Patents

Literature

114results about How to "Overcoming processability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

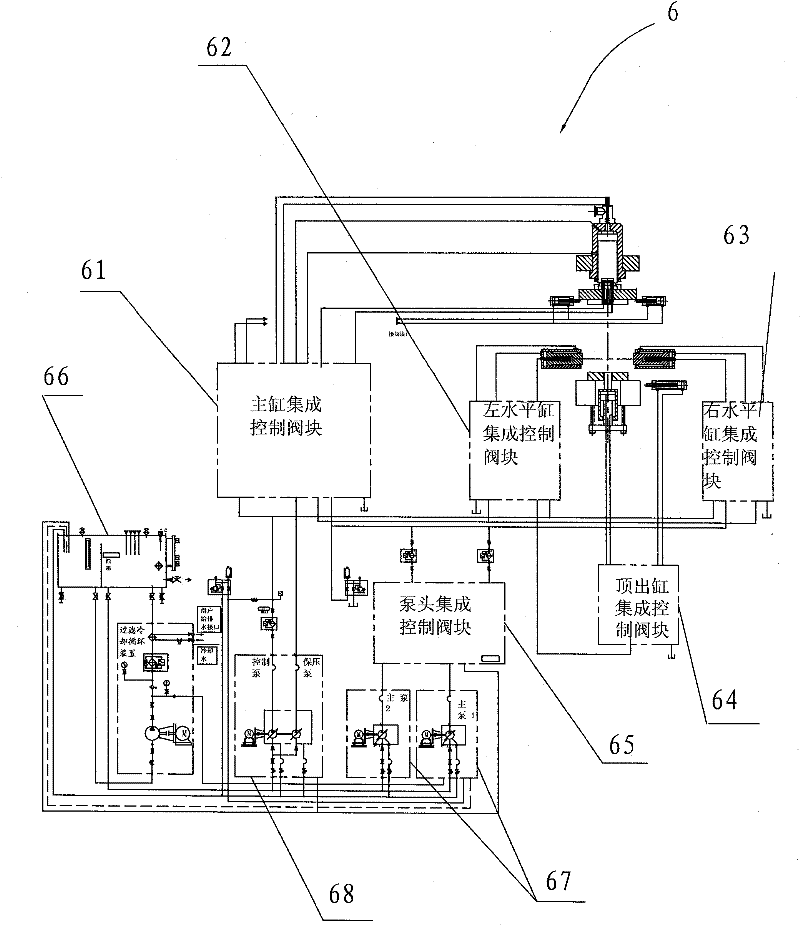

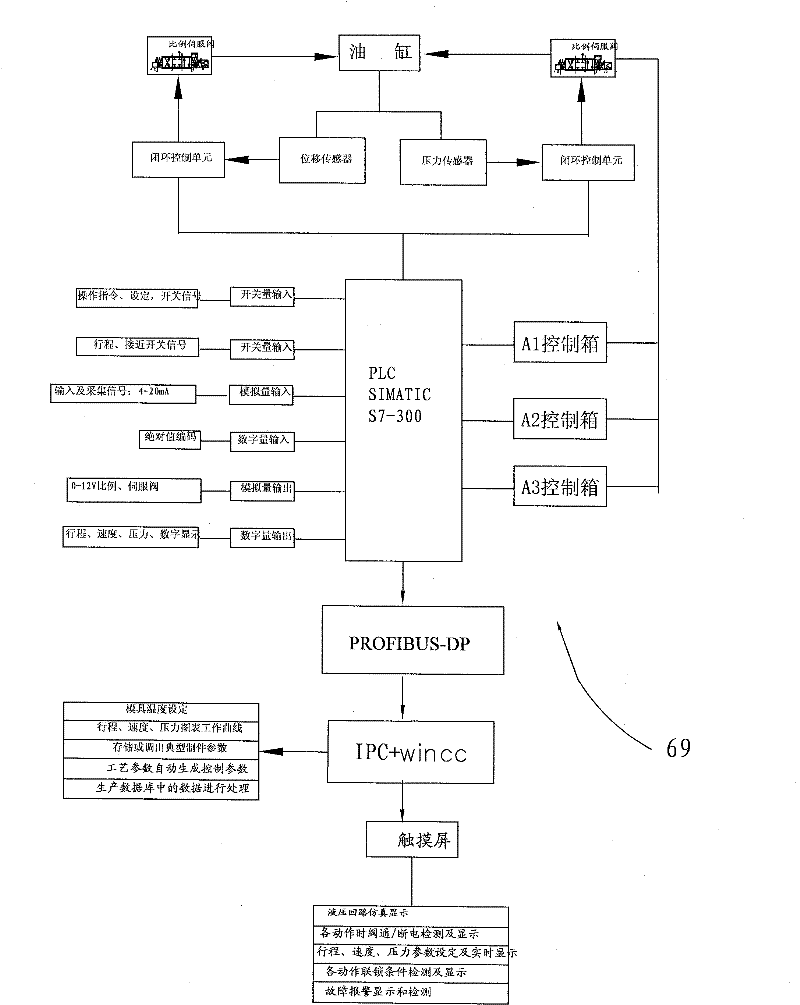

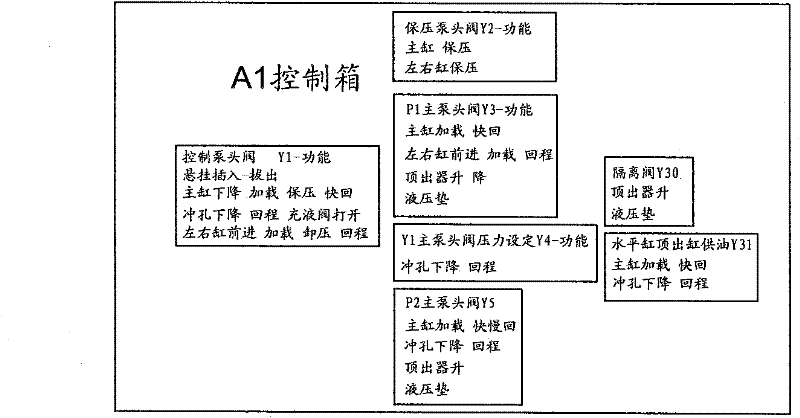

Multidirectional numerical control hydraulic press for metal plasticity forming

ActiveCN102049461AOvercoming single axisOvercoming processabilityForging press drivesNumerical controlPunching

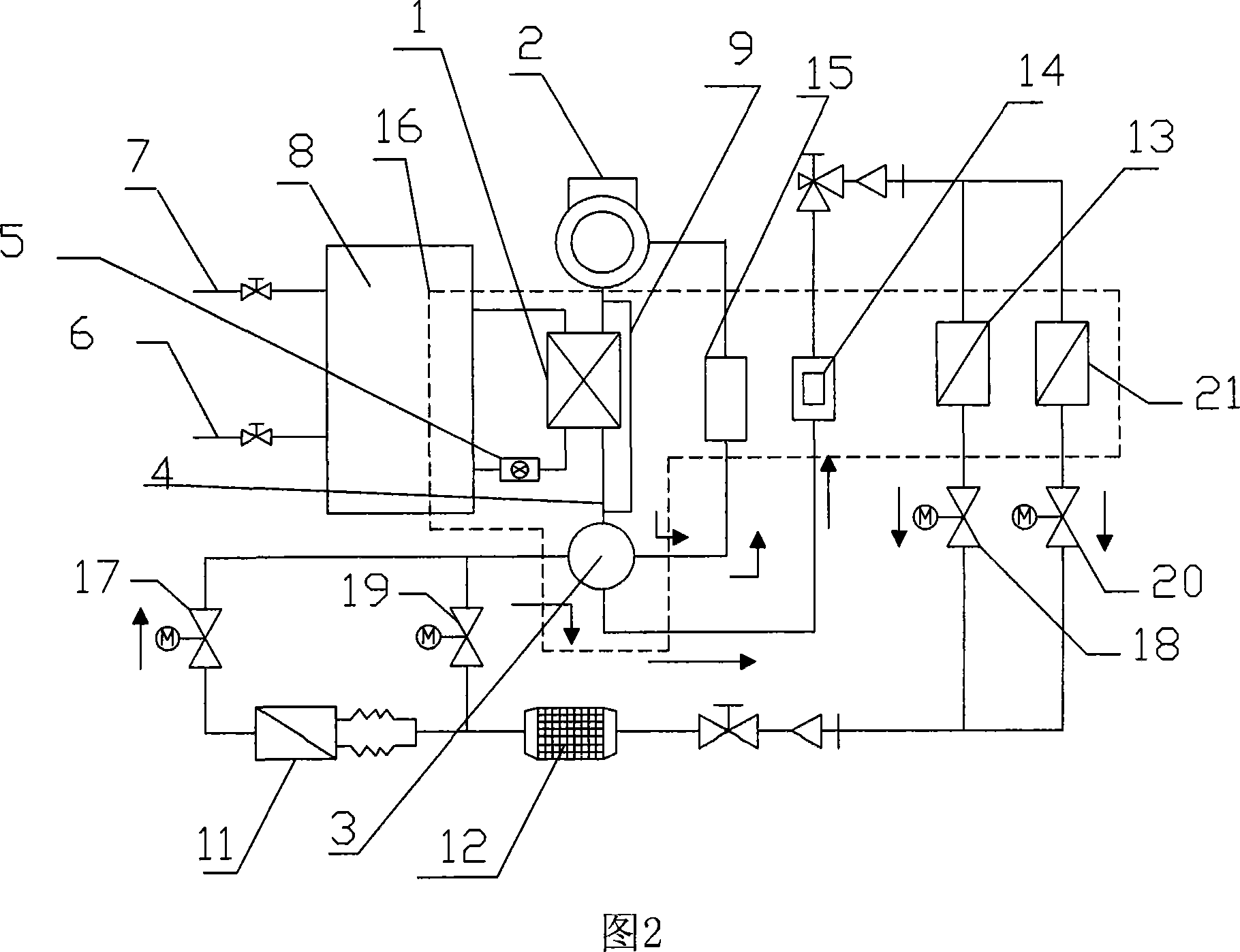

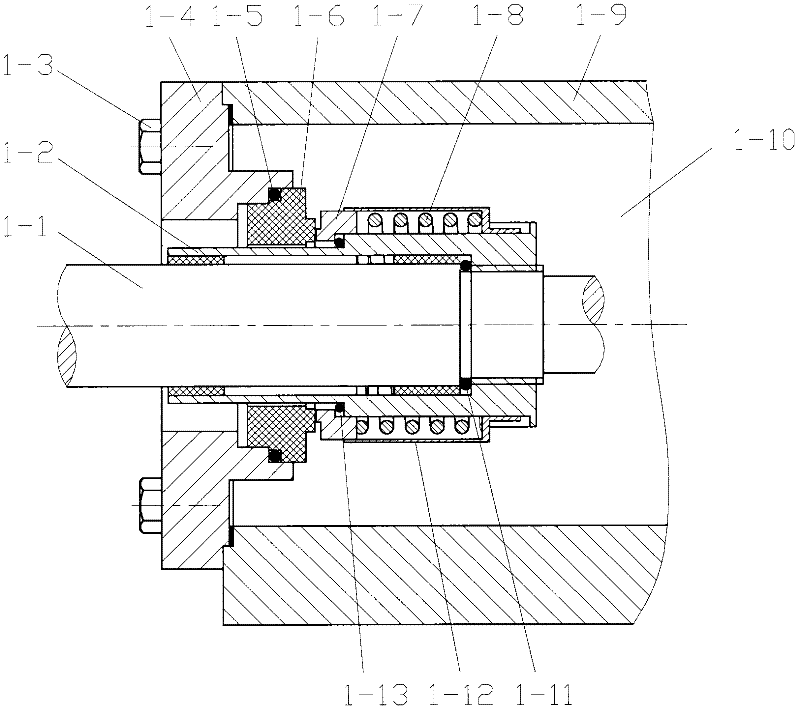

The invention mainly discloses a multidirectional numerical control hydraulic press for metal plasticity forming. A vertical main working cylinder, two horizontal cylinders and a push-out cylinder are mounted on a stress frame; a punching cylinder is combined inside the vertical main working cylinder stroking downwards, the two horizontal cylinders are a left horizontal cylinder and a right horizontal cylinder both of which stroke in the opposite directions, and each horizontal cylinder is combined with a quick-speed cylinder; the push-out cylinder is positioned below the vertical main working cylinder and adopts an inverted cylinder acting structure; and all cylinder bodies are controlled by a hydraulic control system. In the invention, an oil pump is used for direct driving, numerical control closed loop servo control is achieved, and meanwhile, axial loading and transverse loading are performed at the same time, so as to form high-precision parts with branch shaped or cavity-like complex structures in different directions.

Owner:ZHONGBEI UNIV

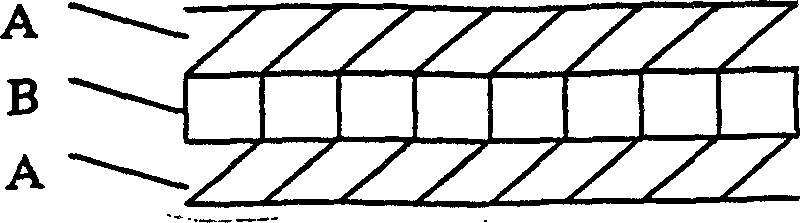

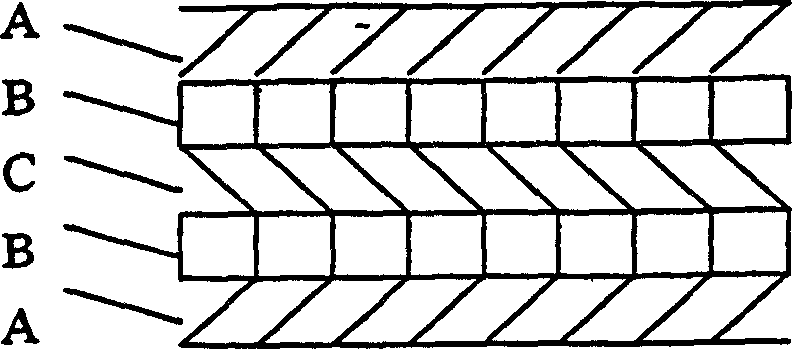

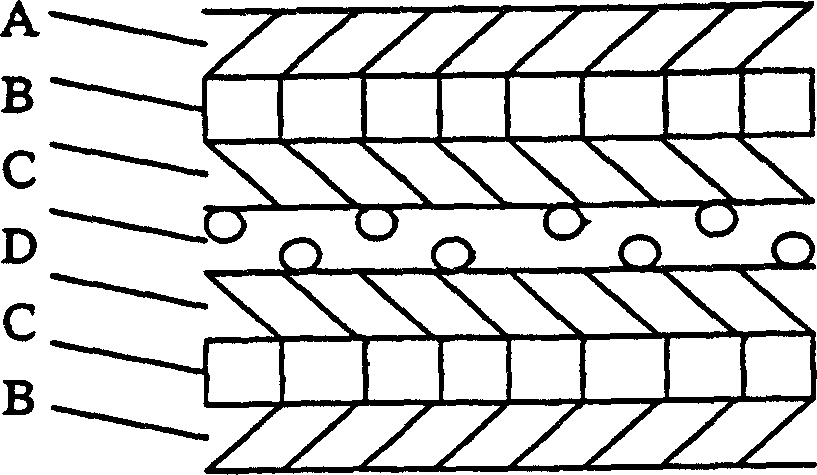

Foodstuff packaging membrane and its manufacturing method

InactiveCN1736813AHigh transparencyGood air resistanceFlexible coversWrappersPolymer sciencePolyolefin

The invention discloses a production of food packaging film and the method for preparation, specifically a degradable complex film prepared with degradable nanometer PA polymer as the obstruct material. Said complex film has a layer structure containing at least two outer layers and one interlayer, at least one layer among which is the obstruct layer, the obstruct layer being made up of degradable nanometer PA polymer, and others being made up of degradable polyolefin or polyolefin. Compared with the high-obstruct film prepared with PVDC, the invention overcomes the shortcomings that the manufacture is hard, the cost is high, environmental pollution is serious, and the recovery is hard. And the high-obstruct packaging film prepared mainly with nanometer PA has identical obstruct effect with PVDA film.

Owner:朱春英

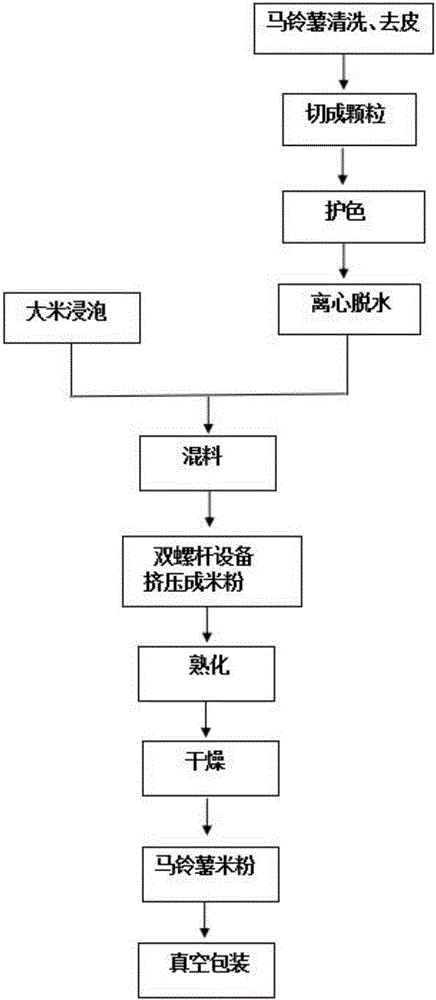

Processing method of fresh-cut potato rice-flour

ActiveCN106063545AReduce moisture contentOvercoming high moisture contentFood scienceTemperature controlSolanum tuberosum

The invention discloses a processing method of fresh-cut potato rice-flour. The method mainly contains the following steps: Step 1, soaking rice to obtain soaked rice; dicing fresh potatoes, and carrying out centrifugal dehydration until water content is 65-75% to obtain fresh-cut potato granules; Step 2, extrusion forming: mixing the soaked rice and the fresh-cut potato granules according to the mass ratio of 1-3:1, and carrying out extrusion forming to obtain primarily-processed rice flour, wherein technological conditions of the extrusion forming are as follows: bore diameter of a rice-noodle producing board is set as 1.5-2.0 mm; feed speed is 54-70 r / min; twin-screw speed is 130-170 r / min; and middle area temperature of an extrusion cylinder is 95-110 DEG C; Step 3, curing, letting the primarily-processed rice flour stand at the temperature of 18-20 DEG C at the relative humidity of 75-85% for 13-18h so as to obtain cured rice flour; and Step 4, drying: drying the cured rice flour by a gradient temperature-control and humidity-control oven drying method so as to obtain the rice flour.

