Waterproof stain-resistant water-based coating for interior walls used in kitchens and preparation method of coating

An interior wall coating and anti-stick technology, applied in the field of coatings, can solve the problems of foaming, easy mold growth and damage of the coating film, and achieve the effect of solving the penetration of stains

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

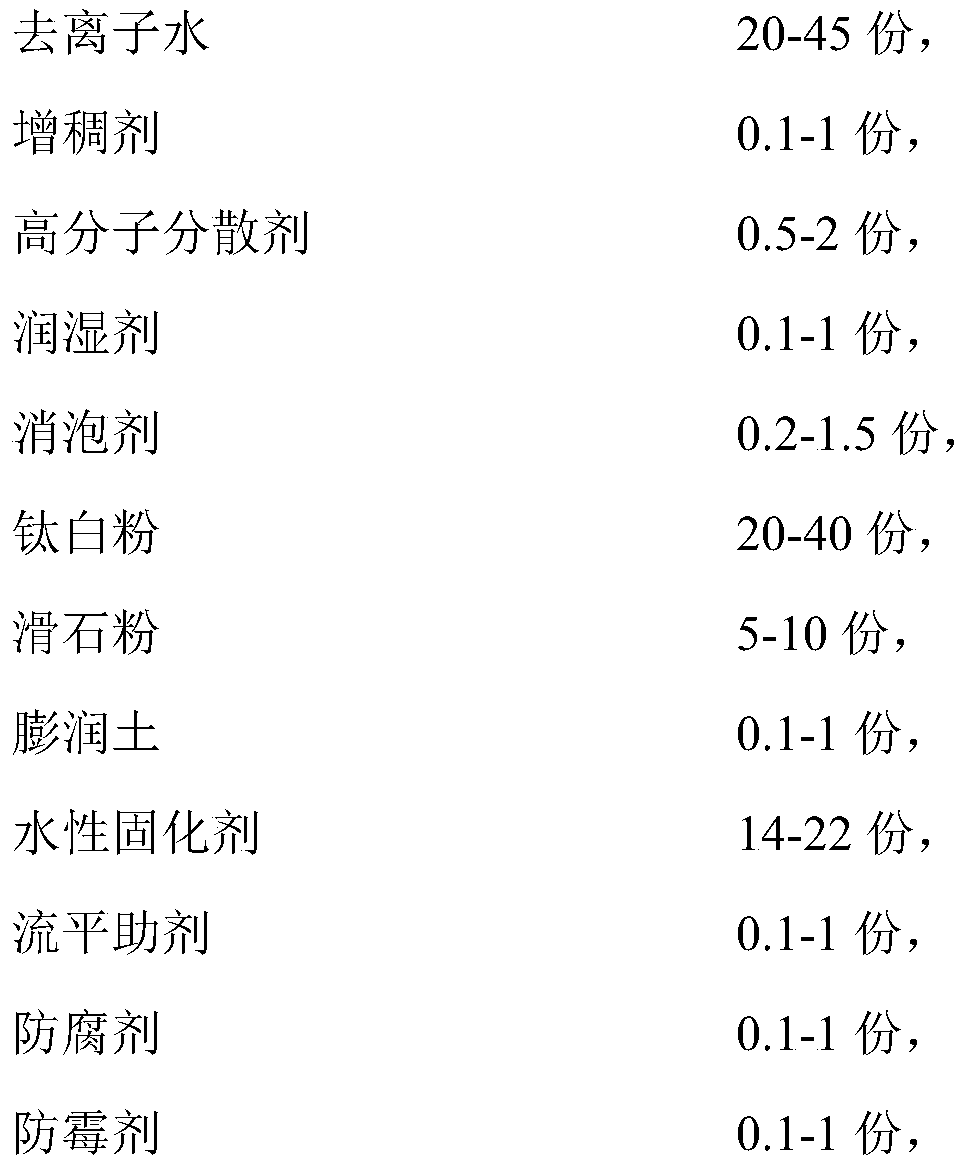

[0038] A waterproof and stain-resistant interior wall paint for kitchens, the waterproof and stain-resistant interior wall paint for kitchens includes component A and component B in a weight ratio of 1:1, wherein component A includes

[0039]

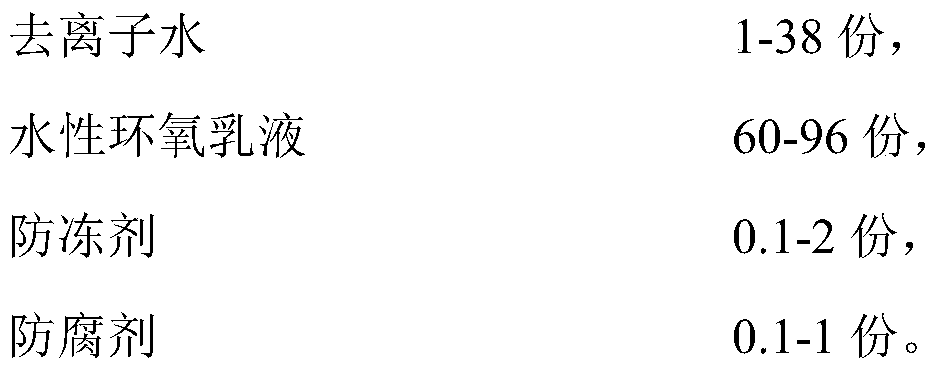

[0040] The B component includes

[0041]

