Patents

Literature

89results about How to "Solve penetration" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Spraying quick-setting rubber asphalt waterproof coating material

ActiveCN103627258AWith anti-adhesive effectImprove adhesionConjugated diene hydrocarbon coatingsNatural rubber coatingsComposite constructionWater based

The invention relates to a spraying quick-setting rubber asphalt waterproof coating material. A special technology is adopted for preparation of the spraying quick-setting rubber asphalt waterproof coating material. The spraying quick-setting rubber asphalt waterproof coating material is a water-based spraying paint prepared according to a ratio, and a preparation method of the spraying quick-setting rubber asphalt waterproof coating material comprises following steps: a liquid rubber asphalt latex emulsion is prepared by mixing superfine, suspended and micro-emulsion modified emulsified asphalt with high-molecular polymer rubber latex; and the liquid rubber asphalt latex emulsion is mixed with a coagulant. Cold spraying construction is adopted for preparation of the spraying quick-setting rubber asphalt waterproof coating material; elastic coating film elongation is more than 1000%; restoration ratio is more than 95%. The spraying quick-setting rubber asphalt waterproof coating material possesses ultraviolet resistance, high construction efficiency, high bonding strength, excellent high-temperature resistance, excellent low temperature flexibility, and better quick setting effect; and is capable of forming films in 3 seconds. The spraying quick-setting rubber asphalt waterproof coating material is water based; is friendly to the environment; possesses no toxicity, and excellent endurance; is quick and convenient for construction; and is a novel environmental friendly waterproof paint with a wide application range. The spraying quick-setting rubber asphalt waterproof coating material is mainly used for various waterproof and anticorrosion projects. The spraying quick-setting rubber asphalt waterproof coating material is used for individual construction of waterproof projects, for composite construction of waterproof projects together with waterproof roll, and for individual construction of anticorrosion projects.

Owner:SHANDONG NORTH CHUANGXIN WATERPROOF SCI & TECH GRP CO LTD

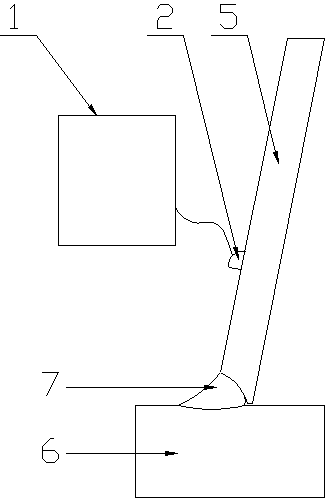

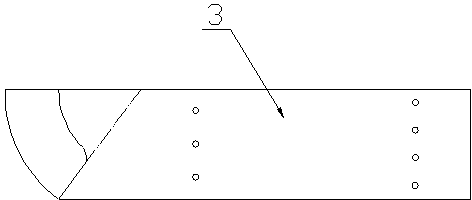

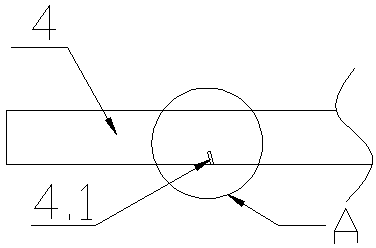

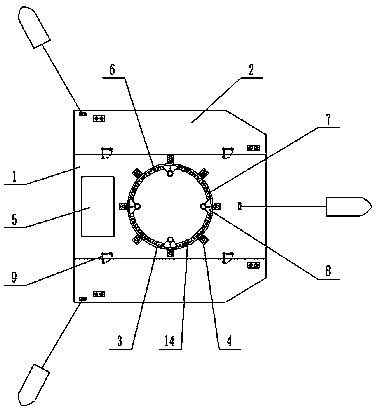

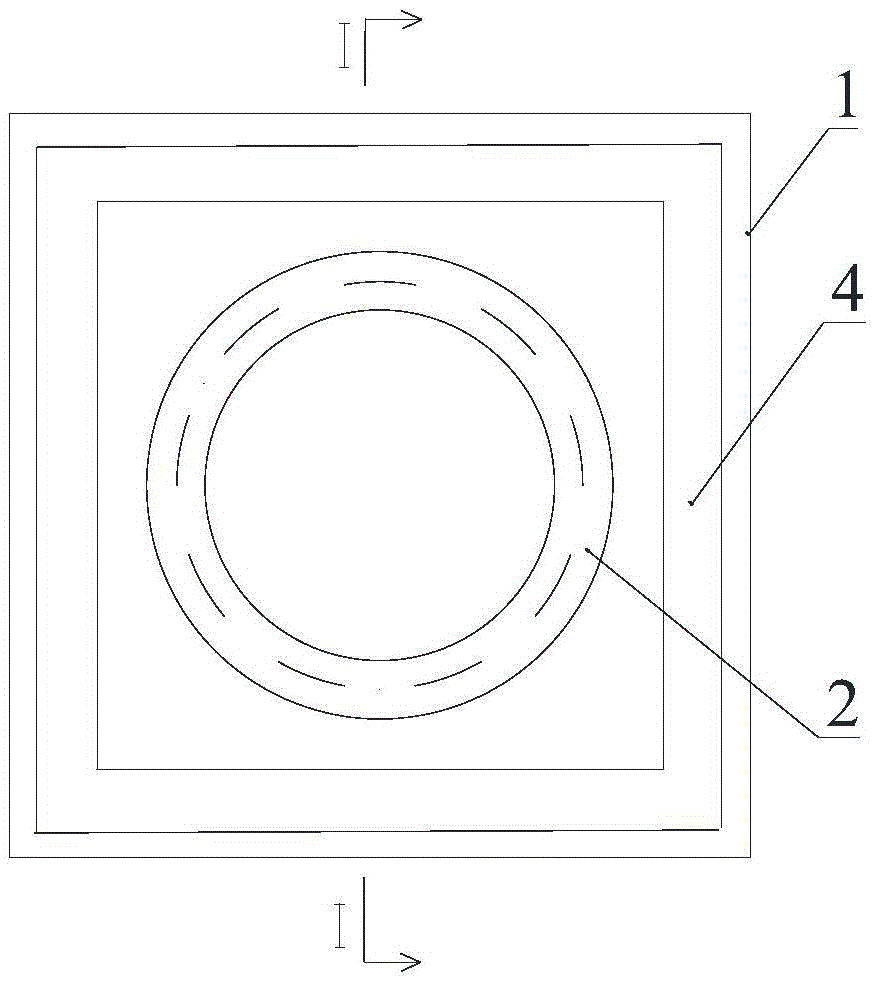

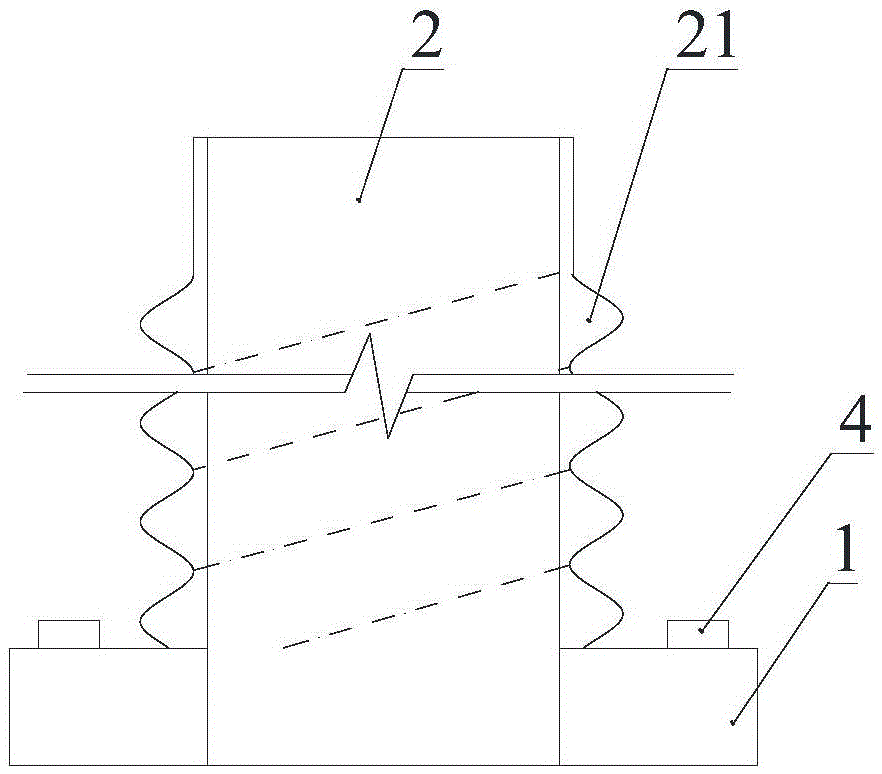

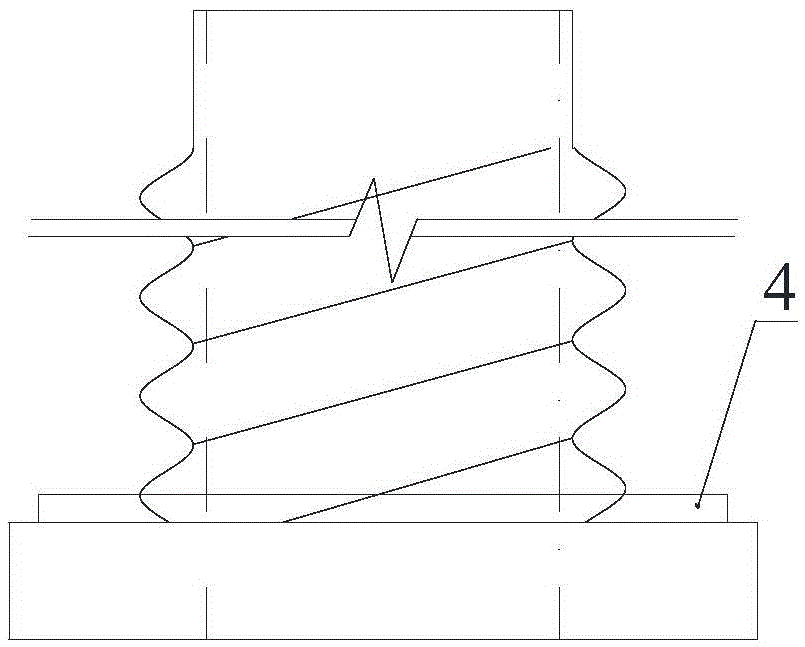

Ultrasonic phased array detection method of steel box beam U-rib angle welding seam

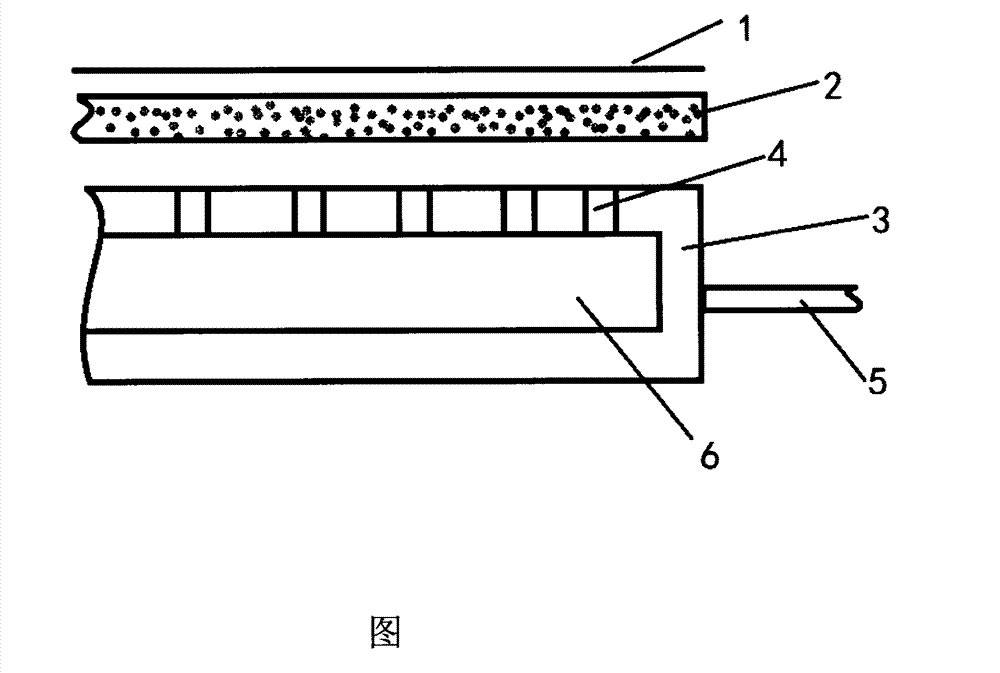

ActiveCN103293224ASolve penetrationResolve detectionAnalysing solids using sonic/ultrasonic/infrasonic wavesHorizonWeld seam

