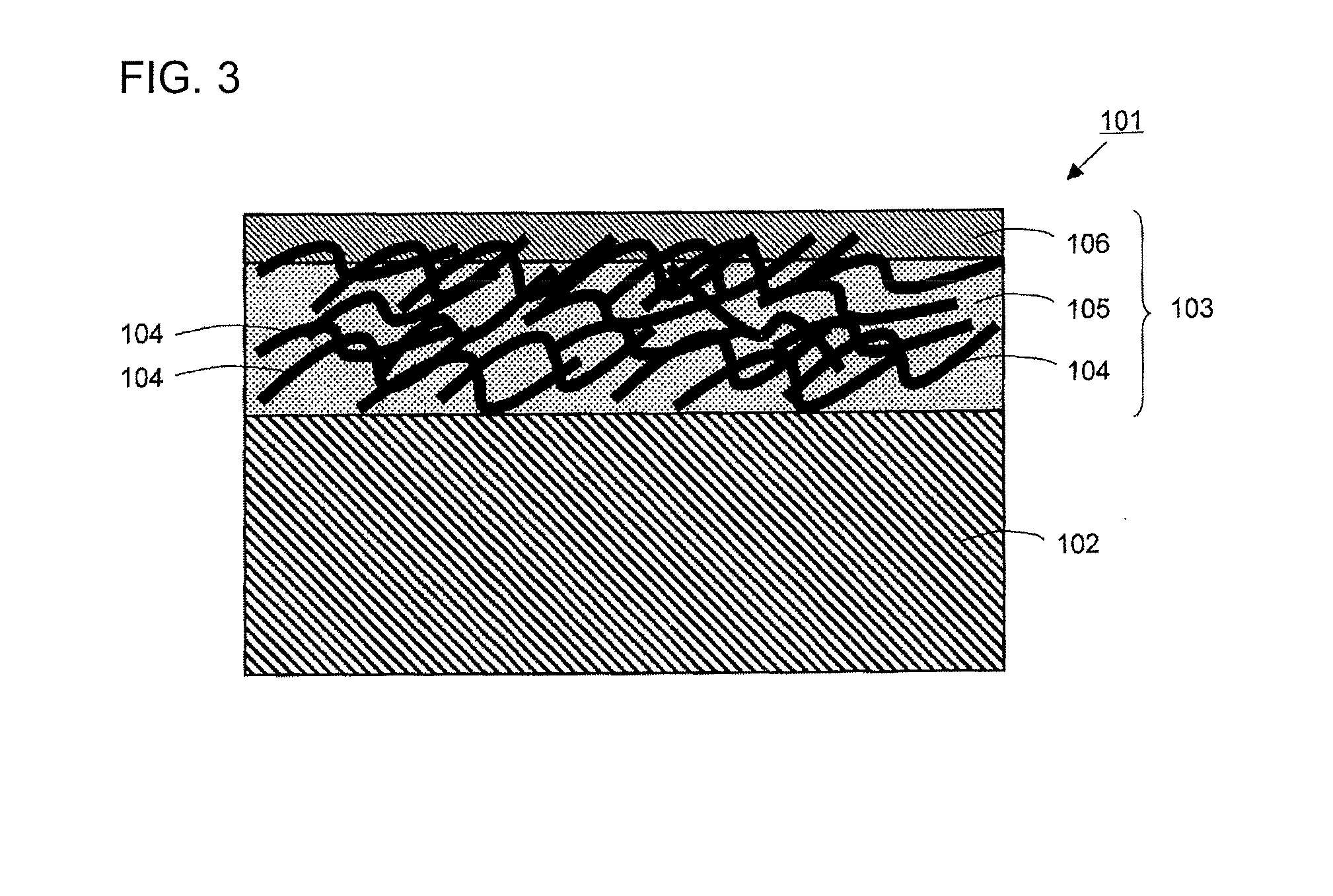

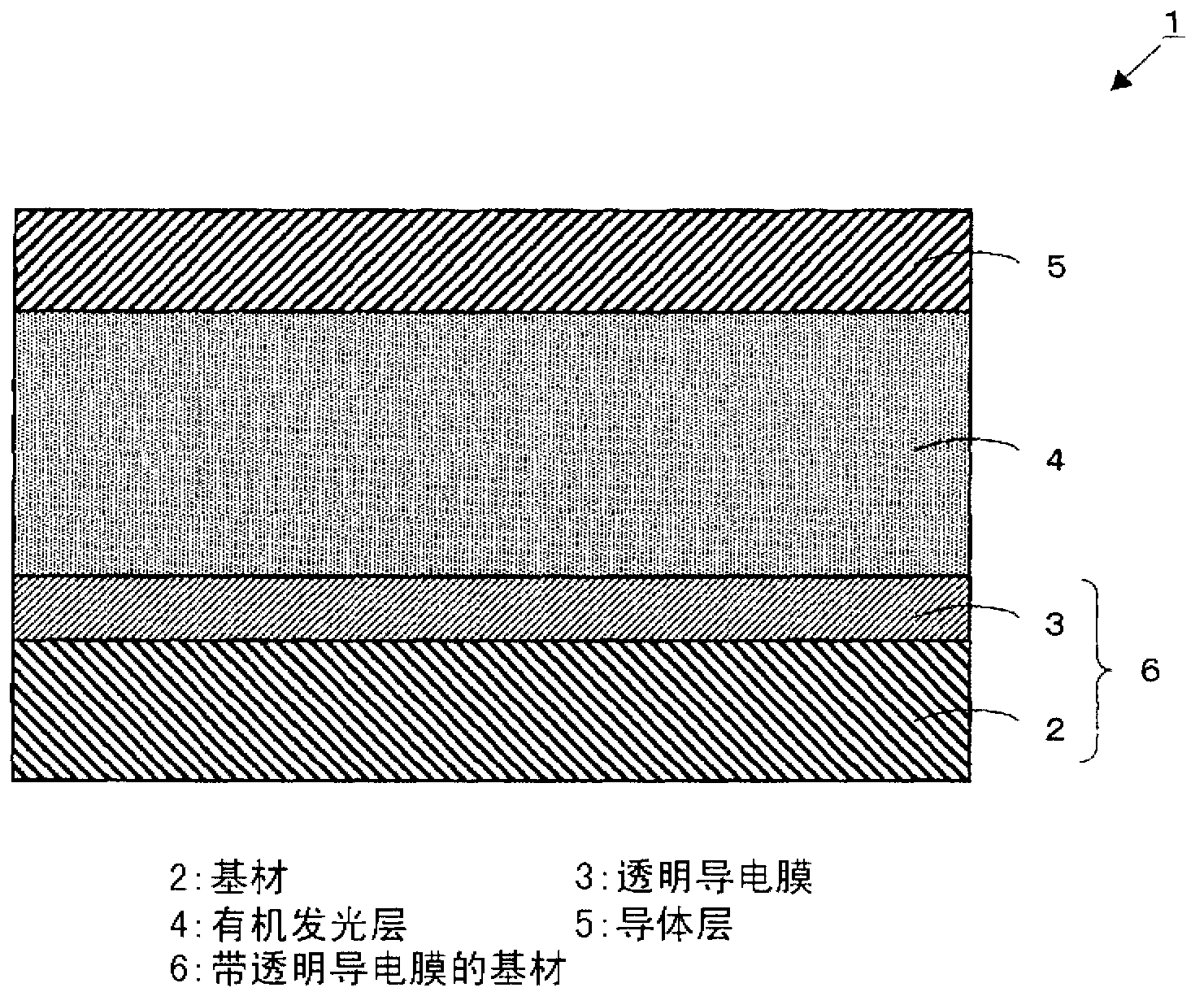

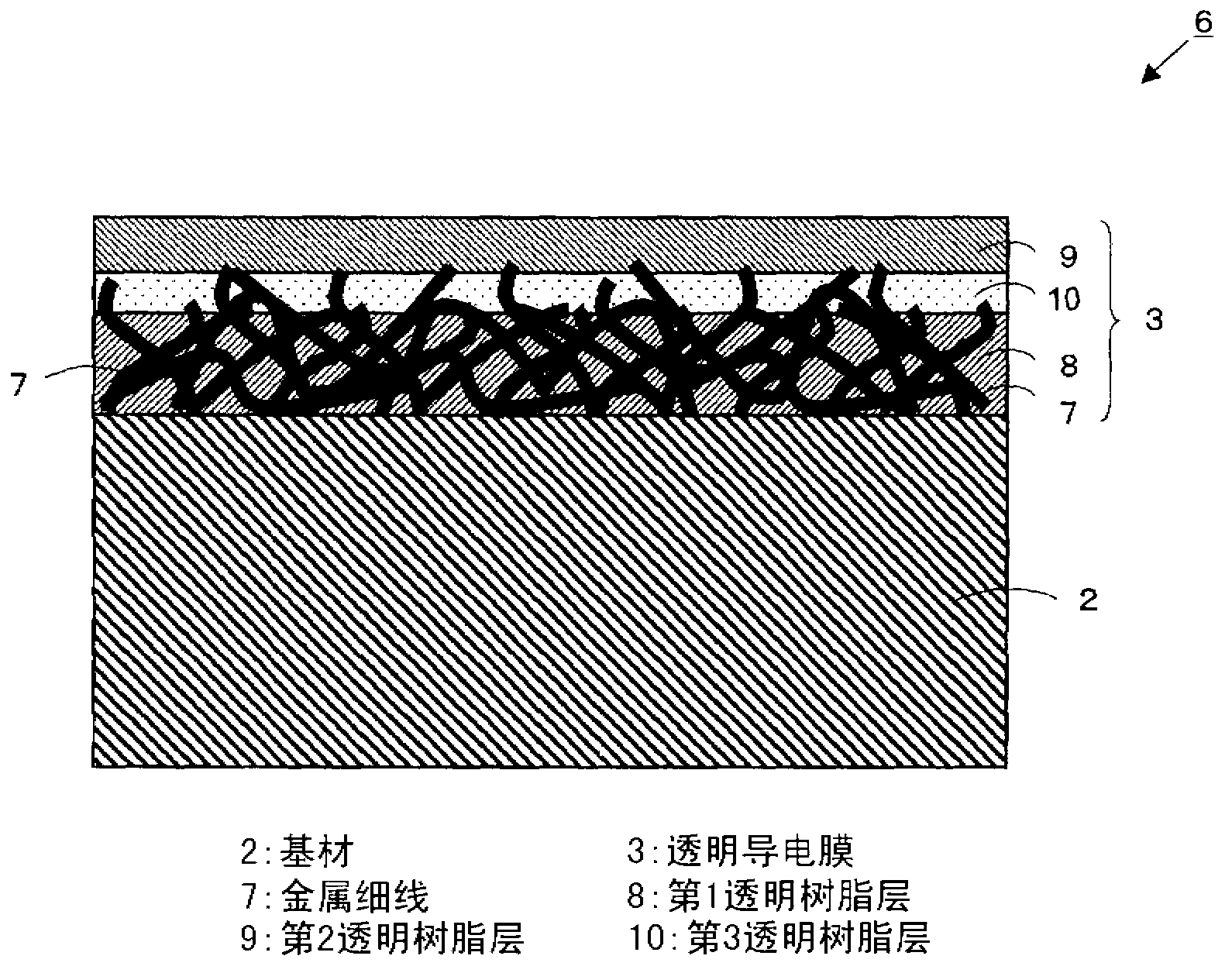

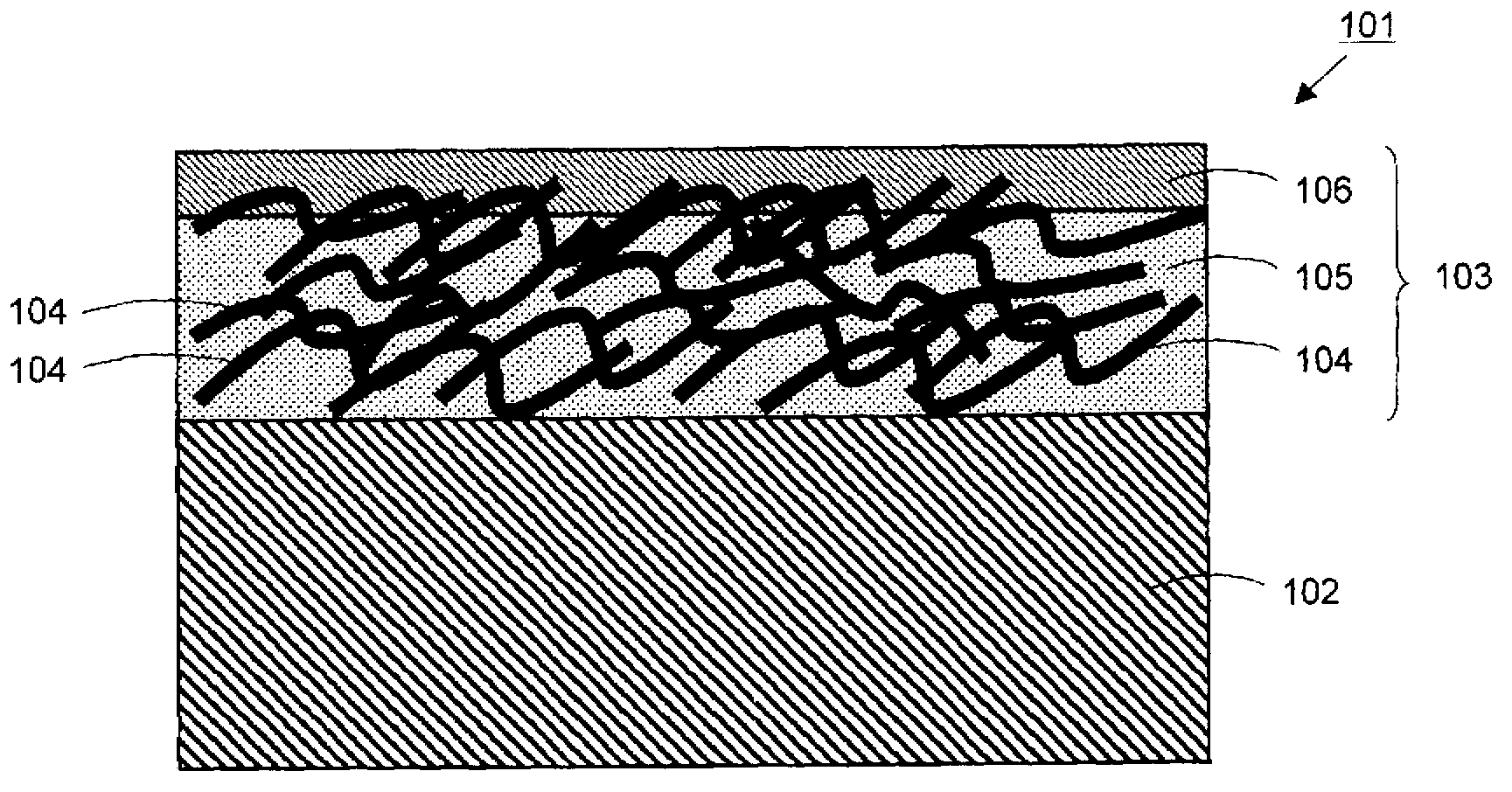

Transparent conductive film, substrate with transparent conductive film, and organic electroluminescence element using the same

ActiveUS20130122279A1Flat surfaceUniform conductivitySynthetic resin layered productsConductive materialPolymer scienceConductive polymer

A transparent conductive film includes a first transparent resin layer including a plurality of thin metallic wires, a second transparent resin layer containing a conductive polymer, and a third transparent resin layer provided between the first transparent resin layer and the second transparent resin layer. The second transparent resin layer contains a resin which is soluble in water, and the third transparent resin layer contains a resin which is insoluble in water or has water resistance. The third transparent resin layer can suppress mixing of the second transparent resin layer with the first transparent resin layer and can make the second transparent resin layer less likely to be damaged by the first transparent resin layer. Therefore, a surface of the second transparent resin layer is made smooth and electrical conductivity is made uniform.

Owner:PANASONIC INTELLECTUAL PROPERTY MANAGEMENT CO LTD

Copper-chromium-zirconium alloy and preparation method thereof

Copper-chromium-zirconium alloy is characterized by being prepared from the following raw materials in percent by weight: 0.2-1.2% of chromium, 0.05-0.2% of zirconium, 0.06-0.10% of magnesium, 0.05-0.5% of scandium and the balance of copper. The invention further provides a preparation method of the copper-chromium-zirconium alloy. The preparation method sequentially comprises the following steps:(1), proportionally preparing copper, chromium, zirconium, magnesium and scandium elements, performing vacuum smelting, and performing split casting to obtain a casting blank; (2), performing homogenizing treatment and hot extrusion on the casting blank to obtain a bar blank; (3), performing solid solution treatment to the bar blank; (4), performing cold deformation processing on the bar blank obtained after the solid solution treatment; (5), performing aging treatment to a material obtained after the cold deformation processing to obtain the needed copper-chromium-zirconium alloy. The copper-chromium-zirconium alloy has high tensile strength, high electrical conductivity and high elongation and has relatively high high-temperature tensile strength and excellent comprehensive performance.