Owner:INST OF AGRO FOOD SCI & TECH CHINESE ACADEMY OF AGRI SCI

Method for producing typified form under assistance of BIM (building information modeling) model

InactiveCN105447278AGuaranteed interoperabilityOvercome detailingGeometric CADSpecial data processing applicationsDesign phaseShop drawing

The invention provides a method for producing a typified form under the assistance of a BIM (building information modeling) model, relates to the technical field of building construction, and aims to solve the problem that the conventional BIM technology is still in a design phase and cannot guide deep design and production of complex special-shaped forms. The method comprises the following steps: I, building a BIM model of a typified form with a structure to be poured with concrete via three-dimensional modeling software Autodesk Revit; II, exchanging BIM model data of the typified form and data of Inventor software; and III, reading data received by the Inventor software in the step II via Solidworks software, outputting an accurate construction drawing of the typified form with the structure to be poured with concrete, and carrying out processing and production. As a three-dimensional design model of the typified form is introduced into the Solidworks software via data exchange, and the accurate construction drawing is generated automatically, deep design and accurate processing of a mold of the typified form can be realized.

Owner:SHANGHAI NO 4 CONSTR

Processable aluminium oxide base composite ceramic material and preparation method thereof

The invention discloses a processable aluminium oxide base composite ceramic material, which comprises the following raw materials in parts by mass: 60-88 parts of Al203, 5-15 parts of MgO, 5-15 parts of TiO2, 1-5 parts of SiO2 and 1-5 parts of CaO. The preparation method thereof comprises the following steps: mixing Cao powder and SiO powder in a proportion of 1:1 to prepare a sintering assistant; premixing MgO powder and TiO2 powder, then mixing with Al203 powder and the sintering assistant, ball-milling, drying the powder by ball-milling, and hot pressed sintering and molding at vacuum atmosphere. The invention overcomes the shortages that the aluminium oxide ceramic has higher hardness, and is difficult to process, produces a compound ceramic material with certain processability, and is especially applicable to a full ceramic reparation material in dentistry.

Owner:SHIJIAZHUANG TIEDAO UNIV

Silver-tin oxide electrical contact material and preparation method thereof

InactiveCN1624838APromote internal oxidationLower internal oxidation temperatureContact materialsRare-earth elementAlloy

The invention discloses silver tin oxide electrician contact material and its preparation method. Its chemical composition (weight ratio) is that the SnO2 is from three percent to ten percent; the mixed rare earth oxide (Sm2O3, Gd2O3, Y2O3) is from 0.1 percent to 2.0 percent; the surplus quantity is Ag. The preparation method is that the Ag, Sn, rare earth element are made up according to the alloy design proportion of ingredients, alloying in the vacuum melting furnace; then the AgSnRE is made after quickly solidification. At first the alloy is formed to thread, panel, profiled bar or rivet by extrusion, rolling, drawing, heat treatment. Then it is formed to AgSnO2 mixed rare earth oxide electrician contact material by produce internal operation. It can be used in AC and DC contactor, relay, controller, circuit breaker, switch, and so on.

Owner:KUNMING INST OF PRECIOUS METALS

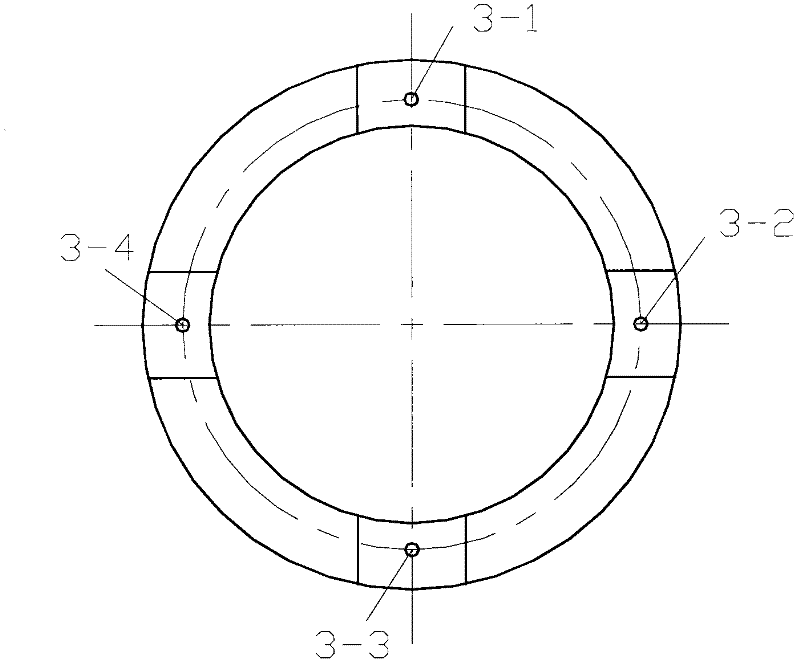

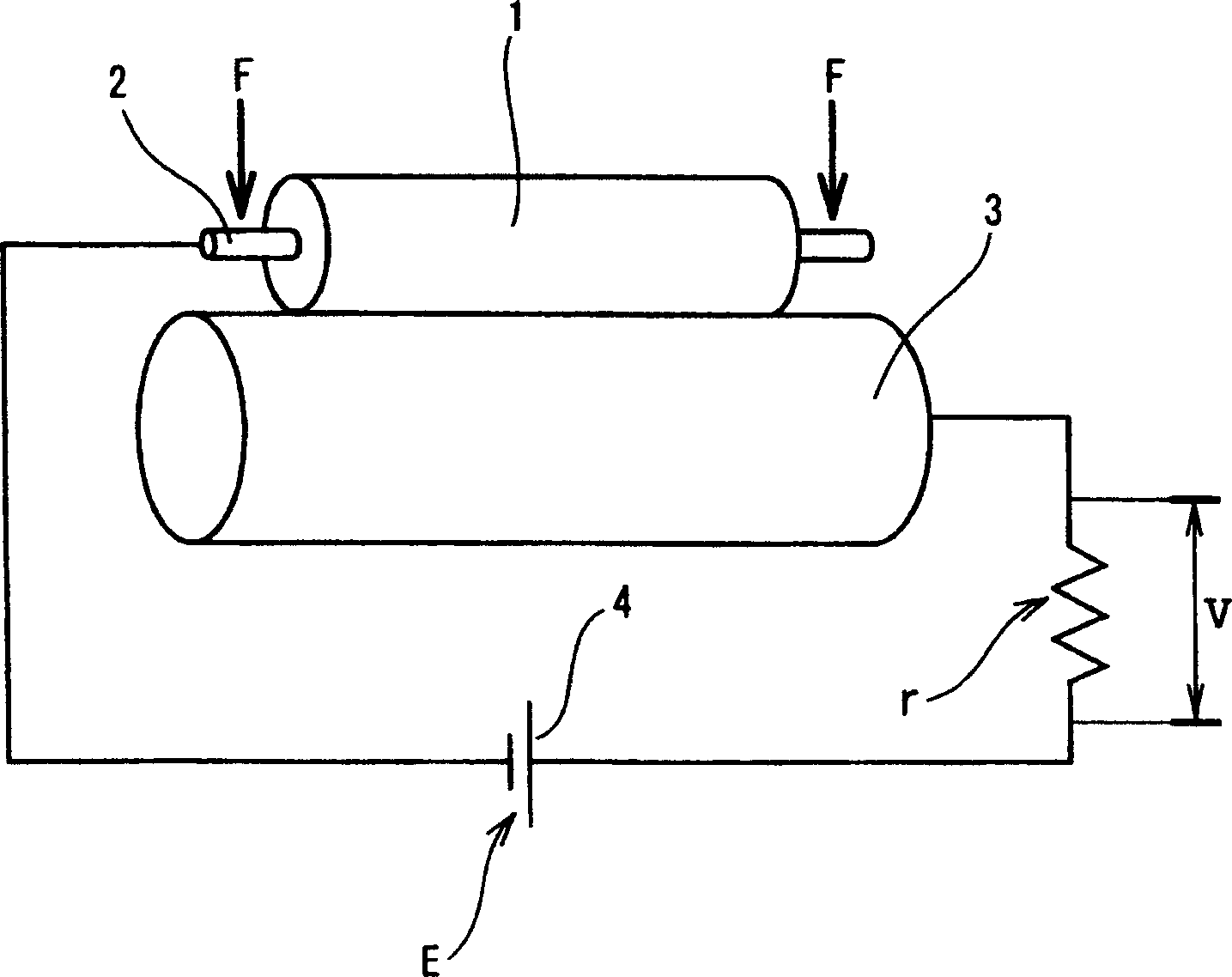

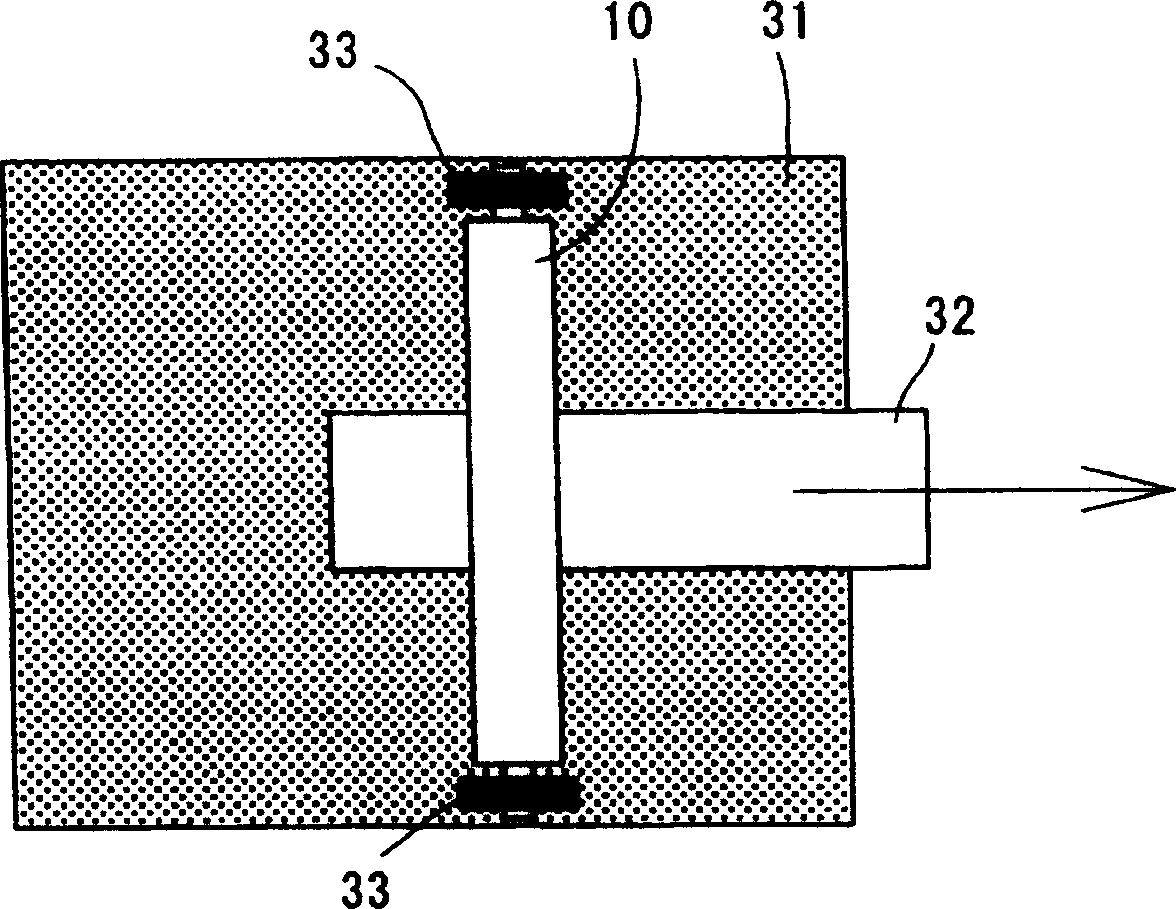

MEMS (Micro-Electro-Mechanical Systems) processing technique-based cylindrical capacitive sensor

InactiveCN102607394AReduce edge effectsHigh measurement accuracyDecorative surface effectsUsing electrical meansCapacitanceCopper electrode

The invention discloses an MEMS processing technique-based cylindrical capacitive sensor. The MEMS processing technique-based cylindrical capacitive sensor comprises a rotary spindle electrode and a cylindrical fixed electrode coaxially mounted on the outside of the rotary spindle electrode; in the rotary spindle electrode, a first insulating layer, a copper spindle electrode and a second insulating layer outwardly and sequentially wrap the outer cylindrical surface of a spindle; and in the cylindrical fixed electrode, a third insulating layer, an equipotential protective ring, a fourth insulating layer and four arc-shaped electrodes equidistantly embedded in the inner circle of the fourth insulating layer are inwardly and sequentially wrapped in the cylindrical hole of an electrode base. The MEMS processing technique can be adopted to process the electrodes to be ultrathin, the complex processing and assembly process of the main conventional method in producing the cylindrical capacitive sensor can be overcome, the size of the sensor is reduced, moreover, the edge effect of the sensor can be inhibited as well, and the cylindrical capacitive sensor is suitable for monitoring the rotation error of the spindle. Due to the technique, the miniaturized cylindrical capacitive sensor can be easily produced, and the sensor can also be easily produced in batches.

Owner:ZHEJIANG UNIV

Split die vacuum bag-autoclave forming method of irregular composite material

To solve the problems in the prior art that the surface quality and the shape of a non-adhered die plane need to be completed and accomplished through processes of mechanical machining, polishing, painting and the like in the vacuum bag-autoclave forming process, the invention provides a split die vacuum bag-autoclave forming method of irregular composite materials. A lower die and an upper die are manufactured according to the appearance size and the shape of a composite material part to be formed; a raw rubber sheet layer is paved on the split plane of the upper die and the lower die; and the thickness of the raw rubber layer meets the requirement that the sum of the rubber thickness of the vulcanized raw rubber and the height of the forming chamber of the die is equal to the thickness of the composite material part to be formed. The method has the beneficial technical effects that advantages that the vacuum bag-autoclave forming process is high in density and uniform in distribution and the die forming process is accurate in appearance size and shape are both considered.

Owner:CHENGDU AIRCRAFT INDUSTRY GROUP

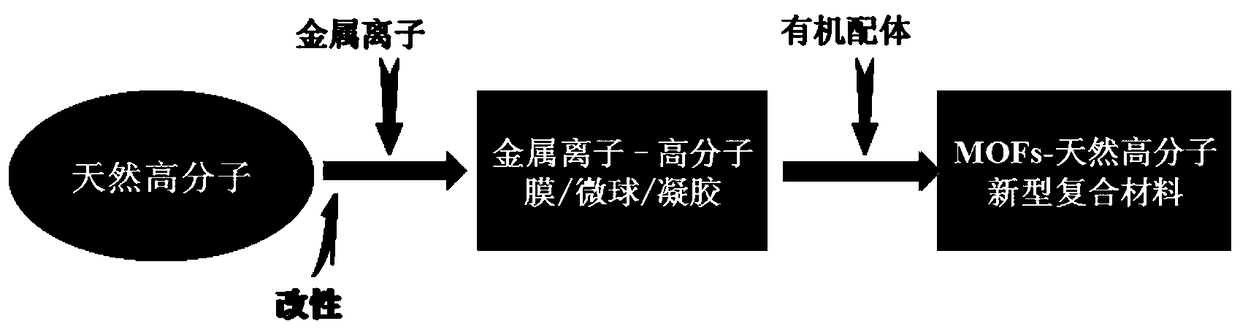

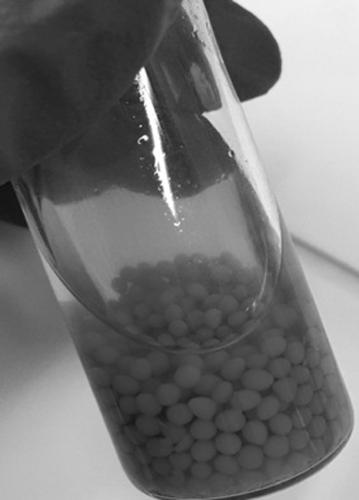

Method for macroscopically preparing MOFs (metal-organic framework)@natural polymer novel composite material

ActiveCN109320733AQuickly control macroscopic shapesControl macroscopic shapePolymer sciencePolymer substrate

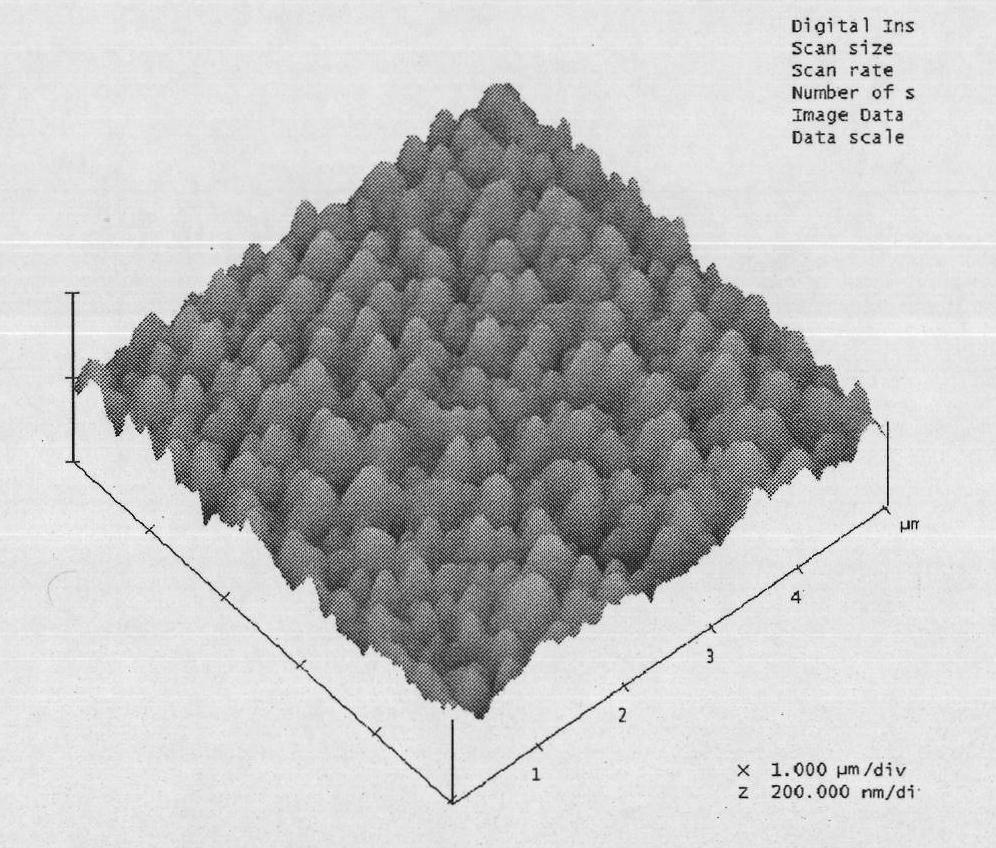

The invention relates to the field of metal-organic framework compounds, in particular to a method for macroscopically preparing an MOFs (metal-organic framework)@natural polymer novel composite material. The method takes a natural polymer material, metal salt and a carboxylic acids organic-ligand as raw materials to prepare the novel composite material, wherein the weight ratio of the metal saltto the natural polymer to the carboxylic acids organic-ligand is (1-10) to (2-20) to (0.5-5). The technology is simple and universal; the natural polymer is wide in source and green and free of toxicity; the morphological structure of MOFs can be controlled and changed by regulating the surface roughness of a polymer substrate; the material has the advantages that the material is easy to be controlled to form, the size and morphology of the microscopic MOFs particles are controllable, and the material can be macroscopically and controllably prepared. The method widens the practical applicationof MOFs, and explores a new route to prepare other MOFs@natural polysaccharide novel composite materials with controllable macroscopic shape and programmable property.