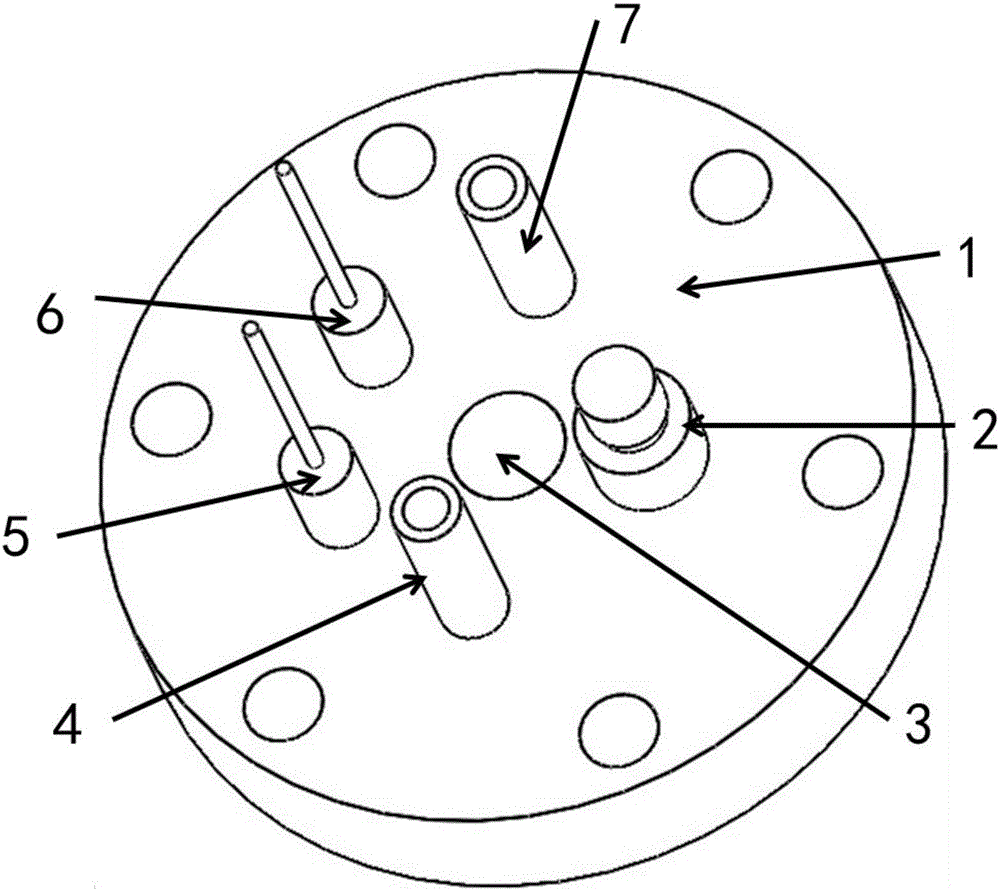

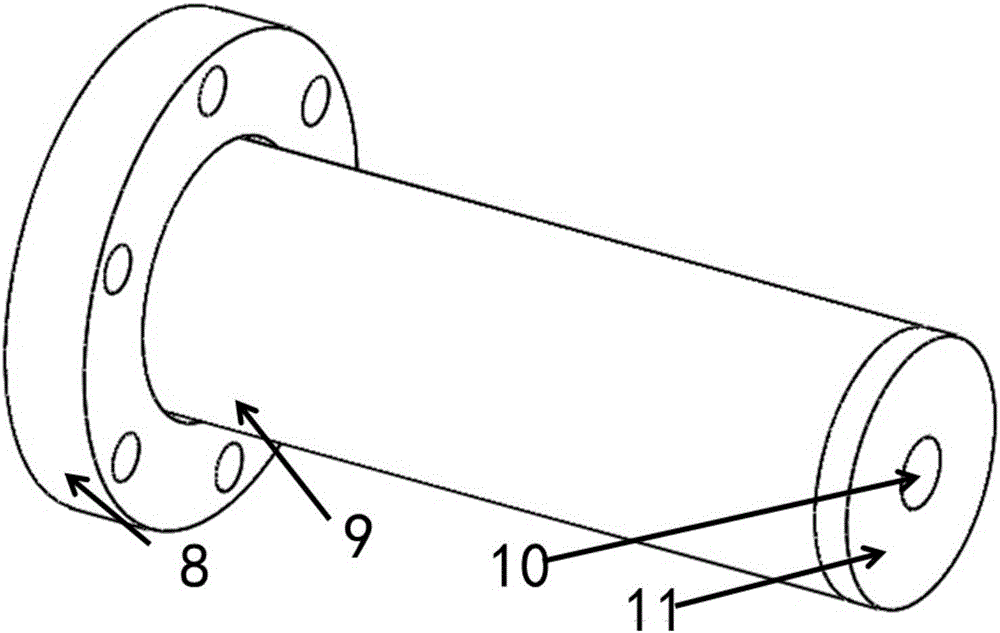

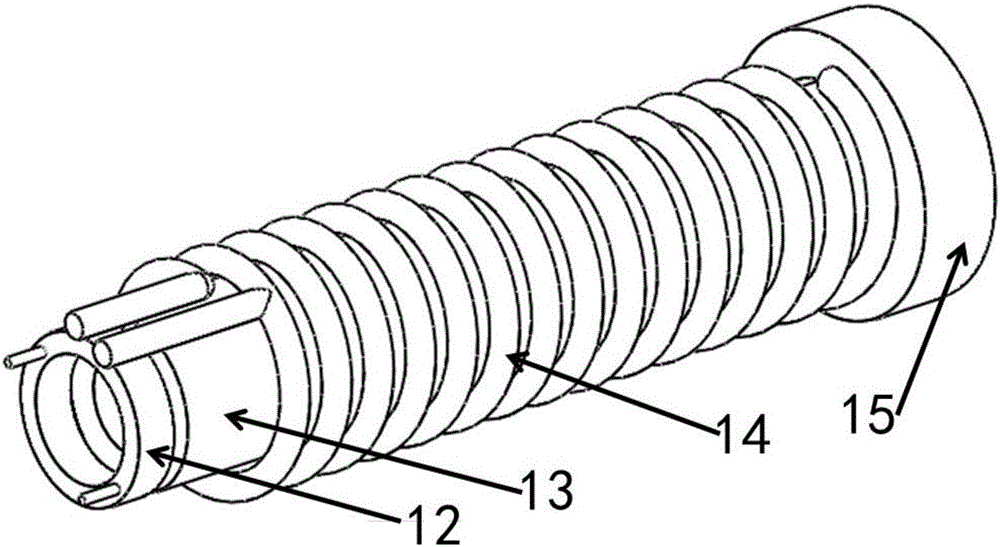

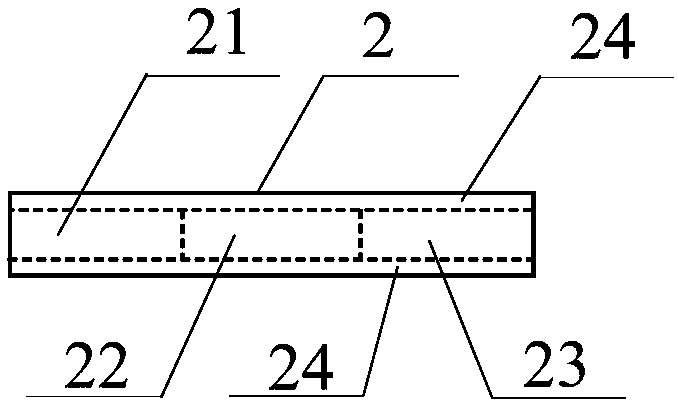

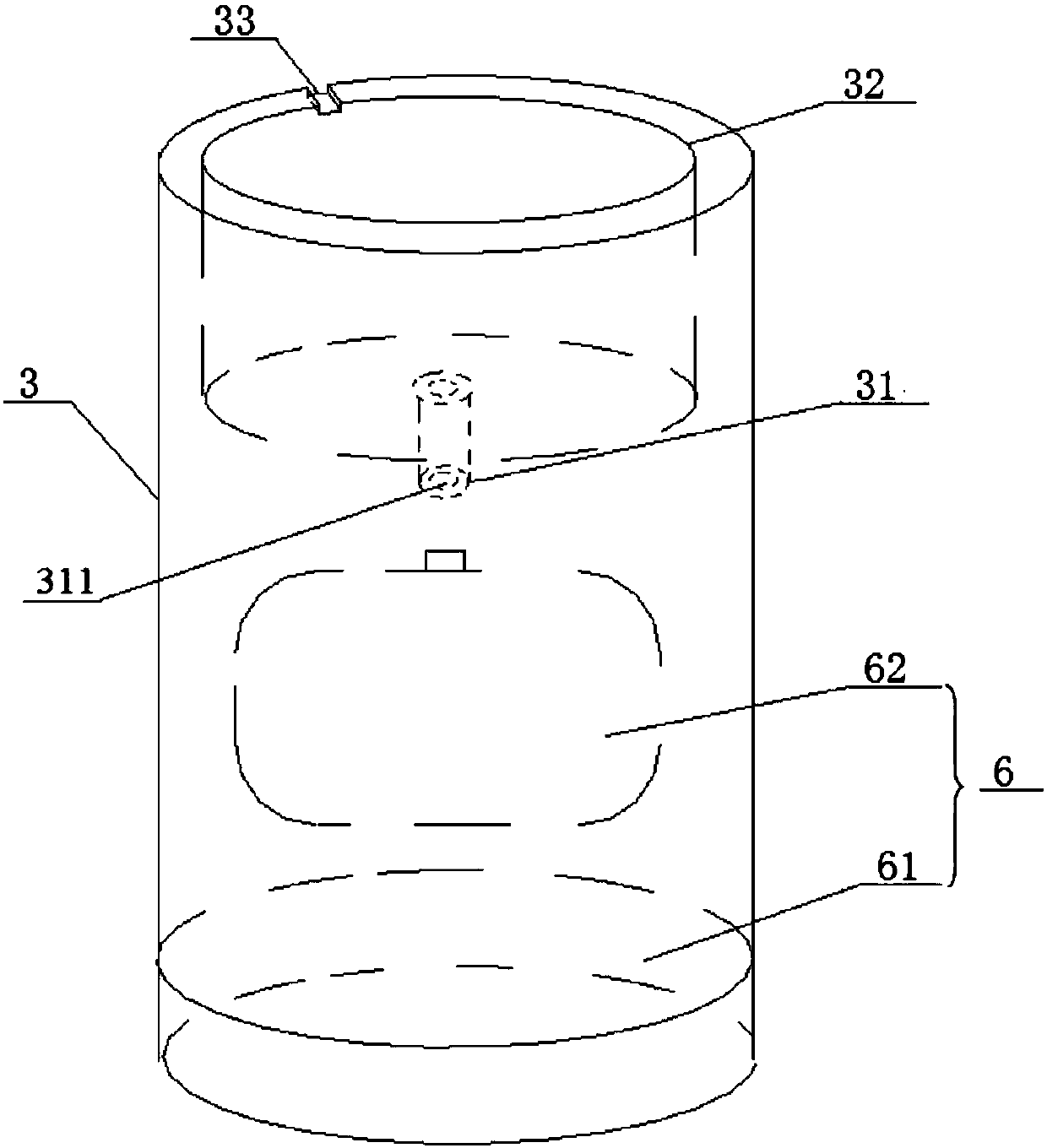

The invention relates to an ultrasonic phased array detection method of a steel box beam U-rib angle welding seam. A detection device of the method comprises an ultrasonic phased array detection instrument (1), a phased array probe (2), a CSK-IA test block (3), a reference block (4), a U-rib web plate (5), a panel (6) and an angle welding seam (7). The ultrasonic phased array detection method of the steel box beam U-rib angle welding seam provided by the invention comprises the following steps of: regulating the sensitivity of the equipment by utilizing the reference block, recording the horizon distance from the front end of the phased array probe to a groove, then, scratching a detection line on the U-rib web plate, and finally detecting the fusion depth and internal defect of the welding seam by adopting the phased array probe. The method provided by the invention solves the problem of detecting the fusion depth and internal defect of the steel box beam U-rib angle welding seam, and the welding quality of the steel box beam U-rib angle welding seam is effectively controlled.

Owner:JIANGSU FASTEN MATERIAL ANALYSIS & INSPECTION

Novel wall lightweight heat-insulating material and method for preparing same

InactiveCN101139200AImprove insulation effectLow thermal conductivitySolid waste managementFiberOXALIC ACID DIHYDRATE

The present invention discloses a new type wall body light heat-preservation material, which is characterized in that: the present invention comprises the following raw materials according to the weight ratio: 10-15 percent of magnesia or magnesium hydrate, 3- 7 percent of magnesium chloride, 4-8 percent of perlite, 1-5 percent of alkali resisting fibre, 6-12 percent of powder coal ash or calcium carbonate and 0.3-1 percent of modifier, wherein, the modifier is made of the following components according to weight ratio: 6-10 percent of ferrous sulfate, 1-3 percent of oxalic acid, 1-3 percent of tertiary sodium phosphate, 0.5-2 percent of hexametaphosphate and 12-18 percent of aluminium sulphate. Compared with the original heat-preservation system, the material is with much better heat-preservation performance, much lower heat-conductivity coefficient, much lower density, and much lower water content and water absorption ability. The present invention is with much better performance in heat-preservation, heat-insulation as well as sound absorption and sound insulation and so on. The present is able to bear or endure acid, alkali and corrupted. The manufacturing cost is much lower and the construction process is much more convenient. The present is easy to be popularized.

Owner:成都市圣欧实业有限公司

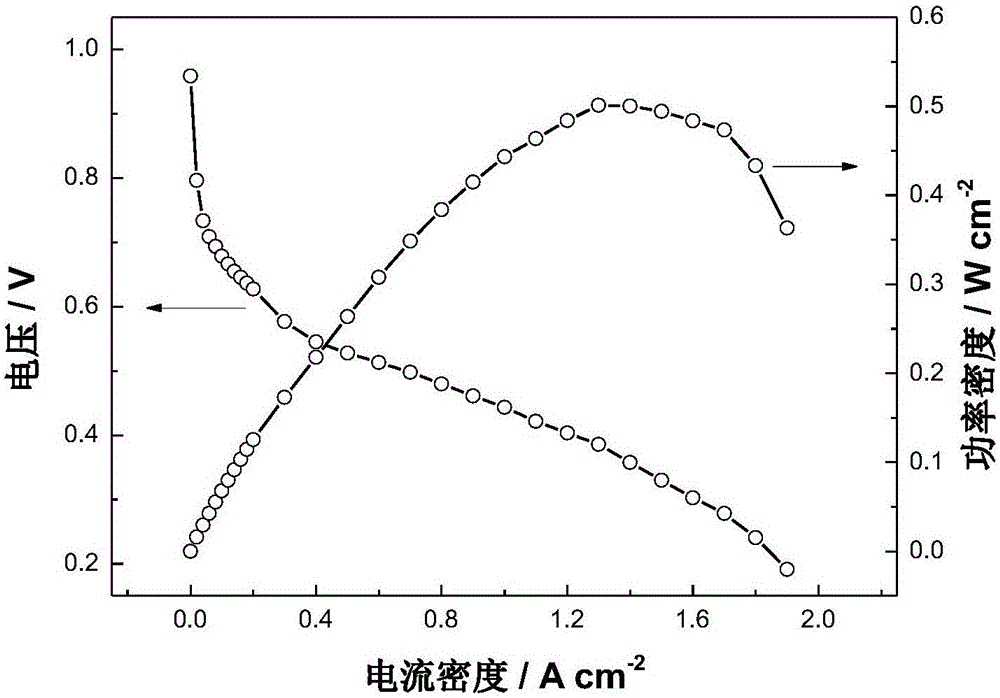

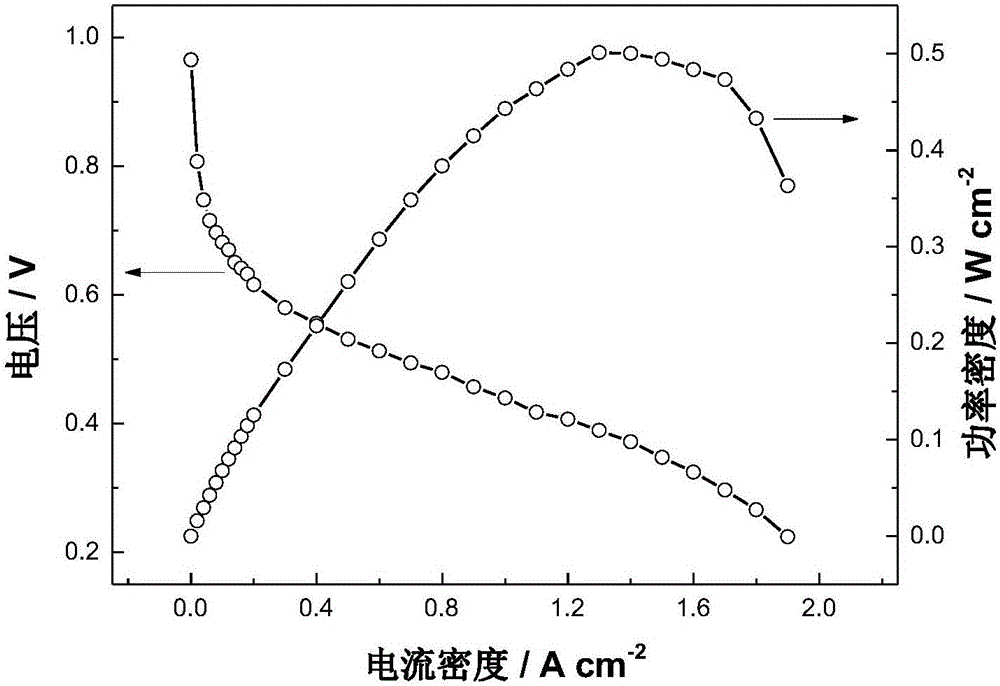

Preparation method of composite proton exchange membrane

ActiveCN101864163AInhibit swellingImprove proton conductivityFinal product manufactureCell component detailsElectrical conductorHeteropoly acid

The invention discloses a preparation method of a composite proton exchange membrane, comprising the following steps of: sulfonating, preparing a sulfonated polyether ether ketone solution; preparing polyaniline filter liquid, preparing membrane preparing liquid, casting to form a membrane, and the like. The composite membrane is prepared by using SPEEK (sulfonated polyether ether ketone) as a basal body and PANI (Polyaniline) and HPA (Heteropoly acid) as dopants, a material source is wide and does not need to be imported, a preparation process is simple, and used instruments are simple, thereby the cost of the membrane is reduced. A hydrogen bond formed by PANI and SPEEK is used for avoiding the swelling of the SPEEK and reducing methanol penetration, and the proton conductivity of the composite membrane is improved by the HPA. By changing the composition and the ratio between an alkaline polymer and a proton conductor, the novel PEM (proton exchange membrane) reaches optimum balance among high proton conductivity, low methanol penetration and low HPA dropout rate, the proton conductivity reaches 10-2S / cm, the methanol penetration rate of the composite proton exchange membrane is a half lower than that of an Nafion 117 membrane, and the HPA wastage rate does not reach 5 percent.