Owner:GUANGDONG HUAXING HEAT EXCHANGE EQUIP CO LTD +1

Transparent conductive film, substrate with transparent conductive film, and organic electroluminescence element using same

InactiveCN103068573AFlat surfaceUniform conductivityConductive layers on insulating-supportsElectroluminescent light sourcesWater insolubleTransparent conducting film

A transparent conductive film (3) comprises a first transparent resin layer (8) having a plurality of thin metallic wires (7), a second transparent resin layer (9) comprising a conductive polymeric molecule, and a third transparent resin layer (10) provided between the first transparent resin layer (8) and the second transparent resin layer (9). The second transparent resin layer (9) contains a water soluble resin, and the third transparent resin layer (10) contains a water insoluble resin or a water resistant resin. Because of the presence of the third transparent resin layer (10), the second transparent resin layer (9) can be prevented from mixing with the first transparent resin layer (8), and there is hardly any damage to the second transparent resin layer (9) by the first transparent resin layer (8). Accordingly, the surface of the second transparent resin layer (9) can be smooth and can have a uniform conductive property.

Owner:PANASONIC INTPROP MANAGEMENT CO LTD

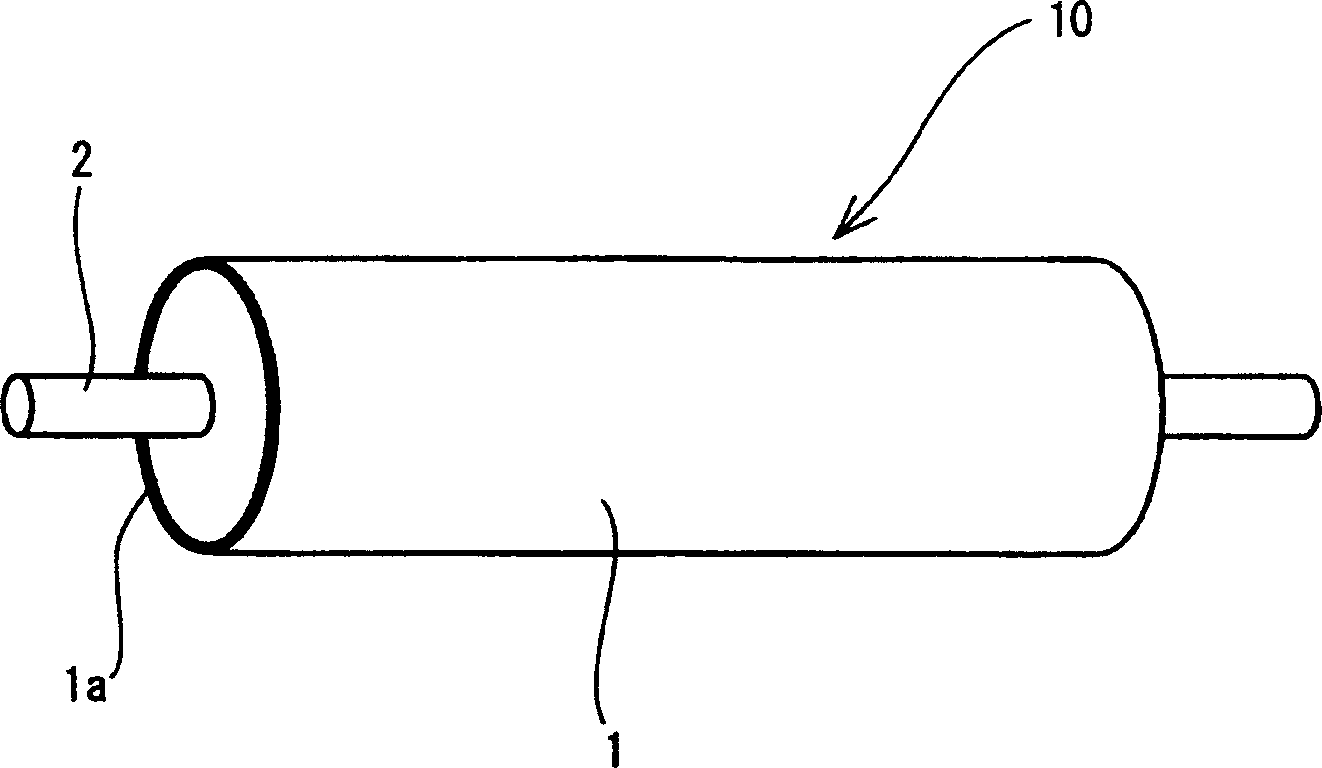

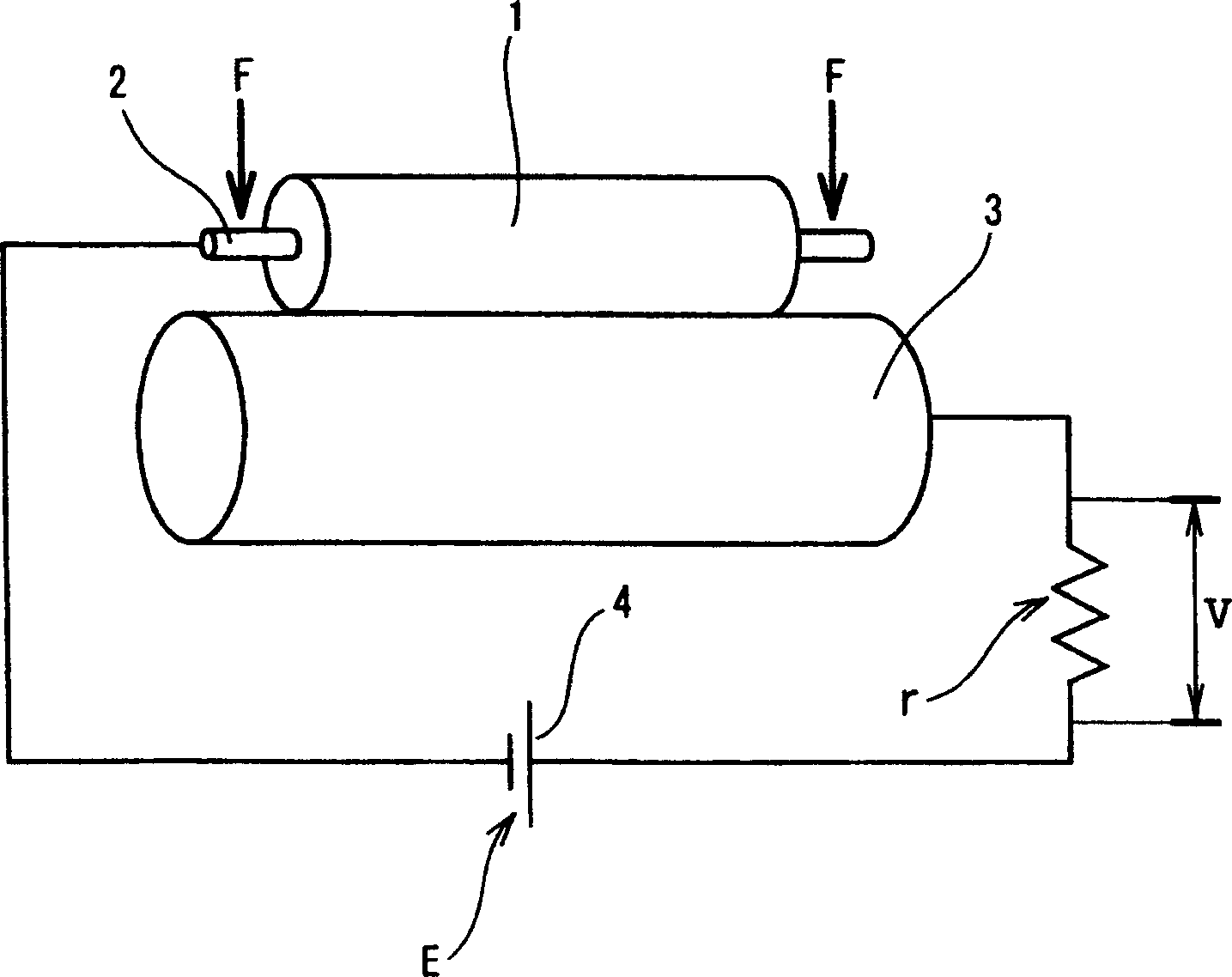

Semi-conductive rubber part

InactiveCN1655288AOvercoming high surface free energyOvercoming processabilityNon-insulated conductorsShaft and bearingsForeign matterEngineering

To provide a semiconductive rubber member causing no substantial sticking of foreign matter represented by a toner outer additive for a long period through reducing the surface free energy of the rubber member while maintaining its electrical properties' uniformity and design values' repeated reproducibility, excellent in processability and substantially exhibiting no surface defects including molding unevenness and cracks. This semiconductive rubber member is obtained by compounding 100 pts. mass of an ionically conductive rubber including a rubber having polyether linkages with 0.1-5 pt(s). mass of a wax. In this rubber member, it is preferable that the rubber having the polyether linkages to be used consists of a polymer made from a halogen-containing ether-based monomer and, when desired, a halogen-free ether-based monomer and / or a copolymerizable unsaturated epoxide-based monomer.

Owner:SUMITOMO RUBBER IND LTD

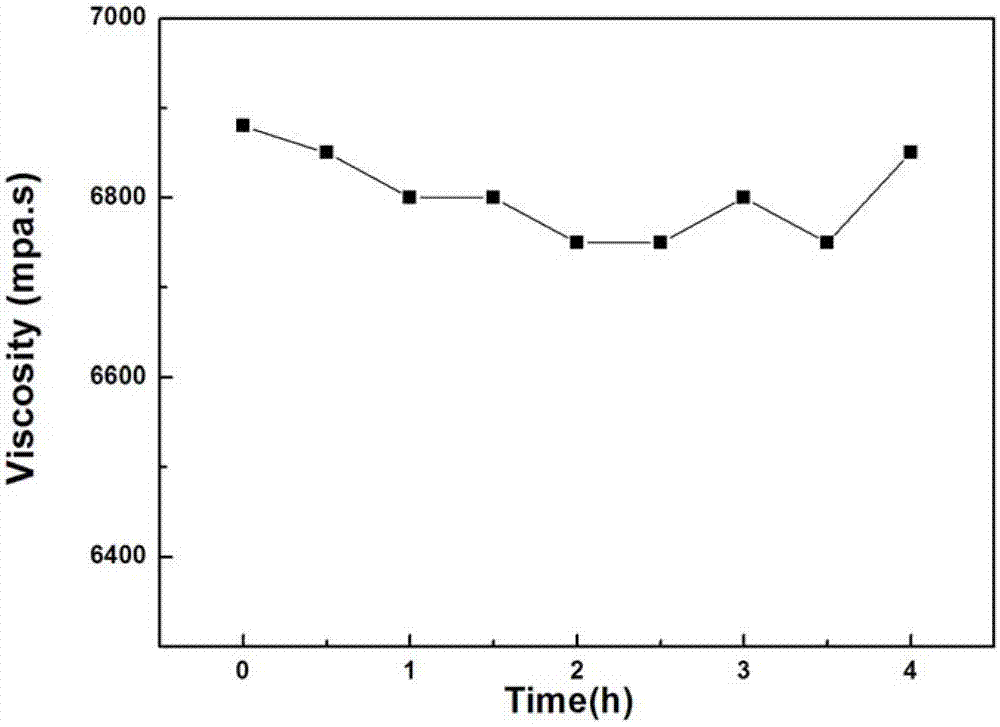

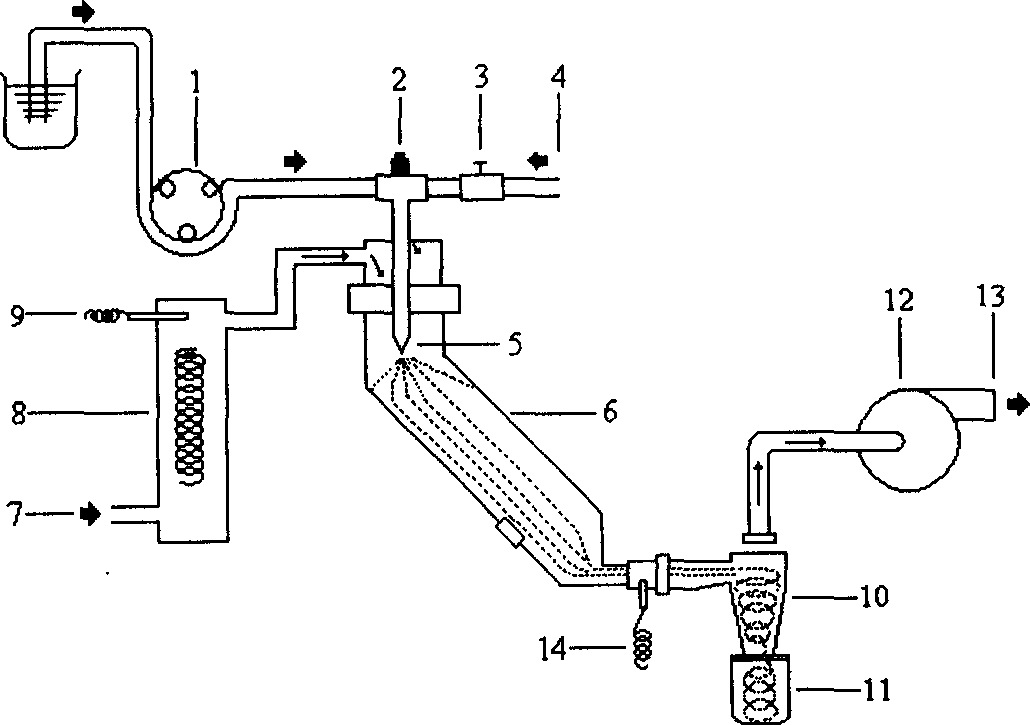

Process for dispersing carbon nanotubes in electroconductive adhesive of lithium ion battery

InactiveCN102709523AScattered fitAvoid loop dead endsElectrode manufacturing processesLithium iron phosphateAdhesive

The invention relates to a process for dispersing carbon nanotubes in an electroconductive adhesive of a lithium ion battery. The process comprises the following steps of: firstly, mixing and stirring a solvent, a conductive additive and a dispersant, adding lithium iron phosphate, lithium titanate and aluminium oxide, mixing and stirring uniformly to obtain a pre-mixed electroconductive liquid of the lithium ion battery, and then placing the premixed electroconductive liquid of the lithium ion battery into an internal circulation system composed of a stirring tank and a high-speed dispersing machine for cyclic stirring and dispersing to obtain a uniform electroconductive liquid of the lithium ion battery; and adding a bonding agent into the conductive liquid, and mixing and stirring uniformly to obtain the electroconductive adhesive of the lithium ion battery. According to the invention, by means of controlling the particle size distribution range of the lithium iron phosphate, the lithium titanate and the aluminium oxide, a ball milling effect is produced in a stirring and dispersing process, so that the dispersion uniformity of the carbon nanotubes is increased effectively. Particularly, by adoption of the internal circuit system for cyclic stirring and dispersing, circulation dead angles can be prevented in the stirring tank, and the dispersion effect of the carbon nanotubes can be increased further. The process disclosed by the invention has the advantages of simpleness, convenience for operate, dispersion uniformity of the carbon nanotubes in a slurry preparation process of the lithium ion battery, long-term stability of the viscosity of the slurry and good reproducibility, and is suitable for industrial application.

Owner:HUNAN FENGYUAN YESHINE KINGCO NEW ENERGY

Production method of interphase carbon-coated graphite negative electrode material

The invention provides a production method of an interphase carbon-coated graphite negative electrode material. The production method is characterized in that natural graphite or artificial graphite with median particle diameter being 10 to 30 micrometers is adopted as a raw material A, interphase carbon microspheres are adopted as a raw material B, and nano-grade micro powder asphalt is adopted as a raw material C. The raw material A is carbonized at the temperature of 1200 to 1500 DEG C or is graphitized at the temperature of 2800 to 3200 DEG C. The raw material B is crushed into nano powder with median particle diameter being less than or equal to 80nm by utilizing a nano crushing method. The raw material A and the raw material B are mixed in a ratio of 100 / (3-10) to be primarily coated and modified, the raw material C is added into the mixture of the raw material A and the raw material B according to a ratio of (A+B) / C being equal to 100 / (5-10) to be secondarily coated and modified, and finally the mixture is secondarily and thermally treated at the temperature of 1200 to 1500 DEG C or 2800 to 3200 DEG C. The production method has the advantages that the conductivity is good, the capacity is high, the cycling performance is good, the service life is long, and compatibility with electrolyte is good.