Owner:GUANGXI UNIV

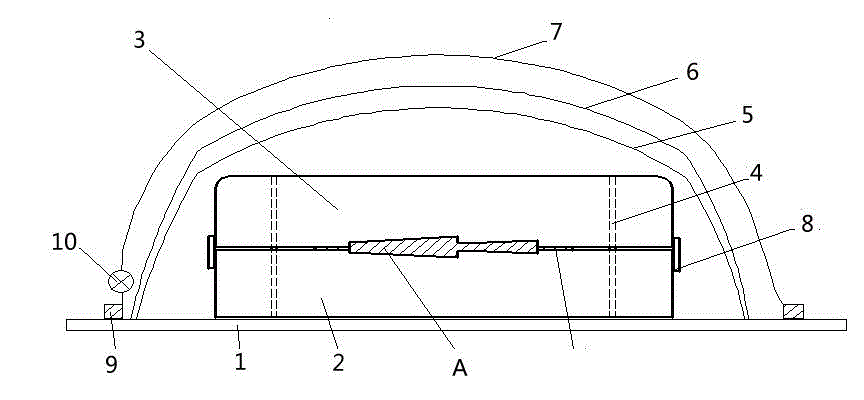

End-face-sealed friction surface temperature measuring method

ActiveCN102128692ARealize scientific measurementOvercoming processabilityThermometers using electric/magnetic elementsUsing electrical meansHeat resistanceThermocouple

The invention relates to an end-face-sealed friction surface temperature measuring method. N axial blind holes with the diameter of 1 are uniformly distributed and processed in the same diameter at the back of the seal face of a stationary seal ring along the circumferential direction; the distance from the bottoms of the blind holes to the end faces of a rotating seal ring and the stationary seal ring are respectively h1, h2..., hn mm; thermocouple temperature sensors are buried in the blind holes by adopting insulating glue; and the signal wires of the thermocouple temperature sensors are led out along the inner hole wall of an end cover of a sealed device. The temperatures measured in n positions in the testing process are regressed into a temperature-distance end face depth curve shown as the expression: T=f (h), thus the end face temperature in the position h=0, namely the end face friction temperature is obtained by utilizing an extrapolation method. The blind holes are formed, thereby ensuring the integrality of a seal end face; and the depths of the blind holes are not specially limited, thereby overcoming the difficulty in processing the blind hole which is infinitely close to a friction end face, and overcoming the influence of heat resistance on measurement. Thus, the end-face-sealed friction surface temperature measuring method has high measuring precision and good stability, and is suitable for a field device to monitor the end-face-sealed friction surface temperature and a testing device to measure various end-face-sealed friction surface temperatures.

Owner:NANJING FORESTRY UNIV

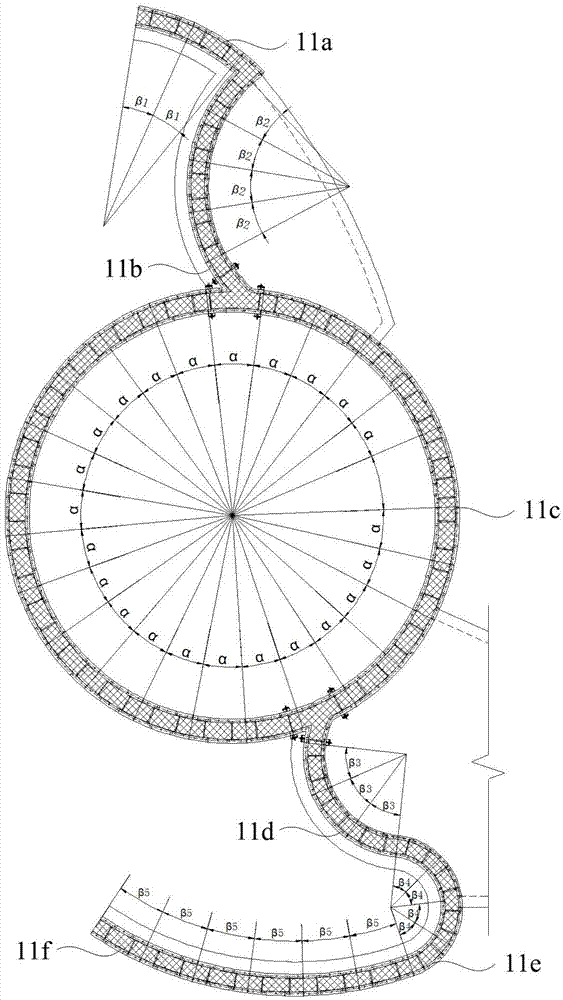

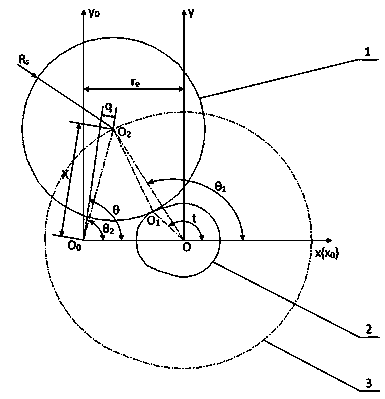

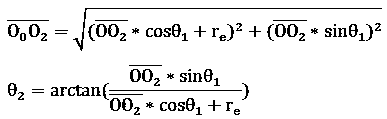

Planar special-shaped non-circular grinding contouring control method

ActiveCN103659600AEasy to determineImprove general performanceGrinding feed controlAutomatic grinding controlEngineeringHeight difference

The invention relates to a planar special-shaped non-circular grinding contouring control method which includes the steps of (1) initializing parameters including rho, t, Rs, re and q; (2) finding a grinding wheel center position O2 and a grinding wheel center track rotation angle theta 1 by means of the formula, wherein the grinding wheel center position O2 and the grinding wheel center track rotation angle theta 1 correspond to any special-shaped contouring point O1 under a coordinate system xOy, and the coordinate system xOy takes the rotation center O of a special contouring as the coordinate origin; (3) shifting the coordinate system according to an eccentric distance re, and calculating the grinding wheel center displacement and a grinding wheel center track rotation angle theta 2 under a coordinate system x0O0y0, wherein the coordinate system x0O0y0 takes the rotation center O0 of a C-axis as the coordinate origin; (4) solving a grinding wheel center displacement X and a grinding wheel center track rotation angle theta with a center height difference q; (5) determining a C-X axis interpolation relation according to the obtained grinding wheel center track rotation angle theta and the grinding wheel center position X.

Owner:SHANGHAI MACHINE TOOL WORK

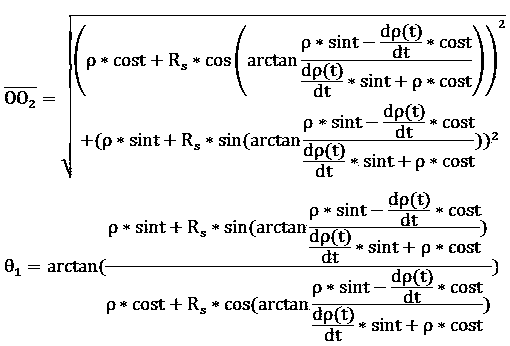

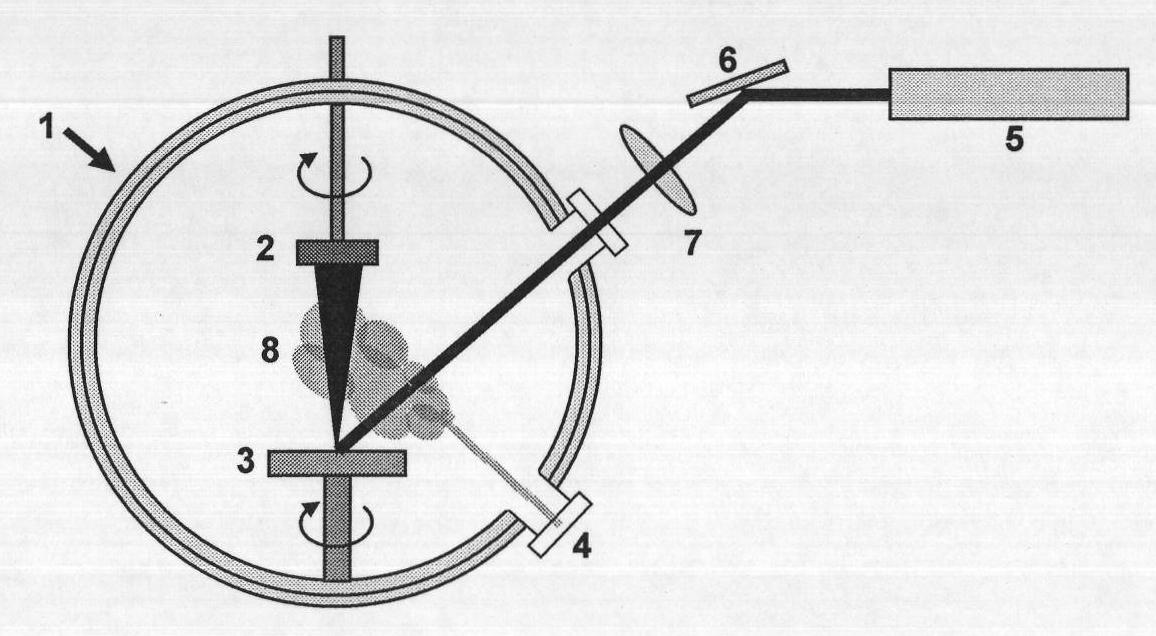

Method for preparing barium dititanate (BaTi2O5) ferroelectric film on silicon (Si) single crystal substrate

InactiveCN101818327AImprove compatibilityOvercome high pricesVacuum evaporation coatingSputtering coatingBarium titanateSingle crystal

The invention relates to a method for preparing a barium dititanate (BaTi2O5) ferroelectric film on a silicon (Si) single crystal substrate. The method comprises the following steps of: 1) conveying the Si single crystal substrate growing along the direction of an a axis and a magnesium oxide (MgO) ceramic target material into a settling chamber and vacuumizing the chamber; heating the substrate and introducing high-purity oxygen; irradiating pulse laser beams on the surface of the target material to make the surface of the target material generate plasma plume; and settling the plasma plume on the substrate to form a MgO film buffer layer; and 2) conveying the Si single crystal substrate on which the MgO film buffer layer is settled and a BaTi2O5 ceramic target material into the settling chamber and vacuumizing the chamber; heating the substrate and introducing the high-purity oxygen; irradiating the pulse laser beams on the surface of the target material to make the surface of the target material generate plasma plume; and settling the plasma plume on the substrate to form a BaTi2O5 ferroelectric film. In the method, the single-phase BaTi2O5 ferroelectric film, which can preferably grow along the direction of a b axis on the Si single crystal substrate, can be obtained by building the MgO film buffer layer matched with the BaTi2O5 ferroelectric film; the compatibility of the BaTi2O5 ferroelectric film and a semiconductor process can be achieved; and the BaTi2O5 ferroelectric film is favorable for integrating with the traditional semiconductor device.