Owner:SUZHOU DACHENG YOUFANG DATA TECH CO LTD

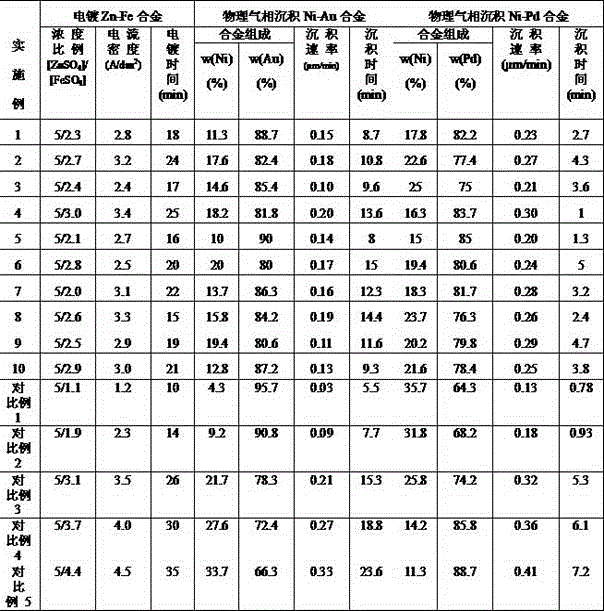

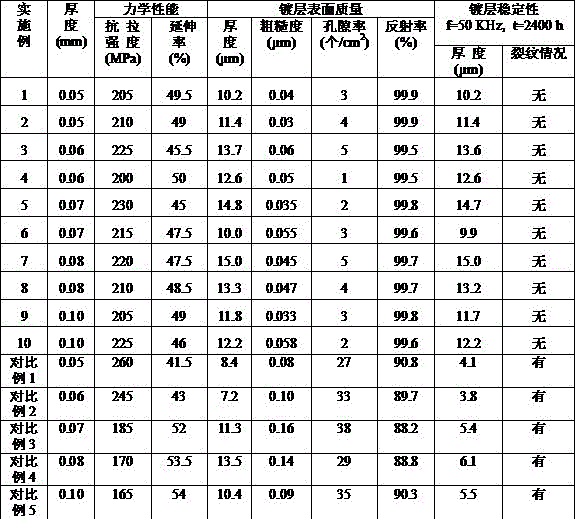

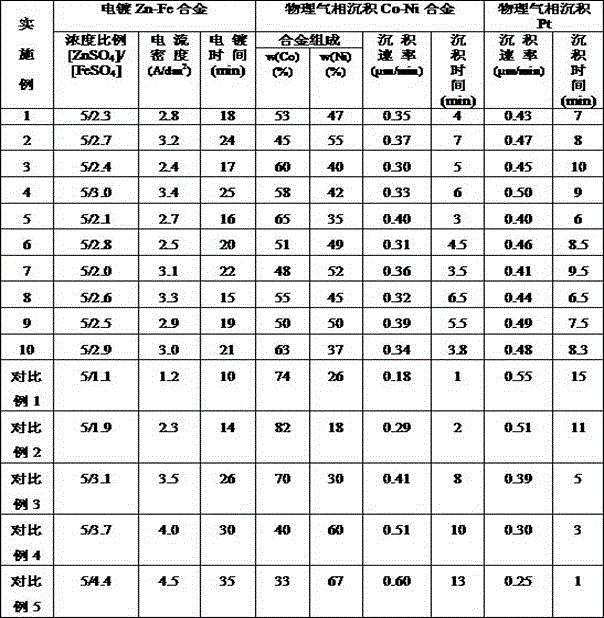

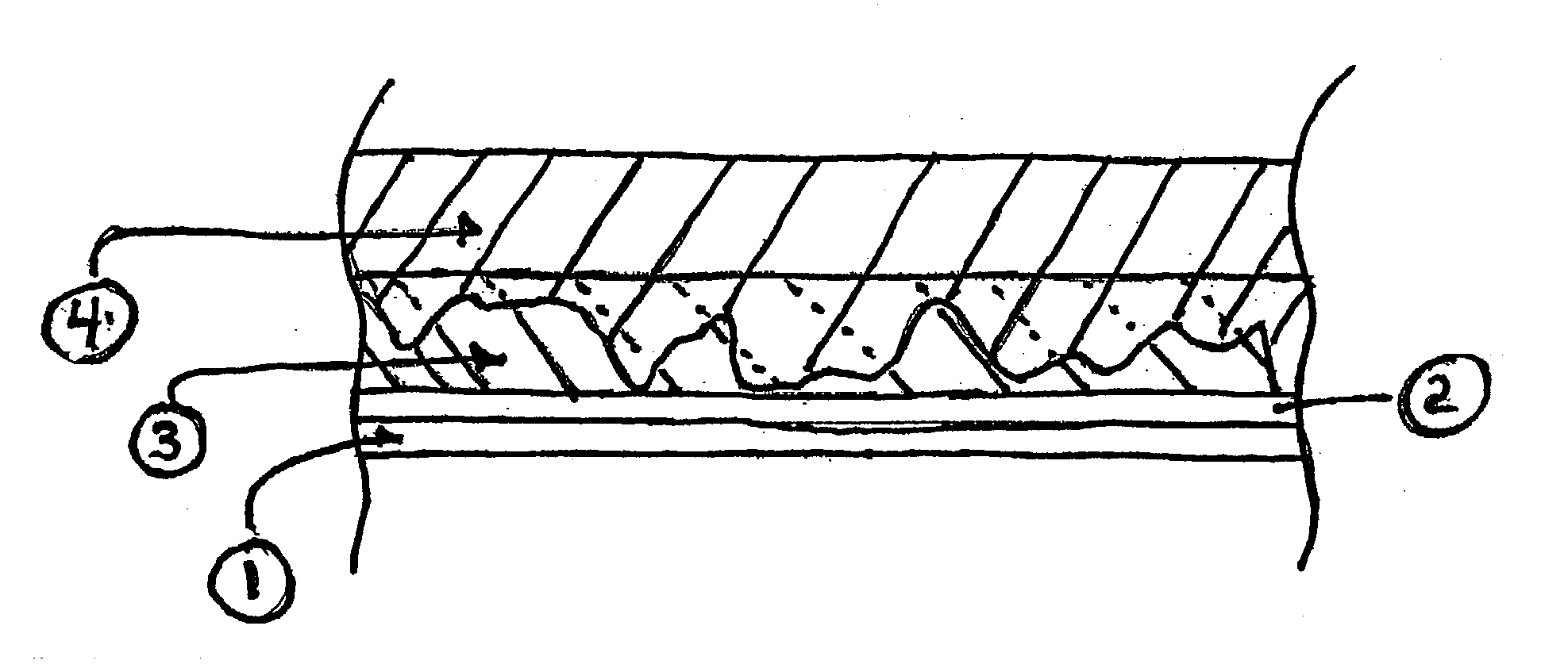

Production method of ultra-thin steel belt plated with precious metal

InactiveCN105887085APrecise thickness controlImprove stabilityVacuum evaporation coatingSputtering coatingLoss ratePorosity

Provided is a production method of an ultra-thin steel belt plated with precious metal. The production method includes the steps that a DC01 cold-rolled steel plate is used as a raw material, and conventional degreasing is conducted after the steel plate is cold-rolled repeatedly; annealing is conducted; the belt is prepared, specifically, uncoiling, striping and burr removal are carried out; Zn / Fe electroplating, primary water-washing and drying, primary physical vapor deposition, secondary water-washing and drying and secondary physical vapor deposition are carried out sequentially; and the belt is rolled after being naturally cooled to be at the room temperature. According to the steel belt, the Rm is 200-230 MPa, the percentage of elongation is 45%-50%, the surface roughness of an Au-plated or Ag-plated coating is 0.05-0.10 micron, and the specular reflection is 99%-99.9%; after the coating is stored on the indoor atmospheric condition for 1800 days, the specular reflection of the coating is 98.7%-99.7%, the gloss loss rate is not higher than 0.5%, and the rate of the corroded area is not higher than 0.05%; after the coating is exposed in air containing 30 ppmH2S for 1200 days, the specular reflection of the coating is 98.5%-99.5%, the gloss loss rate is not higher than 0.6%, and the rate of the corroded area is not higher than 0.08%; for a Pt-plated steel belt, the surface roughness is 0.03-0.06 micron, the porosity is not higher than five each square centimeter, and the specular reflection is 99.5%-99.9%; and after the coating is stored in the 50-KHz ultrasonic environment continuously for 2400 hours, the thickness of the coating is not changed, and the surface has no crack.

Owner:武汉钢铁有限公司

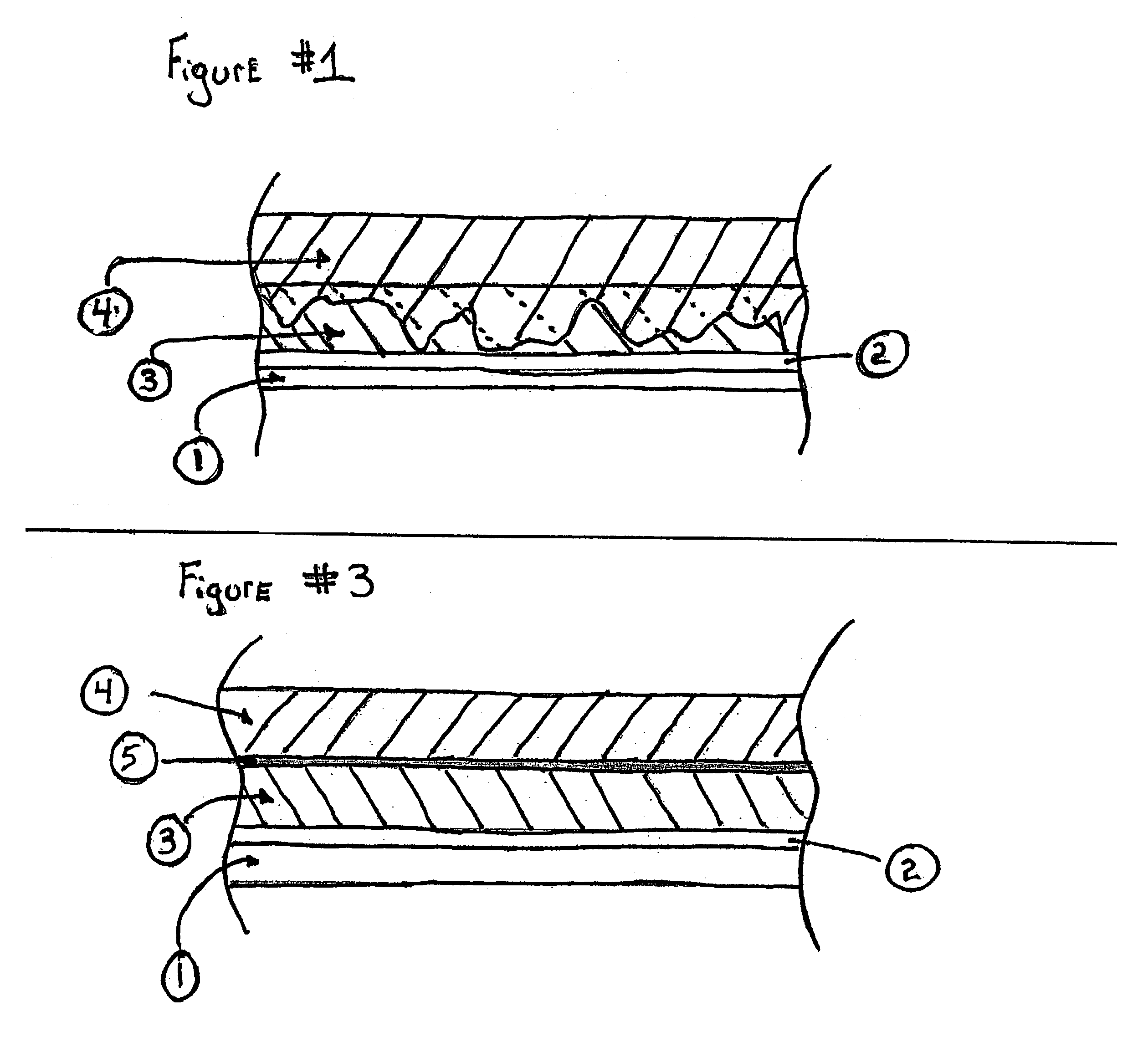

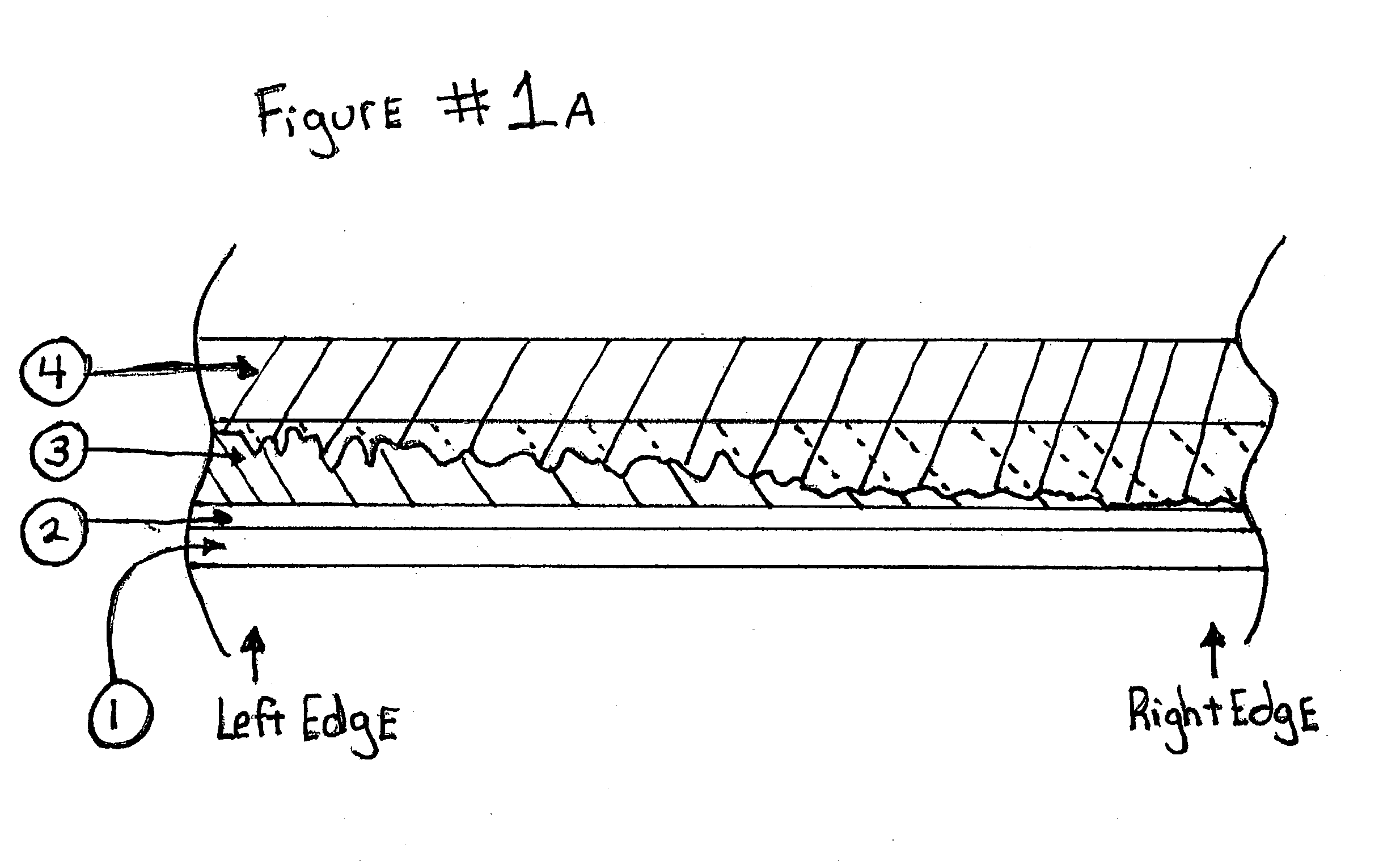

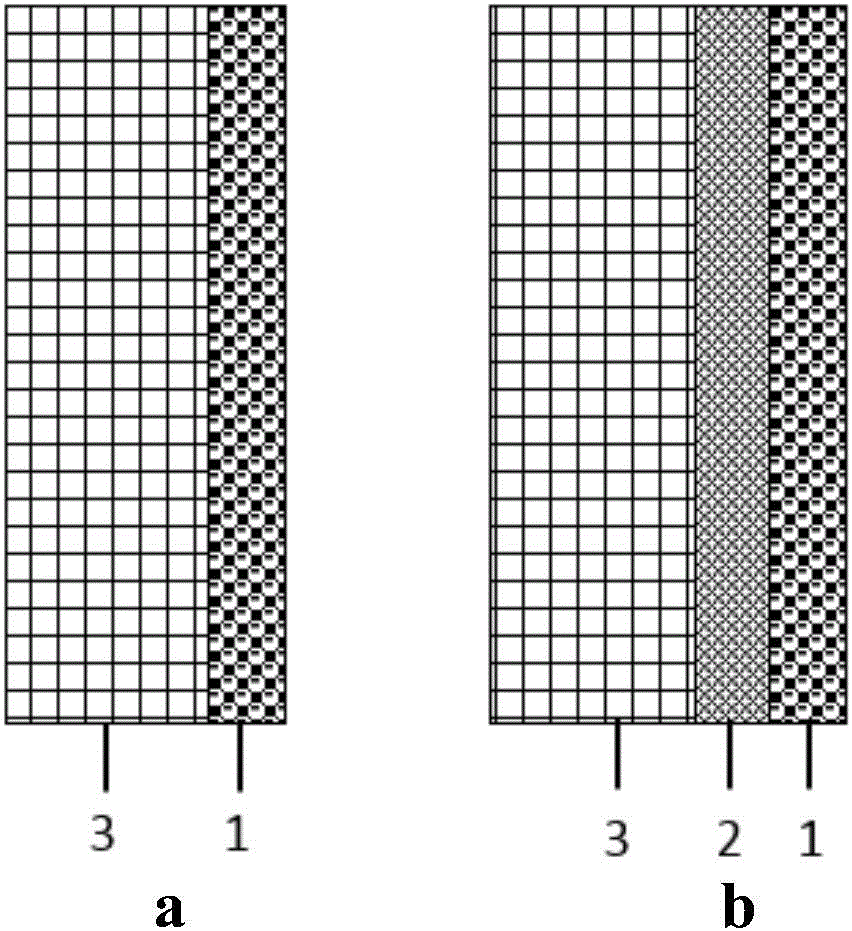

Controlled penetration subpad

ActiveUS8602851B2Solve penetrationUniform penetration depthRevolution surface grinding machinesBelt grinding machinesDepth of penetrationMaterials science

Provided is a seamless polishing pad comprising a seamless polishing layer having a substantially uniform depth of penetration into a porous subpad. In one embodiment, the polishing pad comprises a polishing layer produced by applying to the subpad a hardenable fluid. In another embodiment, the subpad is coated with a barrier before coating with the hardenable fluid. In each embodiment, the depth of penetration of the polishing layer and / or barrier is substantially uniform. Also provided is a method of producing a seamless polishing pad comprising a seamless polishing layer having a substantially uniform depth of penetration into a porous subpad.