Owner:大连宏光锂业有限责任公司

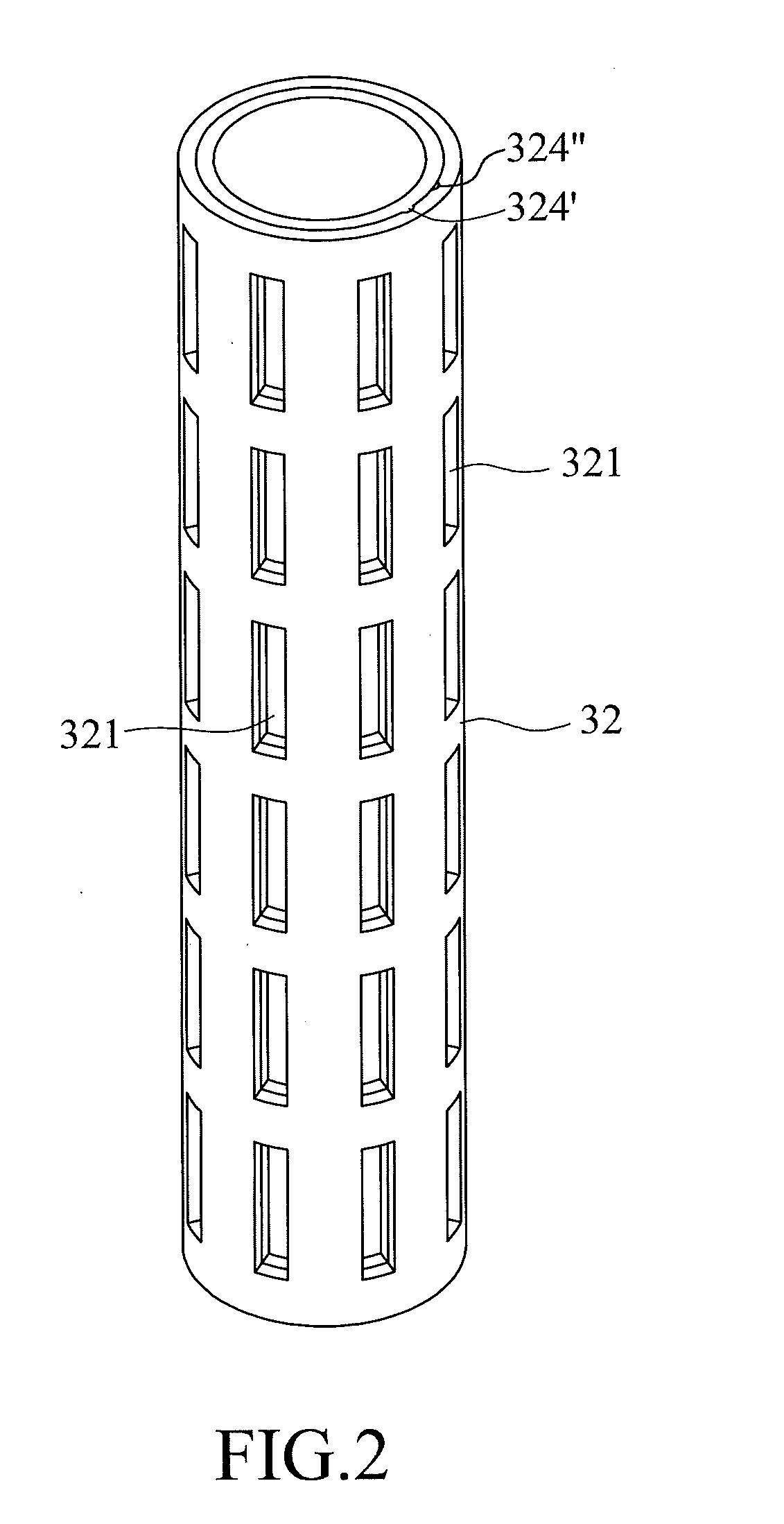

Anode Electrode

ActiveUS20160020462A1Increase surface areaImprove efficiencyElectrode carriers/collectorsNegative electrodesElectricityLithium metal

A lithium metal electrode is disclosed in this invention. The lithium metal electrode includes a lithium metal layer, several gate layers and a current collector layer having several openings. The gate layers are located in the openings. The lithium metal layer is located corresponding to the gate layers and is substantially contacted with the current collector layer. The lithium metal layer is insulated via the gate layers and / or the current collector layer before formation. While the gate layers are alloyed with the lithium ions from the media such as the electrolyte, the alloyed gate layers may provide the ionic access for the lithium metal layer so that the lithium metal layer may feedback the lithium ions back to the chemical system of the electricity supply system. Also, at the same time, the potentials of all the gate layers may be kept equally to the potential of the lithium metal layer.

Owner:PROLOGIUM HLDG

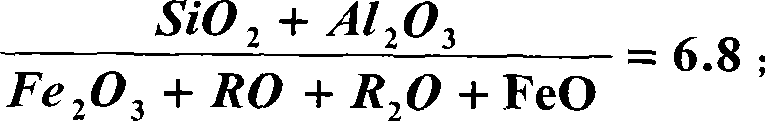

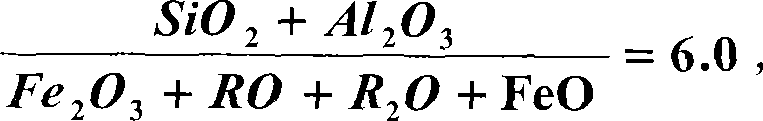

Haydite used as conductive concrete aggregate and preparation thereof

The invention relates to a porcelain granule used as a conductive concrete aggregate and a preparation method thereof. The porcelain granule used as a conductive concrete aggregate is characterized in that the weight percentage of each material is as follows: 77 to 94 percent of clay, 3 to 10 percent of iron powder, 3 to 5 percent of coke dust, as well as 0 to 8 percent of FeO3; the sum of the weight percentage of each material is 100 percent. The preparation method for the porcelain granule used as a conductive concrete aggregate is characterized by comprising the following steps: 1) preprocessing the materials: the clay selected from soil is dried to have a water content being equal to or less than 5 percent, after being cracked, the clay is grinded to the powder the grain diameter of which is equal to or less than 0.1mm; then the coke sold in the market is cracked, and grinded into the powder the grain diameter of which is equal to or less than 0.1mm to obtain the coke dust; 2) selecting the materials; 3) shaping a blank: water is added for stirring, and the stirred materials are prepared into the ball-shaped grain blanks the grain diameters of which are between 5mm and 15mm by a pan-pelletizer; and 4) baking the porcelain granule to obtain the porcelain granule used as a conductive concrete aggregate. The porcelain granule used in the concrete as the aggregate can enhance the conductive performance of the concrete.

Owner:WUHAN UNIV OF TECH

Reinforced electrolyte membrane for fuel cell, membrane-electrode assembly for fuel cell, and polymer electrolyte fuel cell comprising the same

ActiveUS20110287335A1Increased durabilityIncrease productionFinal product manufactureConductive materialPorous substratePolyelectrolyte

It is an object of the present invention to provide a fuel cell electrolyte membrane reinforced with a porous substrate which has excellent durability and in which the amount of cross leakage as a result of chemical deterioration of electrolyte membrane components due to the presence of peroxide and / or radicals is particularly reduced. The present invention relates to an electrolyte membrane for a fuel cell comprising a polyelectrolyte, which contains a porous substrate and a radical scavenger dispersed in the polyelectrolyte.

Owner:TOYOTA JIDOSHA KK +1

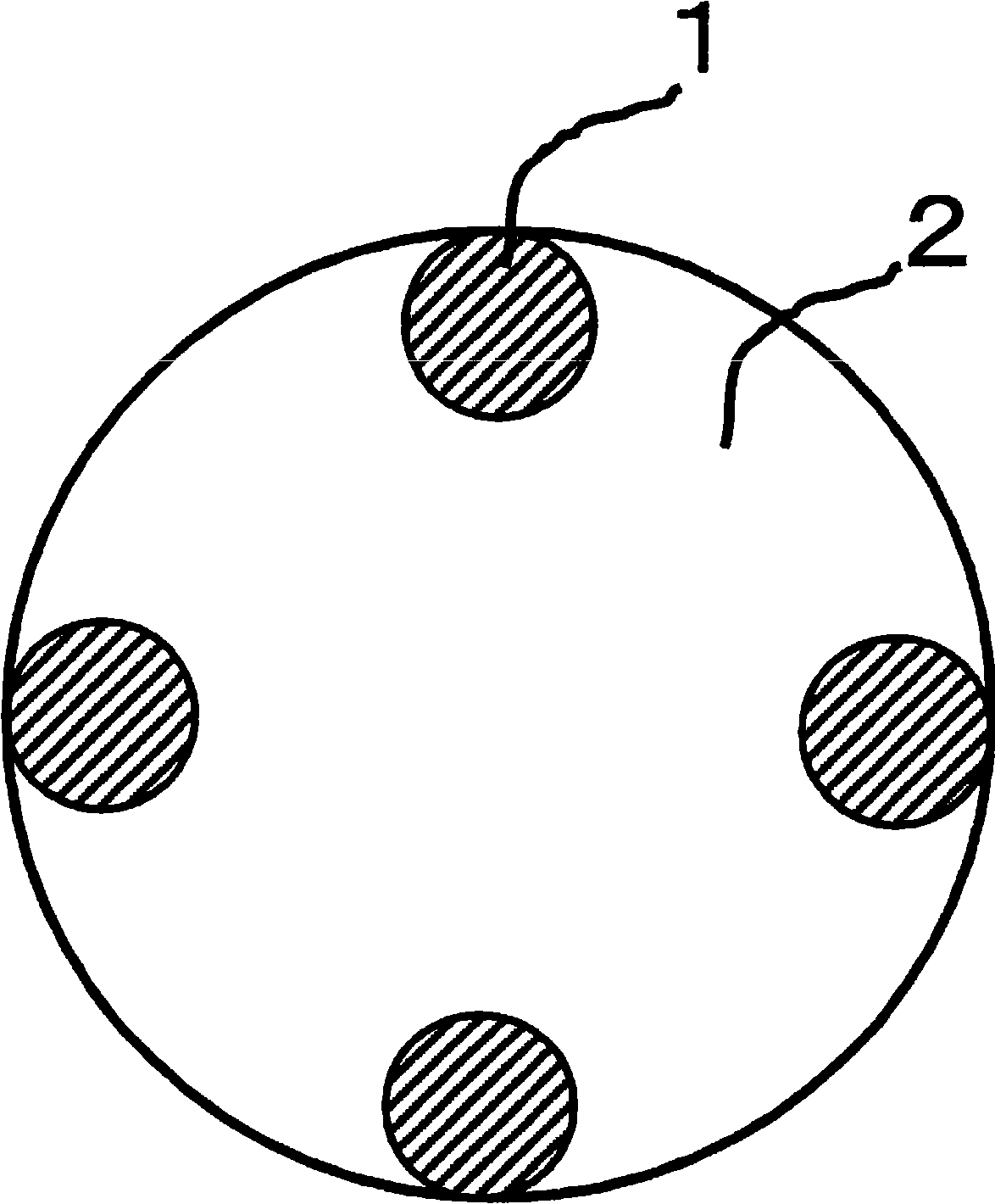

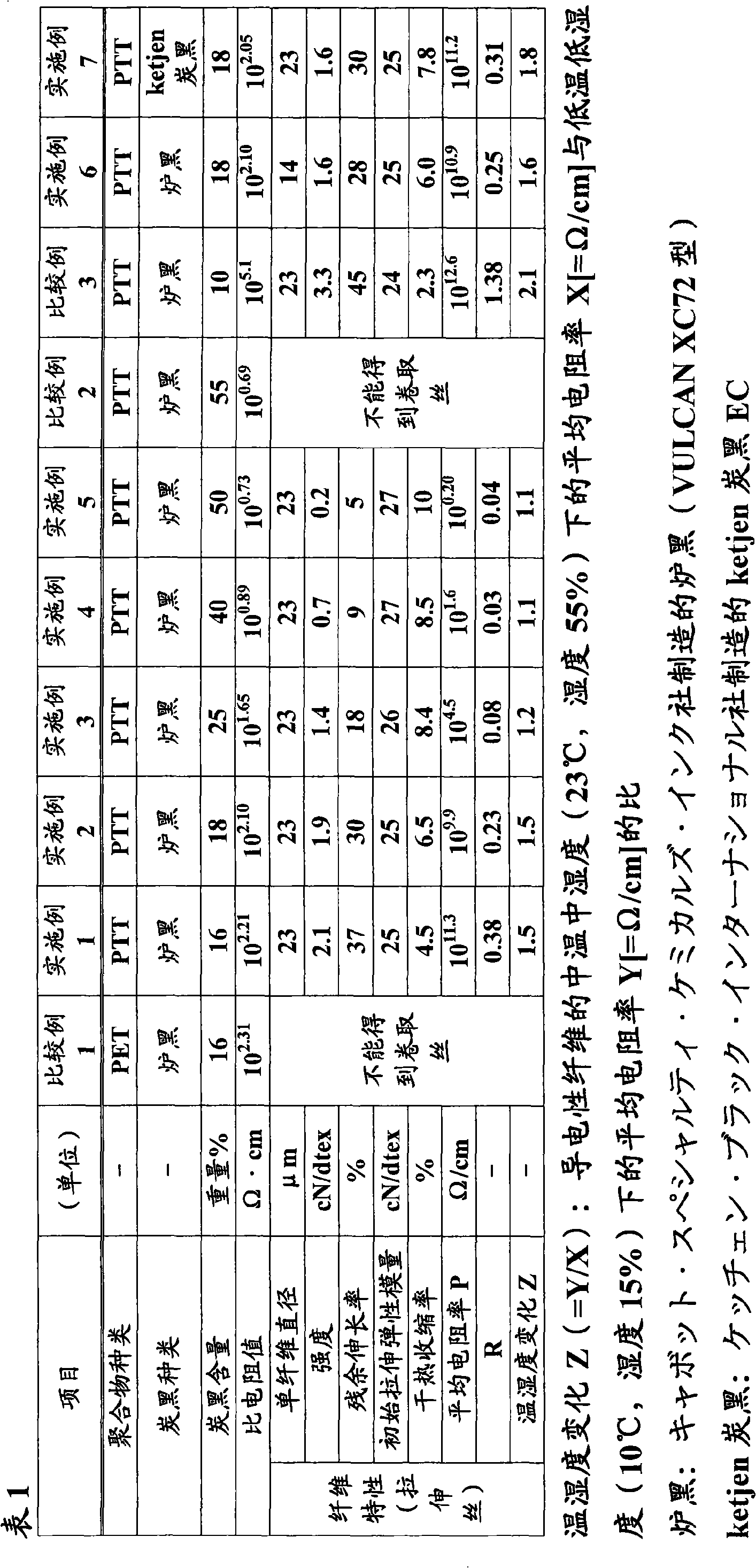

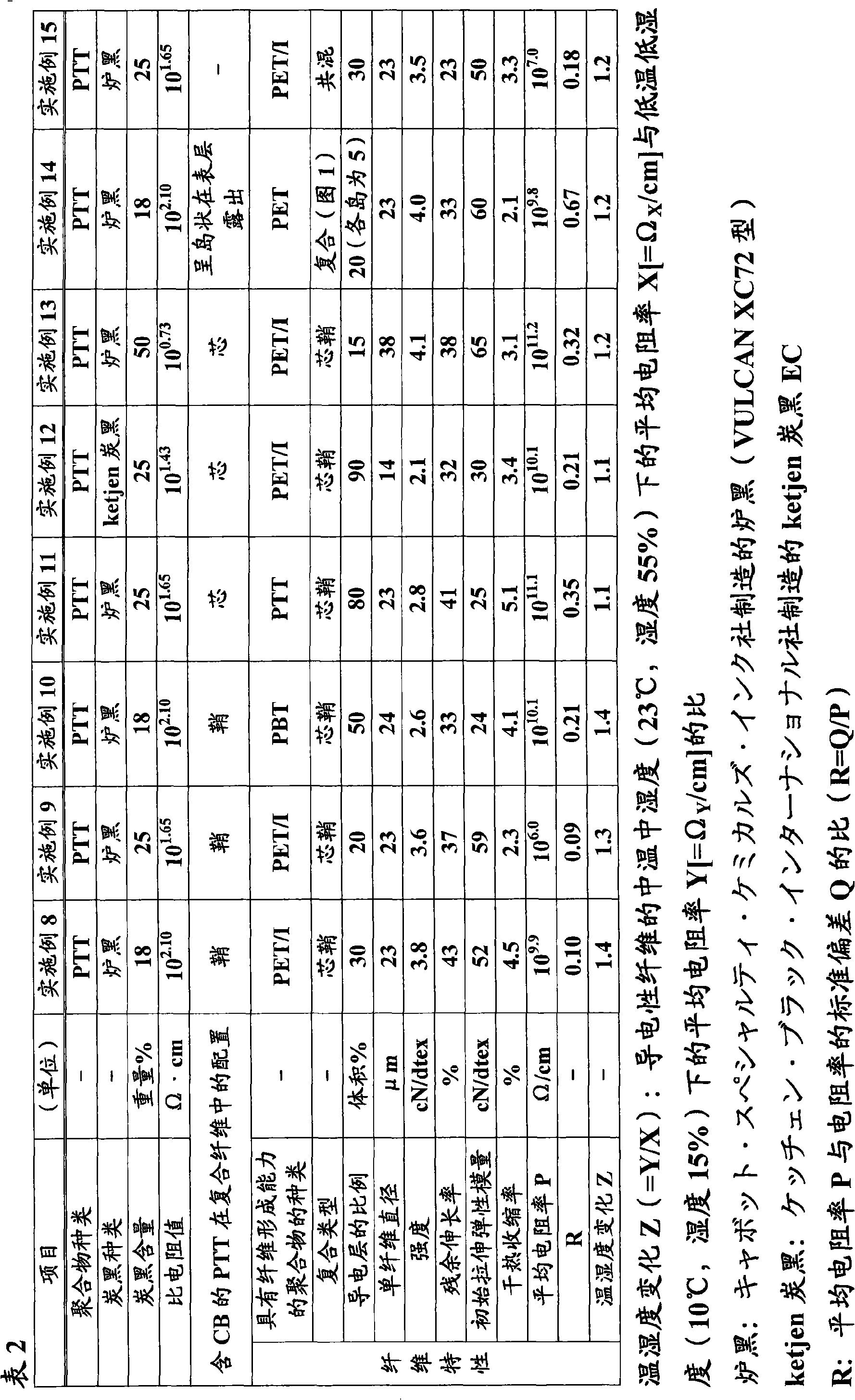

Polyester fiber and textile product comprising the same

ActiveCN101278080APromote formationImprove conductivityElectroconductive/antistatic filament manufactureWarp knittingFiberPolyester resin

Polyester fibers characterized by comprising a polyester resin composition which comprises trimethylene terephthalate units as the main repeating structural units and contains carbon black and by having an average resistivity (P) of 1.010<12> [O / cm] or lower; and a polyester textile product at least part of which is made of the polyester fibers. The polyester fibers have high conductivity and are highly excellent in conductivity stability to humidity fluctuations. The textile product comprising the polyester fibers has excellent performances, and examples thereof include a fibrous brush.