Owner:WUHAN UNIV OF TECH

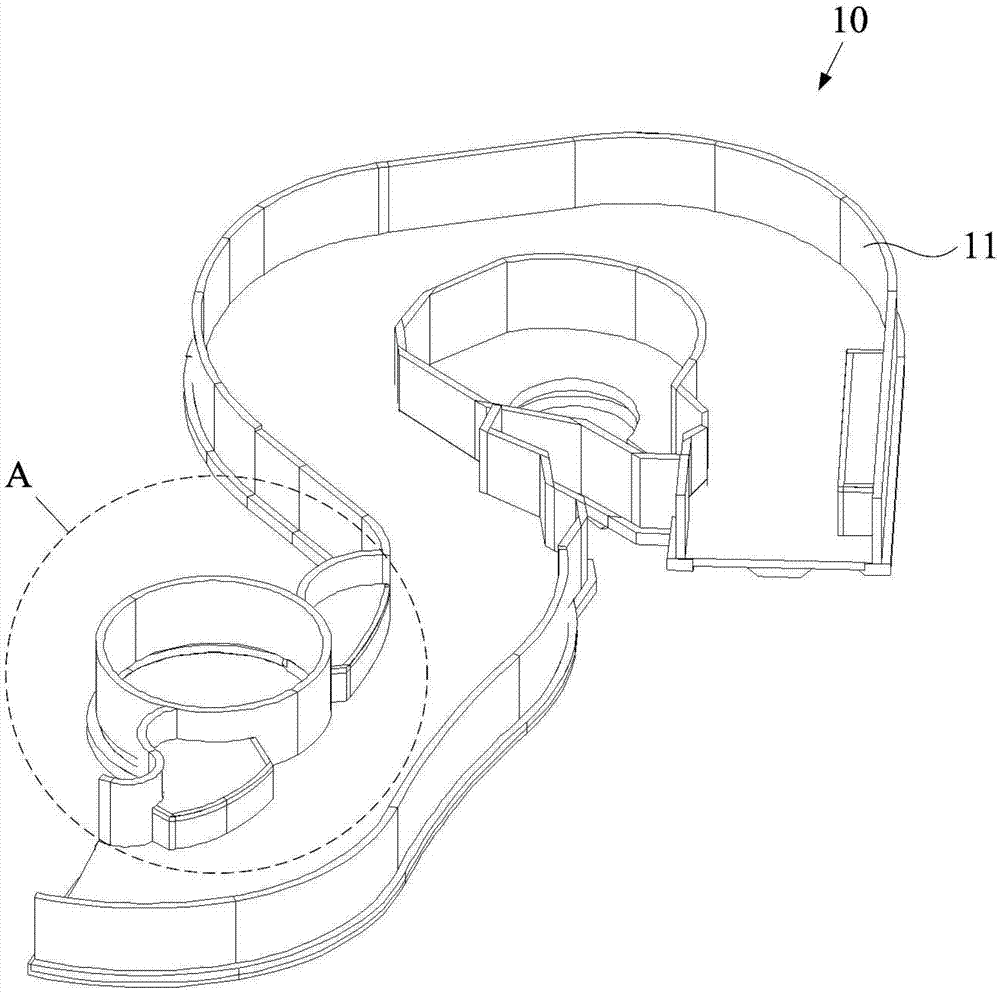

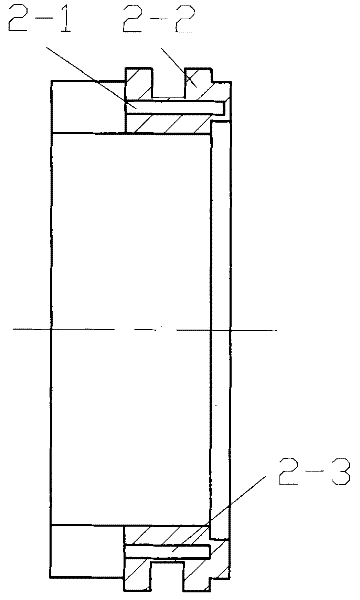

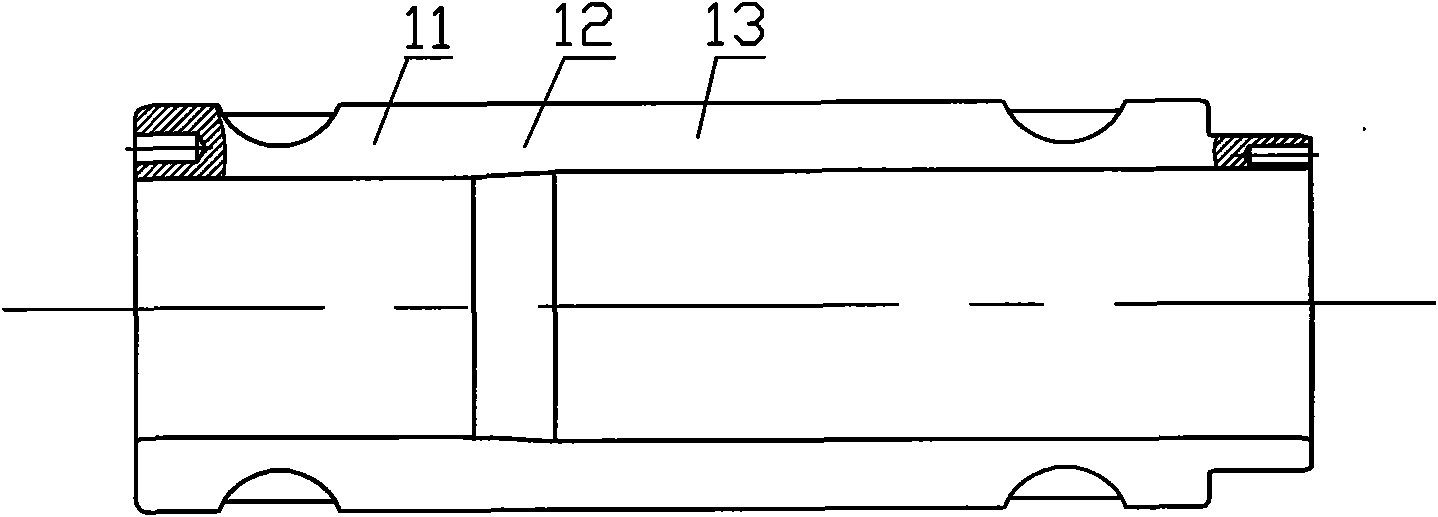

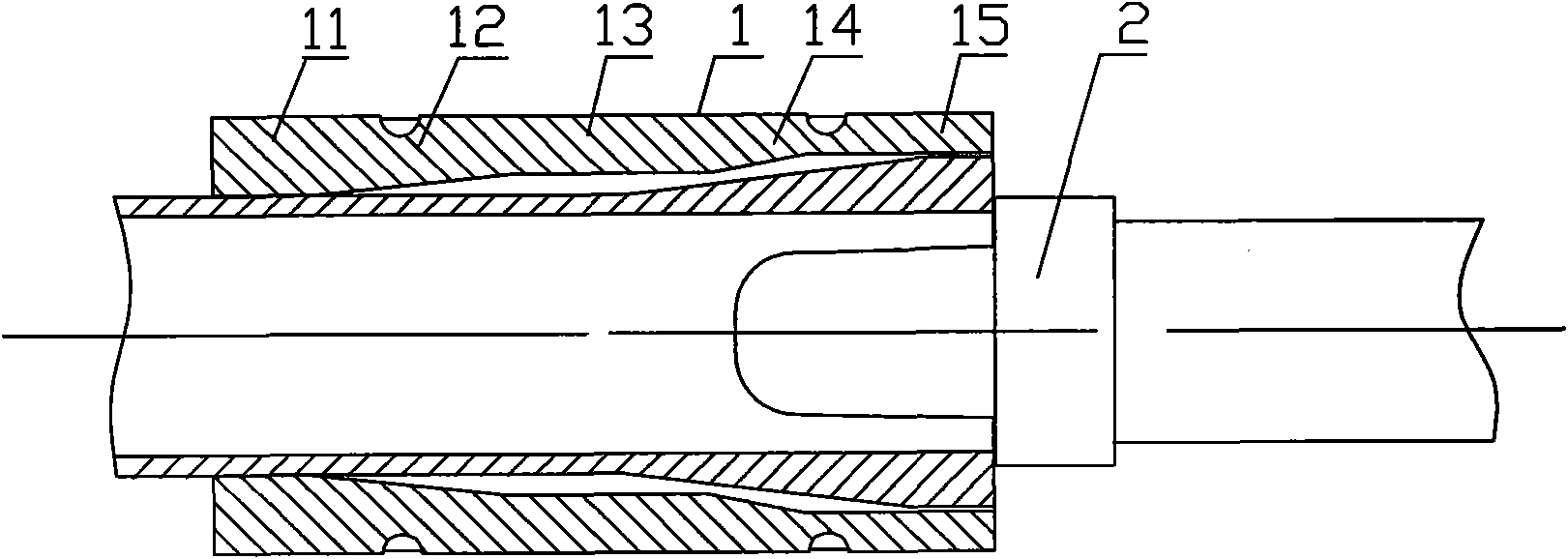

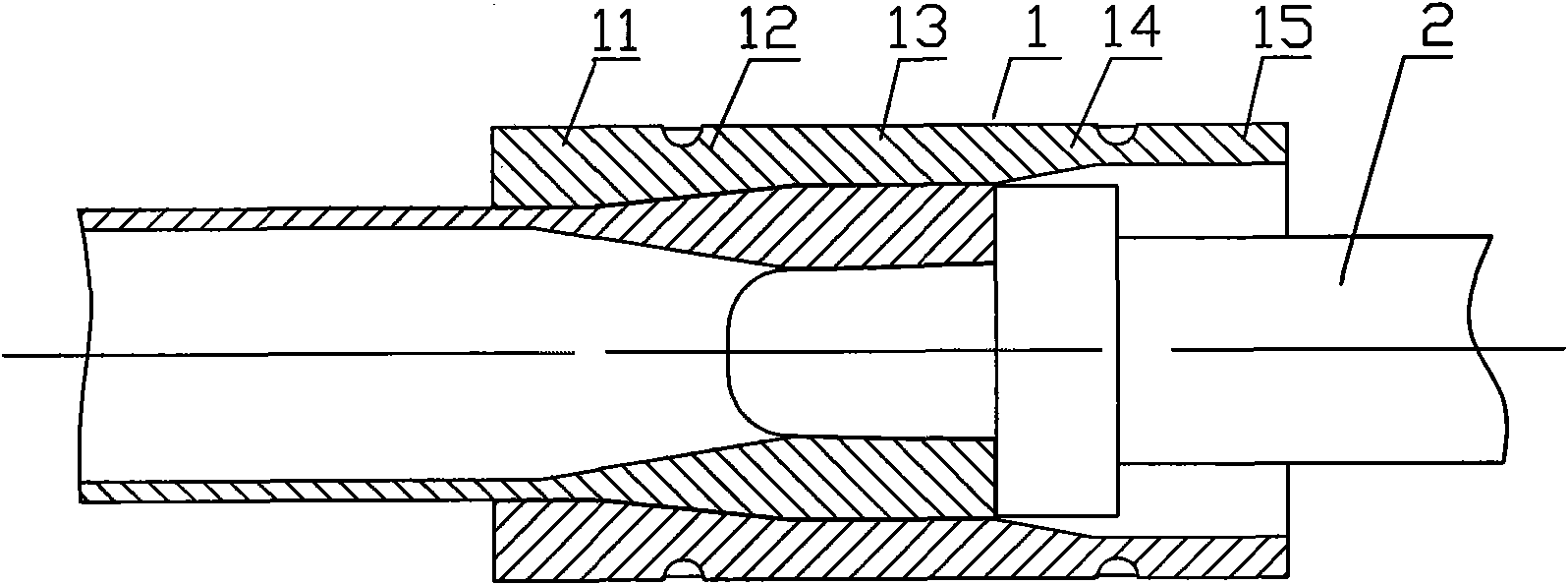

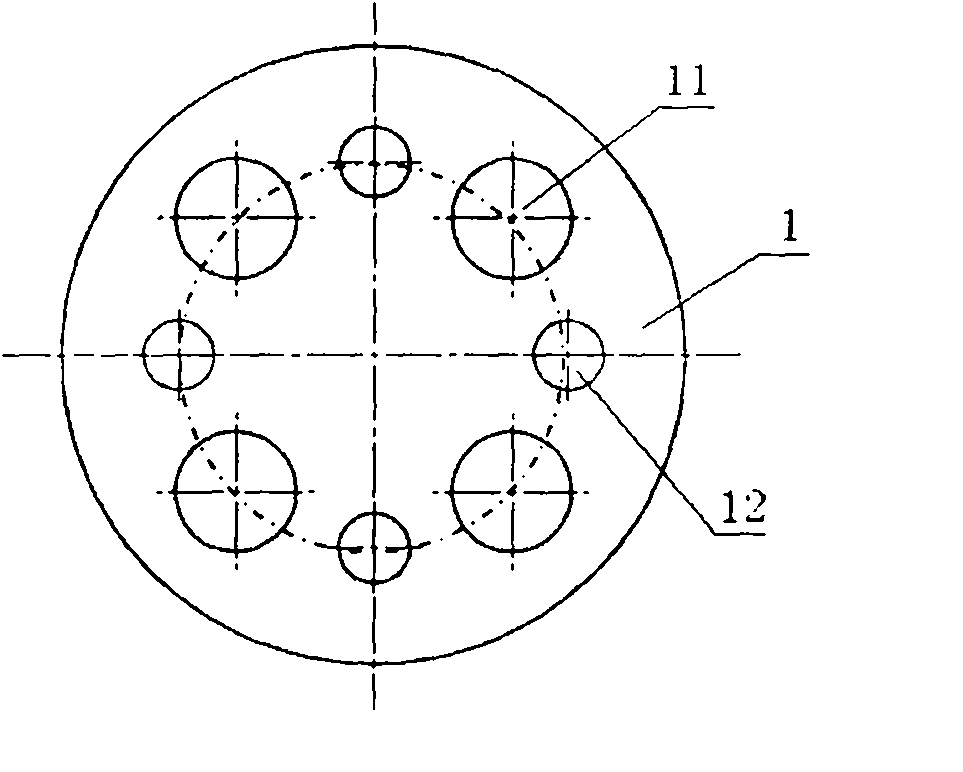

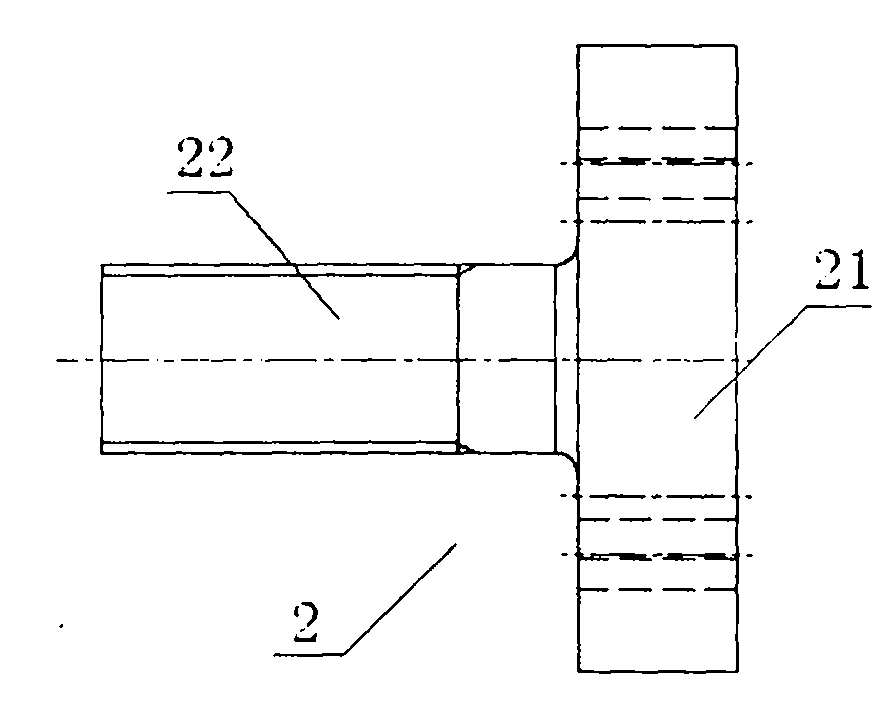

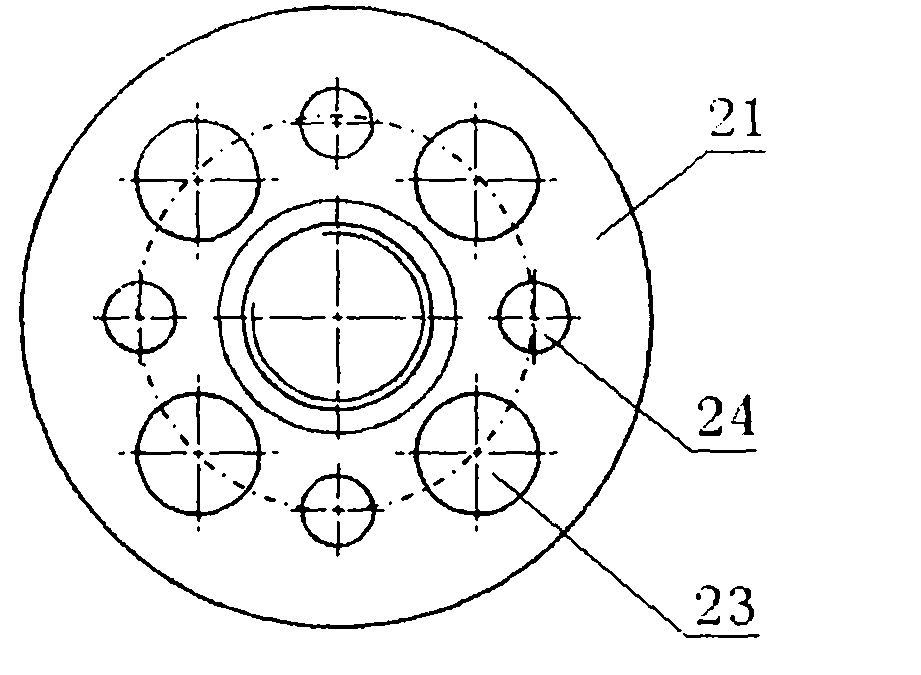

Drill stem thickening process and thickening module

InactiveCN101767173AOvercoming uneven shapeOvercoming processabilityForging/hammering/pressing machinesStress concentrationPunching

The invention relates to a drill stem thickening process and a thickening module. The thickening module comprises a thickening module 1 and a punching module 2. a third time thickening module is a final forming module, namely an inner thickening copying module, which comprises a clamping area 11, a transition belt 12, a thickening area 13, a transformation transition belt 14 and a starting area 15 which are orderly connected with the thickening area 13. The length of the transition belt of the thickening module is prolonged and the transition is performed in the manner of S-shaped smooth transition. The invention overcomes the shortcomings of the prior art that the shape of the transition belt in the drill stem is uneven, lathe work is required, the stress concentration is easily occurred, the service life of the drill stem is short, and the like. Compared with the prior art, the thickening transition belt in the drill stem can naturally smooth transit so the stress concentration in the deformation area and the probability of generating vortex caused by size change during usage are greatly decreased, the stress at the thickened tube joint part is reduced, the inner transition belt of the final products is unnecessary to form, the use life of the drill stem is prolonged and the drill stem quality is ensured.

Owner:HENGYANG VALIN STEEL TUBE +1

Path integrating device

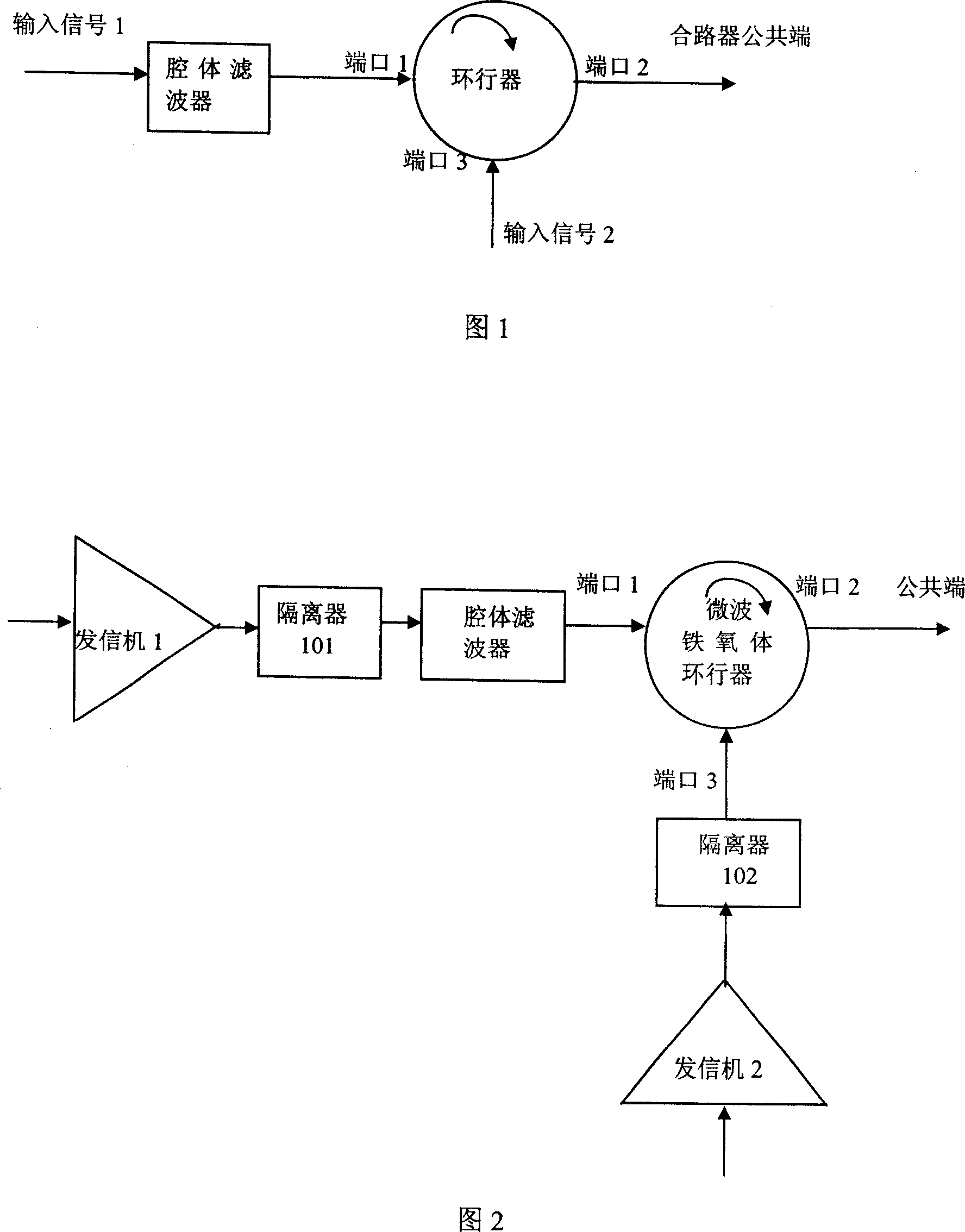

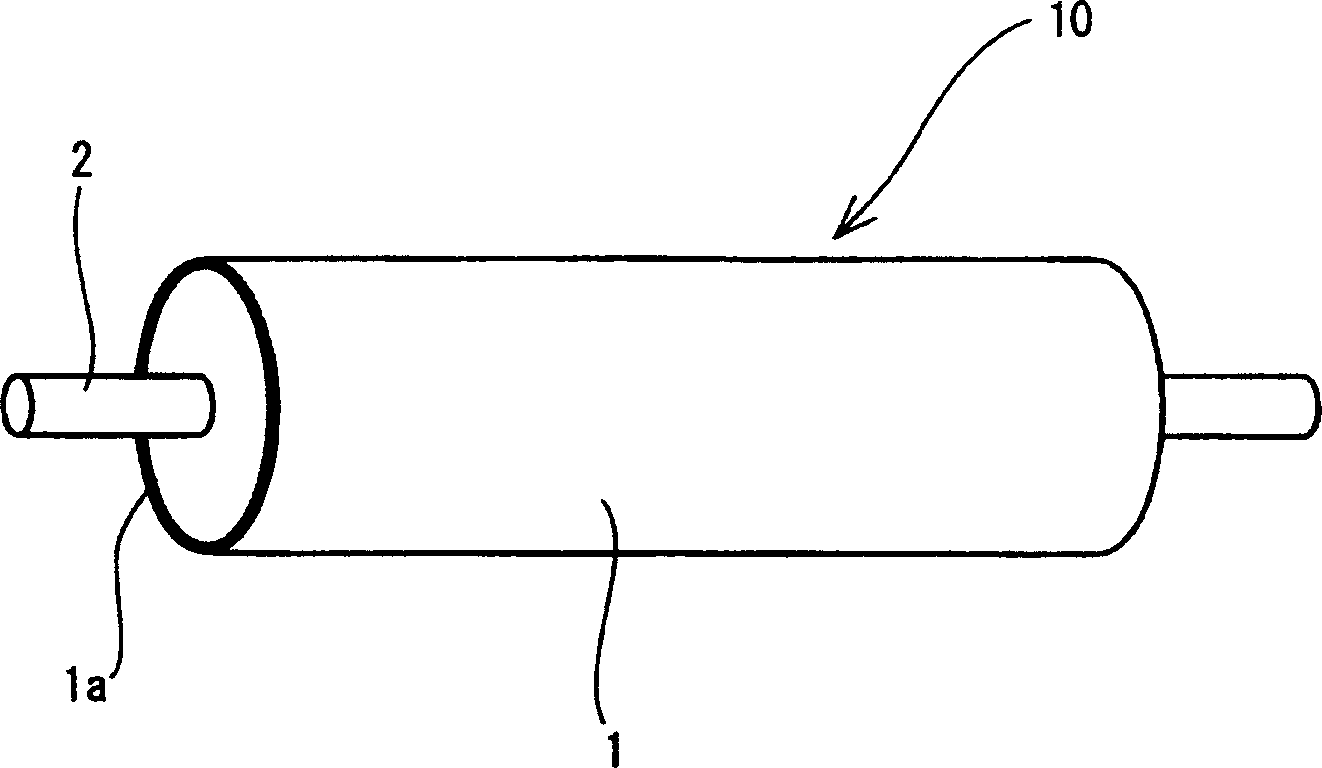

InactiveCN1988248AImprove consistencyOvercoming processabilityWaveguide type devicesEngineeringMechanical Processes

This invention discloses a low loss 2:1 path synthesizer including a cavity filter and a microwave ring device, in which. the energy circulation direction of the electromagnetic waves in the microwave ring device is set frpm port 1 to 2, and port 2 to port 3, said cavity filter is connected with port 1 of the ring device, and the cavity filter and port 1 of the microwave ring device make up of the input of the synthesizer, port 2 of the rign device is the public output port of the synthesizer and port 3 of the ring device constitutes input 2 of the synthesizer, since only the cavity filter is processed mechanically, it is simple for its mechanical process and debugging and the volume is reduced too.