Owner:ROHM & HAAS ELECTRONICS MATERIALS CMP HLDG INC

Proton exchange membrane

The invention belongs to the technical field of a fuel cell, in particular to a proton exchange membrane. The proton exchange membrane is prepared from a combination comprising a sulfonated poly ether ether ketone solution, sulfonated polyphenylene oxide sppo, a polyaniline filter liquid, heteropoly acid and a titanium dioxide fluid. The proton exchange membrane has the advantages of favorable mobility and processability; with the combination of the titanium dioxide fluid, the sulfonated poly ether ether ketone solution, the sulfonated polyphenylene oxide sppo and the polyaniline filter liquid, the reduction of proton conductivity can be reduced, the methanol permeability of the composite proton exchange membrane is effectively reduced, the comprehensive performance of the proton exchange membrane is improved, the methanol permeation problem when an Nafion membrane is used for a direct methanol fuel cell (DMFC) is solved, the proton conductivity is also not reduced, and the requirement for PEM used by the DMFC is met; and the proton exchange membrane can be used for the DMFC and also can be used for an alcohol fuel cell such as a direct ethanol fuel cell.

Owner:SHANDONG XINGHUO SCI TECH INSTITYTE

Preparation method and application of high-temperature membrane fuel cell gas diffusion electrode

InactiveCN106328956AReduce transmission resistanceReduce manufacturing costCell electrodesFuel cellsDiffusionFuel cells

The invention discloses a high-temperature membrane fuel cell gas diffusion electrode structure and a preparation method thereof; the high-temperature membrane fuel cell gas diffusion electrode structure is characterized by not comprising a microporous layer and only comprising a gas diffusion back layer and a catalytic layer; the gas diffusion electrode herein is simple in structure and easy to prepare, and the gas diffusion back layer that is treated may deposit the catalytic layer directly on its surface to form the effective electrode structure; the gas diffusion electrode structure has better gas transport capacity, smaller electro transport resistance and lower preparation cost, and a new direction may be provided for improving properties of a high-temperature membrane fuel cell and modifying its parts.

Owner:JIANGSU UNIV

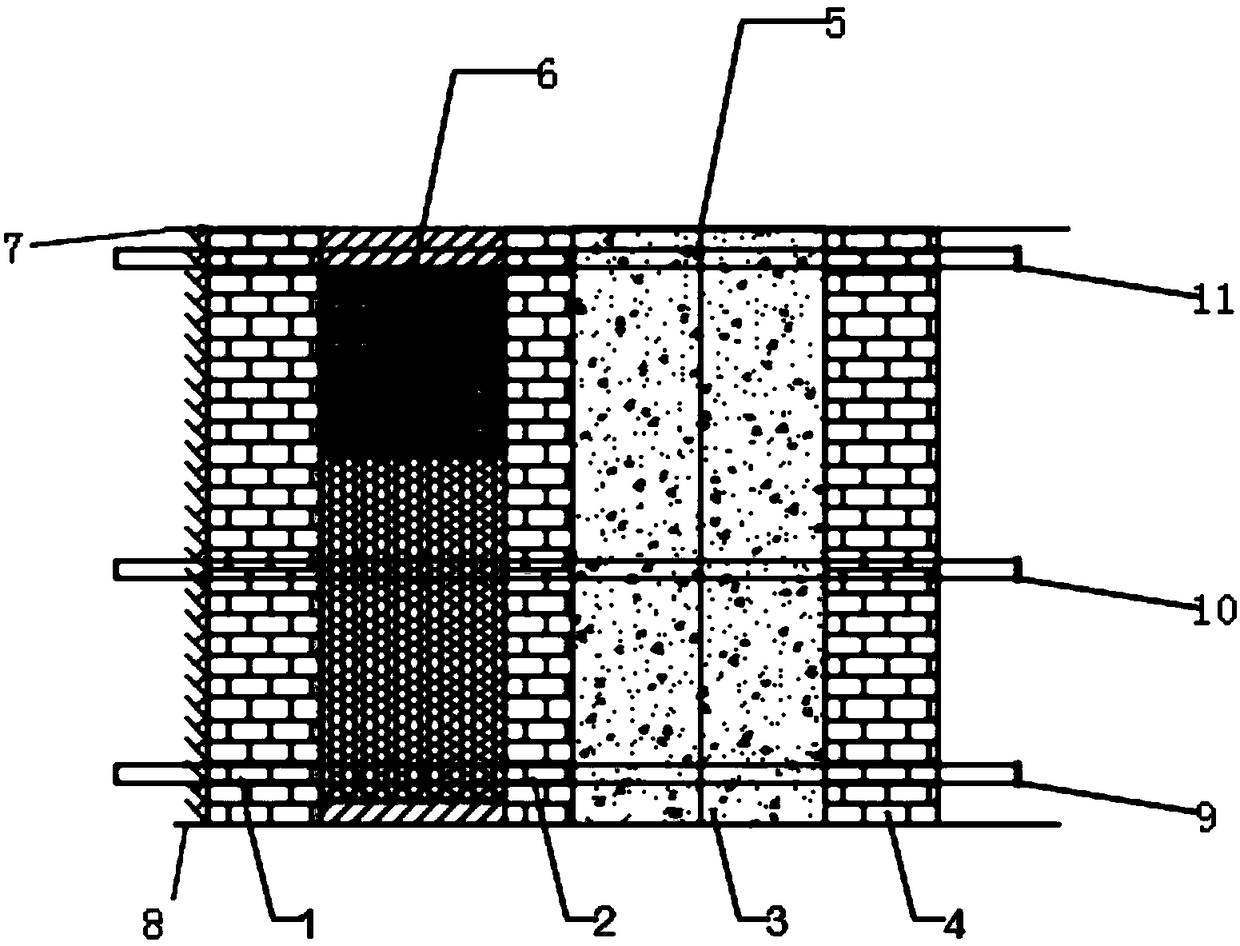

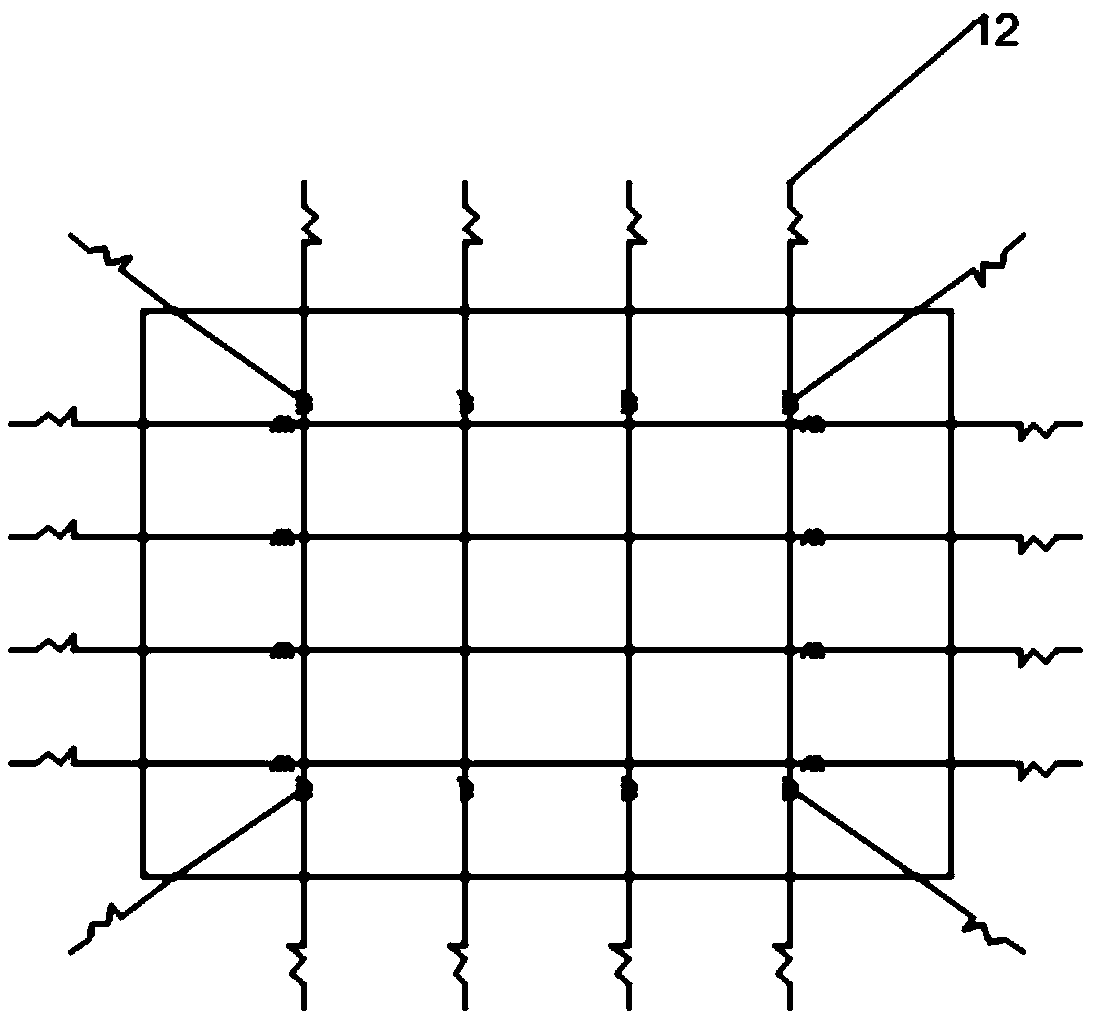

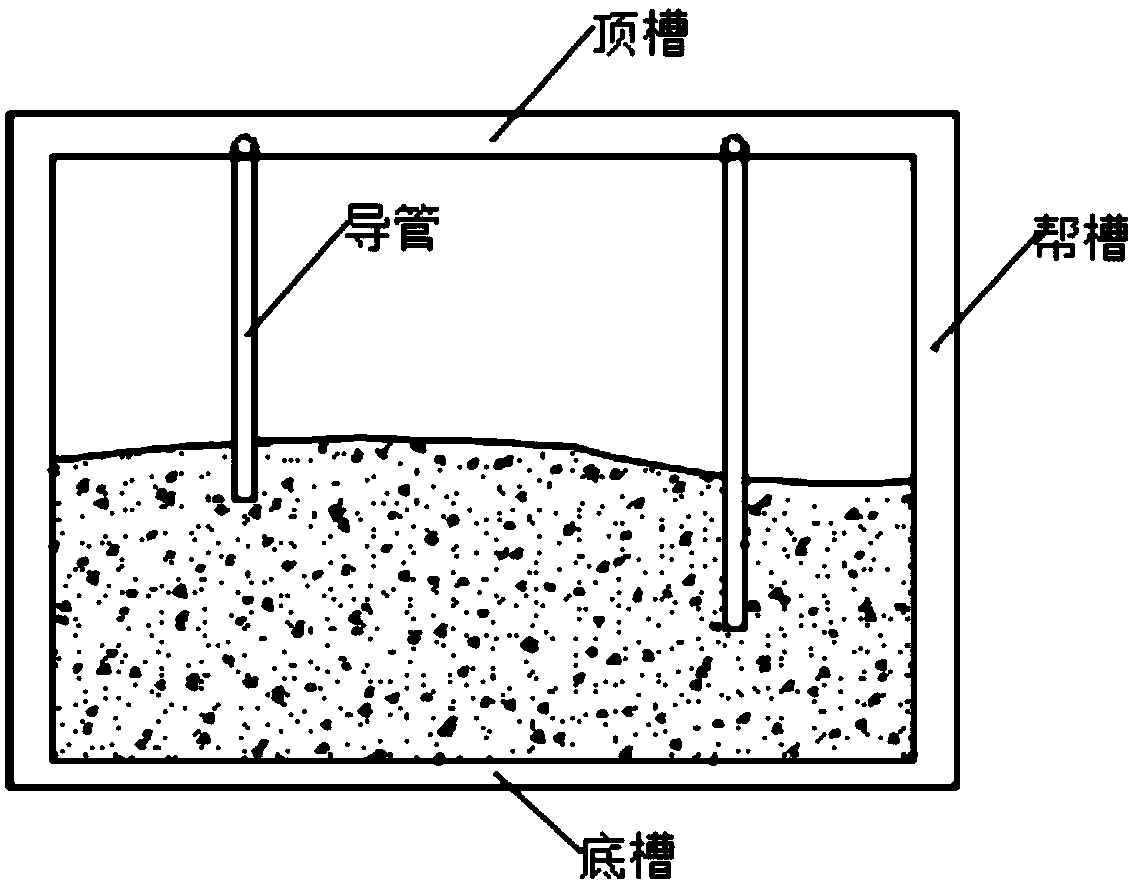

Construction method of high-strength sealing wall with anti-seepage function in mine roadway

The invention relates to a construction method of a high-strength sealing wall with an anti-seepage function in a mine roadway and belongs to the field of protection measures for mine water disasters.The method includes the steps of 1, forming grooves in a top plate and a bottom plate in a sealed place and the two sides of the sealed place and removing waste on the site; 2, determining the positions and size of three holes; 3, constructing a brick wall, installing anchoring rods in grooves formed in a concrete wall and constructing a steel bar framework; 4, before construction of a wall body,filling the holes, adopting a vertical guide pipe insertion method for pouring of the concrete wall until pouring of the concrete wall is finished, and spraying slurry after construction of the wallbody is finished. An anti-seepage concrete wall construction process of a dam is combined, and through installation of an underground anti-seepage high-strength sealing device, the anti-seepage high-strength sealing wall which is convenient in construction, small in seepage amount and high in safety and reliability and can achieve sealing in a water permeation period is provided. The sealing walladopts a combined wall body structure composed of the brick wall, a filling layer and the concrete wall and solves the problem that water can permeate when a water influx accident happens under a welland it is needed to construct a waterproof sealing wall.