Owner:TORAY IND INC

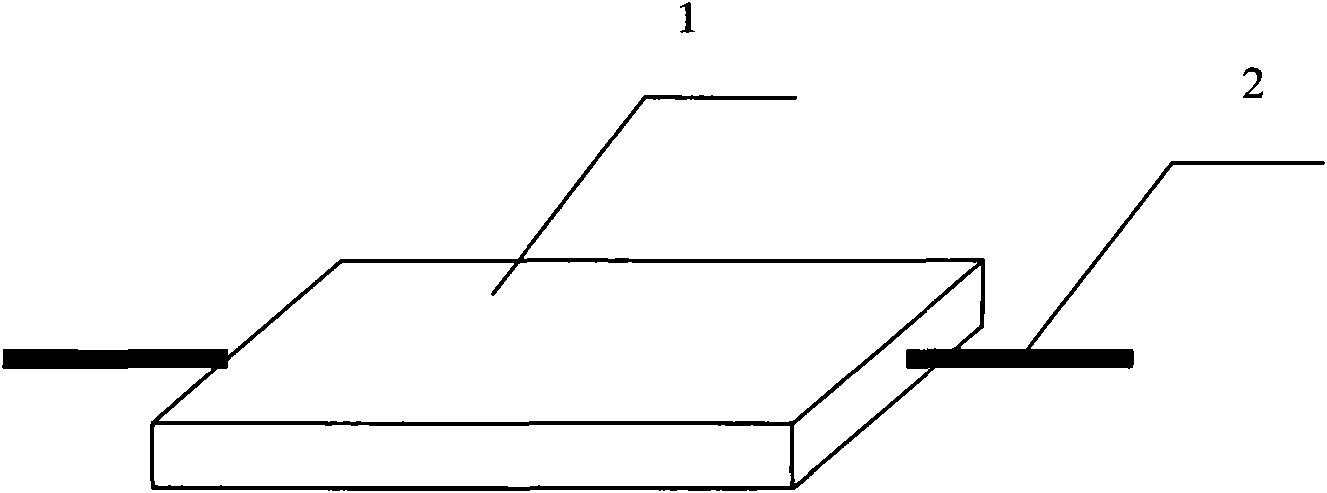

Novel grounded resistance-reducing agent and novel grounded resistance-reducing module

InactiveCN101841086APrevent penetrationPrevent oxidation and corrosionOrganic fertilisersCarbon-silicon compound conductorsAdhesiveConductive materials

The invention provides a novel grounded resistance-reducing agent and a novel grounded resistance-reducing module, which are characterized in that a non-metallic conductive material in the novel grounded resistance-reducing agent and the novel grounded resistance-reducing module is microcrystalline graphite. The novel grounded resistance-reducing agent mainly comprises the non-metallic conductive material namely the microcrystalline graphite and an alkaline gelling material; and the novel grounded resistance-reducing module mainly comprises the non-metallic conductive material namely the microcrystalline graphite, an adhesive and a metal component. An attached drawing is an abridged general view of the novel grounded resistance-reducing module, wherein 1 is a resistance-reducing module, and 2 is an extended part of the metal component. The novel grounded resistance-reducing agent and the novel grounded resistance-reducing module have low electrical resistivity, are long-acting, stable, nontoxic and harmless, can be suitable for meeting requirements on long-acting ground protection of an electrical appliance and a building under the conditions of various atrocious climates and various geologic environments, have low production costs, are simple and convenient to implement, have abundant raw material sources, and are ideal grounded conducting materials.

Owner:任涤权

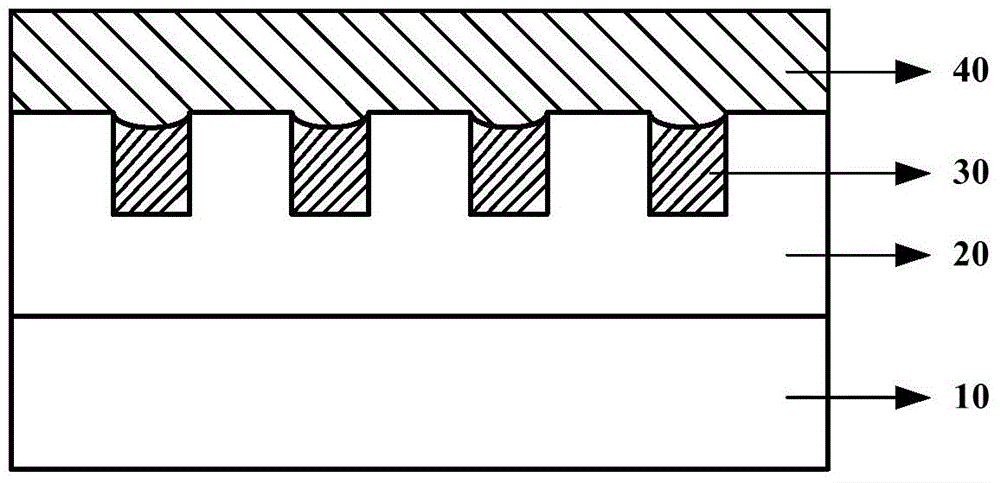

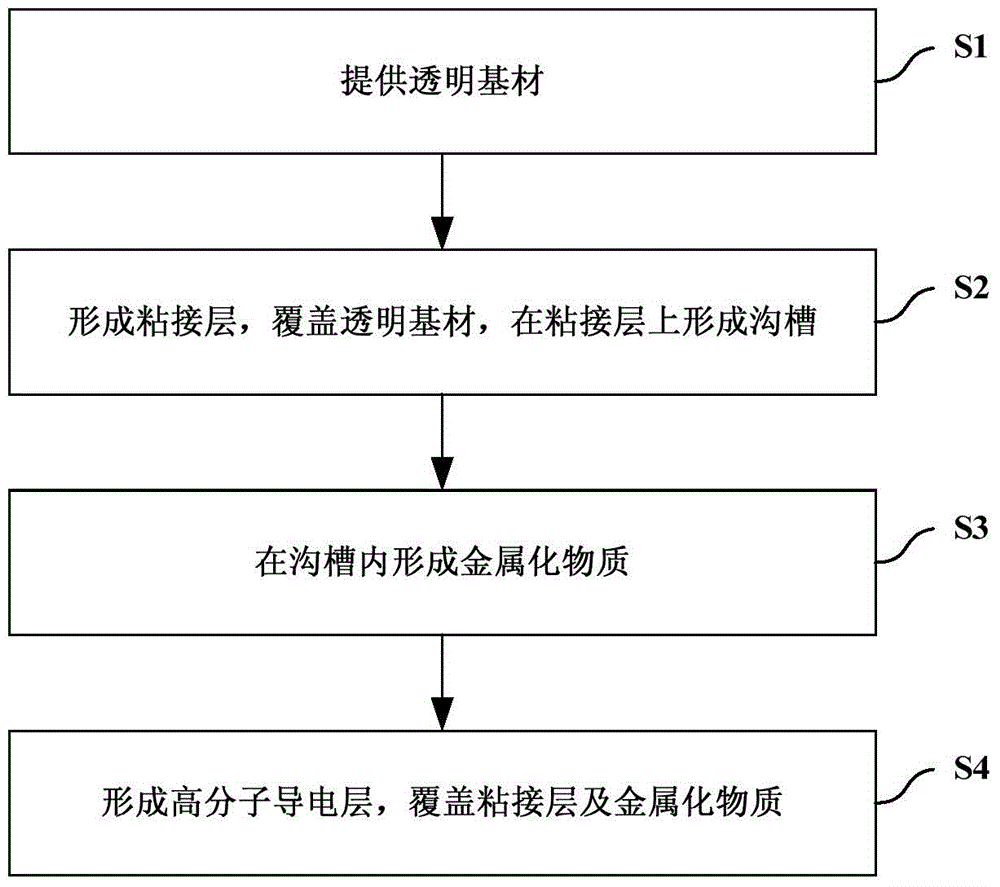

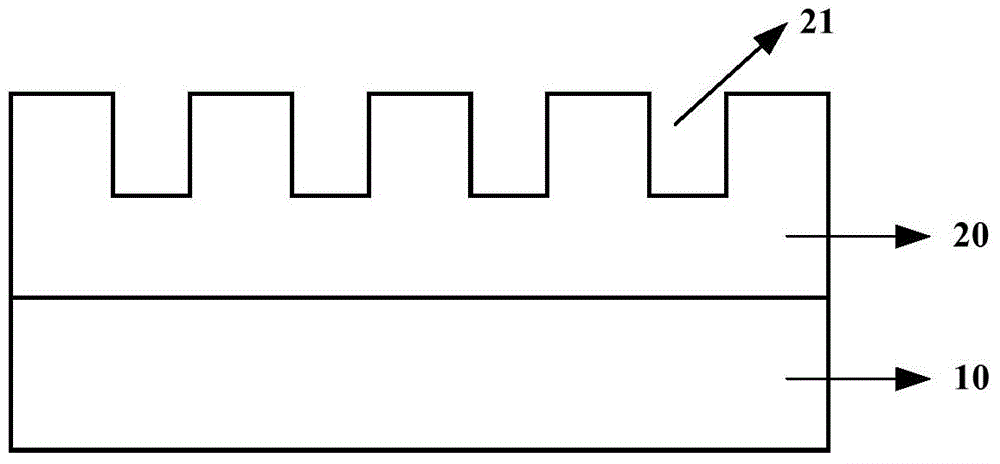

Low-square-resistance transparent conductive film and preparation method for same

ActiveCN104700928ALow costSimple structureConductive layers on insulating-supportsCable/conductor manufactureLiquid-crystal displaySolar cell

The invention provides low-square-resistance transparent conductive film and a preparation method for the same. The low-square-resistance transparent conductive film at least comprises a transparent substrate, a bonding layer with grooves, metal materials in the grooves and a polymer conductive layer. The bonding layer is arranged on the transparent substrate, and the polymer conductive layer is arranged on the bonding layer and the metal materials. The transparent conductive film is simple in structure, environmentally friendly and efficient and low in cost; the square resistance can be reduced to below 10 omega / kou, the conductivity and the color modulation are uniform, the transparent conductive film can be widely applied to the screen display fields of touch panels, liquid crystal displays, solar cells, LEDs and the like and can be applied to electromagnetic wave shielding materials. The method is simple in process and low in cost, and the prepared transparent conductive film square resistance is low, and the conductivity and the color modulation are uniform.

