Cathode material of lithium ion battery, preparation method of cathode, and lithium ion battery

A lithium-ion battery, cathode material technology, applied in battery electrodes, secondary batteries, circuits, etc., can solve the problems of affecting battery performance, high surface energy, difficult process, etc., to improve the rate and cycle performance, improve coating Area density, the effect of optimizing the coating process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

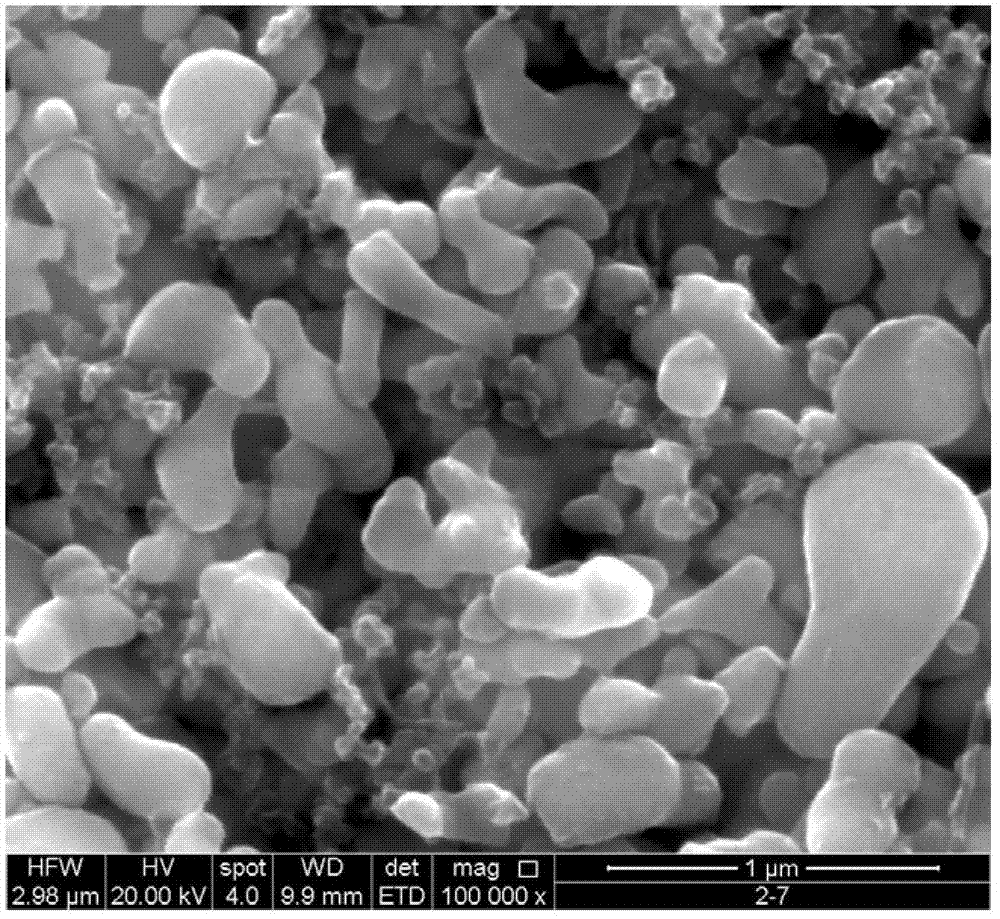

[0047] The positive electrode material of the lithium-ion battery in this embodiment is nano-lithium iron phosphate, polyvinylpyrrolidone, carbon nanotube+VGCF, L132 and deionized water according to the proportion formula of 90:1.5:5:5:77 by weight, carbon The weight ratio of nanotubes to VGCF is 1:1, and the positive current collector is made of pure aluminum foil.