[0042] The preparation method of the above-mentioned waterproof and stain-resistant interior wall paint for kitchens comprises the following steps:

[0043] Prepare component A:

[0044] (1) Under stirring at 300r / min, add hydroxypropyl methylcellulose into deionized water, and continue stirring for 7.5 minutes;

[0045] (2) Add EH-9 alkyl polyoxyethylene ether, 681F mineral oil defoamer, 6028 non-ionic dispersant in sequence, and continue to stir at 300r / min for 3-5min;

[0046] (3) Stop stirring, add half of the modified amine curing agent, then stir at 500r / min for 4min;

[0047] (4) Add R-706 titanium dioxide, 1250 mesh talc powder and ATT-50 in sequence, and disperse at 1000r / min ...

Embodiment 2

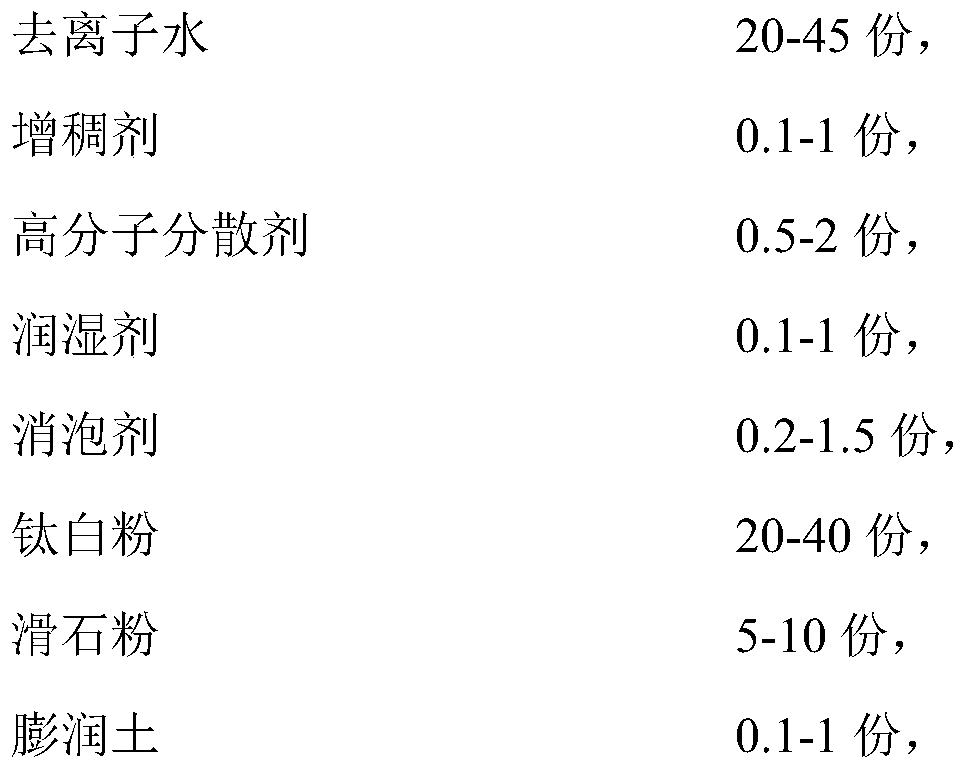

[0053] A waterproof and stain-resistant interior wall paint for kitchens, the waterproof and stain-resistant interior wall paint for kitchens includes component A and component B in a weight ratio of 1:1, wherein component A includes

[0054]

[0055] The B component includes

[0056]

[0057]

[0058] The preparation method of the above-mentioned waterproof and stain-resistant interior wall paint for kitchens comprises the following steps:

[0059] Prepare component A:

[0060] (1) Under stirring at 300r / min, add hydroxyethyl cellulose into deionized water, and continue stirring for 7.5 minutes;

[0061] (2) Add EH-9 alkyl polyoxyethylene ether, 681F mineral oil defoamer, 6028 non-ionic dispersant in sequence, and continue to stir at 300r / min for 3-5min;

[0062] (3) Stop stirring, add half of the modified amine curing agent, then stir at 500r / min for 4min;

[0063] (4) Add R-706 titanium dioxide, 1250 mesh talc powder and ATT-50 in sequence, and disperse at 1000r / m...

Embodiment 3

[0069] A waterproof and stain-resistant interior wall paint for kitchens, the waterproof and stain-resistant interior wall paint for kitchens includes component A and component B in a weight ratio of 1:1, wherein component A includes

[0070]

[0071]

[0072] The B component includes

[0073]

[0074] The preparation method of the above-mentioned waterproof and stain-resistant interior wall paint for kitchen is the same as that in Example 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com