Owner:ZTE CORP

Semi-conductive rubber part

InactiveCN1655288AOvercoming high surface free energyOvercoming processabilityNon-insulated conductorsShaft and bearingsForeign matterEngineering

To provide a semiconductive rubber member causing no substantial sticking of foreign matter represented by a toner outer additive for a long period through reducing the surface free energy of the rubber member while maintaining its electrical properties' uniformity and design values' repeated reproducibility, excellent in processability and substantially exhibiting no surface defects including molding unevenness and cracks. This semiconductive rubber member is obtained by compounding 100 pts. mass of an ionically conductive rubber including a rubber having polyether linkages with 0.1-5 pt(s). mass of a wax. In this rubber member, it is preferable that the rubber having the polyether linkages to be used consists of a polymer made from a halogen-containing ether-based monomer and, when desired, a halogen-free ether-based monomer and / or a copolymerizable unsaturated epoxide-based monomer.

Owner:SUMITOMO RUBBER IND LTD

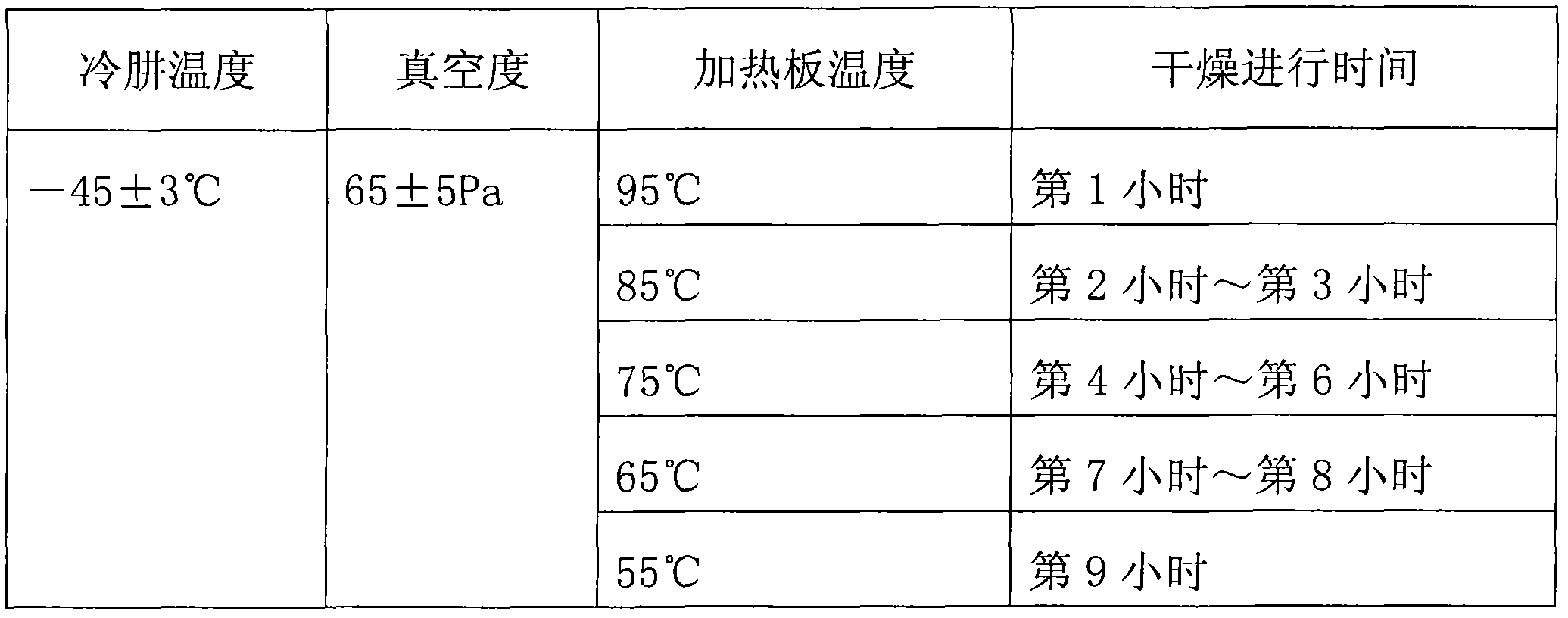

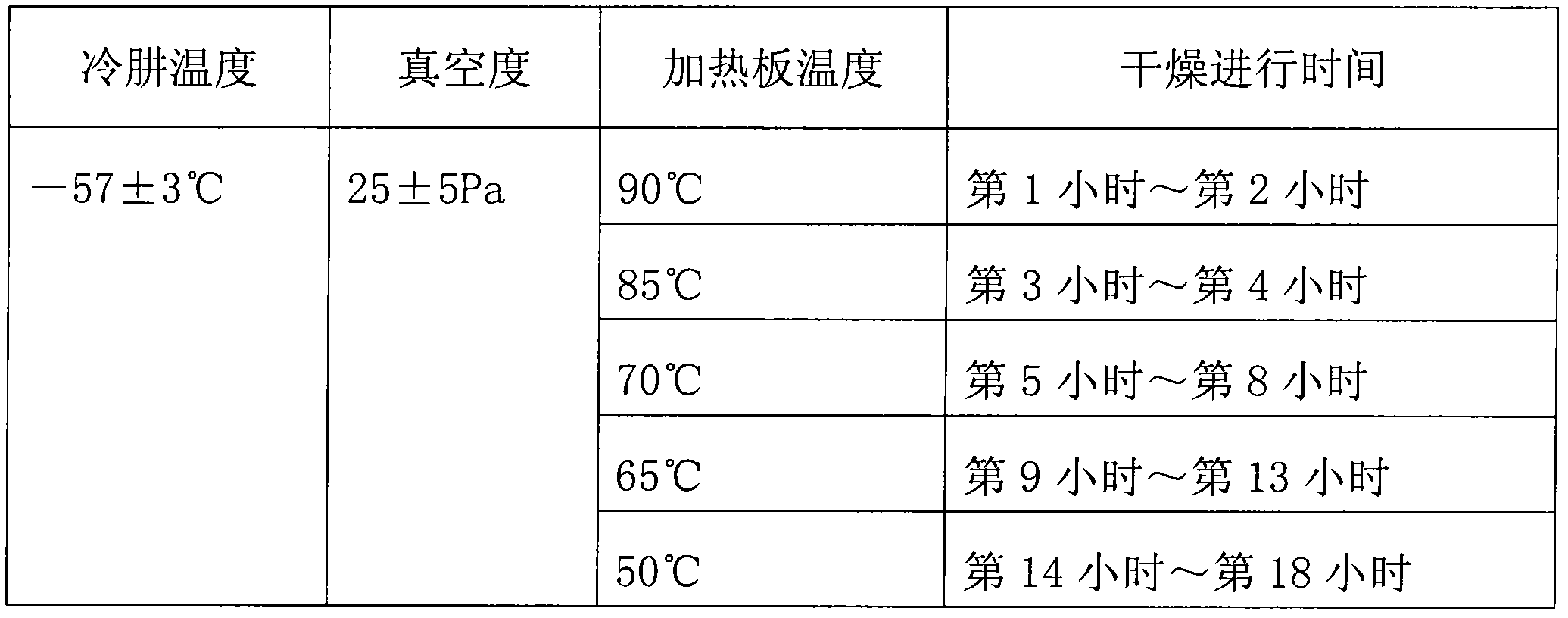

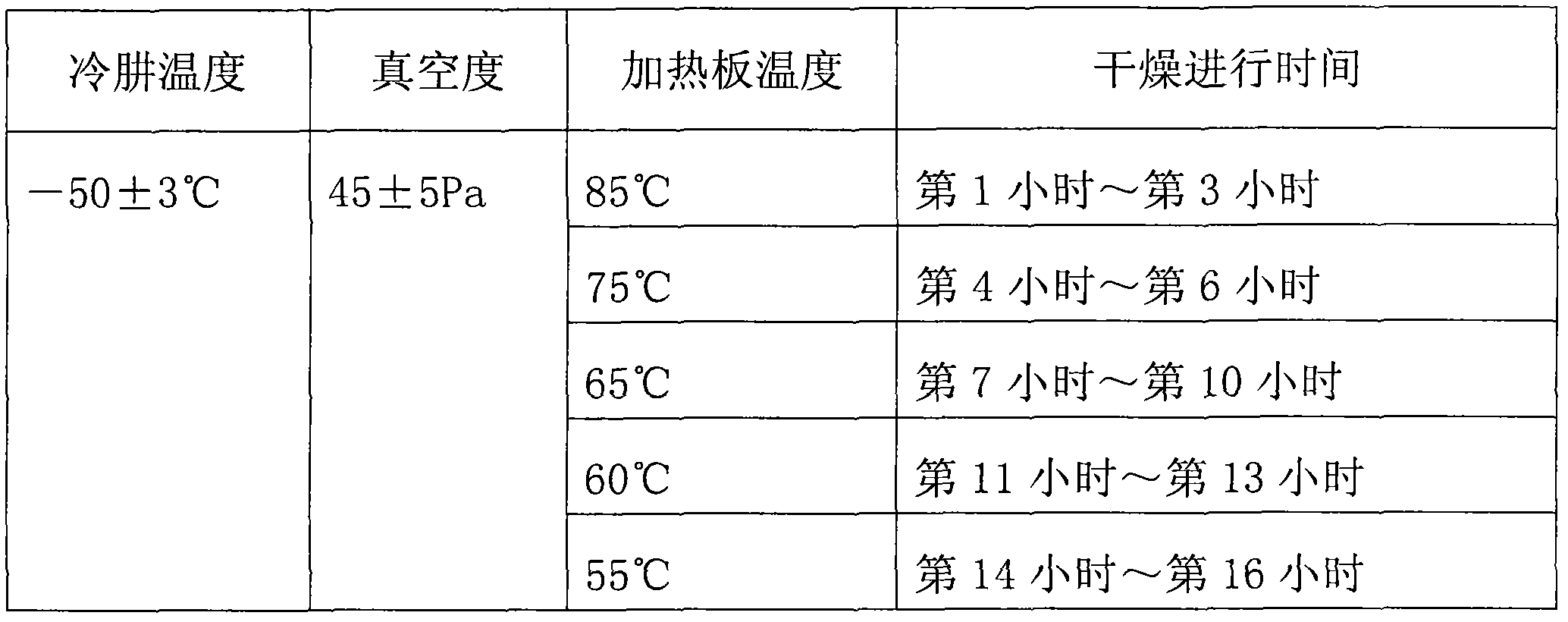

Preparation method of freeze-dried mango blocks

ActiveCN102028161AOvercoming processabilityOvercome drynessFood preparationDisinfectantFreeze-drying

The invention discloses a preparation method of freeze-dried mango blocks, comprising the following steps of: disinfecting fresh mangos with fruit and vegetable disinfectant, and then rinsing and cleaning the disinfected mangos with drinking water; pulping the mangos by a pulping machine; adjusting acidity pH value to be 3.5-5.5, saccharinity to be 10-25% and thickness to be 1.10-1.25g / ml; then heating to 70-90 DEG C, keeping the temperature for 5-10 minutes, and quickly cooling to room temperature; injecting mango pulp into a model, cooling to (-5)-(-20) DEG C for molding; then, demolding, and freezing the mango blocks in a refrigerator to (-25)-(-40) DEG C; and finally, putting the mango blocks into a vacuum freezing dryer, and controlling the vacuum degree to be 20-70Pa, cold hydrazinetemperature to be -40--60 DEG C, heating plate temperature to be 50-95 DEG C, and drying time to be 8-18 hours to obtain the freeze-dried mango blocks. With the method, the characteristics of mango pulp can be integrally reserved, and the color, the fragrance, the taste and the nutrient components of the fresh mangoes can be reserved. In addition, the whole freeze-dried mango block can be directly eaten, is sweet and sour as well as delicious and has long storage period.

Owner:安徽本纪控股有限公司

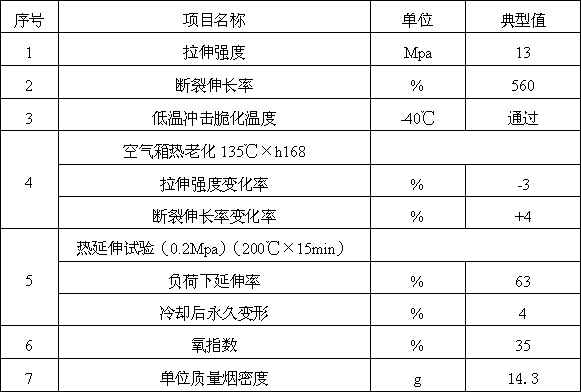

Irradiation crosslinking low-smoke and halogen-free flame retardant cable material and its preparation method

InactiveCN102977468AImprove flame retardant performanceExcellent non-flammabilityElastomerPolymer science

The invention provides an irradiation crosslinking low-smoke and halogen-free flame retardant cable material. The cable material is prepared from the following raw materials, by weight, 100 parts of ethylene propylene diene monomer, 60-80 parts of high-density polyethylene, 9-11 parts of a maleic anhydride grafted polyolefin elastomer, 0.2-0.4 parts of an ultraviolet ray absorber UV-9, 10-20 parts of an EVA resin, 8-10 parts of aluminum hydroxide, 0.5-1.0 part of butyl stearate, 1-3 parts of zinc stearate, 0.2-0.5 parts of dicumyl peroxide (DCP), 1-2 parts of TAIC, 4-6 parts of zinc oxide, 0.5-1.0 part of molybdenum trioxide, 30-50 parts of carbon black N3393, 10-13 parts of nanometer calcium carbonate, 0.5-1.0 part of an antioxidant 4020, 0.1-0.3 part of an antioxidant MB, 8-10 parts of triphenyl phosphate, 12-15 parts of antimony (III) oxide and 6-8 parts of zinc borate hydrate. The cable material has the advantages of excellent flame retardation, very less smoke in combustion, no generation of toxic gases or corrosive gases, good weatherability, good abrasion resistance, good insulation property, and ultraviolet resistance.

Owner:武汉爱邦高能技术有限公司

Material for producing injection molding oil tank and manufacturing method thereof

InactiveCN102617910AOvercome stressOvercoming oil resistanceLow-density polyethyleneLinear low-density polyethylene

The invention discloses a material for producing an injection molding oil tank and a manufacturing method thereof. A material comprises the following raw materials in parts by weight: 48-68 parts of linear low-density polyethylene resin, 12-32 parts of high-density polyethylene resin, 5-15 parts of polypropylene resin, 5-15 parts of a saturated ethylene-octene copolymer, 0.1-0.2 part of a nucleating agent, 0.4-0.6 part of an antioxidant, 0.3-0.7 part of a lubricating agent and 0.1-0.5 part of carbon black. Due to the adoption of the material for the injection molding oil tank, the problems of air tightness, oil resistance, stress cracking resistance, cold resistance and the like are solved.

Owner:重庆嘉良塑胶制品有限责任公司

Preparation method of dried mackerel floss

InactiveCN104544313AOvercoming difficulty in preservationOvercoming processabilityFood preparationDried fishAquatic product

The invention relates to a preparation method of dried mackerel floss, and belongs to the technical field of aquatic product processing. The preparation method of the dried mackerel floss comprises the following steps: (1), pretreating raw materials; (2), removing fish bones; (3), sterilizing, (4), salting; (5), removing fishiness; (6), barbecuing; (7), removing the peel; (8), seasoning; (9), cooking; (10), squeezing; (11), drying and rubbing to form floss; (12), packaging. According to the method disclosed by the invention, the fishiness removal of the mackerel fillet adopts the barbecuing manner, and comprises the step of using an oven to process the grease in the mackerel fillet at a temperature of 250 DEG C, so as to reduce the fishiness in the mackerel fillet raw material; the mackerel fillet can be soaked to remove the fishiness, so as to enable the dried mackerel floss product to be free of fishiness; the mackerel fillet can be pickled with seasonings, so as to further remove the peculiar smell of the mackerel fillet, and meanwhile enable the mackerel fillet to be enriched with freshness and flavor; the cooked mackerel fillet is squeezed to dehydrate, so as to reduce the water content in the mackerel fillet, bring convenience to the following rubbing procedure, further control the water content in the dried fish floss product to be at a low level, and prolong the shelf life of the dried mackerel floss.