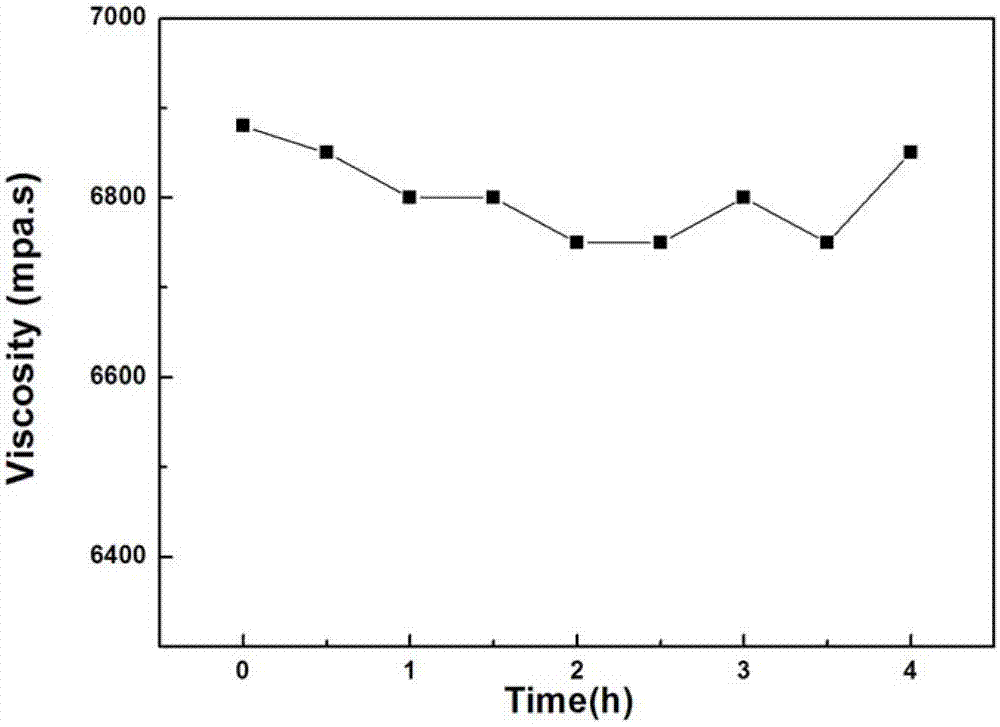

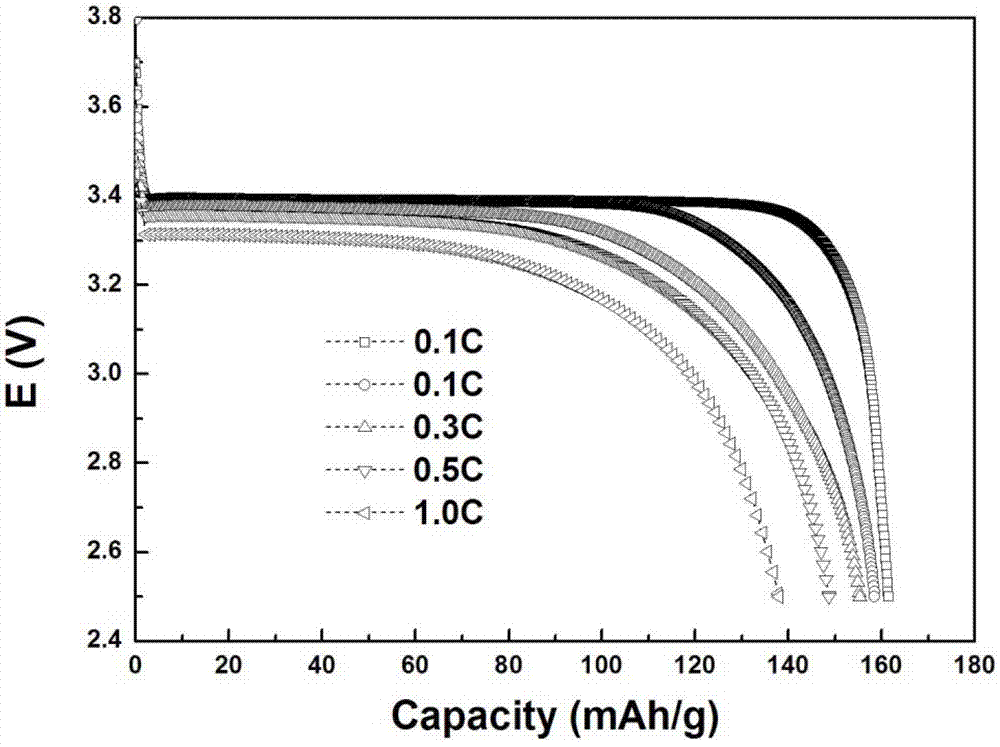

[0048] The preparation method of the positive electrode includes the following steps: accurately take each component of the positive electrode material, evacuate to a vacuum degree of 0.02Mpa, mechanically stir and disperse the slurry, the revolution speed of the stirring is 20 Hz, the rotation speed is 20 Hz, and the stirring time is 5 hours , and then adjust the slurry concentration to 4000mPa.s and then coat the pole piece. The coating temperature is 70°C, the coating speed is 4m / min, and then the pole piece is dried at 70°C for 7 hours.

[0049] The slurry in this embodiment is uniformly dispersed, and the pa...

Embodiment 2~9

[0052] Table 1 Example 2~9 Lithium-ion battery parameters values

[0053]

[0054]

[0055] Table 2 Embodiment 1~8 prepares the performance of the battery

[0056]

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com