Polyester fiber and textile product comprising the same

A polyester fiber and product technology, applied in the field of fiber products, to achieve the effect of stable conductivity and low humidity dependence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

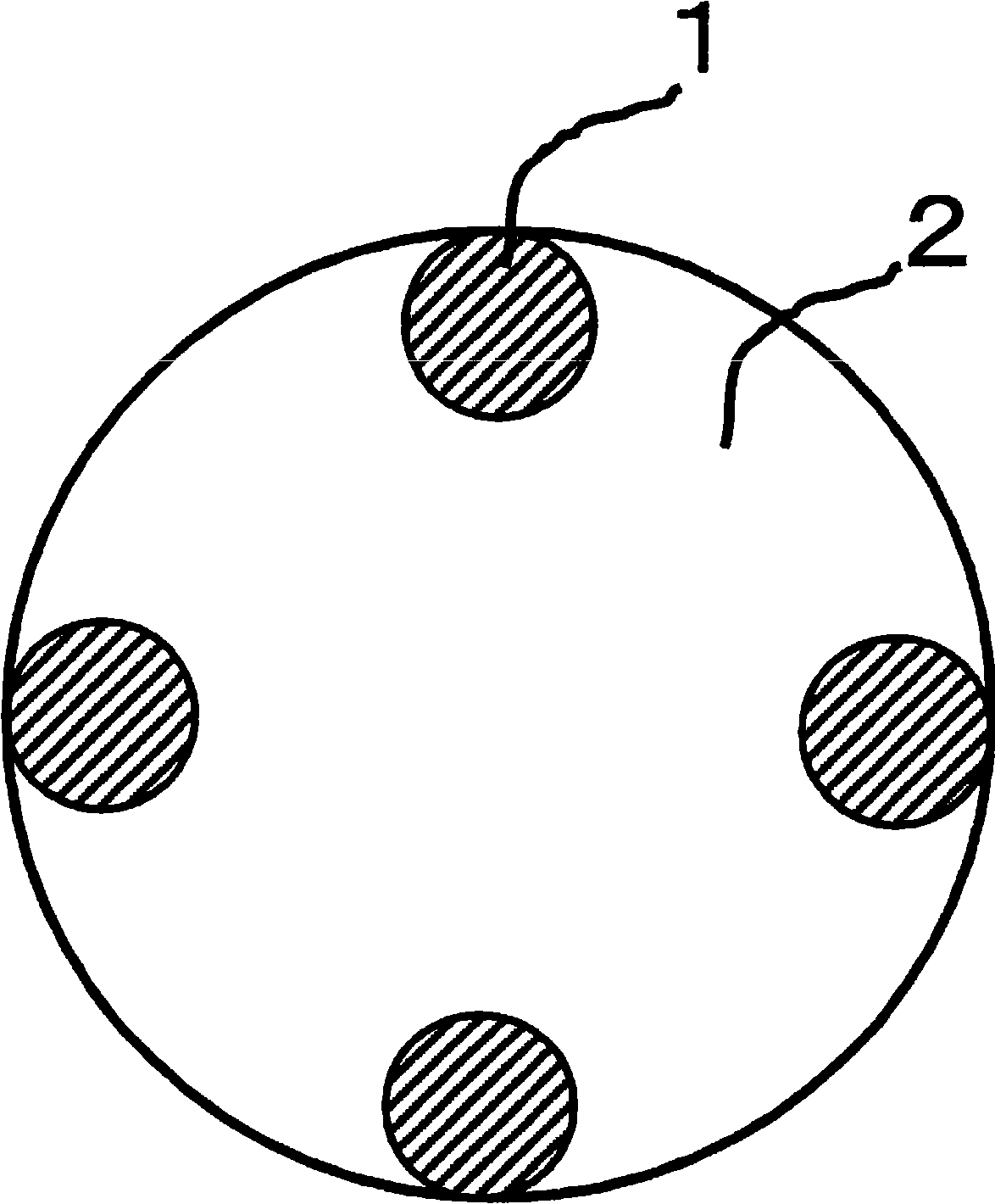

Image

Examples

Embodiment

[0100] The present invention is specifically and more specifically illustrated by the following examples, but the present invention is not limited to these examples. In addition, the physical property value in an Example was measured by the following method.

[0101] A. Determination of fineness [dtex] and single filament fineness [dtex]

[0102] A fiber (multifilament) having a length of 100 m is spun, the weight (g) of the skeined fiber is measured, and the measured value is multiplied by 100. The average value of three results obtained by carrying out the same measurement is taken as the fineness of the fiber. Regarding the single-filament fineness, the value obtained by dividing the above-mentioned fineness by the number of single fibers constituting the long fibers was taken as the single-filament fineness [dtex].

[0103] B. Determination of initial tensile elastic modulus, residual elongation, and breaking strength of fibers

[0104] Initial tensile elastic modulus (...

