Method for manufacturing metal compound pipe by braze welding, hot rolling and continuous welding

A technology for welding metals and manufacturing methods, applied in the direction of manufacturing tools, other manufacturing equipment/tools, etc., can solve the problems of high cost, affecting the performance of composite pipes, poor post-processing performance of composite pipes, etc., and achieve huge economic and social benefits. , to solve the problem of penetration of different elements, the effect of excellent reprocessing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

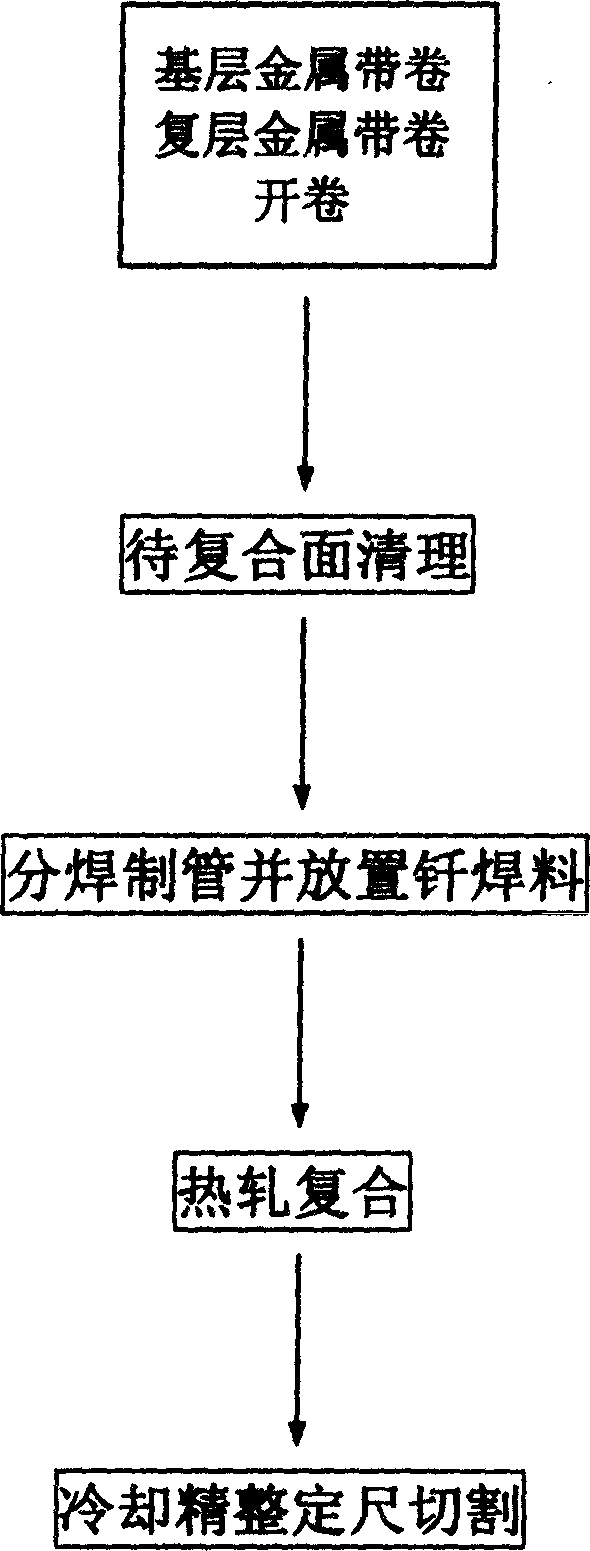

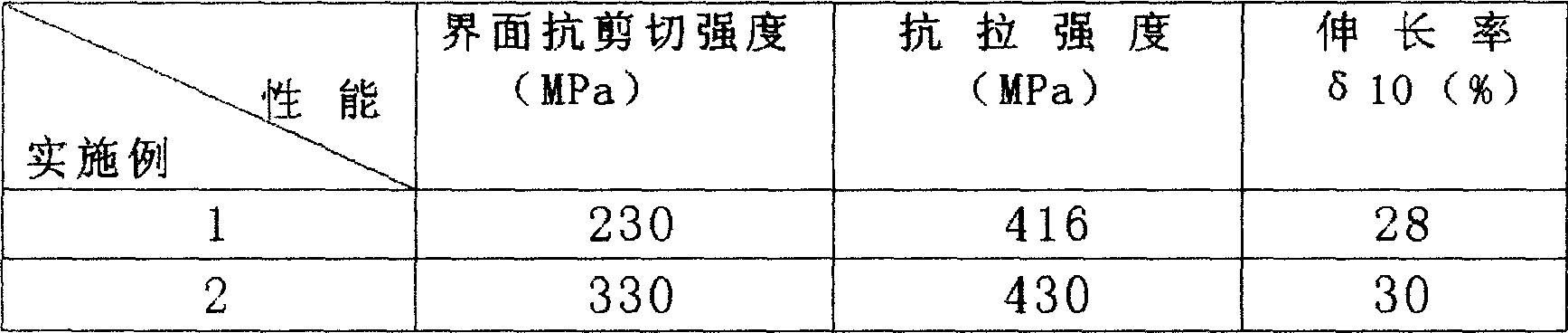

[0026] Using 2.5mm carbon steel strip coil (carbon steel model is Q235) as base metal coil and 0.5mm stainless steel coil (stainless steel model is 316L) as multilayer coil to produce 25mm×3.0mm continuous welded composite steel pipe.

[0027] First, place the 2.5mm base carbon steel strip coil and the 0.5mm multilayer metal stainless steel strip coil in the uncoiler and then enter the cleaning machine for cleaning to remove the surface oil and surface oxides on the surface to be composited; then send them into the composite pipe Welding pipes are divided into the unit, and at the same time, the brazing material foil strip with a thickness of 3 microns is uncoiled by an uncoiler and then placed between the carbon steel strip of the base metal and the stainless steel strip of the cladding metal to obtain a continuous welded cladding The continuous welded clad tube is rapidly heated to 750°C by high frequency, and then directly enters the 12-pass horizontal and vertical continuou...

Embodiment 2

[0029] The 5mm carbon steel strip coil (carbon steel model is Q235) is used as the base pipe and the 2.5mm clad metal stainless steel strip coil is used to produce 176mm×7mm continuous welded composite steel pipe.

[0030] First, place the 5mm base carbon steel strip coil and the 2.5mm multilayer metal stainless steel strip coil in the uncoiler and then enter the cleaning machine for cleaning to remove the surface oil and surface oxides on the surface to be composited; then send them to the composite pipe making unit Inner sub-welding pipe, at the same time, the brazing material foil strip with a thickness of 3 microns is uncoiled by an uncoiler and then placed between the carbon steel strip of the base metal and the stainless steel strip of the clad metal to make a continuous welded clad pipe , the continuous welded clad pipe is heated to 950°C by high frequency, and then directly enters the 12-pass horizontal and vertical continuous rolling mill, and an adjustable diameter ex...

PUM

| Property | Measurement | Unit |

|---|---|---|

| shear strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com