Owner:LIAONING TECHNICAL UNIVERSITY

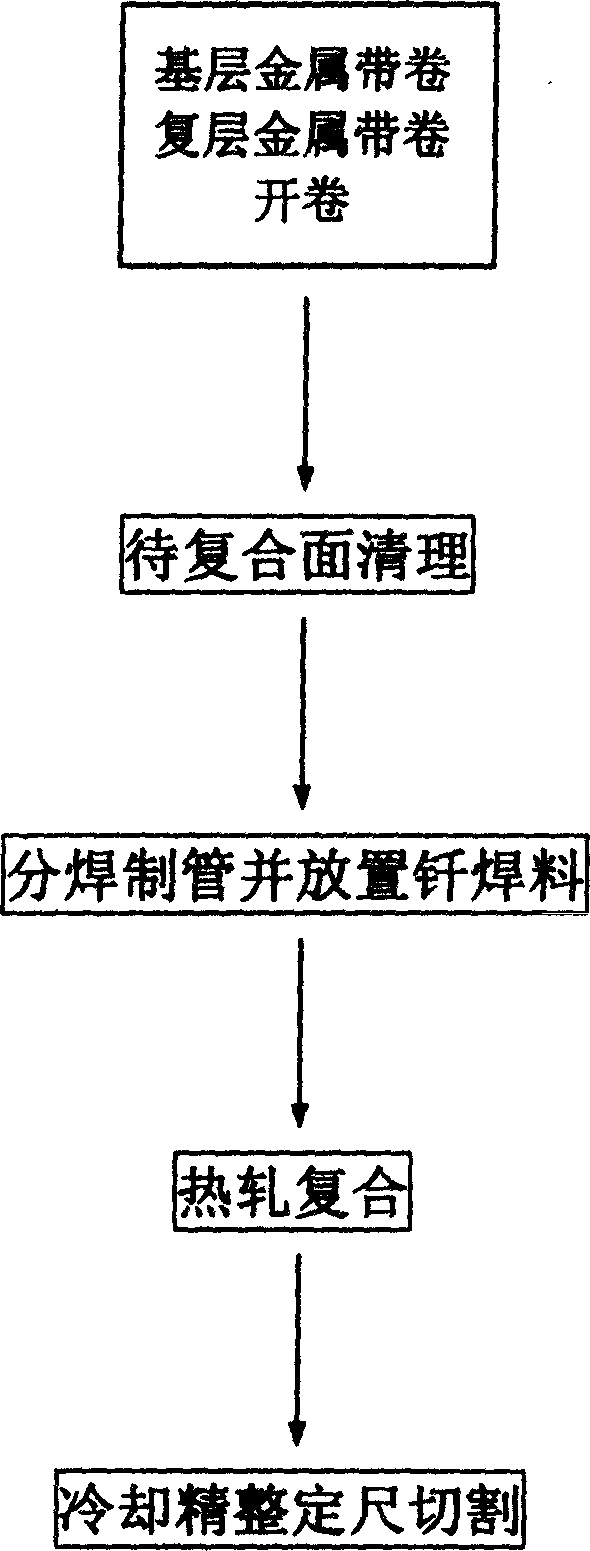

Method for manufacturing metal compound pipe by braze welding, hot rolling and continuous welding

InactiveCN1631569AImprove mechanical propertiesImprove corrosion resistanceOther manufacturing equipments/toolsMechanical propertyLarge applications

The invention offers a producing way to heat roll and connect the metal complex tube, which contains the following craft: base metal tape, complex metal tape open; wash the complex surface; separately roll; heat roll to complex; cool and cut. The rolling temperature in the invention is 750-950 degC. The metal complex tube made by this way has good features of machine, antisepses and reproduce, so it has large application.

Owner:吉欣(英德)热轧不锈复合钢有限公司 +1

Integrated inert-gas frequency standard device for laser frequency locking

ActiveCN105870775AOvercoming the disadvantage of being fragileCompact structureLaser detailsFragilityEngineering

The invention adopts a radio frequency gas discharge manner and provides an integrated inert-gas frequency standard device for laser frequency locking. Integrated design of a sample gas container and a radio frequency discharge system is adopted, a structure of a vacuum chamber is fully used, and the system miniaturization and integration are achieved. According to the scheme, the device comprises an outer-layer high vacuum chamber and an inner-layer radio frequency gas discharge assembly, and glass or a ceramic tube is adopted as the separation part to achieve electrical insulation; an inner-layer radio frequency discharge system is located and fixed by sleeving the glass or the ceramic tube with a spiral discharge coil; a signal input end and a grounding end of the spiral coil are connected to a vacuum flange; an optical window is fixed to the flange surface in a welded manner; the system vacuum degree is improved and the service life is prolonged by means of an adsorption pump; a detachable interface is adopted, and other samples can be injected to be used as the frequency locking standard of various lasers. With the adoption of the design of a stainless steel vacuum chamber, the problem of fragility of a sample reference pond made of glass and the relatively high permeability of quartz crystals to helium and the like can be solved.

Owner:PLA PEOPLES LIBERATION ARMY OF CHINA STRATEGIC SUPPORT FORCE AEROSPACE ENG UNIV

Traditional Chinese painting pneumatic equipment

InactiveCN102963203AInhibition formationSolve penetrationSpecial ornamental structuresEngineeringMechanical engineering

The invention discloses traditional Chinese painting pneumatic equipment, which includes: a flat rigid plate, and a flat and flexible mat. A space angle of 90-180 degrees is formed between the plane normal direction of the flat rigid plate paved with the flat and flexible mat and the gravity direction, so that the flat rigid plate can be placed between horizontal and vertical directions. Painting paper is spread on the rigid plate and the mat parallelly. The equipment is characterized in that: the flat rigid plate at least has over one pressure cavities, and one side of the flat rigid plate paved with the flat and flexible mat is equipped with fine and compact pores uniformly. In addition, the equipment includes at least one pneumatic device connected to the pressure cavities of the rigid plate, and the pneumatic device can generate a tiny negative pressure that is sufficient to adsorb the painting paper and the mat. According to the invention, the pneumatic adsorption equipment and pneumatic adsorption method that can realize barrier-free overall paper-surface free painting are employed to fix the painting paper, and pneumatic intervention is utilized to generate a new painting technical means and a new artistic effect.

Owner:文联强

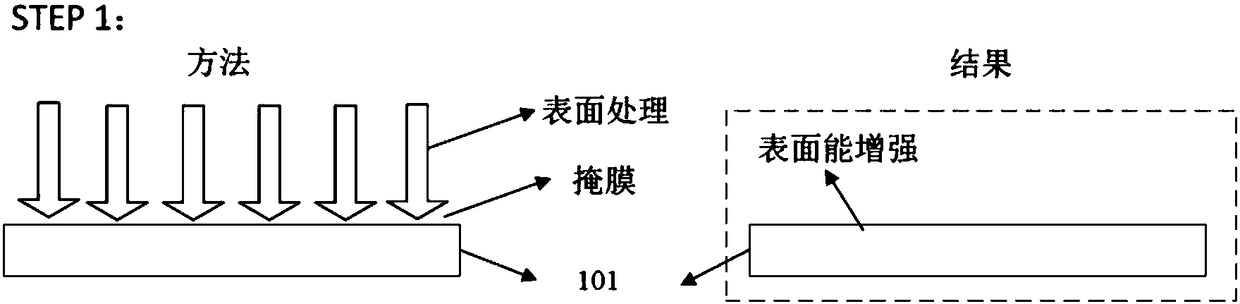

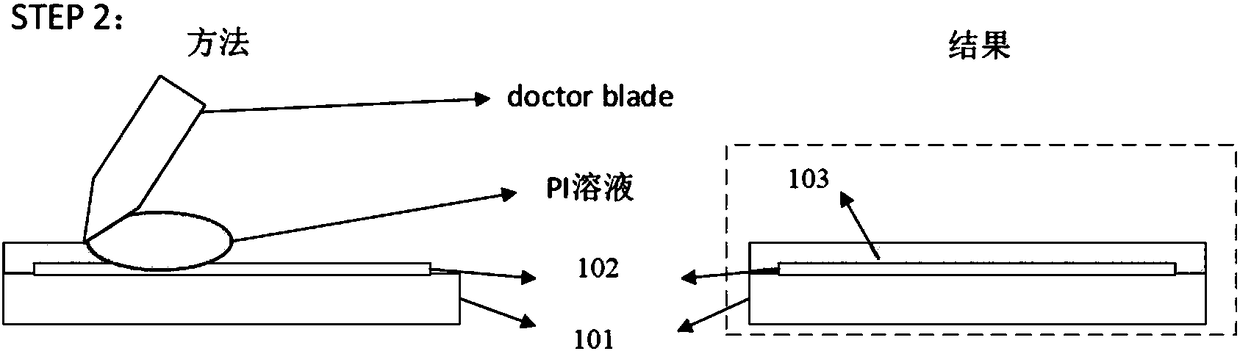

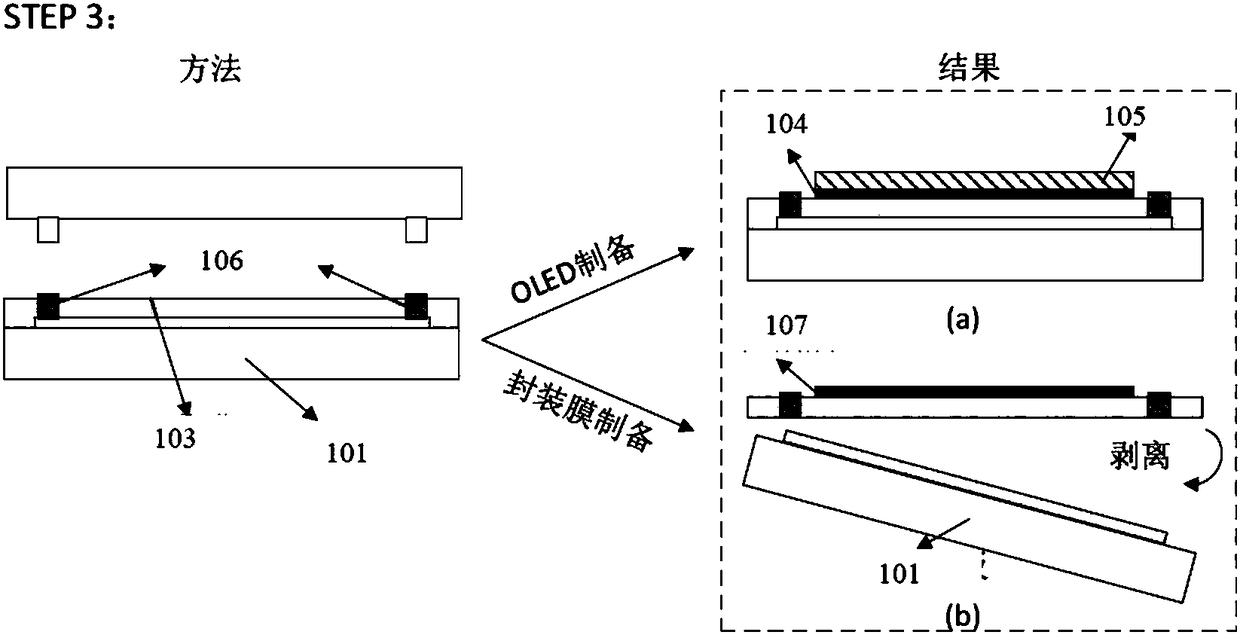

Flexible display device and preparation method thereof

ActiveCN108962935ASolve the problem of not being able to block the side penetration of water vaporSolve penetrationSolid-state devicesSemiconductor/solid-state device manufacturingBlock effectEngineering

The present invention relates to a flexible display device and a preparation method thereof. The flexible display device comprises a flexible film substrate, the surface of the flexible film substratecomprises: a device area and a first package area, and the first package area is provided with a first annular groove; a flexible package substrate, wherein the surface of the flexible package substrate is provided with a second annular groove corresponding to the first annular groove; an electricity light-emitting part stacked at the device area, wherein the first and second annular grooves arefilled with nano glass slurry, the nano glass slurry in the first and second annular grooves are fused to form a nano glass slurry fusion portion to allow the flexible package substrate and the flexible package substrate to form an integrated body and allow the electricity light-emitting part to be packaged between the flexible film substrate and the flexible package substrate. The flexible display device employs the package method mentioned above to greatly improve the blocking effect of common film package on water oxygen and achieve the preparation of a high-resolution transparent flexibleAMOLED display.

Owner:GUANGDONG JUHUA PRINTING DISPLAY TECH CO LTD +1

Method for preparing fuel cell membrane electrode

The invention provides a method for preparing a fuel cell membrane electrode. The preparation method comprises the following steps: (a) respectively coating cathode catalyst slurry and anode catalystslurry on one side face of a microporous layer of a tabulate gas diffusion layer having the microporous layer, so as to form a cathode gas diffusion electrode and an anode gas diffusion electrode after drying; (b) coating electrolyte on one side face of a catalyst of the cathode gas diffusion electrode and / or the anode gas diffusion electrode obtained in the step (a); and (c) respectively placingthe cathode gas diffusion electrode and the anode gas diffusion electrode obtained in the step (b) on both sides of a supporting material, making the side face coated with the electrolyte or the sideface coated with the catalyst of the cathode gas diffusion electrode or the anode gas diffusion electrode face to the supporting material, and laminating the same with the tabulate supporting materialto form the membrane electrode. The novel process has the advantages of both CCM and GDE processes, can greatly improve the performance of the membrane electrode and prolong the service life of the membrane electrode, and meanwhile has a relatively low production cost.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Protection coating for TiAl alloy, and production method thereof

ActiveCN108265259ASimple processEasy to operateMolten spray coatingOxidation resistantCeramic coating

The invention relates to a protection coating for TiAl alloy, and a production method thereof. The protection coating for the TiAl alloy is characterized in that a transition coating is produced on the surface of a TiAl base alloy through a plasma spraying technology, and a ceramic coating is produced on the surface of the transition coating; the coatings can effectively improve the oxidation resistance of the alloy and maintain the mechanical properties of the TiAl alloy in order to meet the requirements of the alloy used as a structural material in a high temperature environment, and the addition of a proper amount of TiO2 can improve the large porosity, poor compactness and other defects of the coating; and the transition coating can enhance the bonding strength between the alloy and the coating, and also can solve the oxygen atom penetration problem caused by the untightness of the ceramic coating, and further enhances the oxidation resistance of the alloy. The method adopted by the invention has the advantages of simplicity, convenience in operation, and high efficiency.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Method of impregnating graphite electrode by using vinylit resin

The invention relates to a graphite electrode, in particular to a method of impregnating the graphite electrode by using vinylit resin, which comprises the following steps: finished graphite electrode product is placed into an impregnation container and then is sealed, the first vacuumizing is performed, the vinylit resin is sucked from a pipe at one side of the impregnation container to impregnate the working surface of the graphite electrode, the second vacuumizing is performed, the first pressurizing is performed, the third vacuumizing is performed, the second pressurizing is performed, a valve of a pressure meter is opened for relieving pressure, an impregnation basket is gripped, the impregnated graphite electrode is taken out, the resin on the surface of the impregnated graphite electrode is removed by using solvent, and the graphite electrode is placed at normal temperature until no liquid flows down on the surface for polymerizing. Air in the clearance of the graphite electrode treated by the method is thoroughly discharged so that the resin is fully impregnated into the inner walls of fine holes of graphite and the inner walls of the fine holes of the graphite are filled with the resin, the polymerization is complete, the surface of the graphite has no phenomenon of bubble flowing, and no overflowing and scaring, and is not easy to oxidize to cause the shedding, therefore, the graphite has good corrosion resistance and long service life. The method has low cost, and better solves the penetration problem.

Owner:殷志军

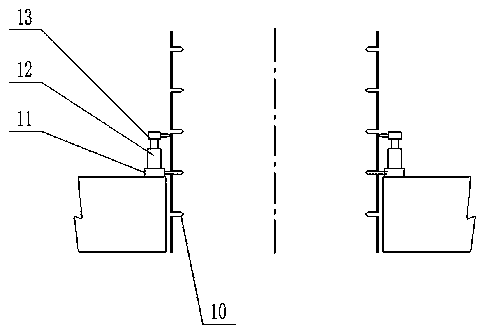

Movable offshore self-mounting dry type work environment construction process

InactiveCN110805016AReduce difficultySolve penetrationArtificial islandsUnderwater structuresArchitectural engineeringWorking environment

The invention discloses a movable offshore self-mounting dry type work environment construction process. The movable offshore self-mounting dry type work environment construction process is characterized in that a main box body and an auxiliary float box are connected and fixed, and the main box body and the auxiliary float box which are assembled together are consigned to the construction point through a barge; three points are selected from the main box body and the auxiliary float box which are connected together to form a regular triangle structure, and triangular barge pulling and positioning can be achieved; through a lifting system, a ballast water tank body is lifted, and a cylinder body penetrates into a seabed; a steel pile is driven into a fixed pile guide groove, and the platform whole stability is improved; and during pulling, through a spraying flushing device, absorbing force is reduced, and through buoyancy of the float box, a work cylinder can be automatically pulled out, through the barge, the float box can be dragged to the next construction position, and operation is carried out in sequence until all construction points are finished. Compared with the prior art,the process has the beneficial effects that the construction process is stable and reliable, cost is low, through the construction process, the dry type environment can be provided for seabed work for a worker, and recycling of a whole system is achieved.