Owner:上海蓝沛信泰光电科技有限公司

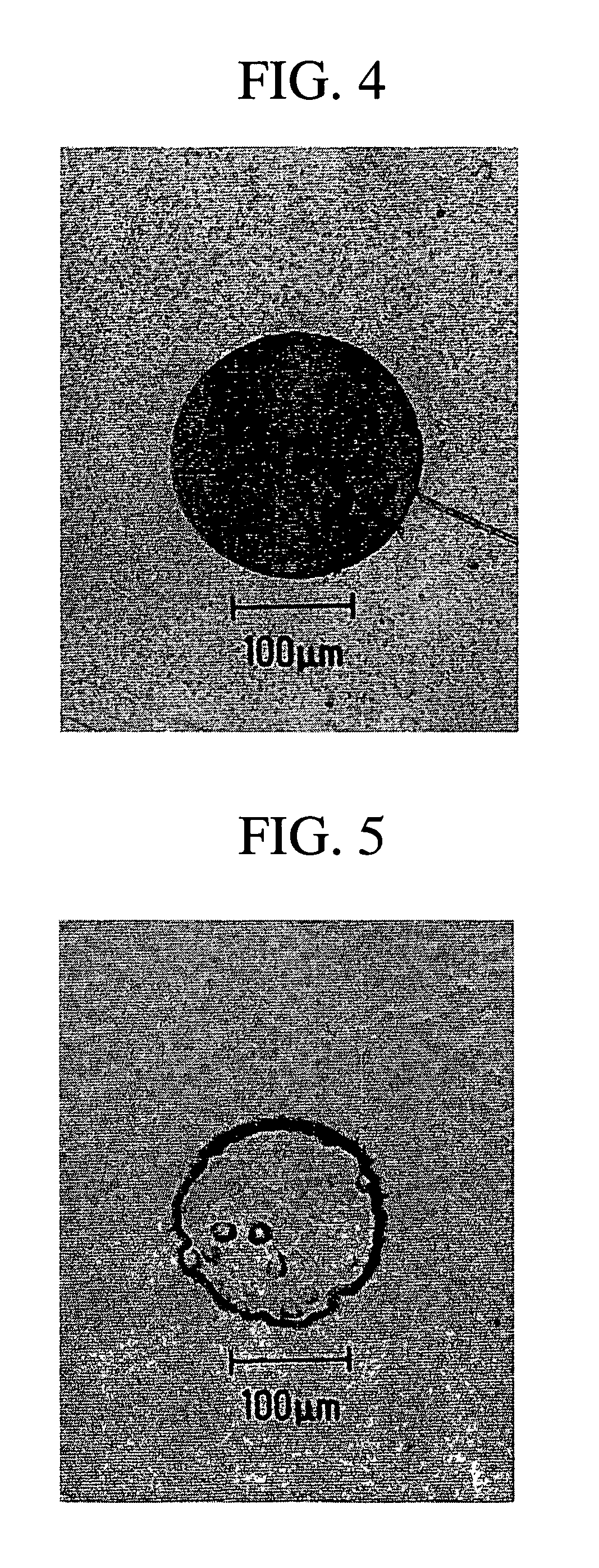

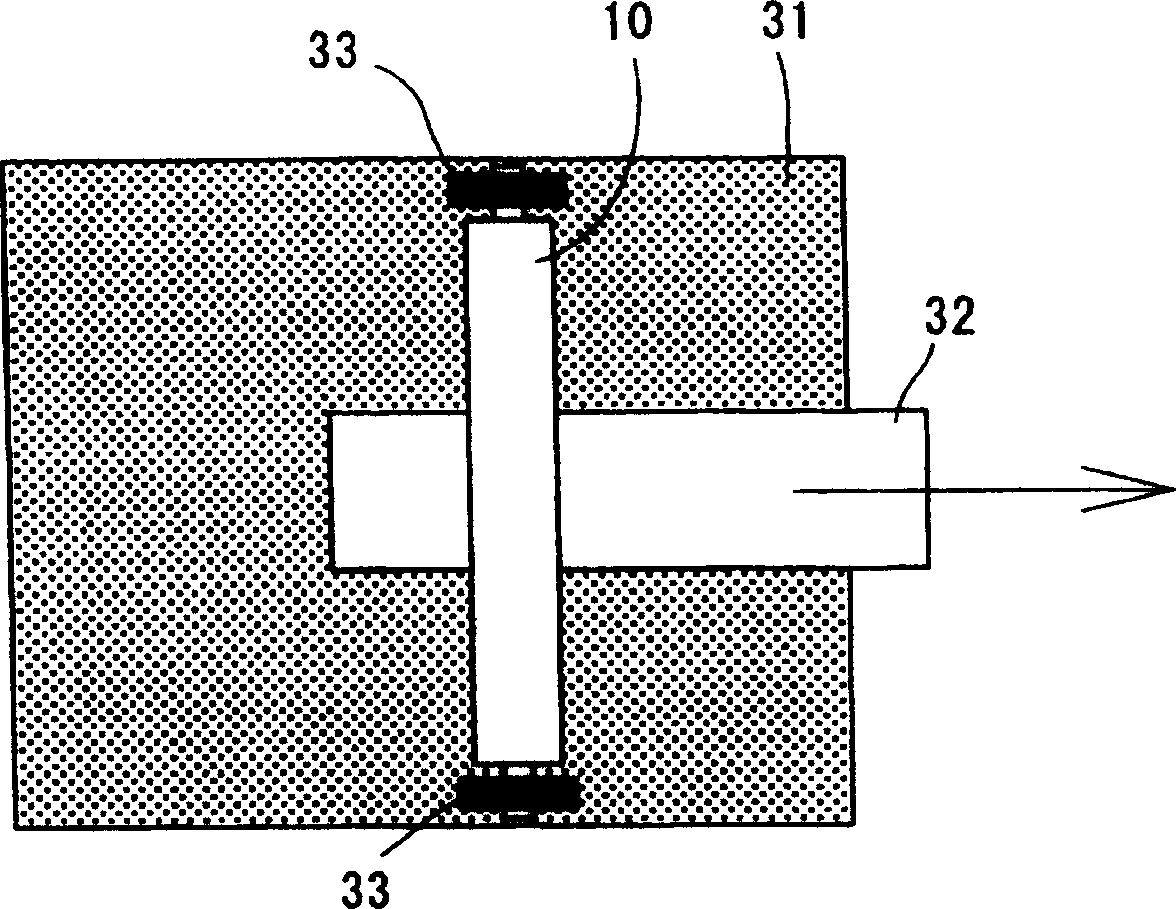

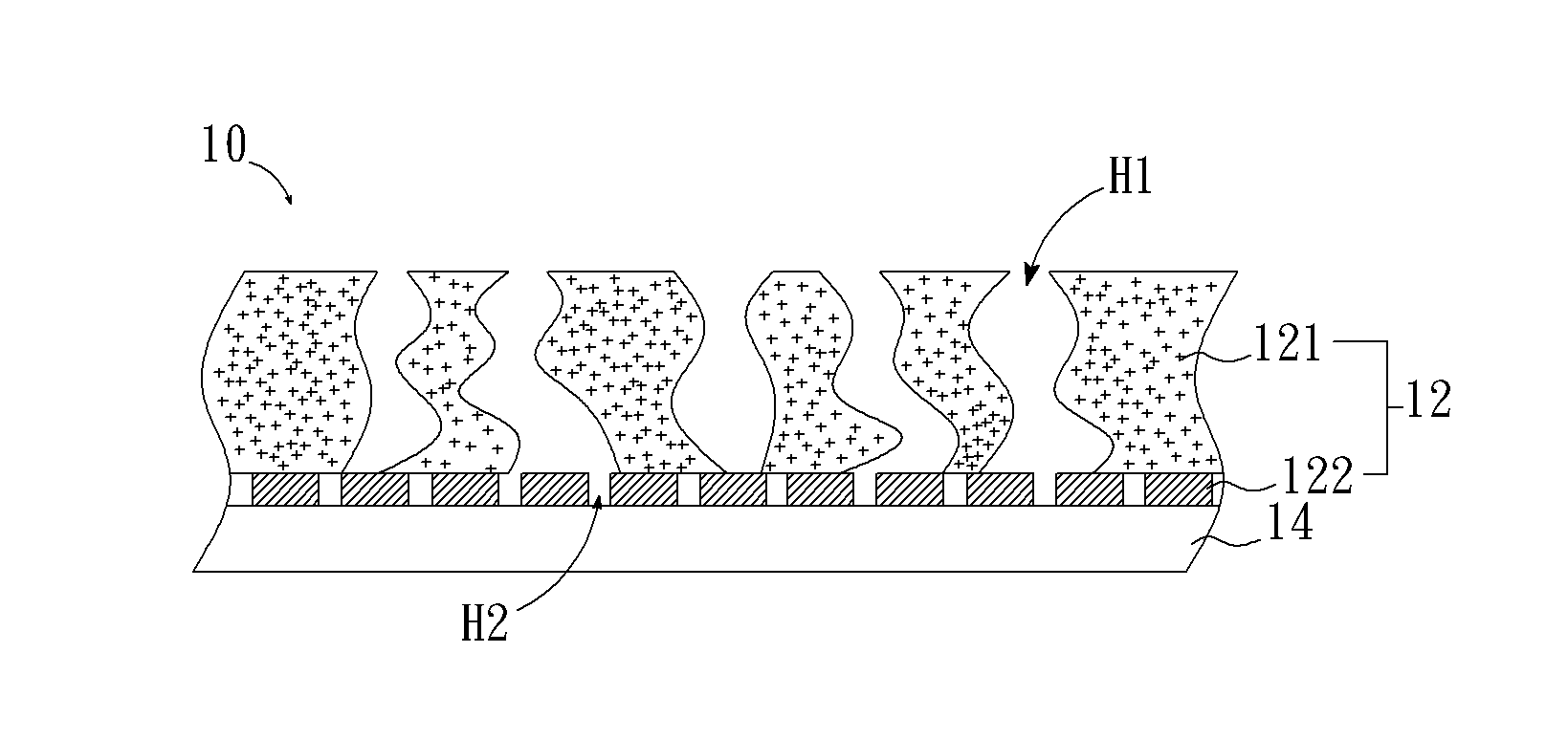

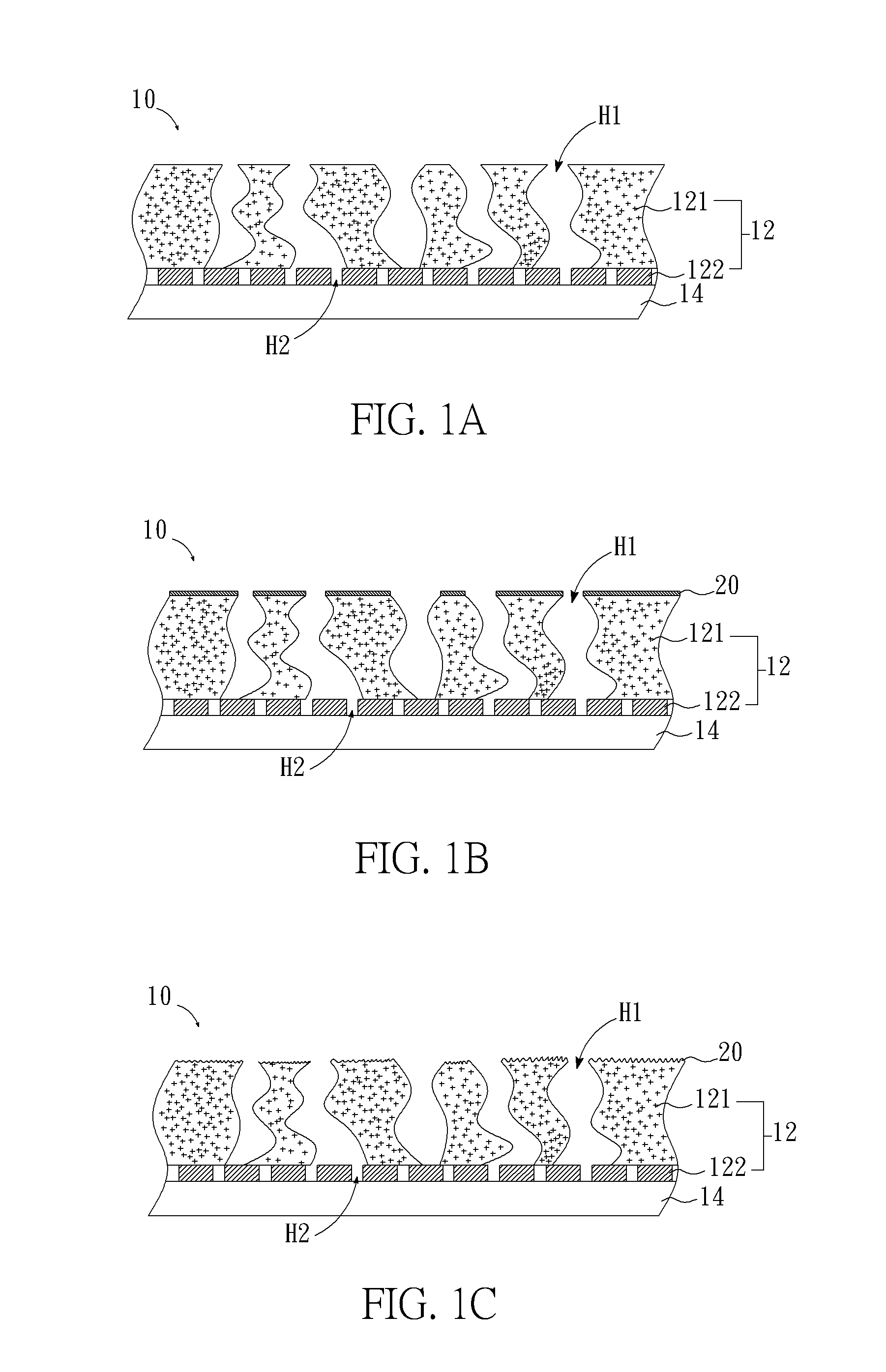

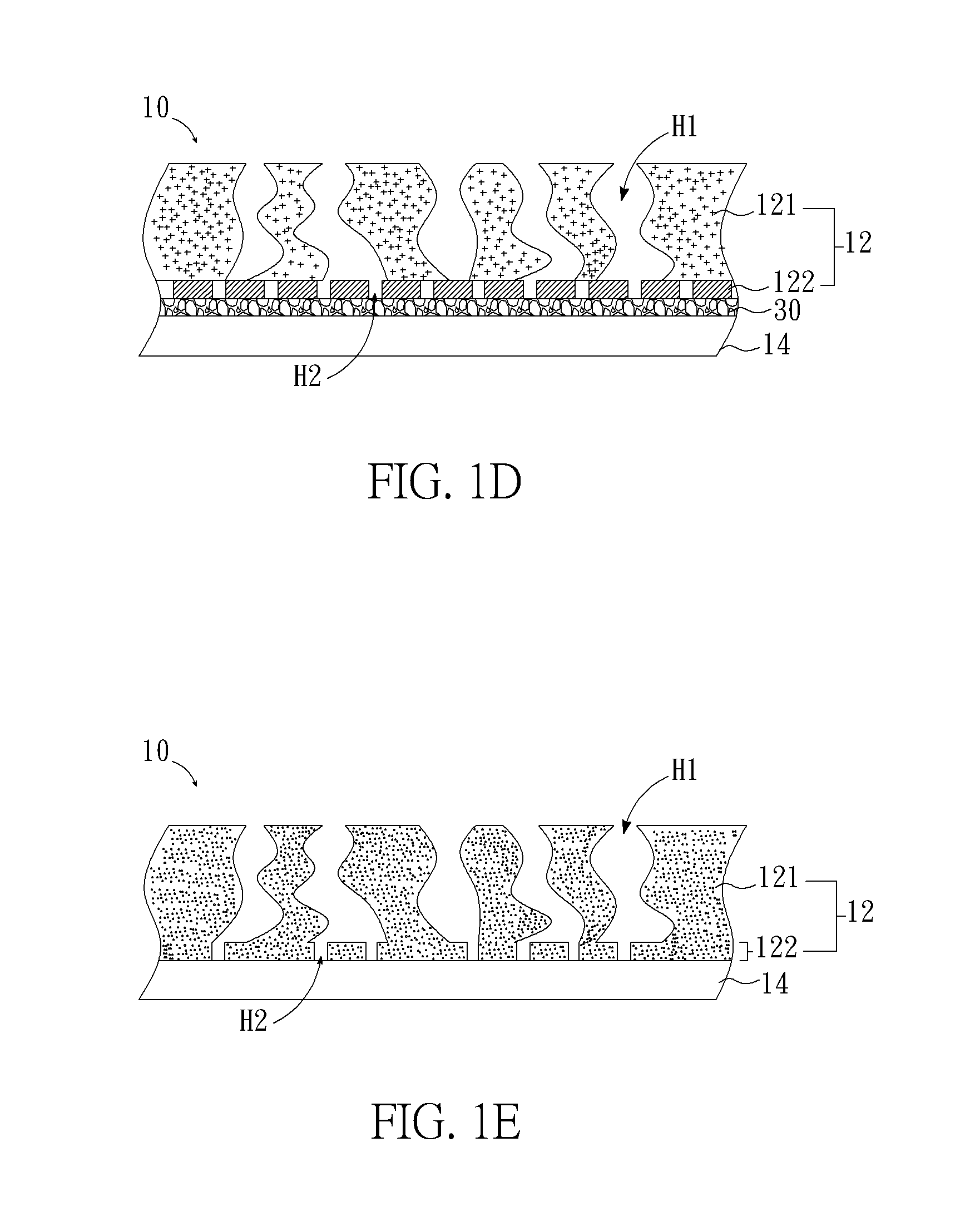

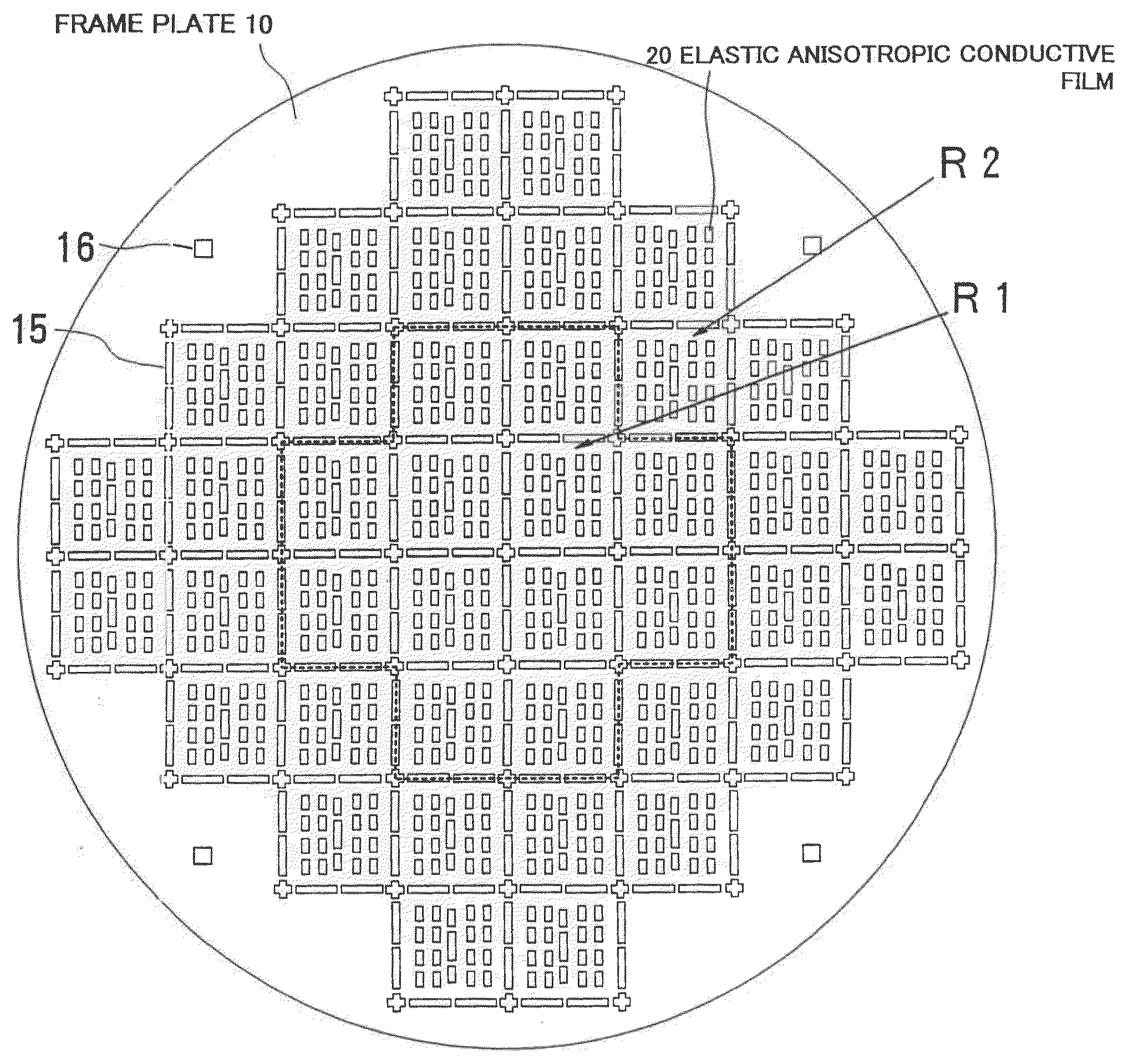

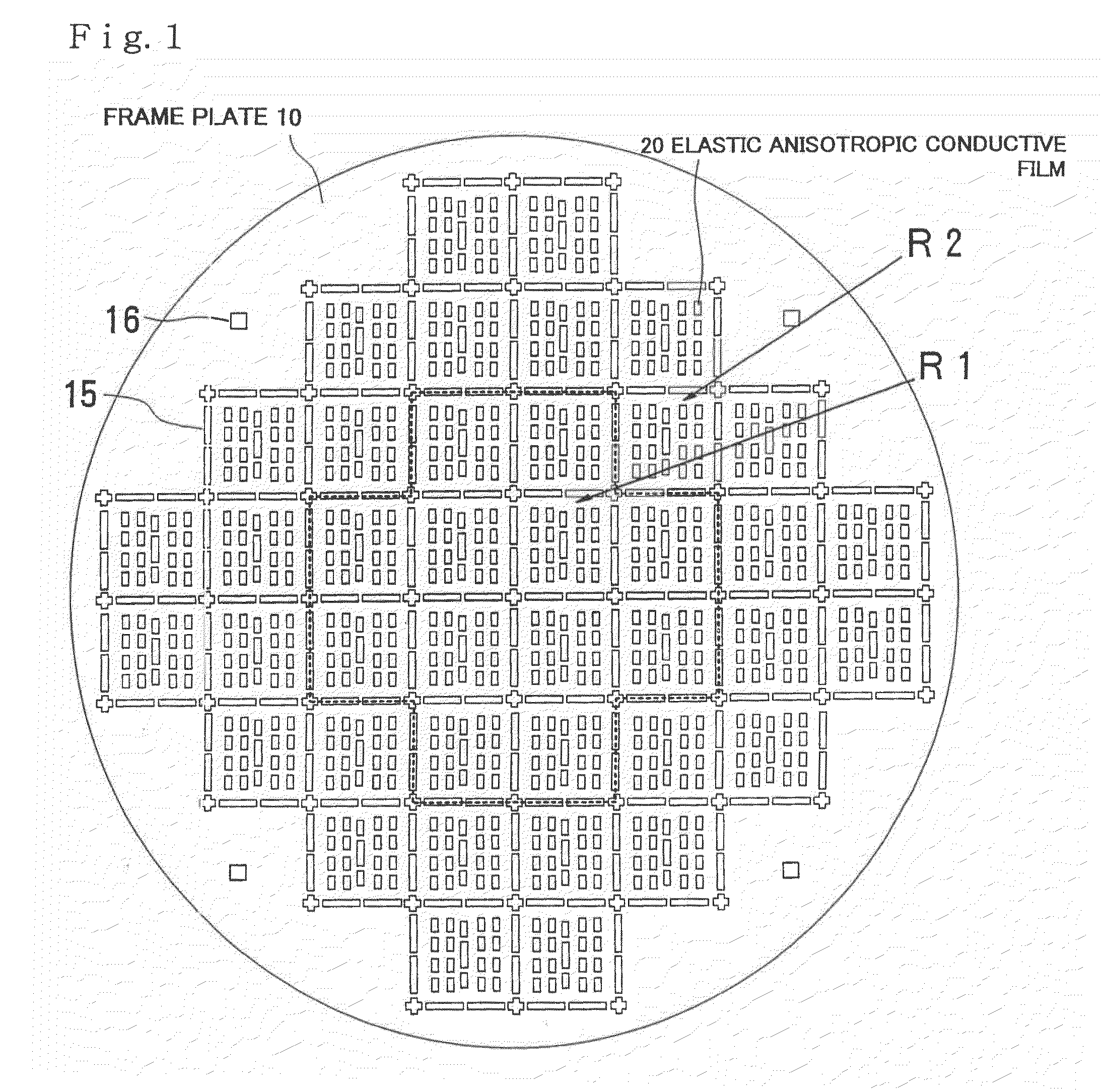

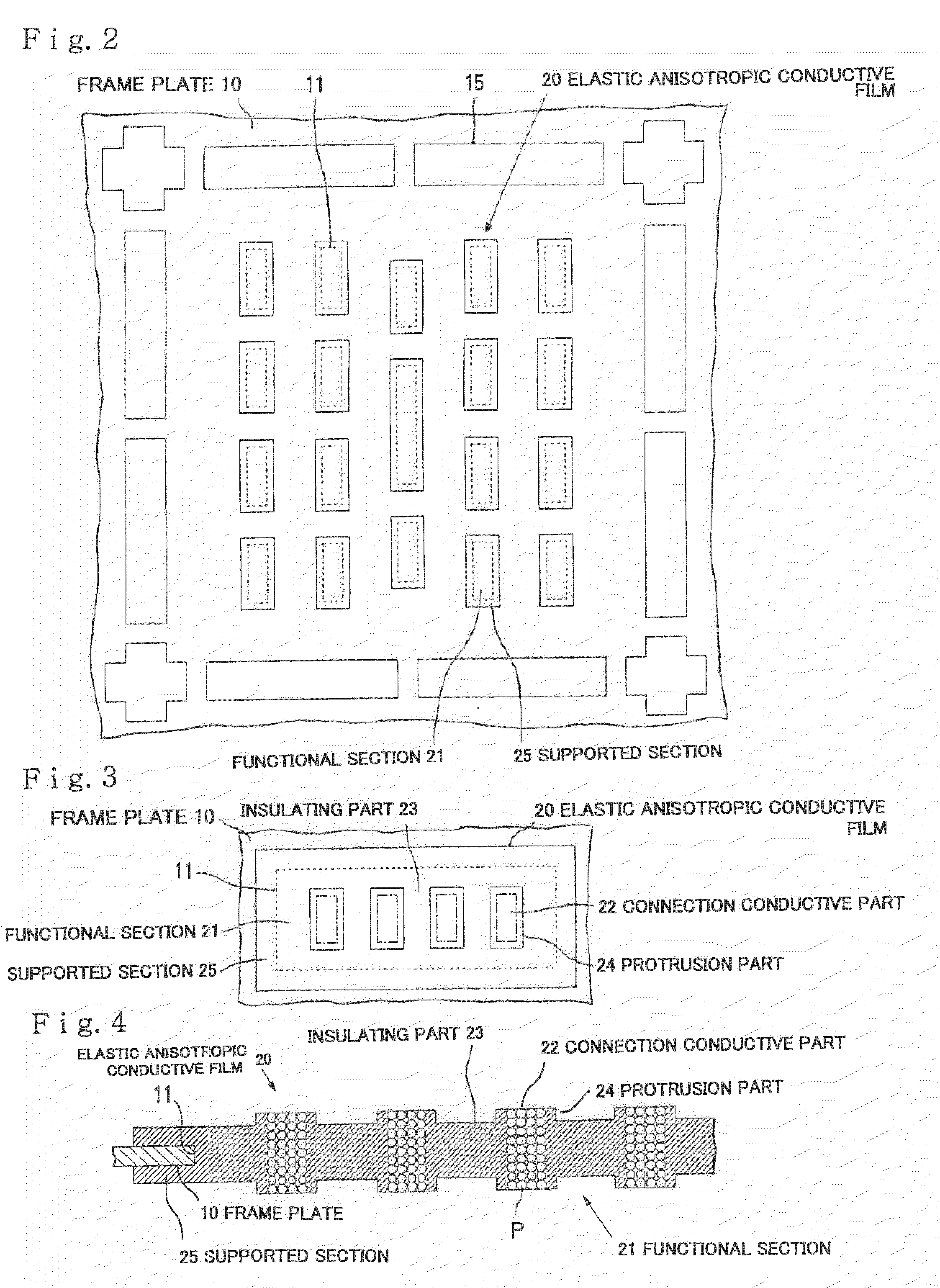

Anisotropic conductive connector, probe member and wafer inspection system

ActiveUS20100127724A1Uniform conductivityDecrease in conductivityNon-insulated conductorsElectrical measurement instrument detailsIntegrated circuitEngineering

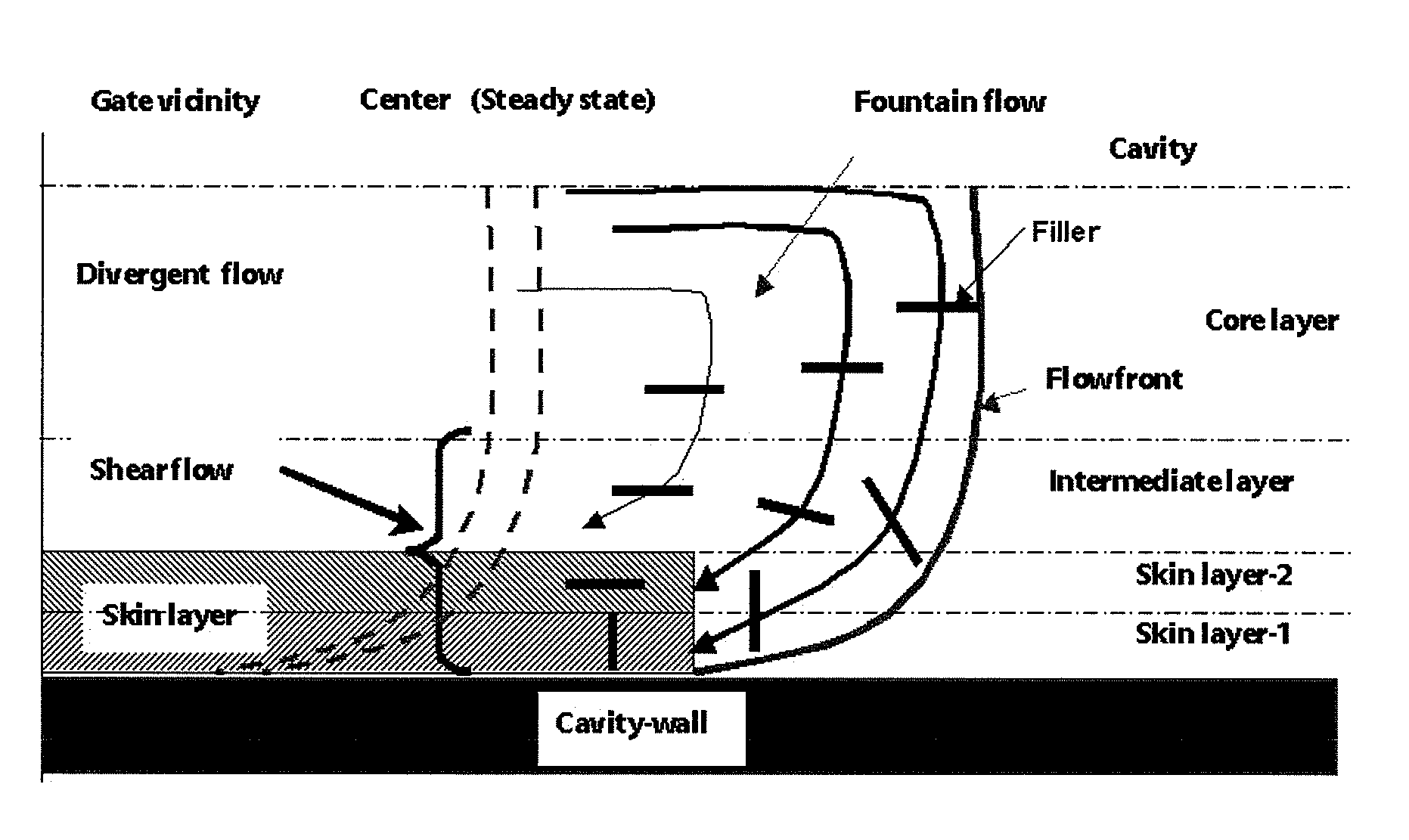

Provided is an anisotropic conductive connector and a prove member, each of which ensures that all of the conductive parts exhibit uniform conductivity when a pressing force is applied, even when the inspection target wafer has a large area and total number of inspection target electrodes of integrated circuits is 10,000 or more, and a wafer inspection system including the probe member. The anisotropic conductive connector includes a frame plate in which a plurality of anisotropic conductive film placement holes are formed, and elastic anisotropic conductive films respectively disposed in the anisotropic conductive film placement holes in the frame plate and supported by a peripheral part of the frame plate around the corresponding anisotropic conductive film placement hole, each of the elastic anisotropic conductive films includes a plurality of connection conductive parts each extending in a thicknesswise direction of the elastic anisotropic conductive film, being disposed corresponding to a connection target electrode, and comprising an elastic polymer substance and magnetic conductive particles densely contained in the elastic polymer substance; and an insulating part that insulates the connection conductive parts to one another, and the connection conductive parts of the elastic anisotropic conductive films disposed in a peripheral area of the frame plate having a thickness smaller than that of the connection conductive parts of the elastic anisotropic conductive films disposed in a center area of the frame plate.