Embodiment 1

[0134] Example 1 (Manufacturing method of polytrimethylene terephthalate, preparation of CB-added polytrimethylene terephthalate component, production of fiber)

[0135] Add 130 parts (6.7 molar parts) of dimethyl terephthalate, 114 parts (15 molar parts) of 1,3-propanediol, 0.24 parts (0.014 molar parts) of calcium acetate monohydrate, 0.1 part of lithium acetate dihydrate ( 0.01 mole parts), carry out transesterification while distilling off methanol to obtain an oligomer, add 0.065 parts of trimethyl phosphate and 0.134 parts of tetrabutoxytitanium to this oligomer, and distill off 1,3-propanediol , while carrying out the polycondensation reaction to obtain fragmented prepolymers. The obtained prepolymer was solid-phase polymerized at 220° C. under a nitrogen flow to obtain an IV of 1.15, a melt viscosity of 493 [Pa·sec] (measurement temperature 260° C., 12.16 [1 / sec]), and a melting point (Tm) of Polytrimethylene terephthalate (hereinafter referred to as PTT) particles at...

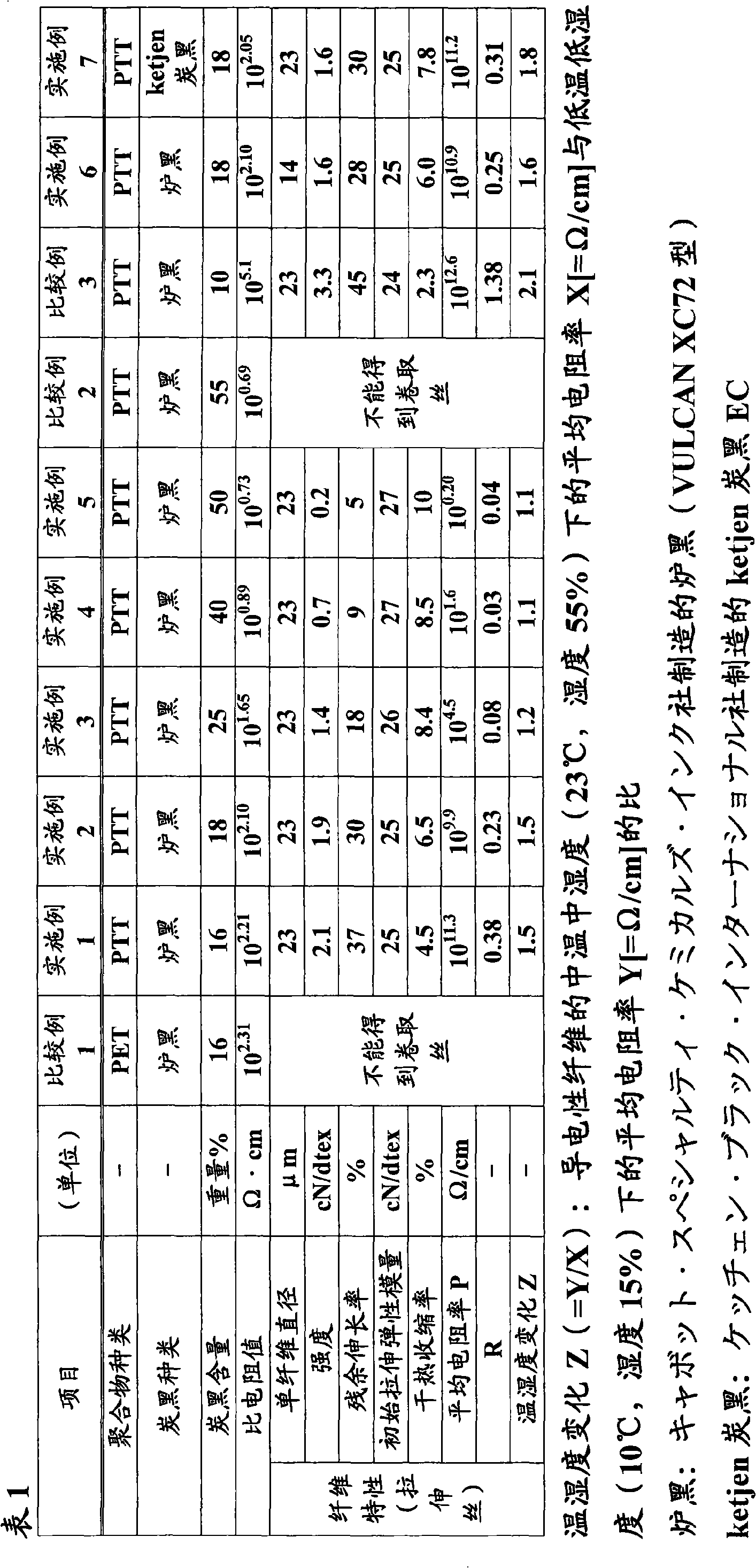

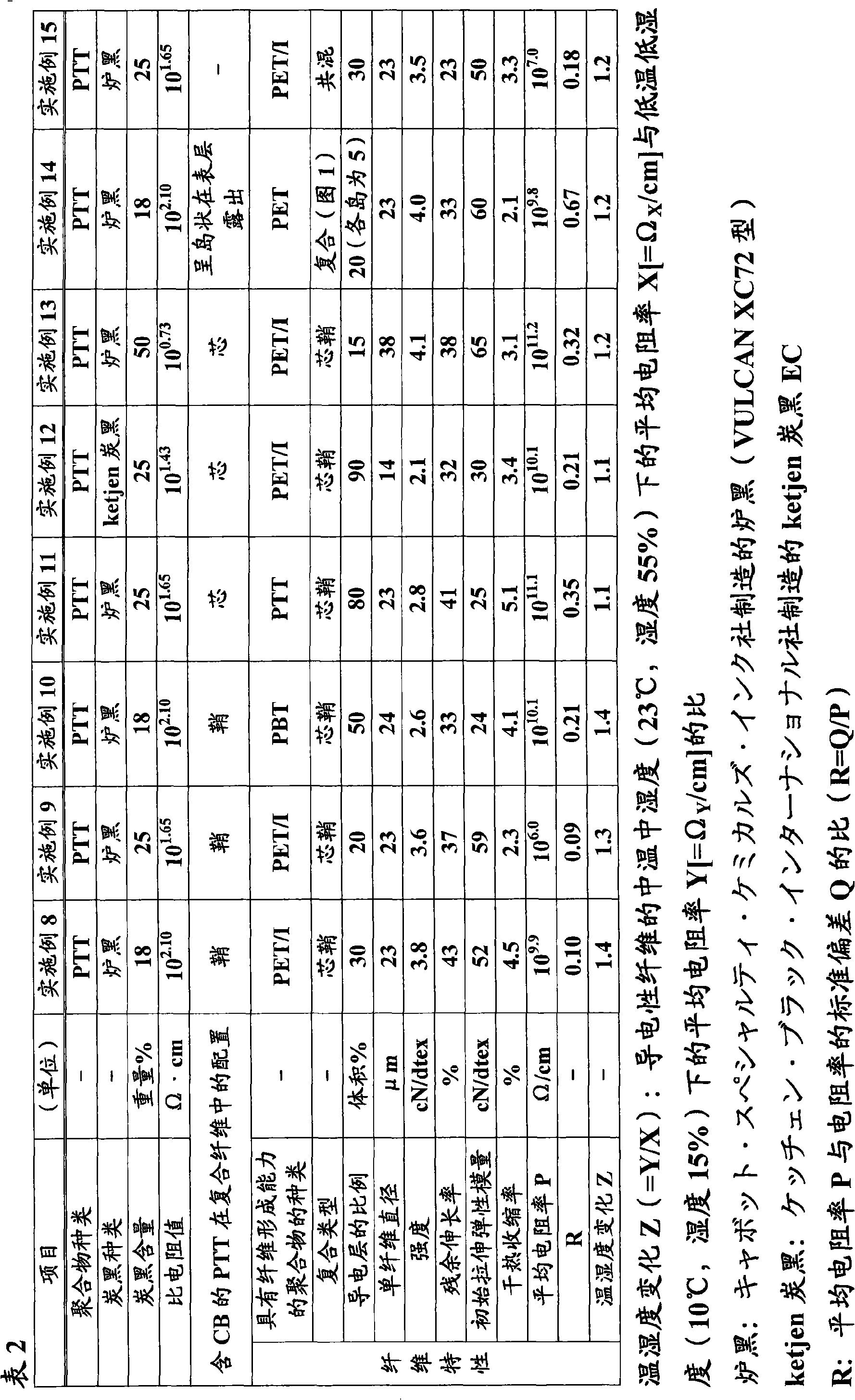

Embodiment 2~7 and comparative example 2、3

[0140] In Example 1, the amount of carbon black (Examples 2 to 5 and Comparative Examples 2 and 3) and the type of carbon black (in Example 7, ketjen carbon manufactured by Ketsutian Black Internasinal Co., Ltd.) were changed according to Table 1. Black EC, specific resistance value 0.2 [Ω·cm], average particle diameter 31nm, hereinafter referred to as KCB), fiber thickness (fiber diameter, 14 μ m in embodiment 6), except that, adopt the same as embodiment 1 Under the spinning conditions of , the same discharge amount (the same volume per unit time [cc / min]) was used in the spinning process. In addition, regarding the drawing conditions, except for the first roll in Examples 3 to 5, Except that the temperature was set at 80° C., the remaining fibers were obtained in the same manner as in Example 1. Even when the type of CB and the fiber diameter were changed, no problem occurred in the spinning property (Examples 6 and 7). In addition, as the CB content increases, among the p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Specific resistance | aaaaa | aaaaa |

| Melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com