Owner:SENUO TECH CO LTD +1

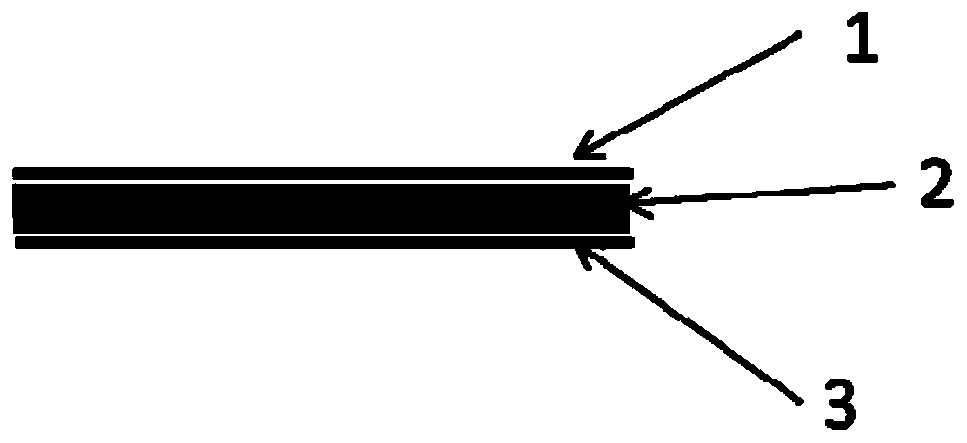

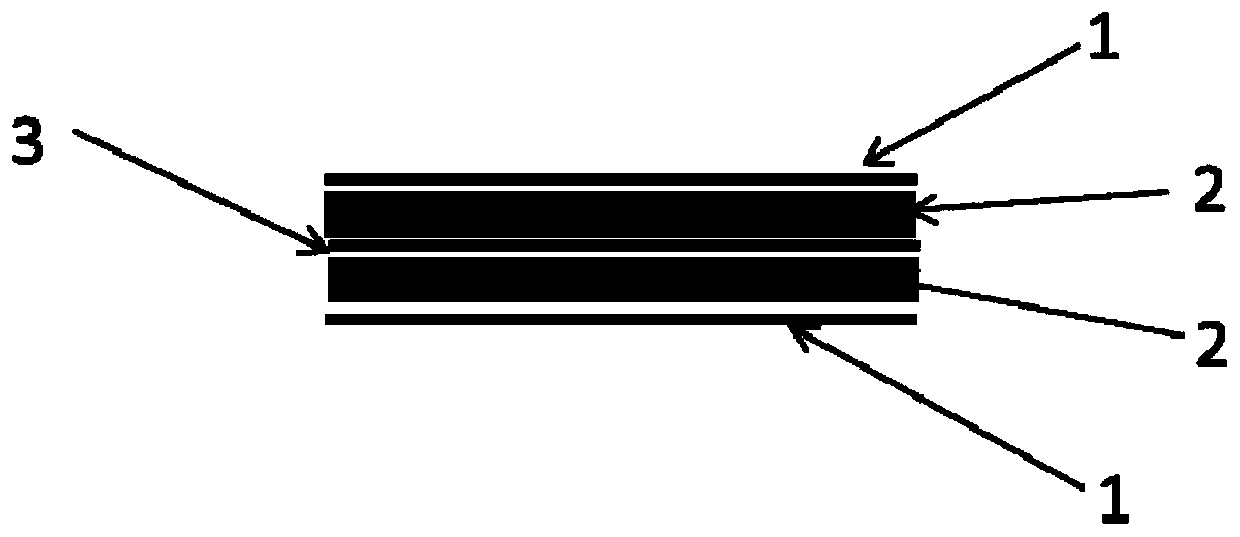

Laminated monopole plate and preparation method thereof, laminated bipolar plate comprising laminated monopole plate and application of laminated bipolar plate

ActiveCN111463447AImprove conductivityReduce thicknessFinal product manufactureCollectors/separatorsClassical mechanicsEngineering

The invention provides a laminated monopole plate and a preparation method thereof, a laminated bipolar plate comprising the laminated monopole plate and an application thereof. The laminated monopoleplate comprises a metal layer, a composite carbon powder layer and a composite material layer. The laminated bipolar plate is advantaged in that conductivity of a through surface of the polar plate can be remarkably improved, a problem of hydrogen permeation of a carbon-based material polar plate is solved, the thickness of the polar plate is reduced, and the volume power density of an electric pile is improved.

Owner:FAW JIEFANG AUTOMOTIVE CO

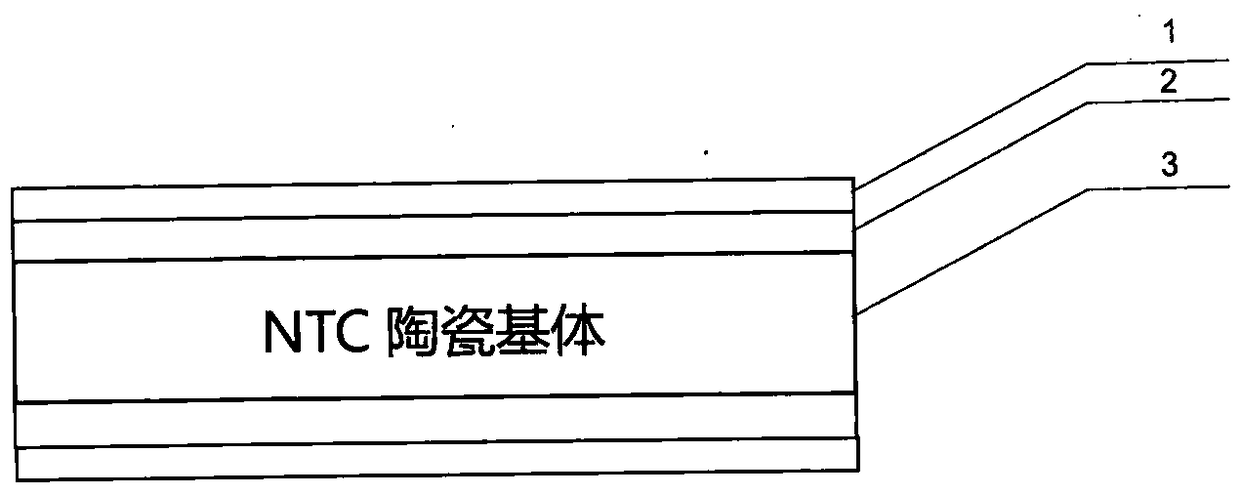

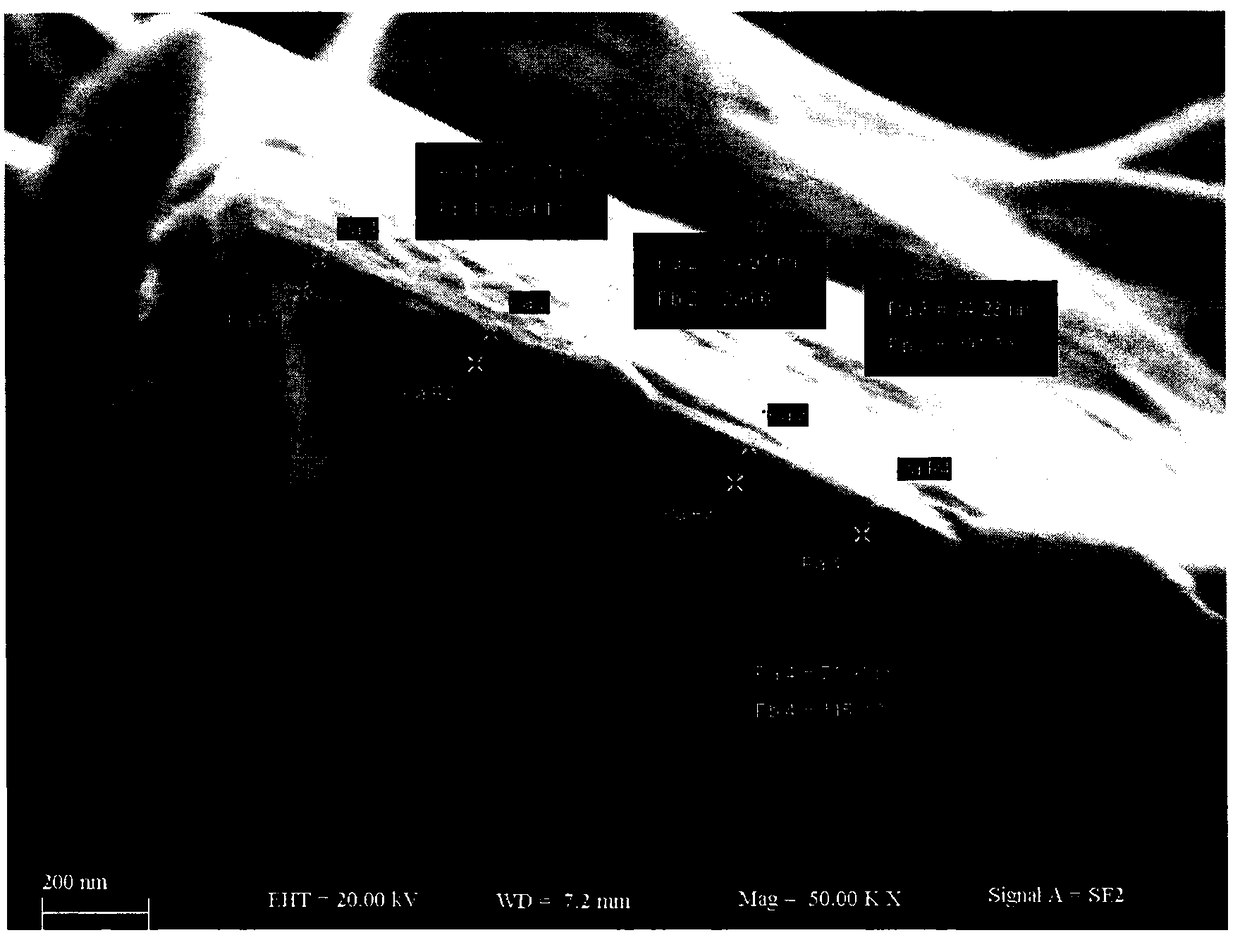

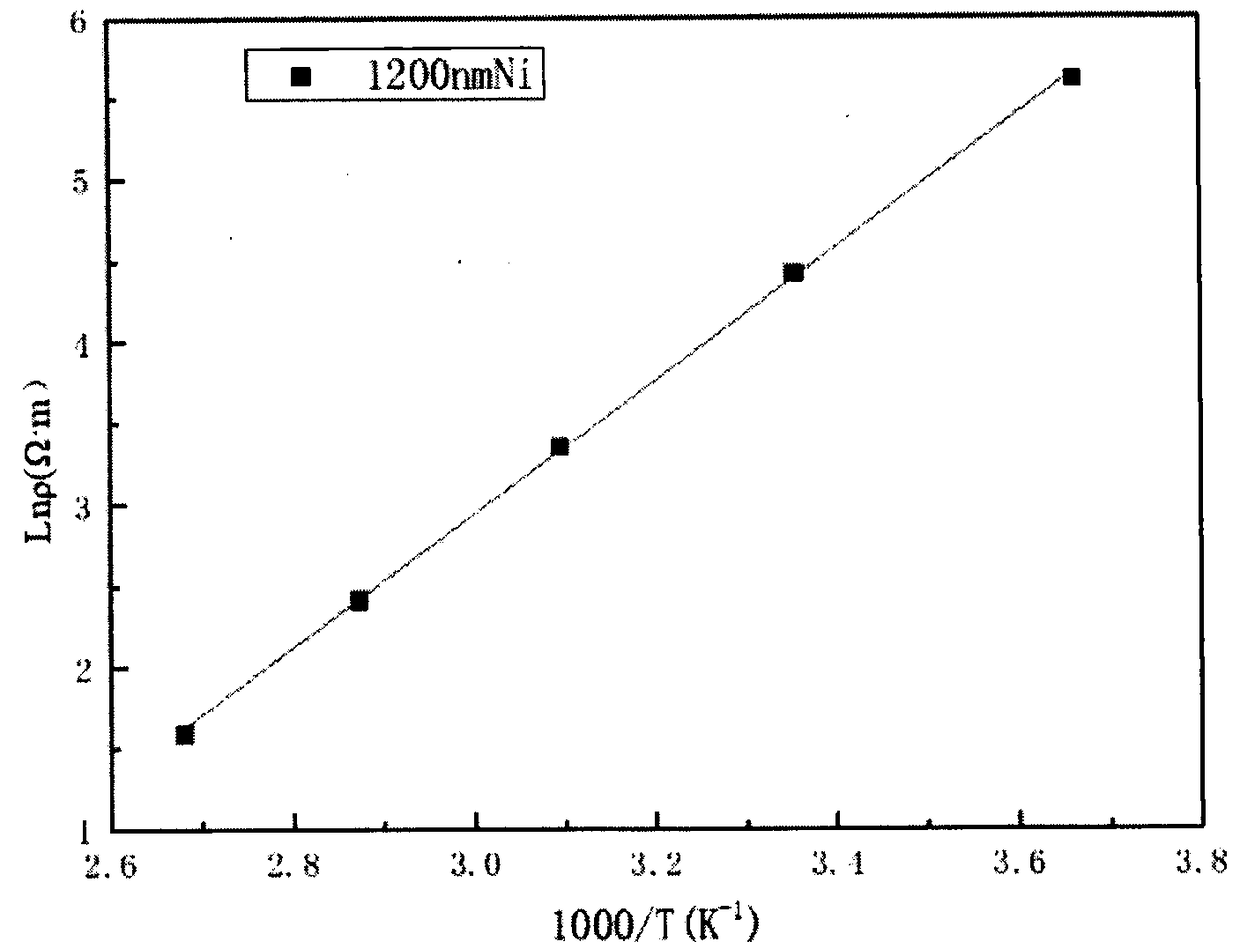

Method for preparing ohmic contact electrode of P-type negative temperature coefficient ceramic material

InactiveCN109461556AMaintain flatness and thermal stabilitySolving Penetration ProblemsNegative temperature coefficient thermistorsResistors adapted for applying terminalsOhmSolderability

The invention relates to a method for preparing an ohmic contact electrode of a P-type negative temperature coefficient ceramic material. The method comprises the following steps: using the DC magnetron sputtering technology and using the existing quaternary cobalt-manganese-iron-zinc P-type negative temperature coefficient ceramic material as a ceramic matrix, firstly evaporating the first layerof 35nm-1200nm Pd or Ni on the surface of the ceramic substrate to serve as a transition layer, then evaporating a layer of 400 nm Ag to serve as a welding layer, and then rapidly annealing at a temperature of 400-800 DEG C to obtain an electrode having good ohmic contact. The test results show that the electrode has good ohmic contact, firm adhesive force, good solderability and stability. According to the method, the metal with a higher work function is used as the transition layer to lower the contact resistance of the metal and the ceramic body, and the transition layer also solves the problem of silver penetration in a P-type negative temperature coefficient ceramic sintered silver electrode.