Owner:ISC CO LTD

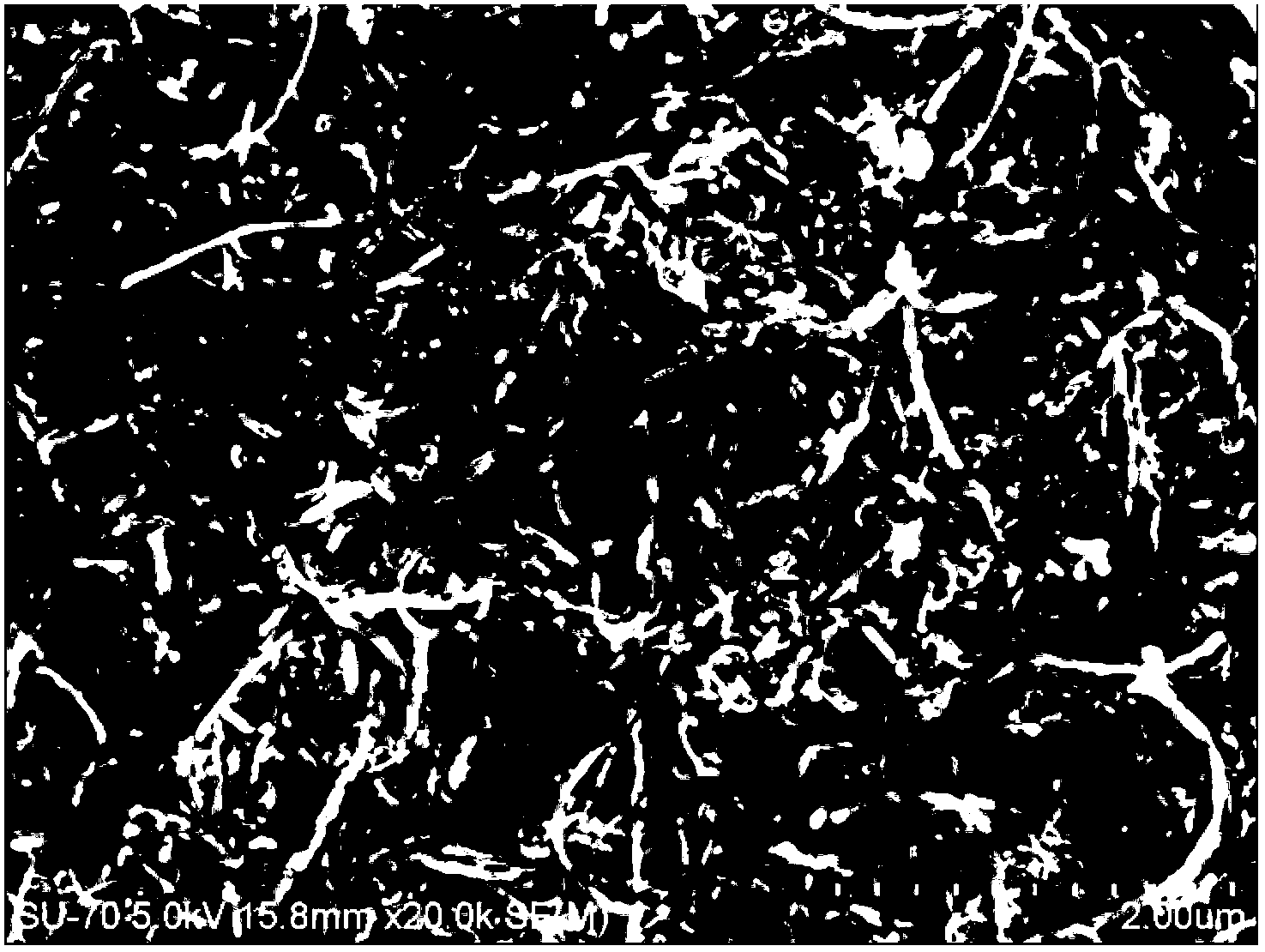

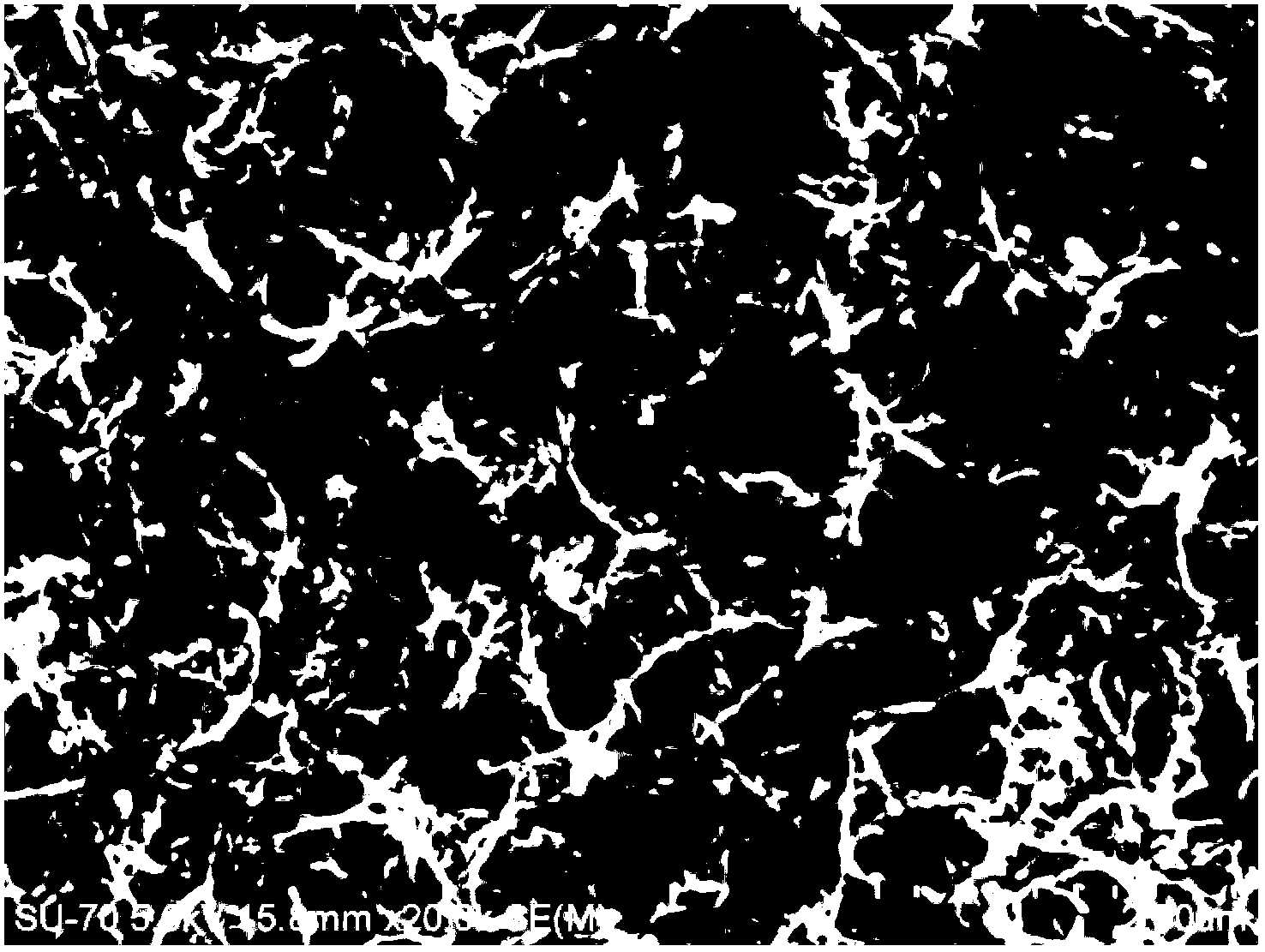

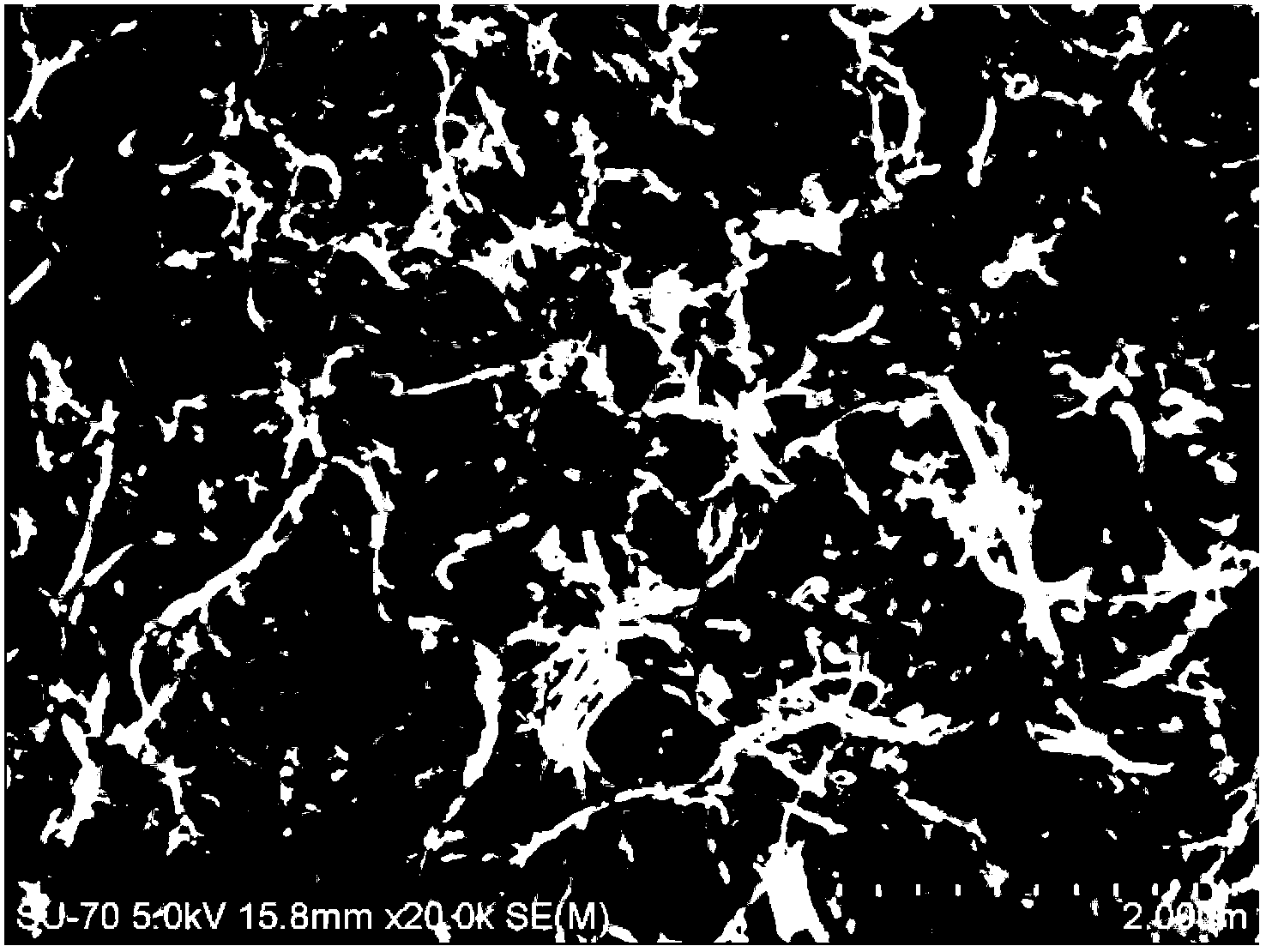

Carbon fibrous aggregator, method for manufacturing thereof, and composite material including thereof

InactiveUS20110168942A1Easy to disperseEvenly distributedMaterial nanotechnologyCarbon nanotubesFiberCarbon fibers

Disclosed is a carbon fibrous aggregator obtained by a chemical vapor phase growing method, which comprises plural granular parts, and plural carbon fibers which are mutually independently extended outwardly from their respective granular parts so that each granular part is associated with two or more of carbon fibers, wherein the carbon fibers show a three dimensional expansion in all; andwhich show a three dimensional network structure of the carbon fibers at least in a part by a state that at least a part of the plural carbon fibers extended from one granular part is linked with another granular part;wherein mean length of carbon fibers which link two granular parts together is of 3.0-20.0 μm, andwherein a coefficient of variation, CV, ((standard deviation / mean value)×100) which is obtained on a determination of outer diameter distribution of the carbon fibers which constitute the aggregator of carbon fiber is not more than 30%.

Owner:HODOGOYA CHEMICAL CO LTD

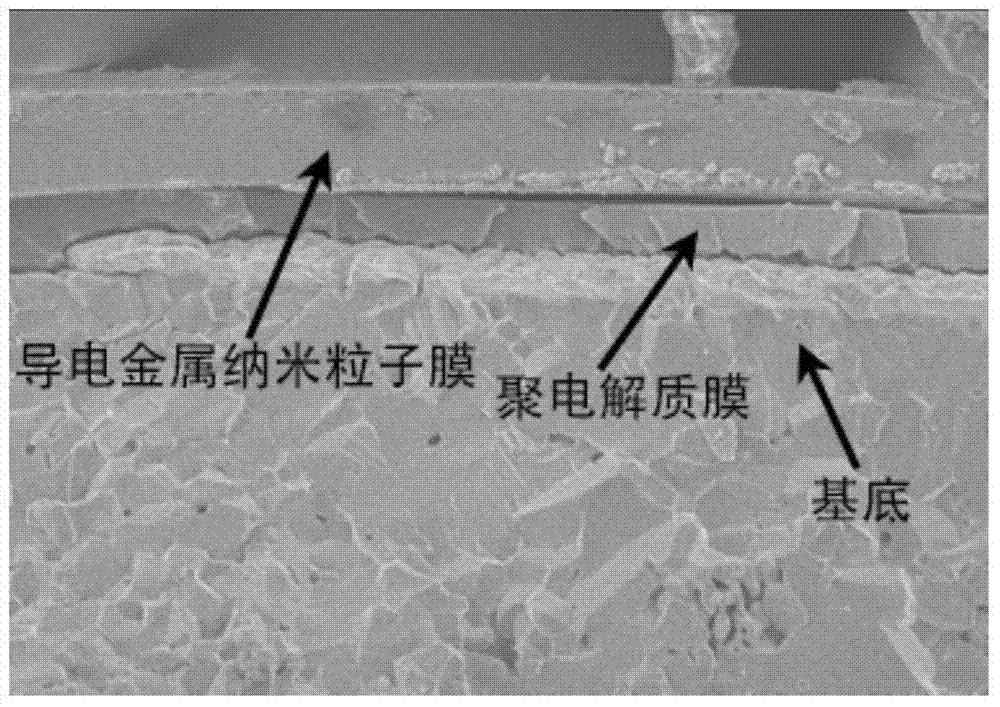

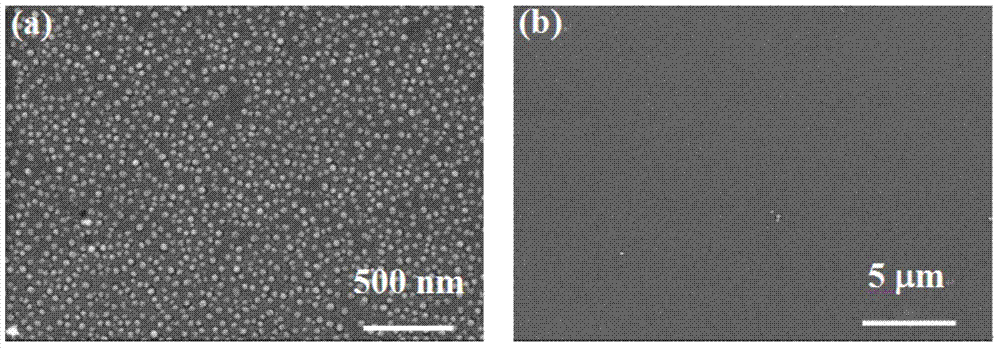

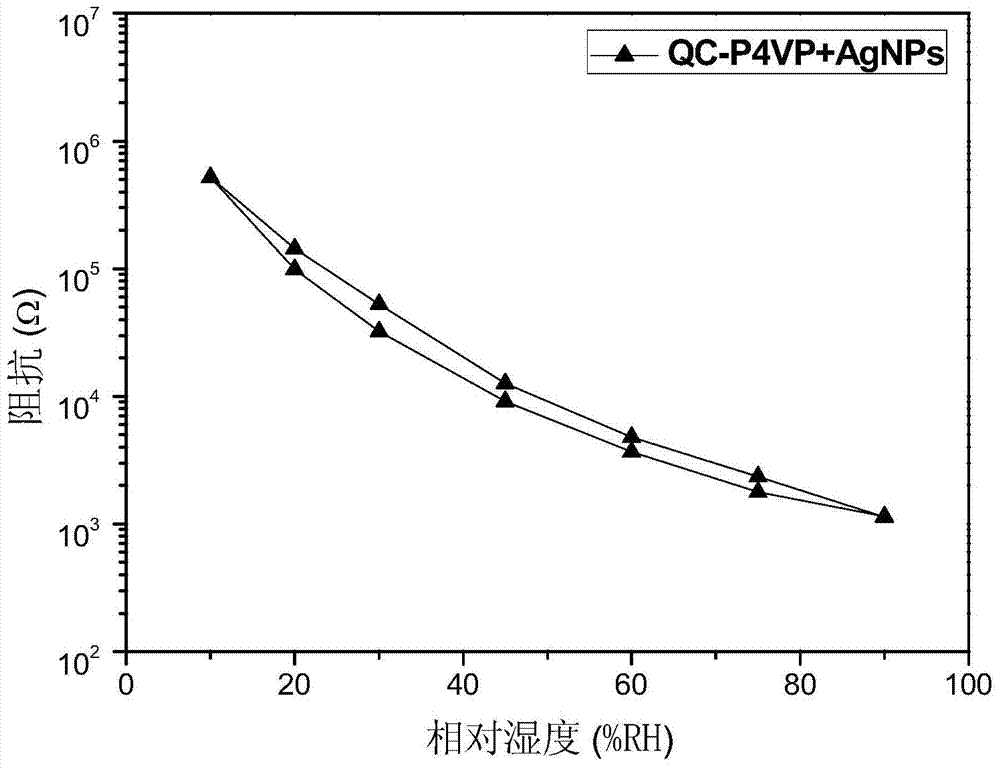

Humidity-sensitive composite membrane, preparation method of humidity-sensitive composite membrane and humidity sensor

ActiveCN104502420AHigh sensitivityImprove conductivityMaterial resistanceResponse sensitivityTransformer

The invention discloses a humidity-sensitive composite membrane. The humidity-sensitive composite membrane comprises a polyelectrolyte membrane and a conductive metal nanoparticle membrane. The polyelectrolyte membrane is obtained by a crosslinked quaternization reaction of a synthetic pyridine ring-containing polymer and dihaloalkane. The metal nanoparticle membrane is obtained by in-situ reduction crosslinking after metal salt-polymer mixed solution film forming. The humidity-sensitive composite membrane has low impedance (less than or equal to 10 megohms and even less than or equal to 1 megohm so that equipment detection is convenient) at low humidity (less than or equal to 30% RH), has high response sensitivity (wherein, preferably, 1-30% RH impedance change rate is 2000%), has good stability and water resistance, can be widely used for environment humidity detection and control in industrial and agricultural production, storage, meteorology, power supply security and protection, and daily life, and is especially suitable for sensitive detection of humidity in low-humidity environments such as insulating gas SF6 in a transformer box.

Owner:ZHEJIANG UNIV

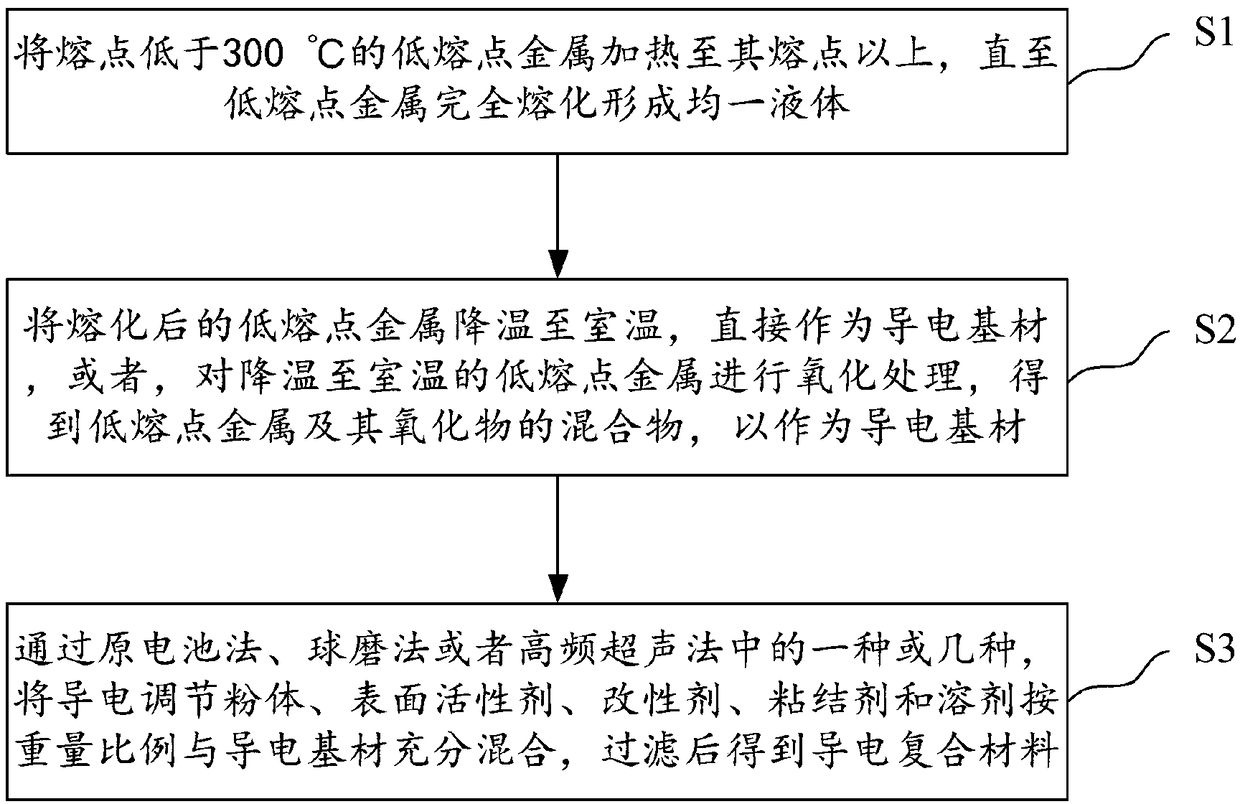

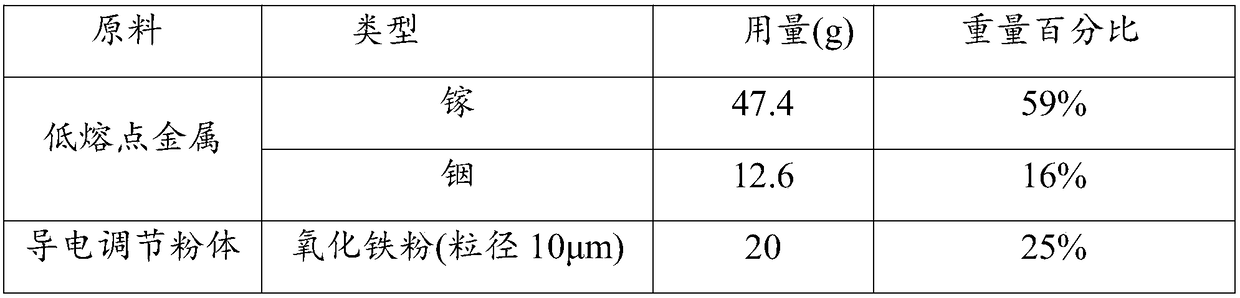

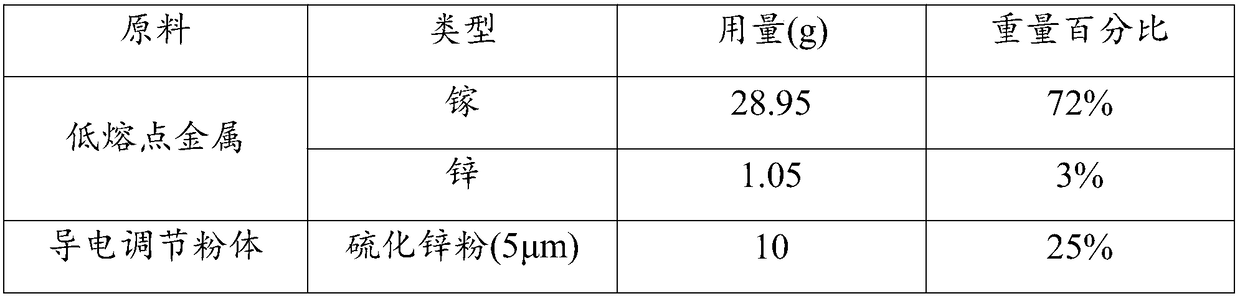

An electrically conductive composite material and a preparation method thereof

InactiveCN108986949AUniform conductivityLow costConductive materialOrganic conductorsSolventSURFACTANT BLEND