Owner:WEIHAI HAIRI AQUATIC FOODSTUFF

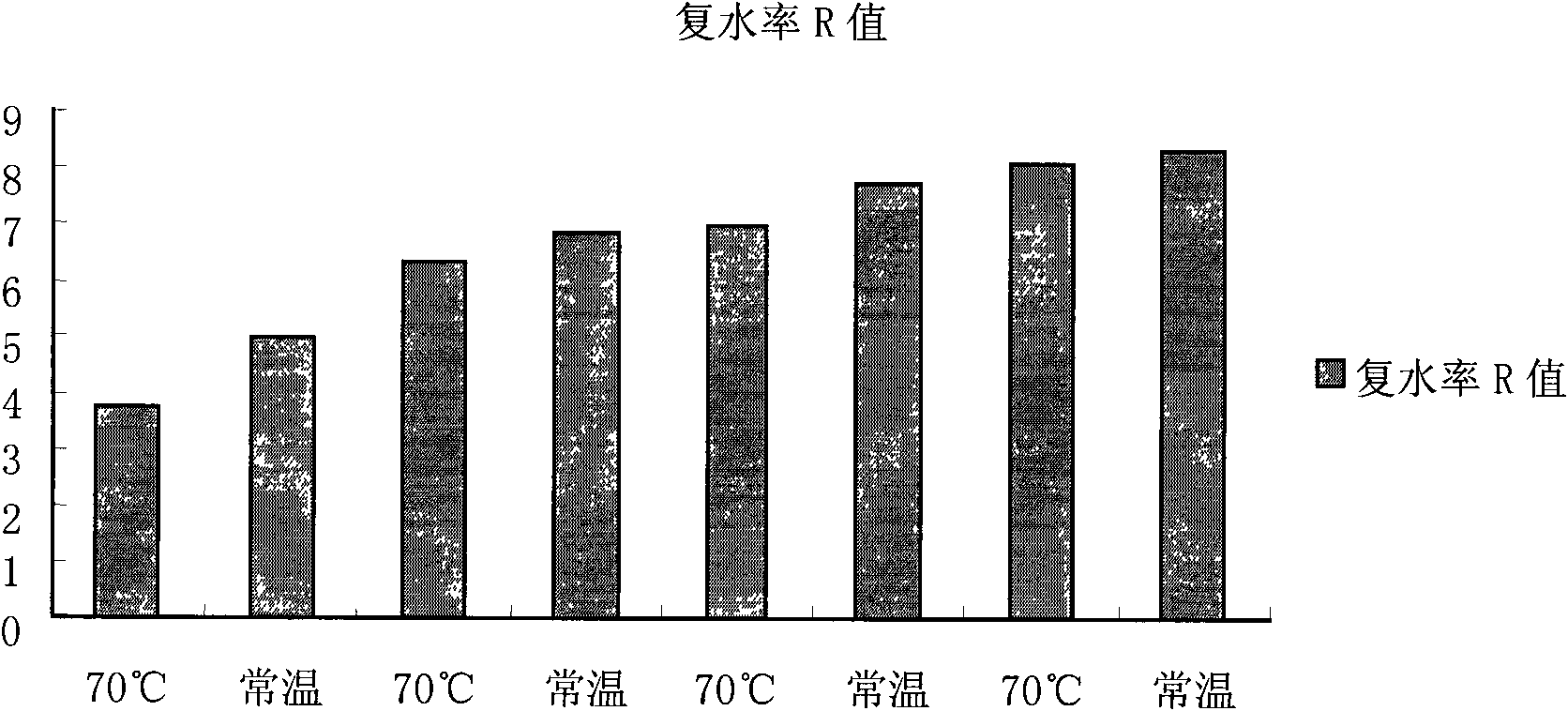

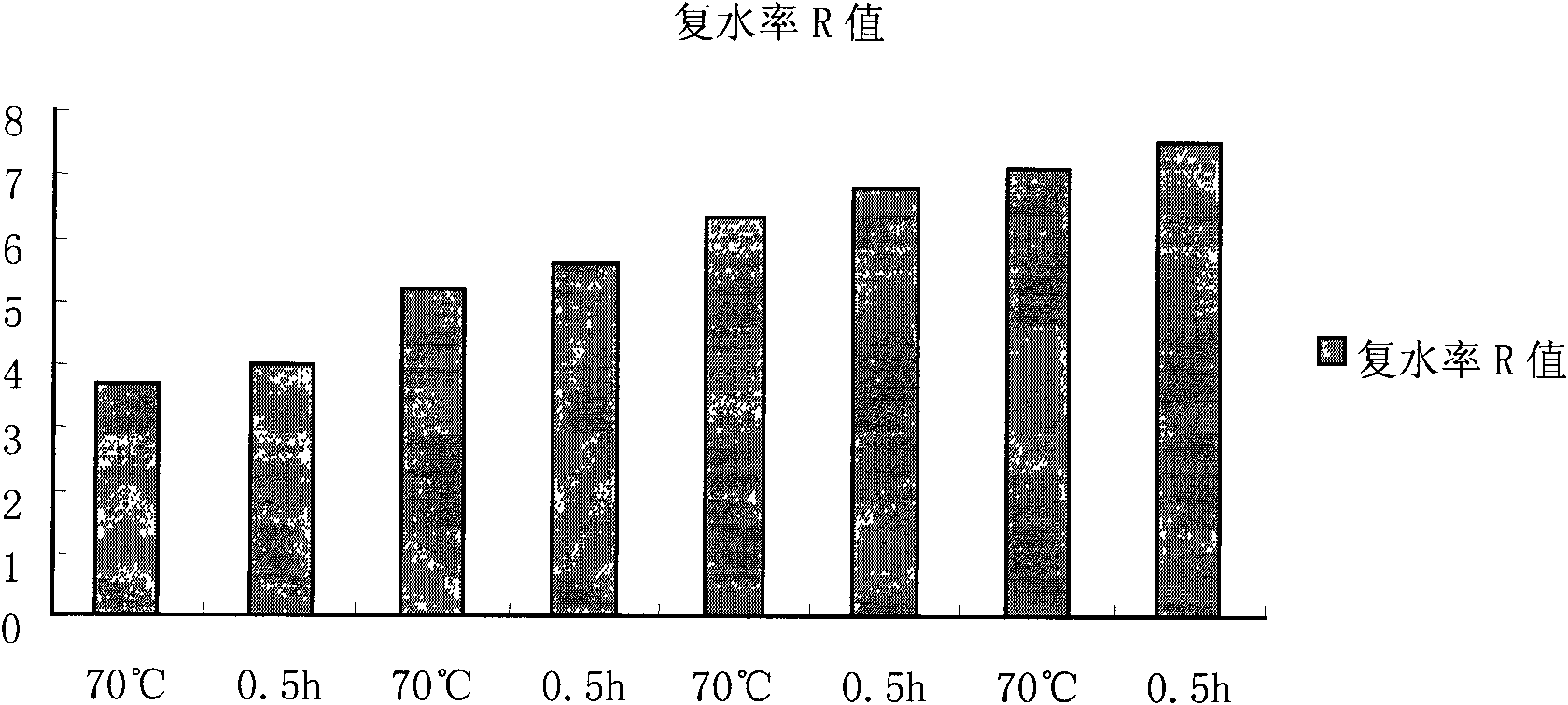

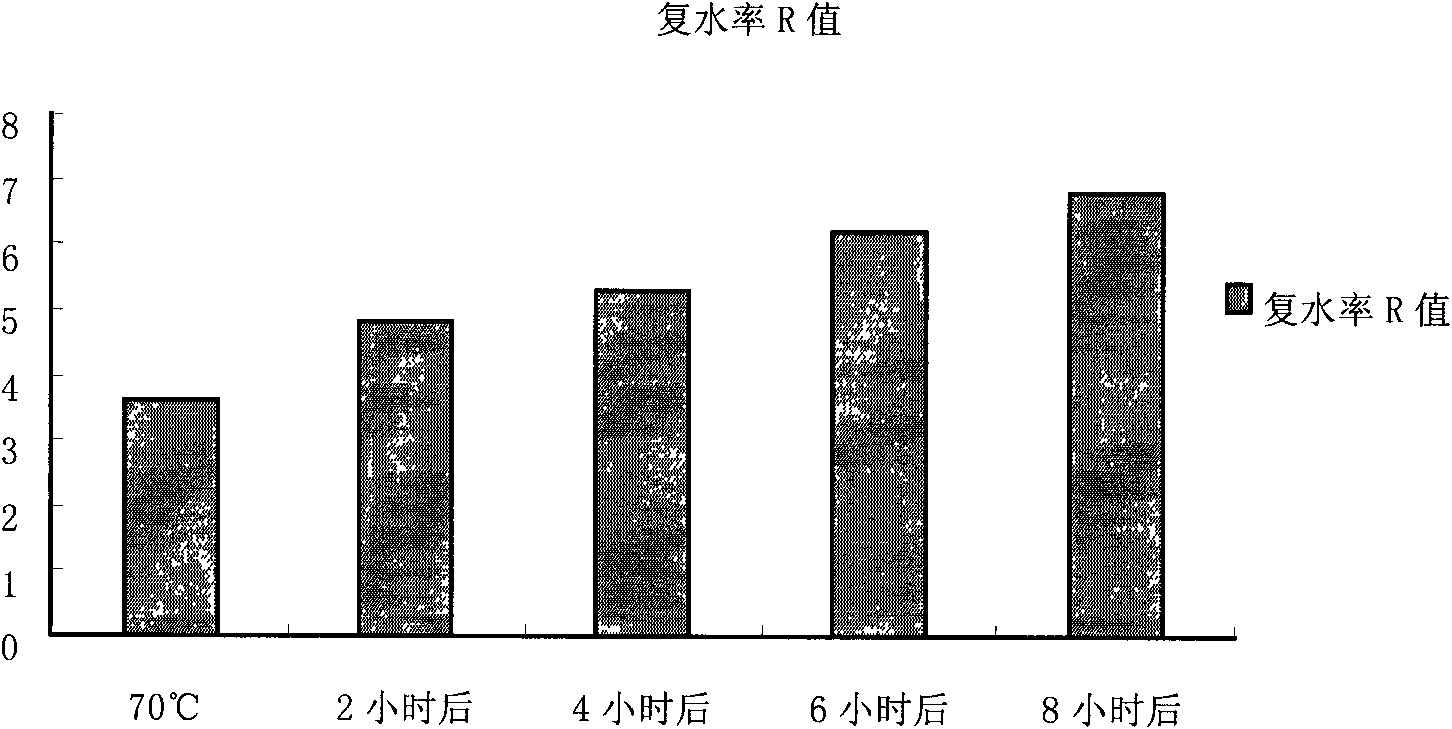

Processing method for rapidly rehydrating dried osmunds

The invention relates to a processing method for rapidly rehydrating dried osmunds, which is characterized by comprising a step of circularly immersing the dried osmunds in a heat soak solution and a normal temperature soak solution, wherein the dried osmunds are immersed for 1 h respectively in the heat soak solution and the cold soak solution each time, the temperature of the heat soak solution is 50-90 DEG C, preferably 70 DEG C, both weight ratios of the dried osmunds to the heat soak solution and the normal temperature soak solution are 1: (20-40), preferably 1: 30, and the total immersing time is 6-10h, preferably 8h. The rehydrating method adopted by the invention is short in immersing time, the rehydrated product has good quality, and the purpose of rapidly rehydrating is achieved so as to be beneficial for post-processing of the dried osmunds; meanwhile, the method optimizes rehydrating parameters and mode, thereby effectively enhancing the rehydrating effect and being beneficial for helping a producer shorten production duration better, save production cost and control quality and commercial performance of the product.

Owner:ZHEJIANG WANLI UNIV

Method for measuring forward tensile strength of welding spots and fixtures

ActiveCN101900651AOvercome formability disadvantagesOvercoming processabilityMaterial strength using tensile/compressive forcesWelding apparatusEngineeringSpot welding

The invention provides a method for accurately measuring forward tensile strength of welding spots and fixtures which are not limited by mouldability of a material. The method comprises the following steps: firstly drilling through holes of the same position and size on two test boards, wherein the through holes are uniformly distributed on one circumference and comprise first through holes with larger bore diameter and second through holes with smaller bore diameter, and the first through holes and the second through holes have equal number and alternately arranged; selecting two fixtures, and drilling through holes with the same position and size as those of the test boards on mounting surfaces of the two fixtures; stacking the two test boards together for spot welding to form the welding spots at the center of the circumference of the first through holes and the second first through holes, and respectively fixing the fixtures with the test boards at the same side by bolts and nuts; and finally stretching the two fixtures at a certain stretching speed until the welding spots of the test boards are ruptured, recording experimental data and carrying out tensile load-displacement curve analysis.

Owner:CHERY AUTOMOBILE CO LTD

Flame retardant charring agent-tetra-{1-oxyphospha-2,6,7-trioxabicyclo-[2.2.2]-octane-(4)-methyl} silicate compound and preparation method thereof

ActiveCN104017025ANovel structureImprove stabilityGroup 5/15 element organic compoundsPolyesterEpoxy

The invention relates to a flame retardant charring agent-tetra-{1-oxyphospha-2,6,7-trioxabicyclo-[2.2.2]-octane-(4)-methyl} silicate compound and a preparation method thereof. The compound has a structural formula shown in the specification. The preparation method comprises the following steps of dropwise adding silicon tetrachloride into a solution of 1-oxyphospha-4-hydroxymethyl-2,6,7-trioxabicyclo-[2.2.2]-octane (PEPA) and an organic solvent at 20 DEG C, heating to 80-140 DEG C, performing stirring reaction for 4-10 hours, adding a fixed quantity of an acid-binding agent, stirring for 1 hours, and ending the reaction when detecting that the pH value of the solution is 5-6; cooling, performing suction filtration, washing by water, and drying to obtain tetra-{1-oxyphospha-2,6,7-trioxabicyclo-[2.2.2]-octane-(4)-methyl} silicate. The compound is the excellent halogen-free phosphorus-silicon synergistic flame retardant charring agent and can be applied to polyolefin, polyester, polyvinyl chloride, polyurethane, epoxy resin, unsaturated resin and the like, the process is simple, the equipment investment is low, and the industrialized production is easy to realize.

Owner:RES INST OF XIANGCHENG SUZHOU UNIV OF SCI & TECH

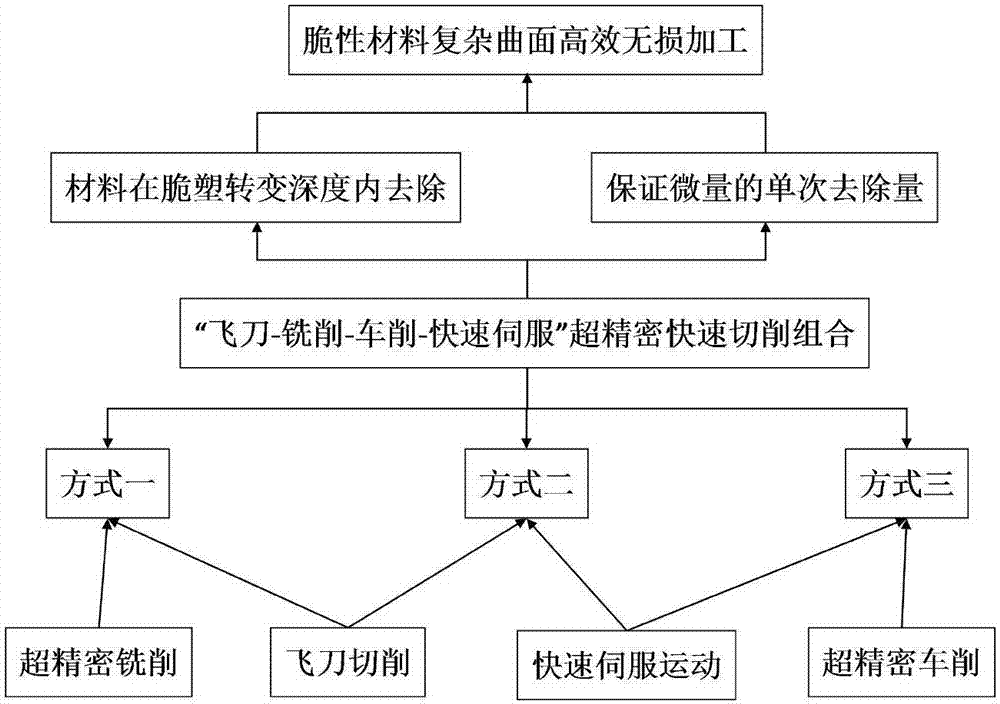

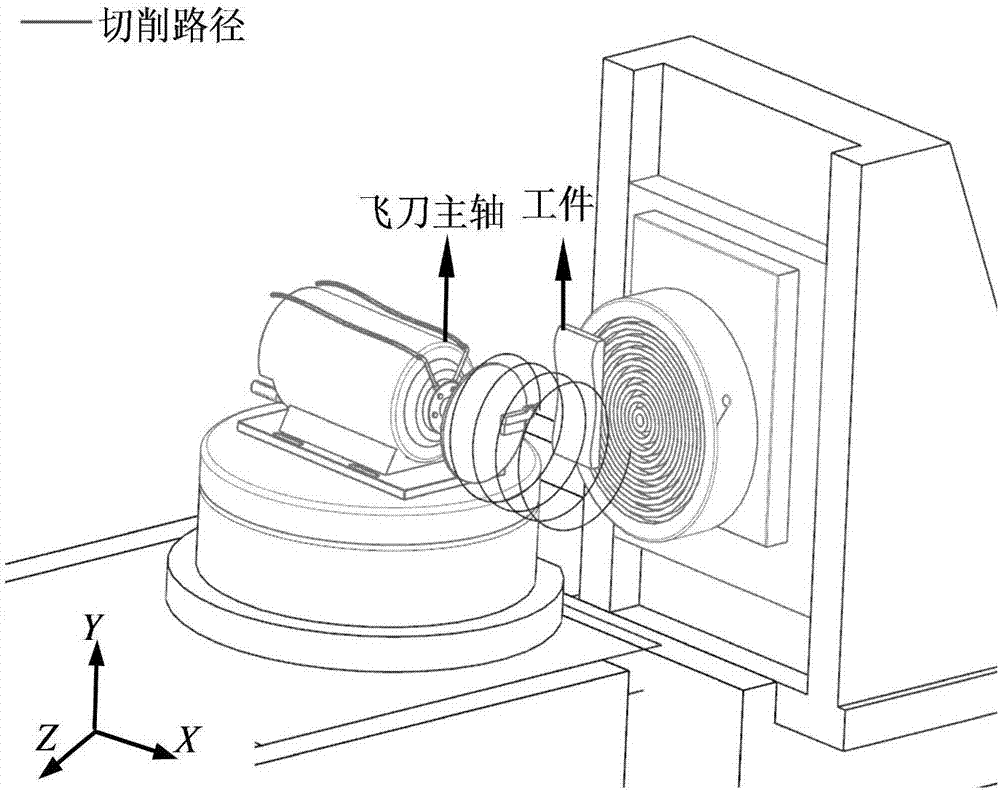

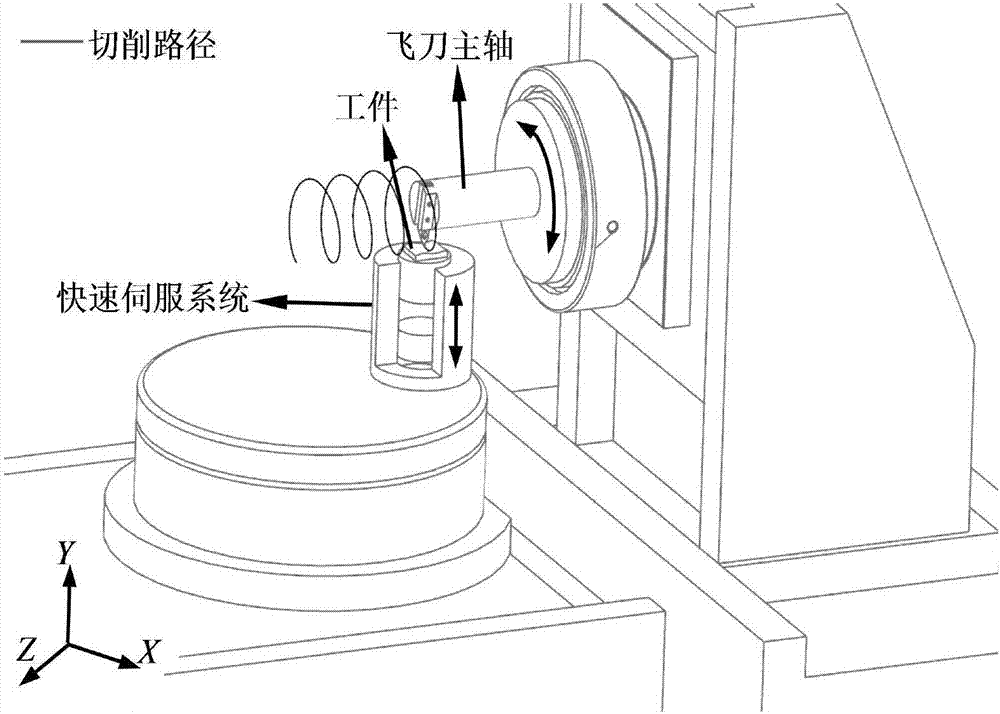

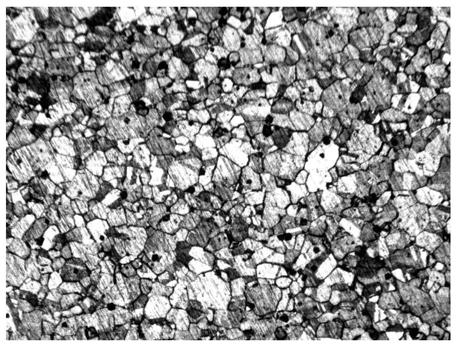

Ultra-precise rapid-cutting-combination machining-forming method for optical complex curved surface of brittle material