Owner:XINJIANG TECHN INST OF PHYSICS & CHEM CHINESE ACAD OF SCI

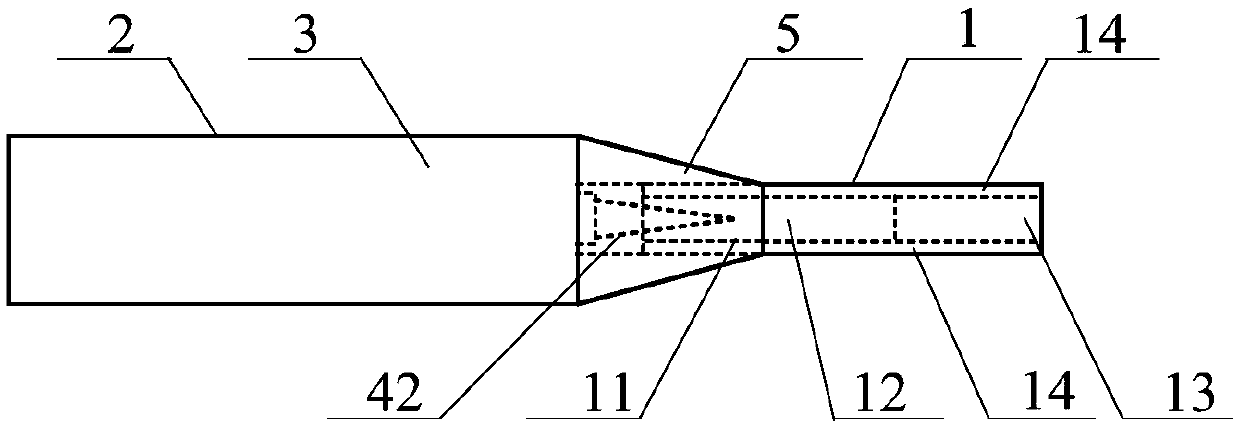

Needle-like heating electronic cigarette

The invention discloses a needle-like heating electronic cigarette. The cigarette includes a device and a cigarette body, and the device includes a shell, a power source part, a heating part and a clamping part; the heating part includes a needle-like insertion supporting part and a heating element; the cigarette body comprises a liquid storage part, a nozzle part and a cigarette packing part, andthe liquid storage part includes a soft structure, tobacco tar and a medium capable of adsorbing the tobacco tar; the device and the cigarette body are matched with each other by inserting the insertion supporting part into the liquid storage part. During smoking, the liquid storage part containing the tobacco tar is inserted into the device and heated to generate smoke for a user to enjoy; aftersmoking, the cigarette body is replaced, and then the electronic cigarette can be used for smoking at the next time. The insertion supporting part with a needle-like top end can be more easily inserted into the liquid storage part, the problem that the tobacco tar leaks to the cigarette packing part and the nozzle part is solved, and the heating efficiency is much higher. The needle-like heatingelectronic cigarette is simple in structure, sanitary during smoking, great in simulation performance, convenient to use and environmentally friendly, the cigarette body is fast to replace, and the oxidative deterioration risk of the tobacco tar and the tar leakage risk are substantially reduced, so that the needle-like heating electronic cigarette has a wide application prospect.

Owner:CHINA TOBACCO HUNAN INDAL CORP

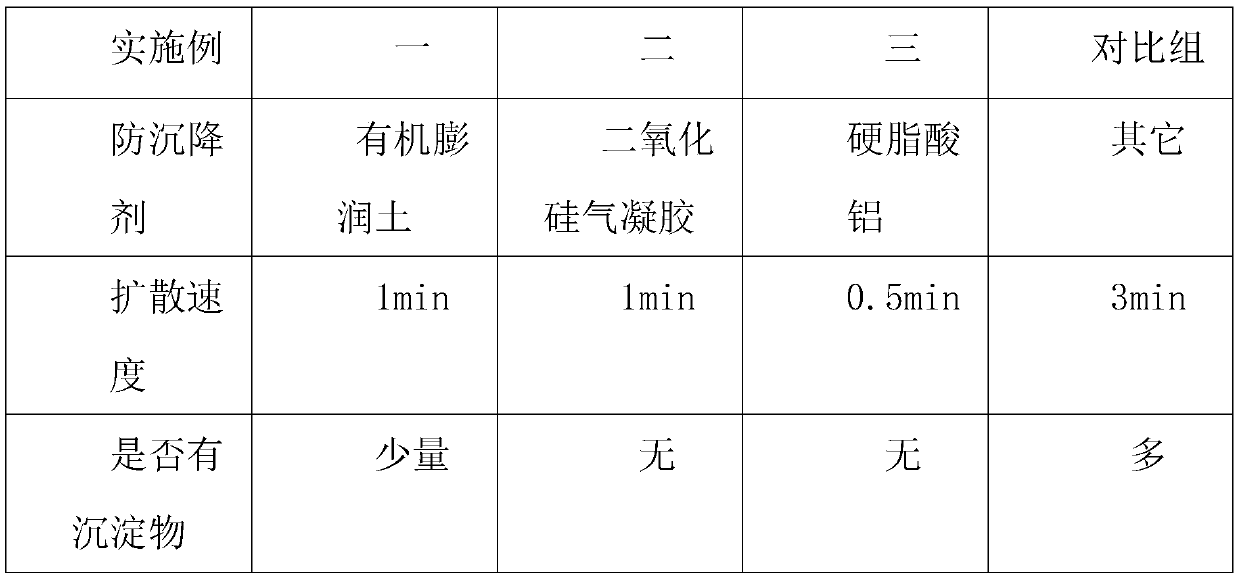

Anti-precipitation ink based on printer inkjet stability

The invention relates to the field of printer ink, in particular to anti-precipitation ink based on printer inkjet stability. The anti-precipitation ink is prepared from the components with parts as ameasuring unit: 30-50 parts of carbon black powder, 20-50 parts of deionized water, 1-2 parts of an anti-precipitation agent, 5-10 parts of a moisturizing agent, 1-3 parts of a PH conditioner, 1-4 parts of a surface active agent, 1-6 parts of a dispersant, 0.5-1 part of a lubricant, 1-5 parts of a thickener, 0.02-0.4 part of a preservative, 0.1-0.3 part of an active dye agent, 0.2-0.5 part of ananti-rust agent, 0.2-0.8 part of a defoamer and 1-3 parts of balsam. A method comprises the following step: S1, screening is conducted, specifically, the carbon black powder in the raw materials is placed into a screen net to be screened. The anti-precipitation ink has the beneficial effects that through the arranged anti-precipitation agent, the anti-precipitation agent has ultra-high pigment diffusivity, wetting performance and lubricity on the ink, thus a pigment in the ink can be durably and evenly distributed under a static or dynamic environment without being precipitated, the multiple common phenomena such as ink gathering, ink dissolving or not-bright color can be easily avoided, the printer inkjet quality is improved, and the service life of a spray head is prolonged.

Owner:珠海市彩诺电子科技有限公司

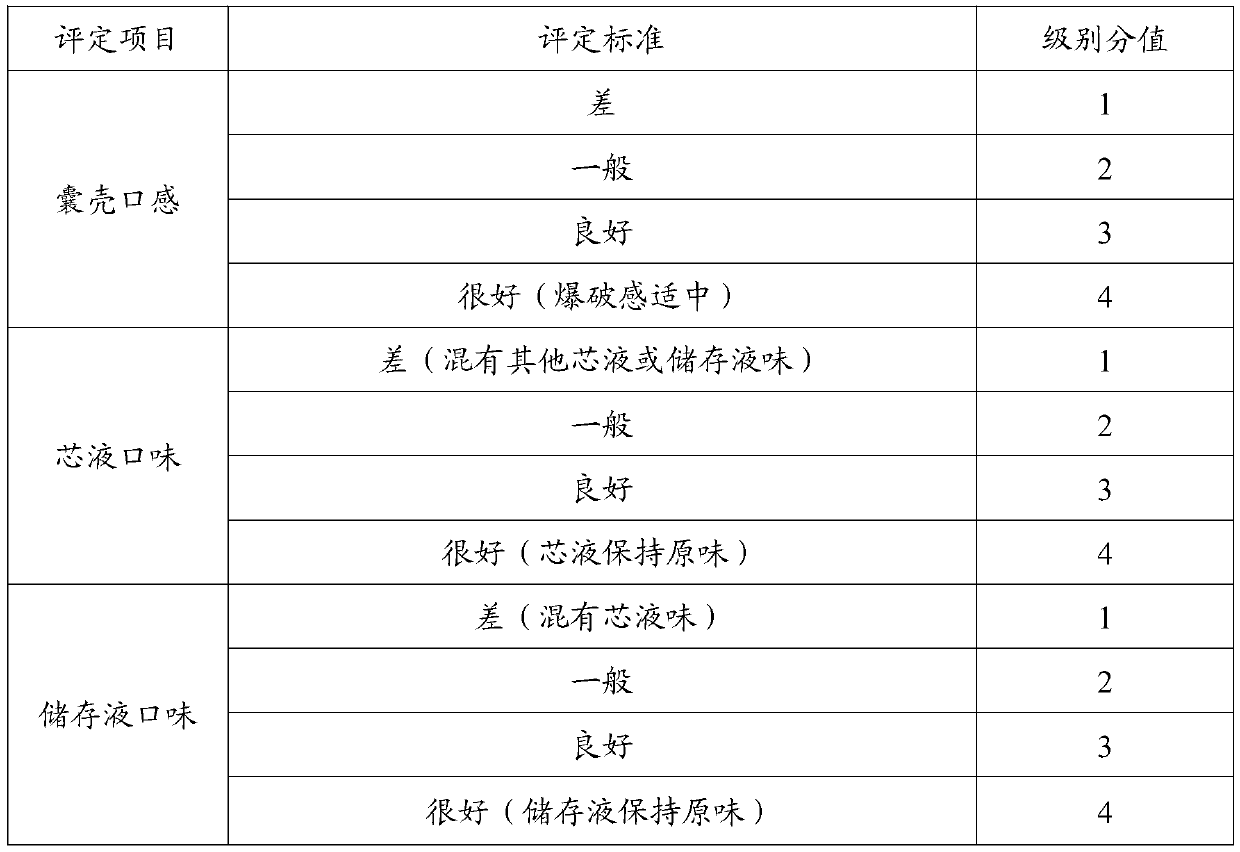

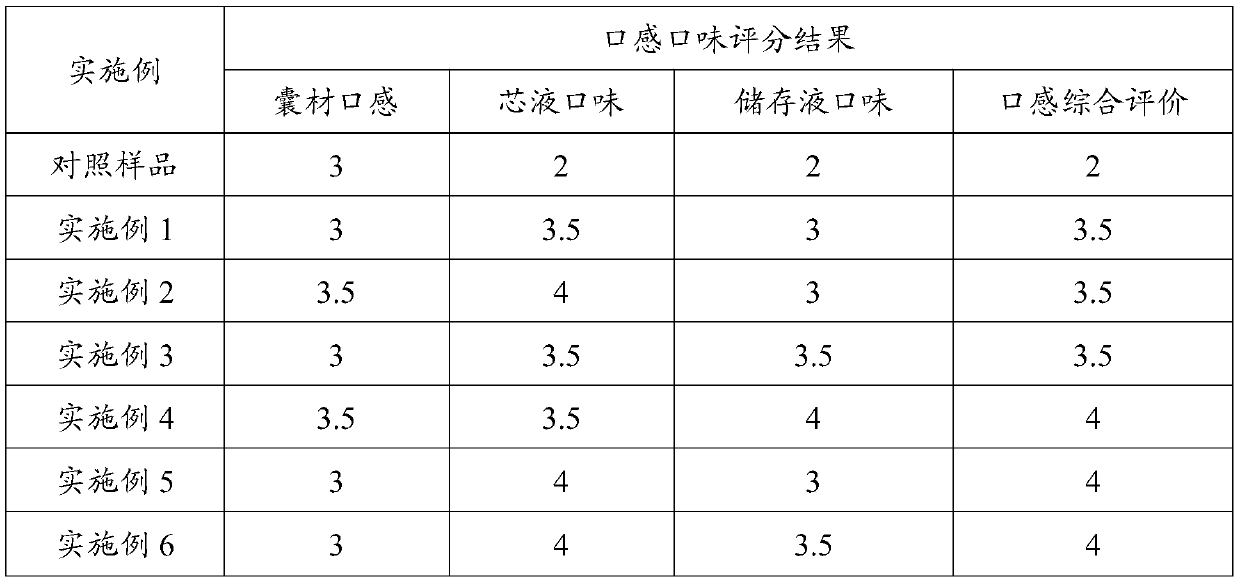

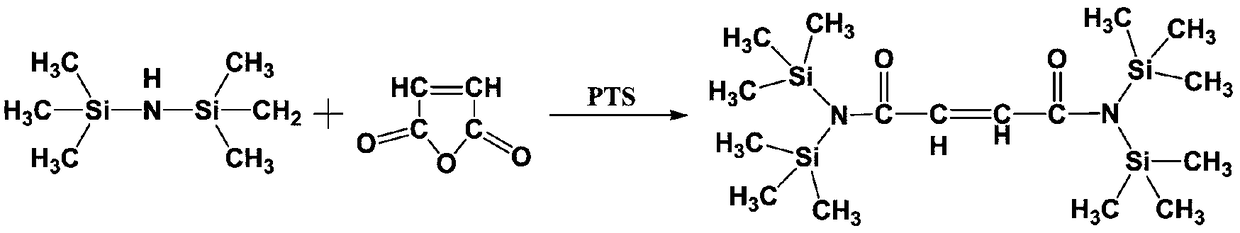

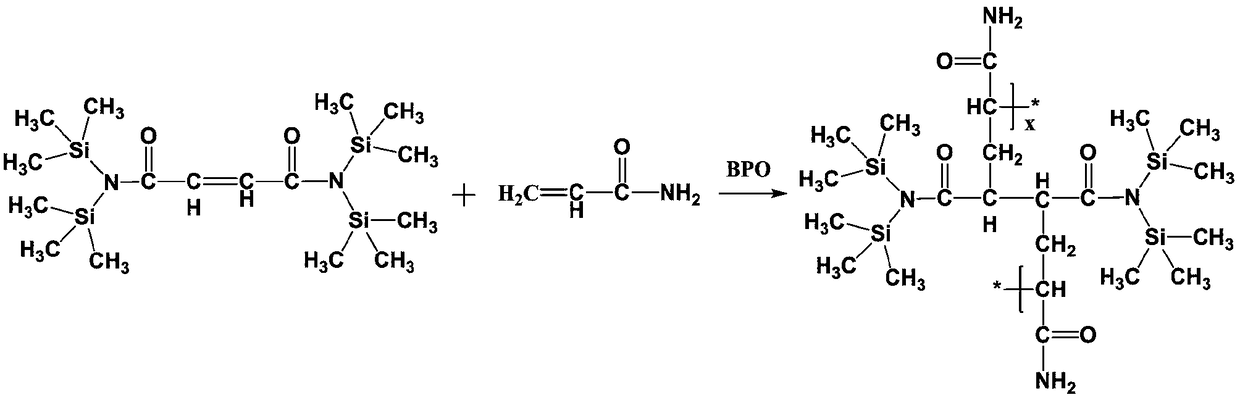

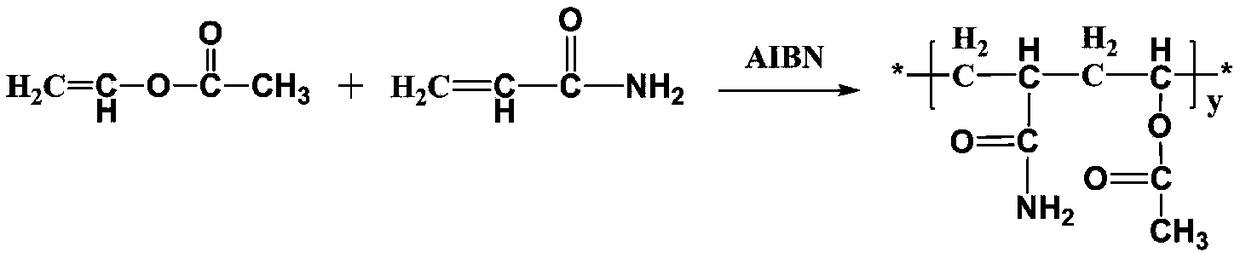

Liquid beverage containing anti-permeation capsules

The invention relates to a liquid beverage containing anti-permeation capsules. The liquid beverage is composed of the anti-permeation capsules with waterproof layers and of different tastes and a beverage storage liquid. The liquid beverage has the advantages that the capsules of various tastes are contained, and the capsules impart rich and varied types of flavor experience to the liquid beverage; natural plant polysaccharides are adopted as a membrane material to greatly improve the mouthfeel in an edible process, the problem of membrane penetration in the prior art is also solved, and theunique taste of the capsules can also be kept for a long time.

