Ferrolithium phosphate and its compound metal phosphide electrode material and producing method thereof

An electrode material, composite metal technology, applied in chemical instruments and methods, phosphorus compounds, battery electrodes, etc., can solve the problems of complex and harsh preparation process conditions, and achieve the effects of simple process, prolonged time and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

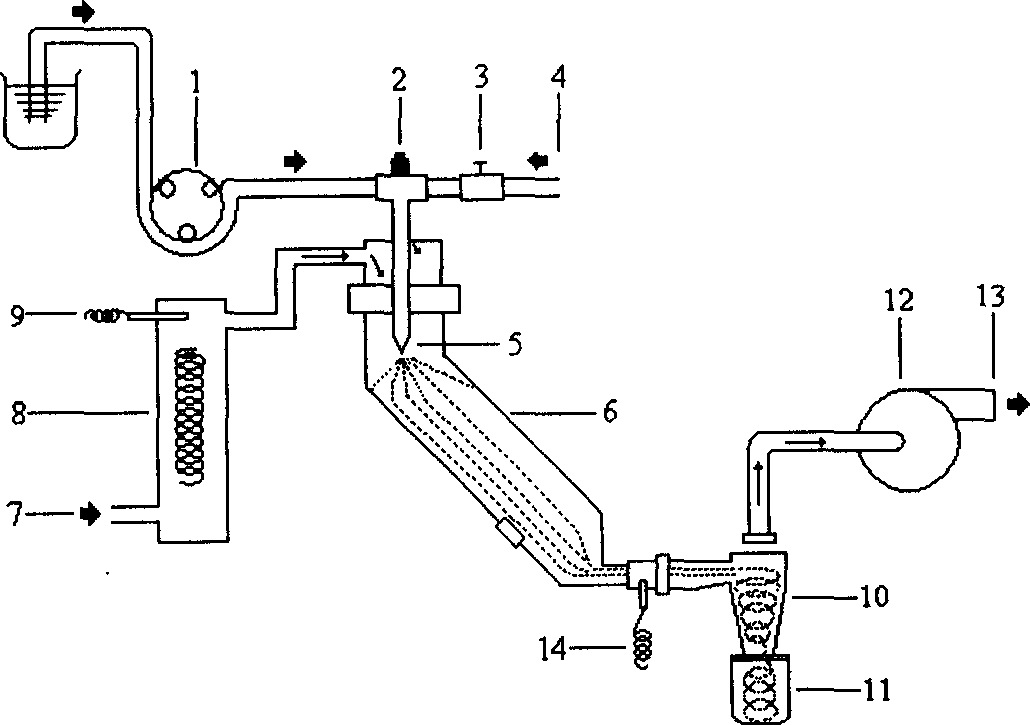

[0033] A spray heating device for preparing high-density spherical lithium iron phosphate such as figure 1 shown. 1-fluid pump, 2-injection valve, 3-needle valve, 4-high pressure nitrogen gas inlet, 5-nozzle, 6-high temperature chamber, 7-air inlet, 8-heater, 9-temperature sensor, 10-cyclone collector, 11-sample container, 12-exhaust fan, 13-exhaust port, 14-exit temperature sensor. One end of the sampling valve is provided with a fluid pump, the other end is provided with a high-pressure nitrogen gas inlet and is connected through a needle valve. The lower end of the sampling valve is provided with a nozzle, which extends into the high-temperature chamber. The cyclone collector is connected to the sample container; an exhaust fan and an exhaust port are arranged above the cyclone collector; an air inlet is arranged at the lower end of the heater, and a temperature sensor is arranged at the upper end. The main body of the high-temperature chamber is in an inclined state (abo...