The invention provides an electrically conductive composite material, which relates to the technical field of composite materials. The electrically conductive composite material provided by the invention is composed of in percentage by weight, 30 to 80 percents of conductive substrate, 20 to 40 percents of conductivity adjusting powder, 0 to 5 percents of surfactant, 0 to 5 percents of modifier, 0to 10 percents of binder and 0 to 5 percents of solvent, wherein that conductive substrate is a low-melting metal with a melting point lower than 300 DEG C, or the conductive substrate is a mixture of a low-melting metal with a melting point lower than 300 DEG C and an oxide thereof. The technical proposal of the invention can uniformize the conductivity of the electrically conductive composite material.

Owner:BEIJING DREAM INK TECH CO LTD

Special anti-flaming conductive polycarbonate material and preparation method thereof

InactiveCN103073870AUniform conductivityUniform flame retardant performanceElectronic componentPolycarbonate

The invention relates to a special anti-flaming conductive polycarbonate material and a preparation method thereof, and belongs to the technical field of anti-flaming conductive plastics. The formula of the special anti-flaming conductive polycarbonate material comprises the following components in parts by weight: 61 to 85 parts of polycarbonate, 5 to 15 parts of flame retardant, 6 to 20 parts of conductive auxiliary, 1 to 15 parts of flexibilizer, 0.1 to 0.5 part of dispersing auxiliary, 0.1 to 0.5 part of coupling agent and 0.1 to 0.5 part of heat stabilizer. The preparation method comprises the following steps: (1) preparing mixture in a mixing machine; (2) adding the mixture into an extruder to melt and plasticize the mixture by heating; (3) extruding, cooling and granulating to obtain the special material. The special anti-flaming conductive polycarbonate material prepared by the method has relatively good flame resistance, electrical conductivity and mechanical property, and can meet the requirement of the packing material of an electronic component.

Owner:田敬华

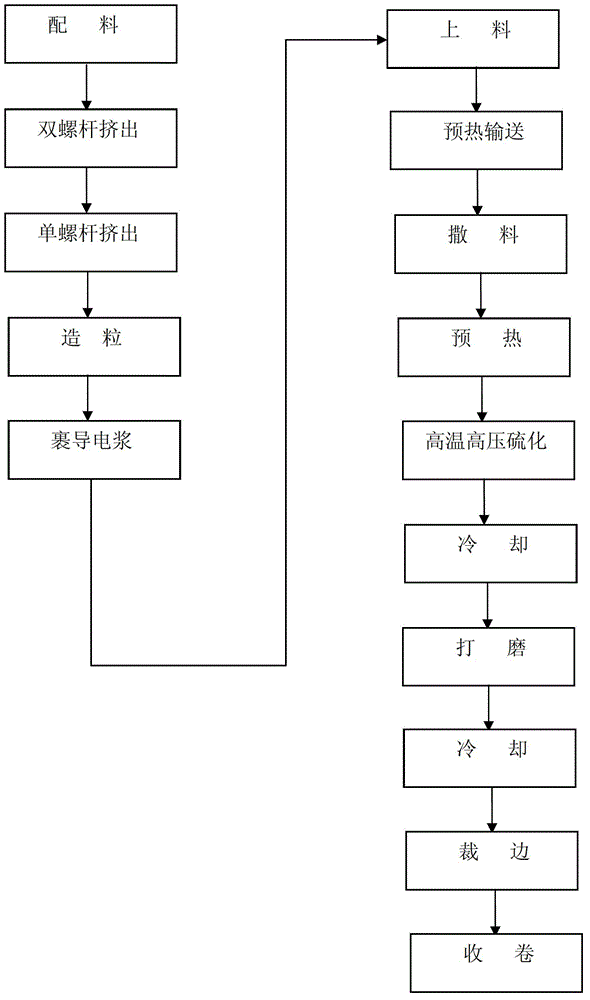

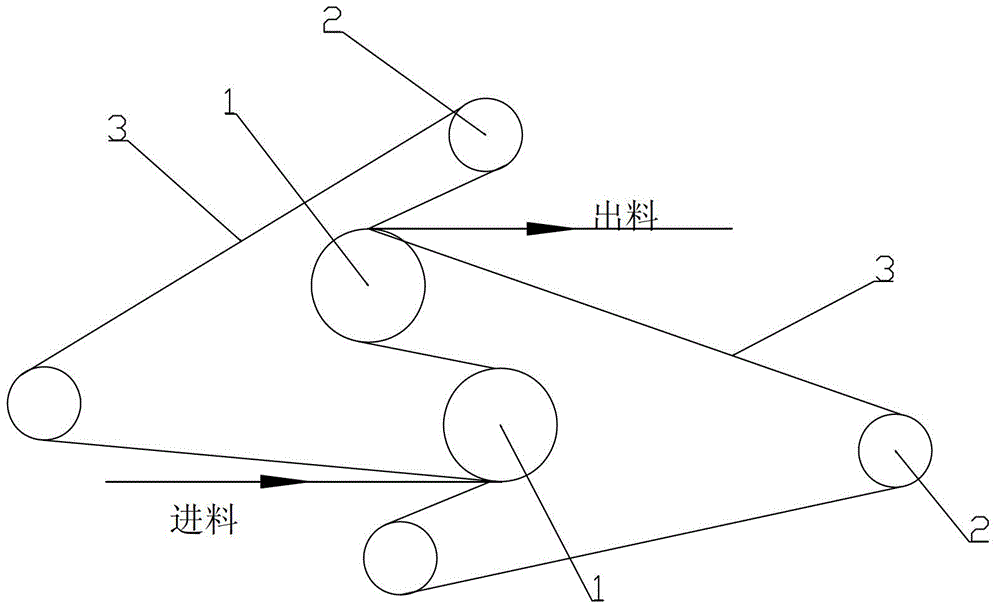

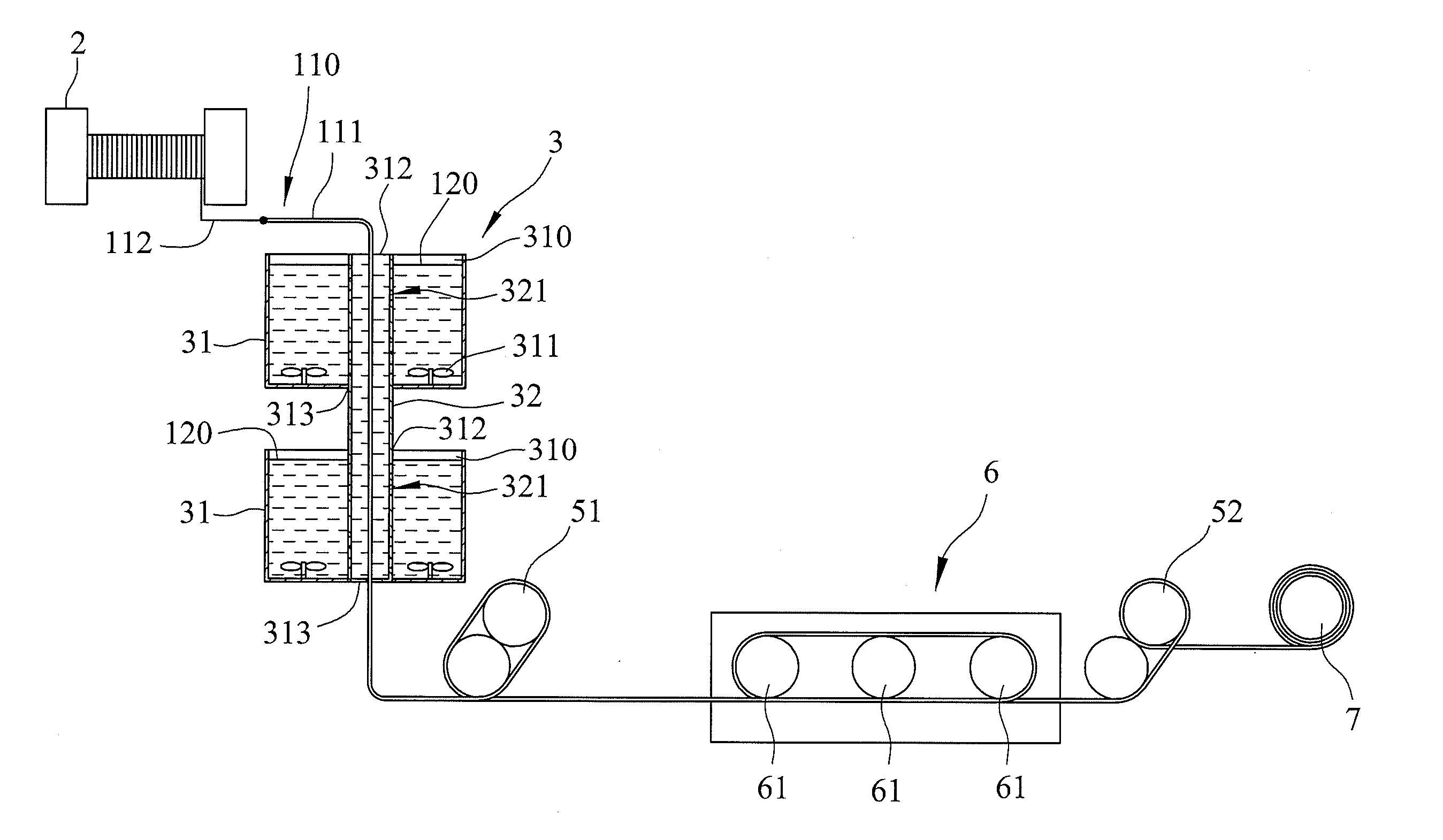

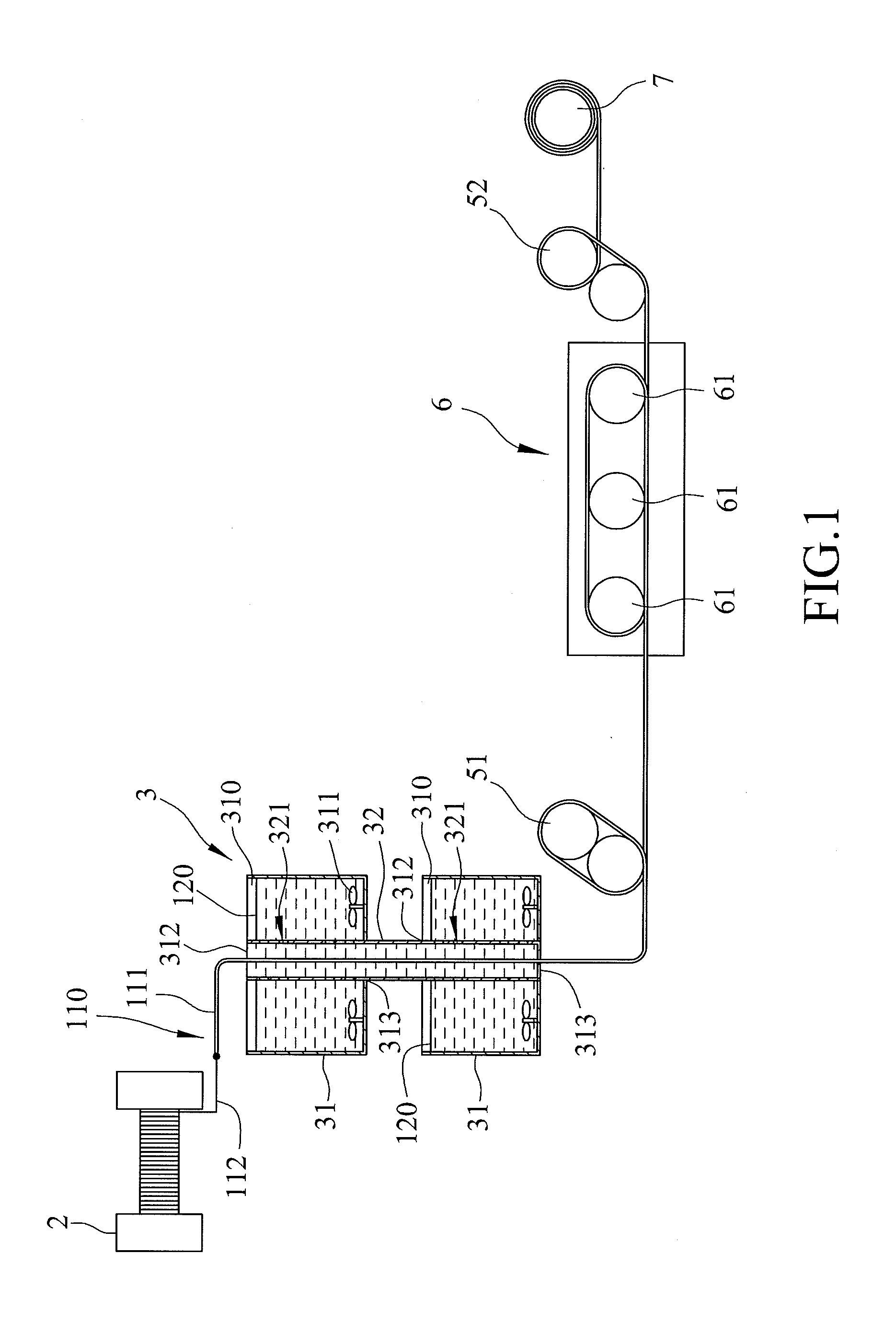

Preparation process of anti-static polyvinyl chloride (PVC) homogeneous through-core coiled material floor board

ActiveCN102873809AExtended service lifeUniform conductivityCovering/liningsVulcanizationPolyvinyl chloride

The invention relates to a preparation process of an anti-static polyvinyl chloride (PVC) homogeneous through-core coiled material floor board. The preparation process includes the following steps: PVC particles are prepared through a PVC granulating process; conductive slurry is wrapped on the surfaces of the PVC particles and dried, and a layer of conductive thin film is respectively formed on the surfaces of the PVC particles; or electric conductors are evenly mixed in the PVC particles; the PVC particles wrapped by the conductive thin film or the PVC particles mixed with the electric conductors are put into a drum-type vulcanizer to be molded through vulcanization; and aftertreatment is processed. The preparation process of the anti-static PVC homogeneous through-core coiled material floor board has the advantages of being simple in manufacturing process, good in stability, long in service life of the manufactured floor board, even in conductivity performance, small in joint during pavement, clear and natural in pattern and strong in third dimension. The dimension of the manufactured floor board can be 2.0m*50m generally or can be longer.

Owner:江苏丰树新材料科技股份有限公司

System for fabricating a conductive yarn from a preformed yarn

InactiveUS20140318445A1Low equipment costImprove processing effectivenessLiquid surface applicatorsCoatingsSlurryEngineering

A system for fabricating a conductive yarn from a preformed yarn includes a yarn spool, a soaking unit, a drying unit, and a yarn winder. The yarn spool is configured for winding and unwinding of the preformed yarn. The soaking unit is configured to receive a conductive slurry and to permit passage of a leading segment of the preformed yarn so that the preformed yarn is moistened with and absorbs the conductive slurry. The drying unit is configured to subject the preformed yarn that exits the soaking unit to a heat treatment to result in the conductive yarn. The yarn winder is configured to be connected to the leading segment of the preformed yarn and is configured for winding of the conductive yarn thereon.

Owner:ASIATIC FIBER CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com