InactiveCN107309657AOvercome machined surface qualityOvercoming processabilityOther manufacturing equipments/toolsMachining processUltra precision

The invention relates to an ultra-precise fast cutting combined processing forming method for optically complex curved surfaces of brittle materials, which meets the processing requirements of different complex curved surface features: according to the characteristics of complex curved surfaces, the degree of non-rotation and curvature of the surface shape are calculated, and a suitable ultra-precise fast cutting method is selected and used. Cutting processing method, the selected processing method; consider the dynamic characteristics of the processing system under fast cutting, design a reasonable tool holder system; design appropriate cutting parameters and tool geometry parameters according to the characteristics of the fast cutting process and the cutting performance of the material; based on the processing parameters Generate and compensate the machining path with the geometric parameters of the tool. The tool contour forms the machined surface after passing through the path; the workpiece is assembled on the machining platform for fast cutting. The high-frequency reciprocating motion of the dimensions is combined and controlled synchronously to produce a controllable cutting depth and form a complex surface shape.

Owner:TIANJIN UNIV

Modification processing method for highly structural-superconducting carbon BP2000

InactiveCN101157806AGood effectOvercoming processabilityPigment treatment with organosilicon compoundsVulcanizationAdhesive

The invention discloses a modification processing method of a high structure superconducting carbon black BP2000. According to the weight ratio, the prescription of the modification processing method is 20 parts of the high structure superconducting carbon black BP2000, 100 parts to 200 parts of ethanol and 2 parts to 7 parts of organic silicon reagent. The method of the invention overcomes the problem that mixed and linked adhesive is seriously tackified when the carbon black is added into peroxide vulcanized rubber, thus leading difficult process and normal vulcanization; in addition, the method of the invention is simple, has low cost and is in favor of industrialized production.

Owner:SHANDONG UNIV

Large-pipe-diameter Ni-V rotary target material containing microelements and preparation method of large-pipe-diameter Ni-V rotary target material

ActiveCN110468382AEasy feedingImprove grain boundary binding forceVacuum evaporation coatingSputtering coatingOxygenBinding force

The invention discloses a large-pipe-diameter Ni-V rotary target material containing microelements and the preparation method of the large-pipe-diameter Ni-V rotary target material. The rotary targetmaterial comprises the following components of, in percentage by mass, 0.01%-0.05% of C, 0.01%-0.08% of B, 0.001%-0.006% of Ti, 0.01%-0.05% of Mg, 6%-8% of V, and the balance Ni and inevitable impurities; and the preparation method comprises the following steps of vacuum melting, hot forging, machining, hot extrusion, acid pickling treatment, solid solution treatment, cold rolling or boring, annealing treatment, the machining or binding. According to the target material and the method, on the basis of Ni-V, trace elements of the C, the B, the Ti and the Mg are added for component optimization,the contents of oxygen, sulfur and the like are reduced, the generation of cracks can be inhibited, the grain boundary binding force and strength of the target material are improved, and crystal grains are refined, so that the yield is improved; and the rejection rate is reduced by optimizing hot working process parameters.

Owner:NANJING DAMAI SCI&TECH IND CO LTD

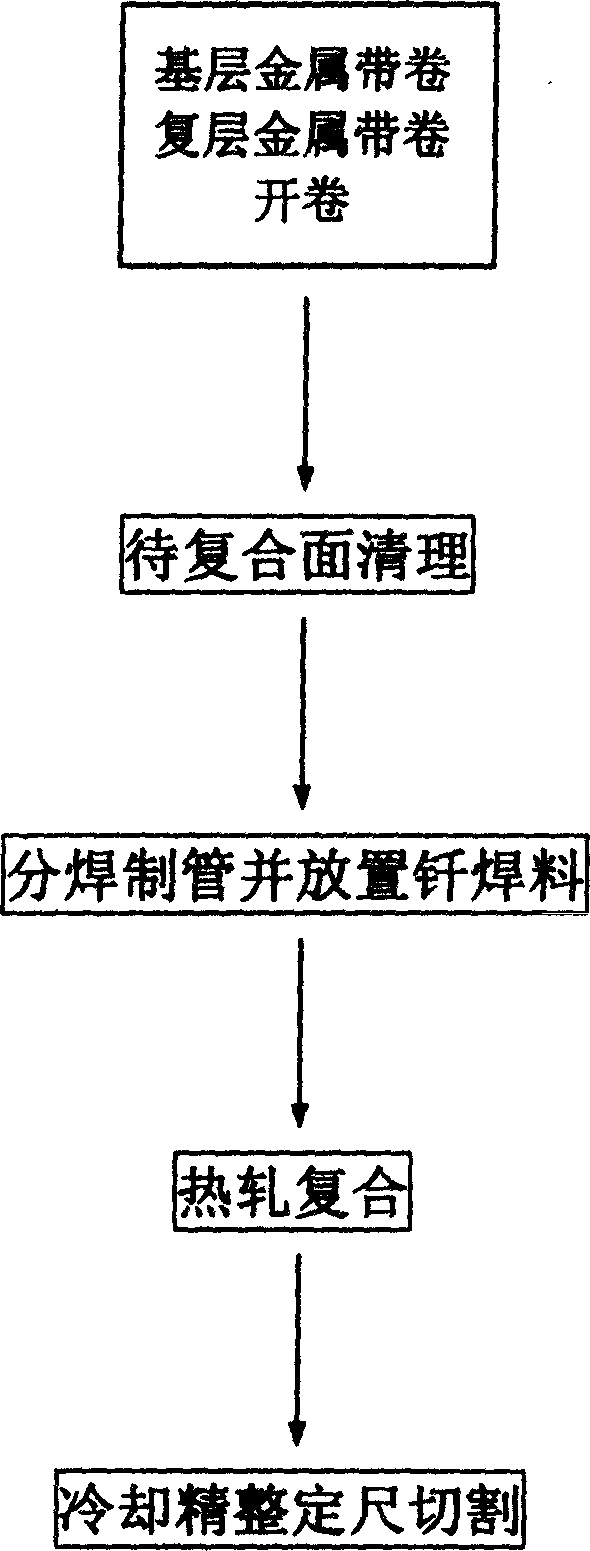

Method for manufacturing metal compound pipe by braze welding, hot rolling and continuous welding

InactiveCN1631569AImprove mechanical propertiesImprove corrosion resistanceOther manufacturing equipments/toolsMechanical propertyLarge applications

The invention offers a producing way to heat roll and connect the metal complex tube, which contains the following craft: base metal tape, complex metal tape open; wash the complex surface; separately roll; heat roll to complex; cool and cut. The rolling temperature in the invention is 750-950 degC. The metal complex tube made by this way has good features of machine, antisepses and reproduce, so it has large application.

Owner:吉欣(英德)热轧不锈复合钢有限公司 +1

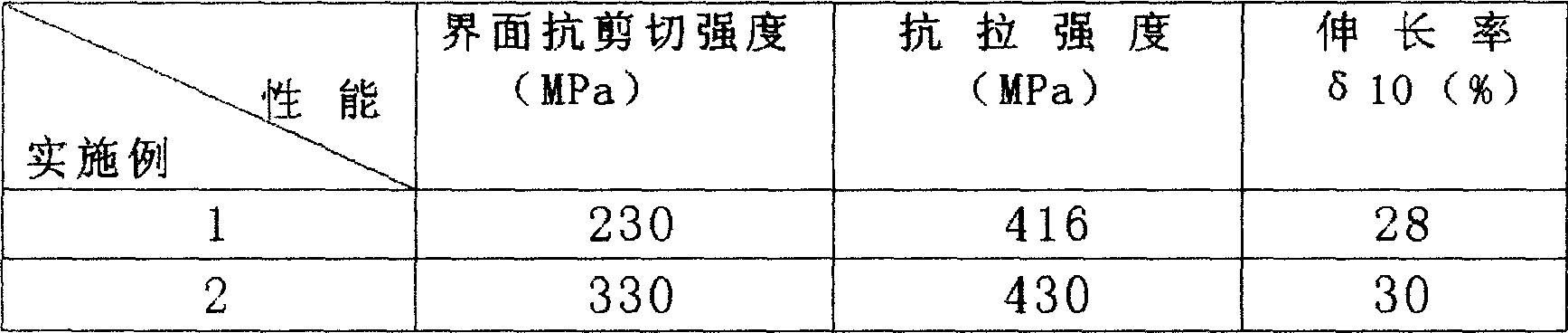

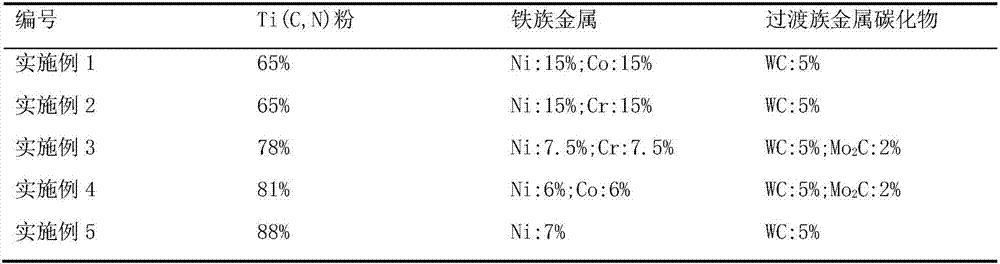

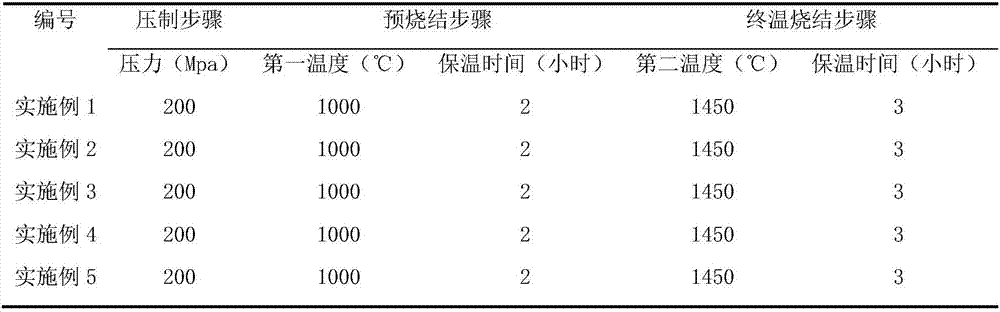

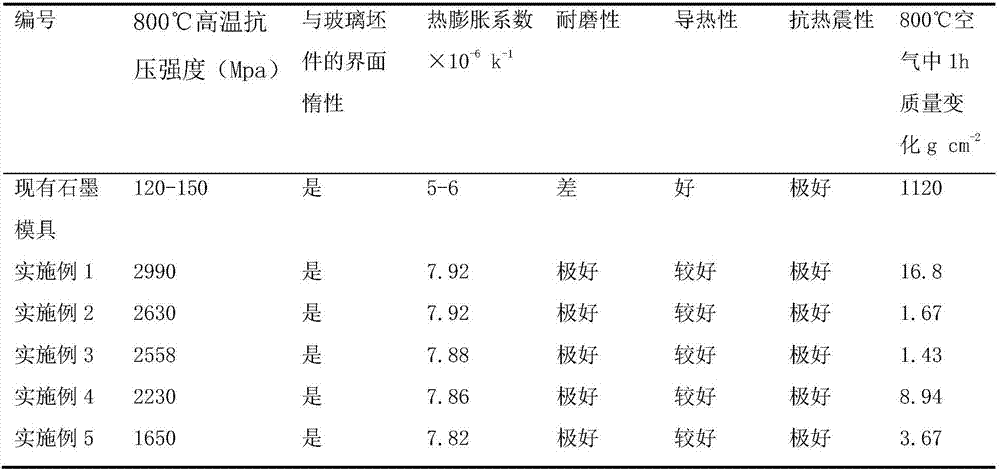

Application of Ti(C,N) base metal ceramic, curved glass hot bending die and manufacturing method of curved glass

ActiveCN107488802AHigh hardnessImprove the problem of not being resistant to oxidation corrosionGlass reforming apparatusForming faceGraphite

The invention discloses application of Ti(C,N) base metal ceramic, a curved glass hot bending die and a manufacturing method of curved glass so as to solve the problem that in the prior art, a curved glass hot bending die manufactured through graphite is not resistant to oxidization corrosion. The application is specifically the application that the Ti(C,N) base metal ceramic serves as a composition material for the curved glass hot bending die, a composition material for a formed face of the curved glass hot bending die or a surface coating material of the formed face of the curved glass hot bending die. The curved glass hot bending die is used for pressing a glass blank at the glass blank softening temperature, then, the curved glass component or the component combination is formed by the glass blank according to the die formed face. The die is composed of the Ti(C,N) base metal ceramic, or the formed face of the die is composed of the Ti(C,N) base metal ceramic, or the formed face of the die is provided with the Ti(C,N) base metal ceramic surface coating.

Owner:CHENGDU MET CERAMIC ADVANCED MATERIALS

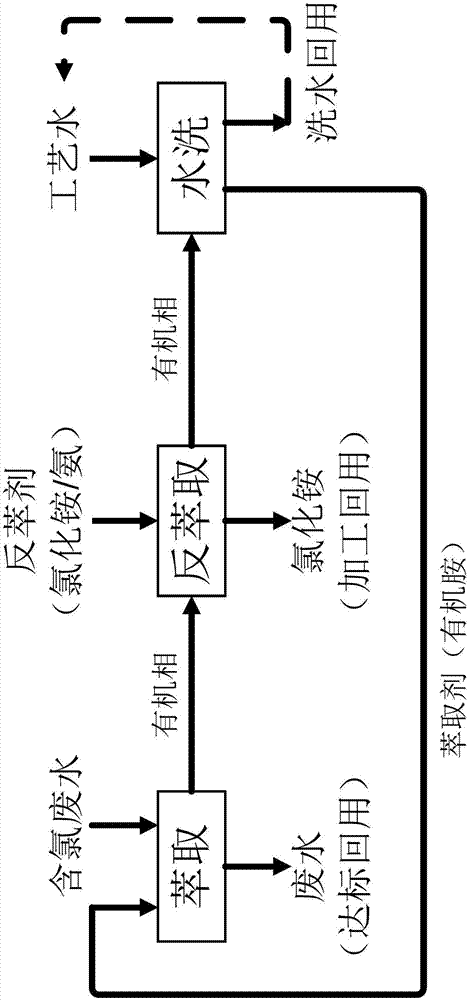

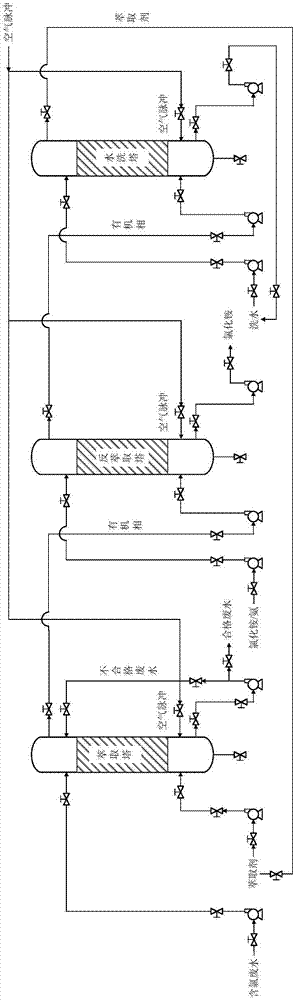

Method for recycling chloride ions in wastewater

ActiveCN106882884AIncrease cycle ratioEmission reductionWater contaminantsMultistage water/sewage treatmentReflux extractionEmission standard

The invention provides a method for recycling chloride ions in wastewater and relates to the technical field of industrial water treatment and comprehensive utilization of resources. The method provided by the invention comprises the following steps: pre-treating chloride-containing wastewater to remove suspension matters; conveying the wastewater into an extracting tower; taking an organic amine as an extracting agent, and carrying out countercurrent extraction and desulfurization to remove the chloride ions in the wastewater; discharging raffinate from an extracting system; when the content of the chloride ions in the raffinate does not reach circulating utilization or emission standards, carrying out reflux extraction; enabling an extracting solution to enter a back extraction tower; carrying out countercurrent back extraction on an ammonium chloride solution containing ammonia to generate ammonium chloride; separating by a water washing tower, cooling and crystallizing to obtain an ammonium chloride product; returning organic amine back into the extracting tower for recycling and returning a washing solution back to the water washing tower for recycling.