Embodiment 2

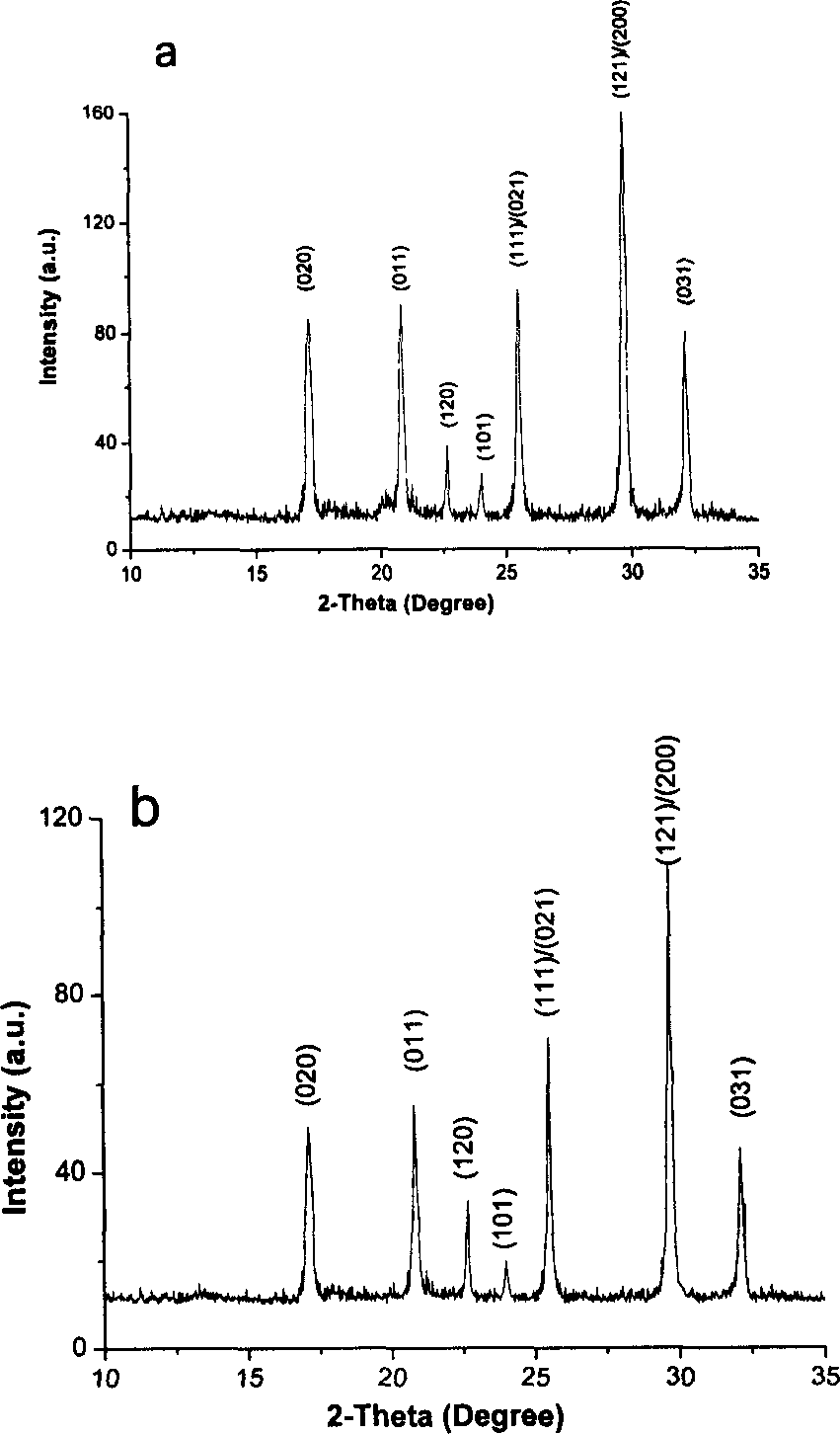

[0035] Example 2: High-density spherical LiFePO 4 preparation of

[0036] At room temperature, 100 mL of 0.1 M Fe(NO 3 ) 3 9H 2 O solution with 100 mL of 0.1M LiH 2 PO 4 The solution is mixed evenly and prepared into a mixed solution with a total volume of 200mL; after the mixed solution is introduced into the spray heating device by the fluid pump at a flow rate of 15mL / min, it is sprayed out from a nozzle with a caliber of 0.5mm along with high-pressure nitrogen gas, and enters with a diameter of 6cm. The high-temperature chamber is 100cm long, and the flow rate of high-pressure nitrogen is controlled at 100L / h. The temperature in the high-temperature chamber is controlled by a heater and a temperature sensor. The temperature at the inlet is 350°C, and the temperature at the outlet at the bottom is 120°C; the droplets ejected from the nozzle are instantly atomized and nucleated under the action of high-speed heat flow nitrogen in the high-temperature chamber ; Subseque...

Embodiment 3

[0037] Example 3: High-density spherical LiFePO 4 / NiP preparation

[0038] At room temperature, prepare 100mL of 0.1M Fe(NO 3 ) 3 9H 2 O solution with 100 mL of 0.1M LiH 2 PO 4 solution and mix well, then add NiSO 4 ·6H 2 O(5mM), Na 3 C 6 h 5 o 7 2H2 O(6mM) and NaH 2 PO 2 ·H 2 O (5mM) mixed solution and mix well. After the mixed liquid is introduced into the spray heating device by the fluid pump at a flow rate of 15mL / min, it is sprayed out from a nozzle with a diameter of 0.5mm along with high-pressure nitrogen gas, and enters a high-temperature chamber with a diameter of 6cm and a length of about 100cm. The flow rate of high-pressure nitrogen gas is controlled at 100L / h; the temperature in the high temperature chamber is controlled by a heater and a temperature sensor, the temperature at the inlet is about 350°C, and the temperature at the outlet at the bottom is about 120°C; the liquid droplets ejected from the nozzle are under the action of nitrogen gas of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com