Owner:YUNNAN TOBACCO BIOLOGICAL TECH CO LTD

Preparation method of composite proton exchange membrane

ActiveCN101864163BInhibit swellingImprove proton conductivityFinal product manufactureCell component detailsPoly ether ether ketoneHeteropoly acid

The invention discloses a preparation method of a composite proton exchange membrane, comprising the following steps of: sulfonating, preparing a sulfonated polyether ether ketone solution; preparing polyaniline filter liquid, preparing membrane preparing liquid, casting to form a membrane, and the like. The composite membrane is prepared by using SPEEK (sulfonated polyether ether ketone) as a basal body and PANI (Polyaniline) and HPA (Heteropoly acid) as dopants, a material source is wide and does not need to be imported, a preparation process is simple, and used instruments are simple, thereby the cost of the membrane is reduced. A hydrogen bond formed by PANI and SPEEK is used for avoiding the swelling of the SPEEK and reducing methanol penetration, and the proton conductivity of the composite membrane is improved by the HPA. By changing the composition and the ratio between an alkaline polymer and a proton conductor, the novel PEM (proton exchange membrane) reaches optimum balance among high proton conductivity, low methanol penetration and low HPA dropout rate, the proton conductivity reaches 10-2S / cm, the methanol penetration rate of the composite proton exchange membrane is a half lower than that of an Nafion 117 membrane, and the HPA wastage rate does not reach 5 percent.

Owner:SUZHOU DACHENG YOUFANG DATA TECH CO LTD

Hydrophobic fixation ink and preparation process thereof

The invention discloses hydrophobic fixation ink. The hydrophobic fixation ink comprises the following components in parts by weight: 28 to 31 parts of modified adhesive material, 43 to 46 parts of amino hydrophobic pigments, 12 to 13 parts of glutaric dialdehyde, 9 parts of sodium hydroxide, 45 parts of methanol, 16 to 18 parts of oxidized starch, 8 to 10 parts of hexamethylene diisocyanate, 2 to3 parts of a defoaming agent, 3 to 4 parts of a dispersing agent, 3 to 4 parts of liquid paraffin, 1 to 2 parts of afilm forming additive, and 150 parts of ethanol. After the surface of the pigment is coated with a layer of hydrophobic composite film, the pigment has the ultrahigh hydrophobic performance; meanwhile, by introducing amino onto the composite film, the viscosity of the modified adhesive material is improved compared with the original polyvinyl alcohol adhesive materialby virtue of the polymerization of vinyl acetate and acrylamide, so that the adhesion performance is improved; and meanwhile, the amino is introduced into the adhesive material, the amino hydrophobic pigment is composited compounded onto the adhesive material under the cross-linking effect in the presence of glutaric dialdehyde, so that the whole adhesive material netted structure comprises a great amount of hydrophobic groups, and the prepared ink has ultrahigh hydrophobic capability.

Owner:汕头市光彩新材料科技有限公司

Manufacturing technology of bipolar plate

InactiveCN108666594ASolve penetrationMeet conductivityFuel cellsManufacturing technologyParaffin oils

The invention discloses a manufacturing technology of a bipolar plate. The manufacturing technology comprises the following steps: (1) selecting and using enough polyethylene paraffin, putting the polyethylene paraffin into a container, and heating until the polyethylene paraffin is completely fused; (2) immersing a graphite plate into the fused polyethylene paraffin, and taking out the immersed graphite plate until no bubble is emitted; and (3) hemming the graphite plate through paraffin immersing treatment to guarantee no weeping inside, and then connecting the hemmed graphite plate with theshell of a battery through PVC glue, wherein two sides of the graphite plate through paraffin immersing treatment are both connected with graphite felts as a positive electrode and a negative electrode of the battery; and (4) then after sealing, forming serially connected connecting points of the positive electrodes and the negative electrodes of two batteries on the graphite plate, namely the bipolar plate. According to the manufacturing technology, the polyethylene paraffin material is selected and used as a filler of the graphite plate, on one hand, the permeation problem of the graphite plate is solved, and on the other hand, the electrical conductivity of the graphite plate in a zinc-iodine battery is met; the bipolar plate with small volume and good electrical conductivity is formed; and the problem of filler fusion caused by the fat that the zinc-iodine battery is heated in the using process is also solved.

Owner:EAST CHINA NORMAL UNIV

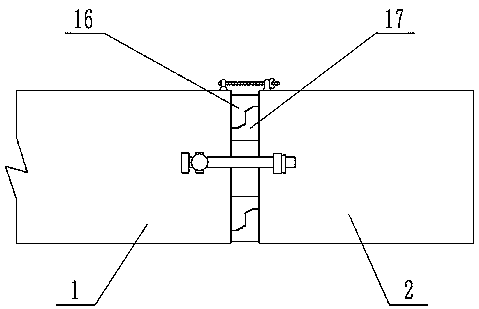

Connecting device of drainage pipeline and inspection well

ActiveCN105544610ASimplified installation stepsEffective installationArtificial islandsUnderwater structuresMechanical engineeringEngineering

The invention discloses a connecting device of a drainage pipeline and an inspection well. The connecting device comprises an annular base plate, an annular upright post and a clamping ring, wherein a waterstop is arranged on the base plate; the first end of the annular upright post is fixedly installed on the base plate, external threads are formed on the upright post, the second end of the upright post is used for being connected with the drainage pipeline, and the upright post and the waterstop are positioned on the same side of the base plate; the clamping ring is matched with the upright post, and internal threads which are matched with the external threads are formed on the inner wall of the clamping ring. During installation, the upright post is installed in the inspection well, and the waterstop on the base plate is positioned between the base plate and the inner wall of the inspection well, so that the problem of permeation is effectively solved. The upright post has the function of the drainage pipeline due to an annular structure, in addition, the external threads on the upright post can be matched with the internal threads on the clamping ring, therefore, gaps do not need to be filled with mortar during installation, and effective installation can be realized only by virtue of thread fitting, thereby simplifying installation steps of the connecting device and improving the installation efficiency.

Owner:胡皓勇

Membrane mobile phase of direct methanol fuel cell, and preparation method

InactiveCN101093892AReplace at any timeSolve the leakSolid electrolyte fuel cellsFuel cell detailsMetallic materialsHYDROSOL

The membrane mobile phase includes membrane carrier (MC), and gel mobile phase (GMP) membrane coated on surface of MC. Being dipped to and lifted from sol mobile phase (SMP), membrane carrier forms GMP membrane after step of air-dry. MC is silk net type metal material with high conducting power, and not dissolved to dilute sulfuric acid. SMP is prepared from methanol, vitriol, water, heteroacid, metallo-organic compound or metal salt. SMP is prepared through following steps: using metallo-organic compound or metal salt as precursor; methanol as dispersion medium in mobile phase; adding vitriol and water; through hydrolytic reaction, polycondensation reaction to form sol; doping heteroacid to produce SMP. The invention solves issue of methanol leakage radically so as to lower poisoning cathode and anode catalyst of direct methanol fuel battery (DMFB). The invention raises performance of DMFB, simplifies structure of battery, and promotes progress of industrialization of DMFB.

Owner:NANTONG UNIVERSITY

Polyester fabric ink-jet printing ageing-washing-free method

PendingCN111188212ASolve the problem of sewage dischargeSolving Penetration ProblemsInksDyeing processPolyesterPolymer chemistry

The invention relates to a polyester fabric ink-jet printing ageing-washing-free method. The polyester fabric ink-jet printing ageing-washing-free method comprises steps of producing treatment liquid,producing high-temperature dispersion ink, spray-printing the treatment liquid, carrying out ink-jet printing, carrying out high-temperature color development and obtaining a finished product, and particularly comprises the steps of: 1, preparing the treatment liquid, which particularly comprises two schemes; 2, producing the high-temperature dispersion ink; 3, carrying out ink-jet printing; and4, carrying out high-temperature color development. According to the method disclosed by the invention, not only is time required for ageing and water washing in direct-jet printing and cold-transferprinting of the existing polyester fabric ink-jet printing shortened, but also a problem of sewage discharge in the ink-jet direct-jet printing is solved. Meanwhile, according to the method disclosedby the invention, a problem of penetration of polyester heat transfer printing is also solved; a cost problem caused when transfer printing is carried out by paper is solved; pollution and tree waste,which are caused by papermaking, are more indirectly avoided; and the polyester fabric ink-jet printing ageing-washing-free method is not only environmental-friendly, but also energy-saving.

Owner:SHAOXING YUANSE DIGITAL TECH

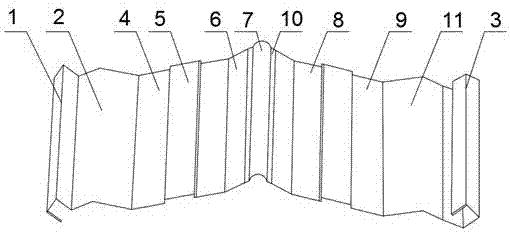

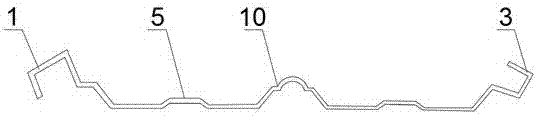

Stable waterproof color steel tile

InactiveCN106948554AImprove stabilityEasy dischargeRoof covering using slabs/sheetsLarge sizeMaterials science

The invention discloses a stable waterproof color steel tile comprising a first tile body, a connecting part and a second tile body which are connected in sequence in the length direction of the stable waterproof color steel tile. The first tile body and the second tile body are located on the same plane; the connecting part is located in the middle position of the first tile body and the second tile body; reinforcing ribs are arranged on the inner sides of the first tile body and the second tile body; the free end of a first face plate is provided with a first hanging part, and the free end of a second face plate is provided with a second hanging part; and the connecting part is composed of a first tilt face plate, a U-shaped plate and a second tilt face plate. According to the stable waterproof color steel tile, the structure is simple, manufacturing is convenient, high applicability is achieved, the whole structure is firm, deformation is not liable to occur, large size manufacturing of the color steel tile can further be achieved, construction speed increasing is facilitated, the vertical height of the color steel tile is increased, a larger drainage section is obtained, rainwater is prevented from permeating from the overlapping edge, and the problem that the rainwater permeates from the edge of the color steel tile is effectively solved.

Owner:响水蓝天彩钢有限公司

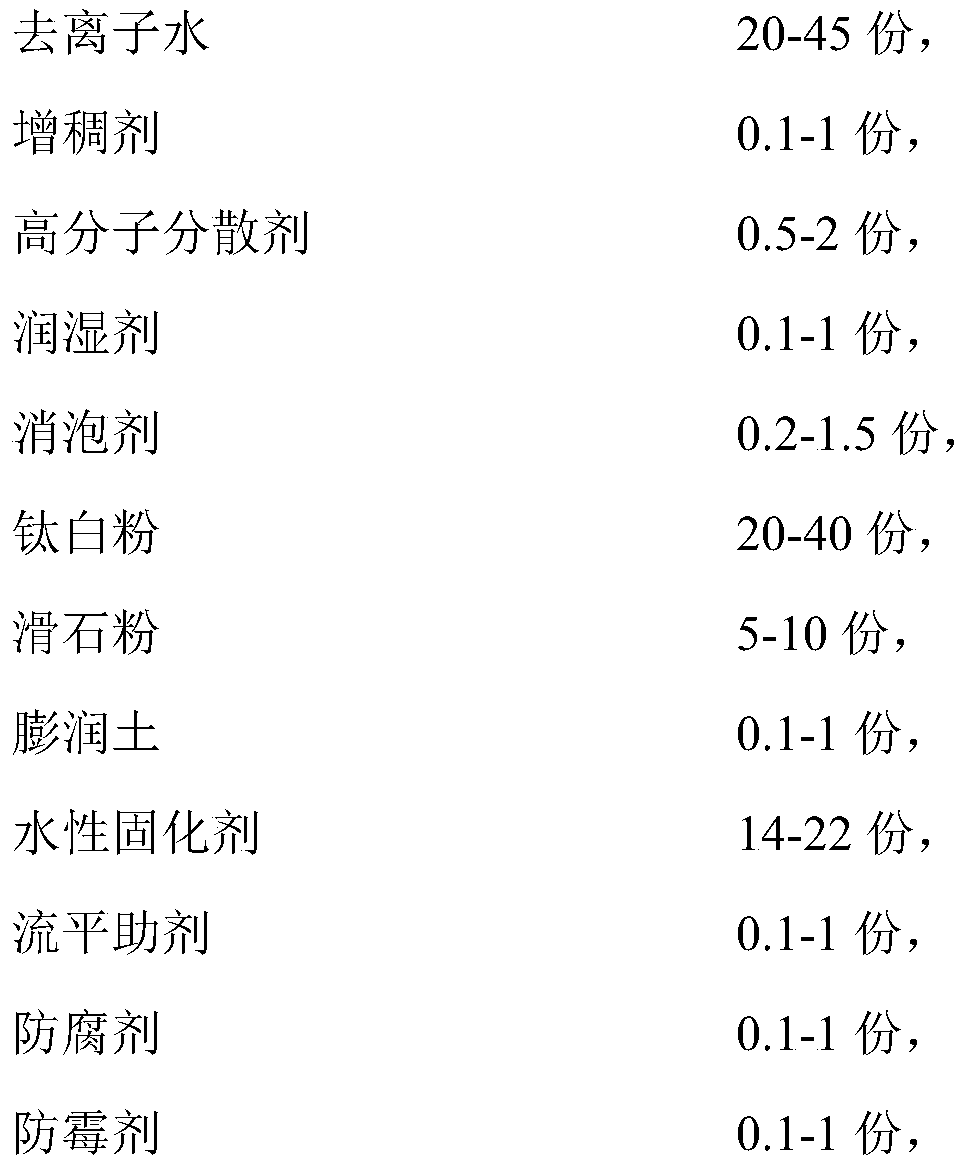

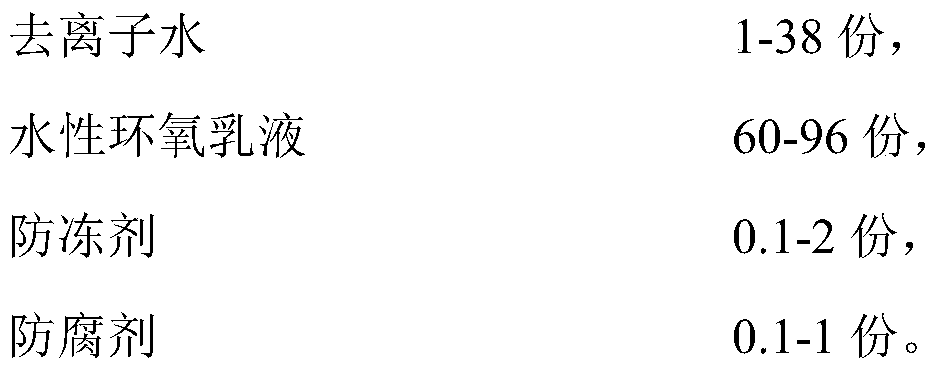

Waterproof stain-resistant water-based coating for interior walls used in kitchens and preparation method of coating

InactiveCN109868041ASolve penetrationWaterproof and stain-resistantAntifouling/underwater paintsPaints with biocidesWater basedEpoxy

This invention relates to the field of coatings. A coating for interior walls comprises an A component and a B component, wherein a weight ratio of the A component to the B component is 1:1; the A component comprises the following materials: 20-45 parts of deionized water, 0.1-1 part of a thickening agent, 0.5-2 parts of a high-molecular dispersant, 0.1-1 part of a wetting agent, 0.2-1.5 parts ofa defoaming agent, 20-40 parts of titanium dioxide, 5-10 parts of talc powder, 0.1-1 part of bentonite, 14-22 parts of a water-based curing agent, 0.1-1 part of a levelling auxiliary agent, 0.1-1 partof a preservative, and 0.1-1 part of an anti-mold agent; and the B component comprises the following materials: 1-38 parts of deionized water, 60-96 parts of a water-based epoxy emulsion, 0.1-2 partsof an anti-freezing agent, and 0.1-1 part of a preservative. The waterproof stain-resistant water-based coating for the interior wall provided by the invention is a two-component coating, has the characteristics of high compactness and strong stain resistance, and is particularly suitable for use in home environments such as kitchens of which walls are easily stained by oil fume.

Owner:SHANGHAI CARPOLY PAINT +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com