Owner:HUADIAN ELECTRIC POWER SCI INST CO LTD

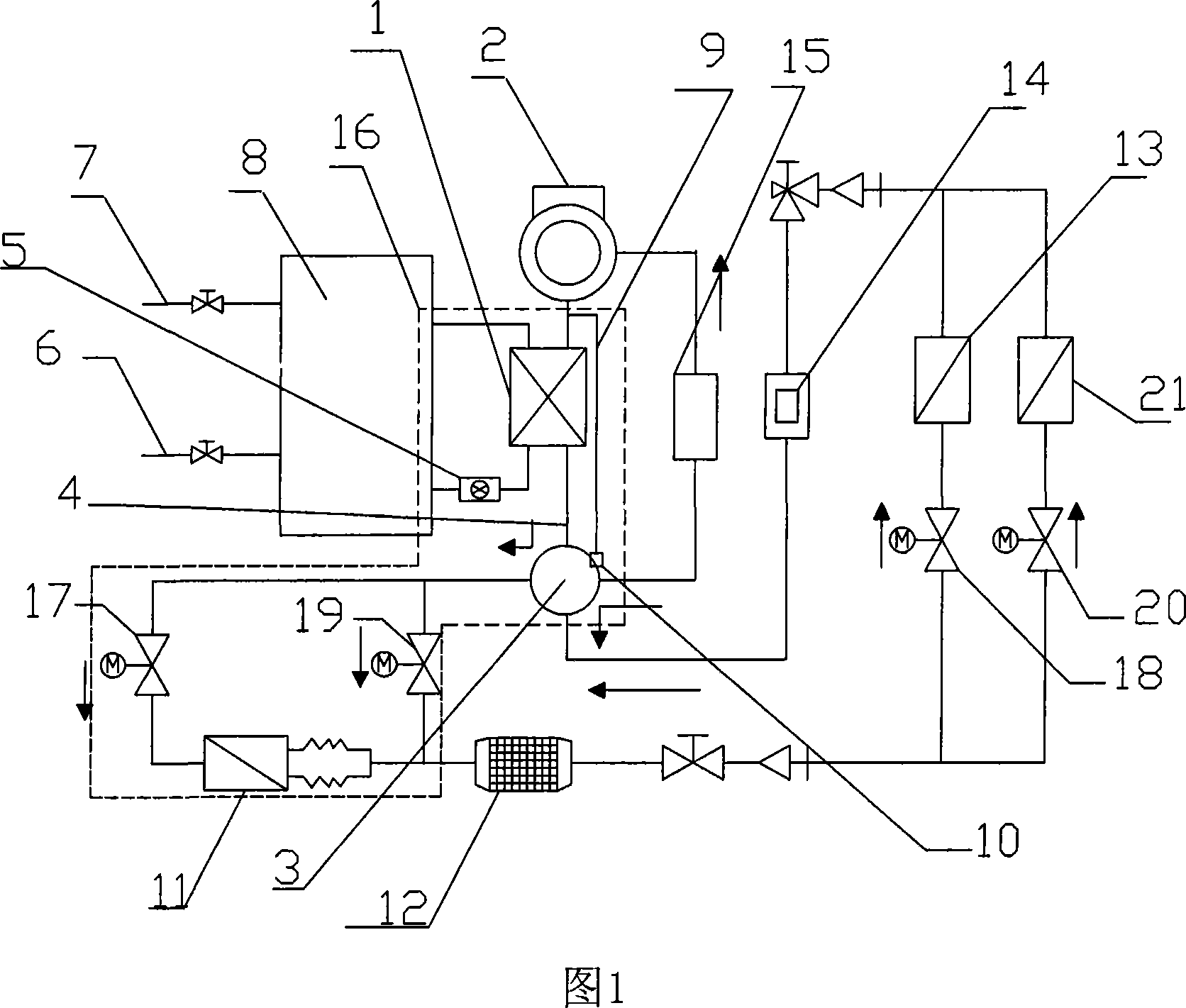

Composite condensing/evaporating four-functional hot water heat pump air conditioner device

InactiveCN101055116AGood cooling and heating effectGuaranteed functionFluid heatersEnergy recovery in ventilation and heatingFour-way valveSolenoid valve

The invention discloses a composite condensation / evaporation four-function hot water heat pump air-conditioning installation. Heat recovery device (1) is connected in series between outlet of compressor (2) and four-way valve (3); one end of bypass control pipe (9) is directly connected to the outlet of the compressor (2), and another end is connected to inlet of pneumatic control pipe of the four-way valve (3) or high pressure side inlet thereof; one end of condenser (11) is connected to the four-way valve (3); one end of condenser (11) is connected to the outlet of the four-way valve (3) via first control solenoid valve (17), and another end of the condenser is connected to the four-way valve (3) via second control solenoid valve (19); air-cooling evaporator (13) and water-cooling evaporator (21) are parallel connected and are respectively connected with third solenoid valve (18) and fourth solenoid valve (20). The invention can realize good cooling and heating effects as well as recovery of condensation heat, and has advantages of stable performance, easy production, and low cost, easy operation.

Owner:HUNAN UNIV

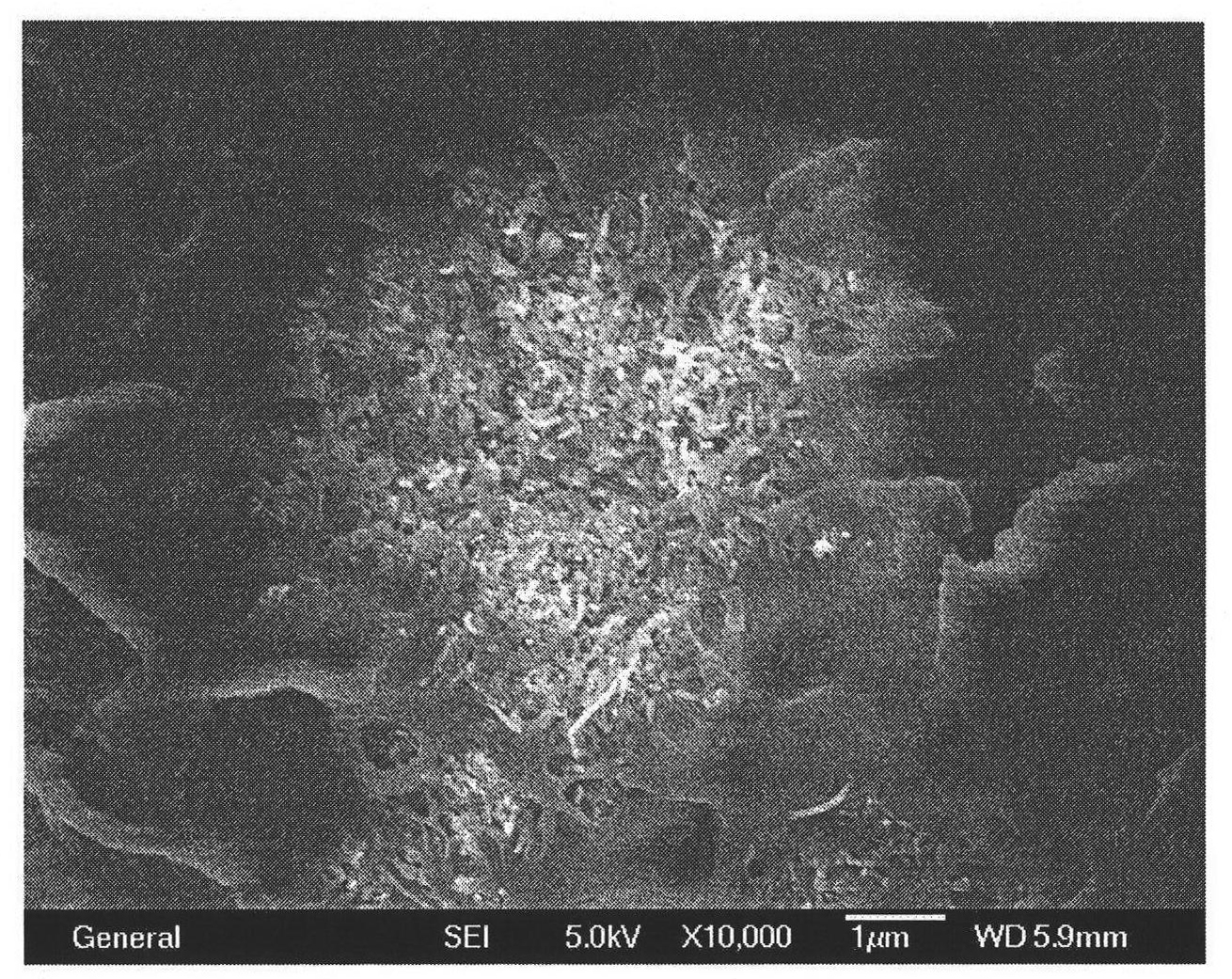

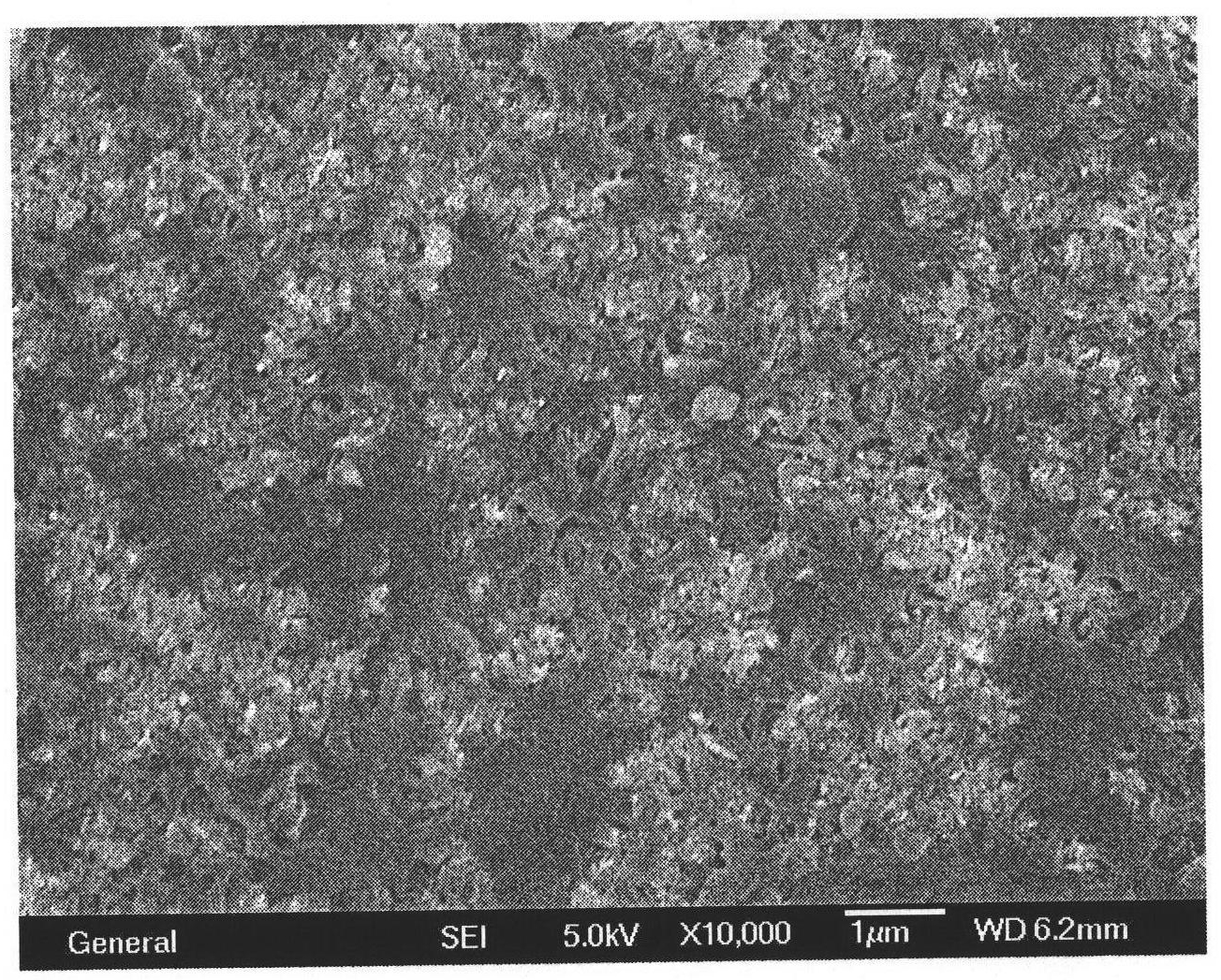

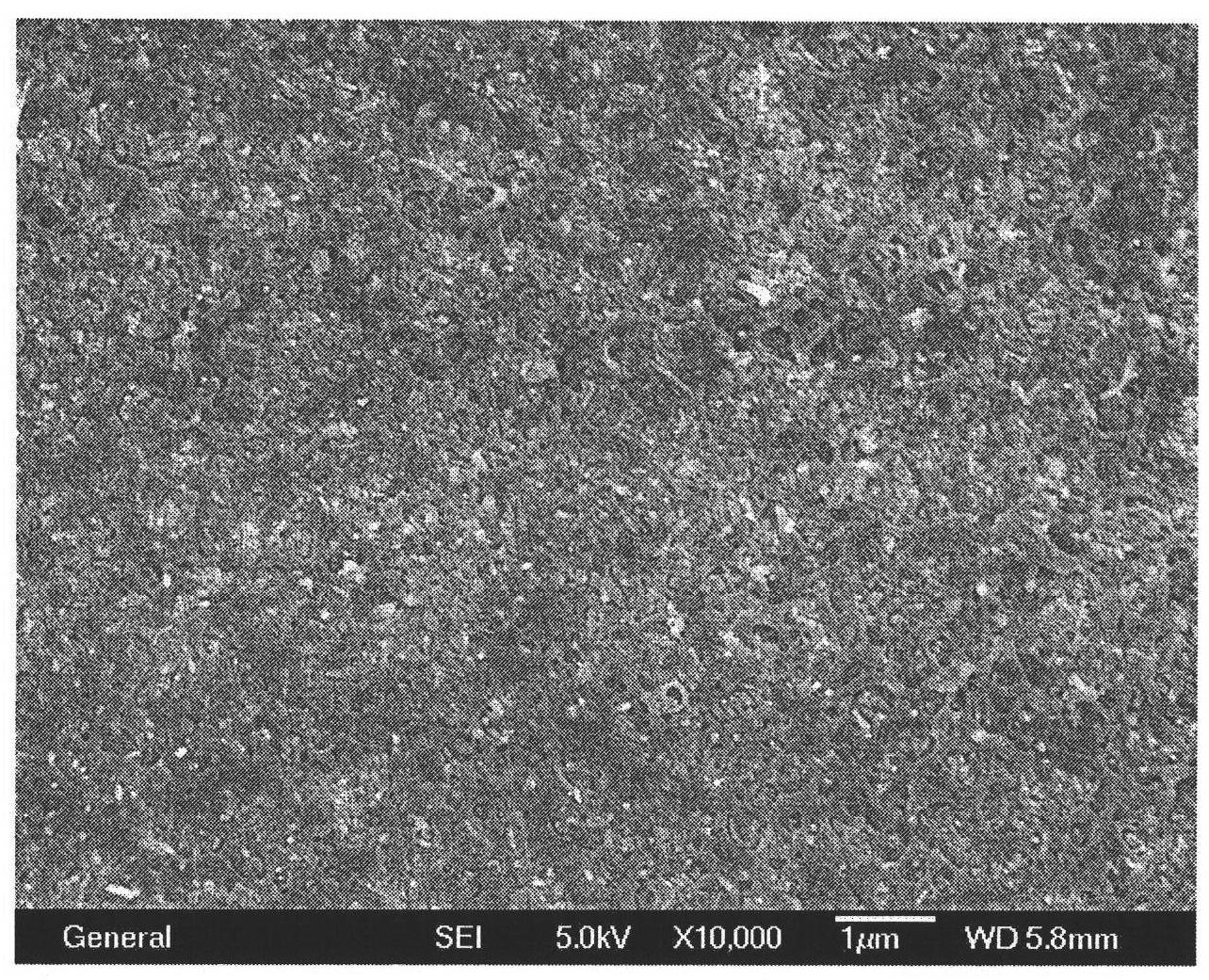

Polyarylether ketone/carbon nanotube composite material with high dielectric property and preparation method thereof

The invention belongs to the technical field of polymer based nano composite materials and preparation methods thereof, and particularly relates to a polyarylether ketone / carbon nanotube composite material with a high dielectric property and a preparation method thereof. The composite material consists of functionalized polyarylether ketone and carbon nanotubes, wherein in terms of the summation (100 percent) of the volume fractions of the functionalized polyarylether ketone and the carbon nanotubes, the carbon nanotubes account for 0.5 to 20 percent and the balance of the functionalized polyarylether ketone. Specifically, the carbon nanotubes (unmodified carbon nanotubes and carboxylic acid modified carbon nanotubes) as modified filling materials, the functionalized polyarylether ketone (sulfonated polyarylether ketone, amino functionalized polyarylether ketone and cyano functionalized polyarylether ketone) as base materials, and a method for solution blending is adopted to prepare the functionalized polyarylether ketone / carbon nanotube composite material with the high dielectric property, and simultaneously solve the problems of high dielectric loss, over-high loading level, reduced processability and the like.

Owner:SINO HIGH CHINA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com

![Flame retardant charring agent-tetra-{1-oxyphospha-2,6,7-trioxabicyclo-[2.2.2]-octane-(4)-methyl} silicate compound and preparation method thereof Flame retardant charring agent-tetra-{1-oxyphospha-2,6,7-trioxabicyclo-[2.2.2]-octane-(4)-methyl} silicate compound and preparation method thereof](https://images-eureka.patsnap.com/patent_img/e5e2c4b8-ddf8-4dea-b5bd-839db3a8733b/HSA0000105126530000011.PNG)

![Flame retardant charring agent-tetra-{1-oxyphospha-2,6,7-trioxabicyclo-[2.2.2]-octane-(4)-methyl} silicate compound and preparation method thereof Flame retardant charring agent-tetra-{1-oxyphospha-2,6,7-trioxabicyclo-[2.2.2]-octane-(4)-methyl} silicate compound and preparation method thereof](https://images-eureka.patsnap.com/patent_img/e5e2c4b8-ddf8-4dea-b5bd-839db3a8733b/HSA0000105126530000012.PNG)

![Flame retardant charring agent-tetra-{1-oxyphospha-2,6,7-trioxabicyclo-[2.2.2]-octane-(4)-methyl} silicate compound and preparation method thereof Flame retardant charring agent-tetra-{1-oxyphospha-2,6,7-trioxabicyclo-[2.2.2]-octane-(4)-methyl} silicate compound and preparation method thereof](https://images-eureka.patsnap.com/patent_img/e5e2c4b8-ddf8-4dea-b5bd-839db3a8733b/BSA0000105126520000021.PNG)