Patents

Literature

76results about How to "Good quick setting effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Spraying quick-setting rubber asphalt waterproof coating material

ActiveCN103627258AWith anti-adhesive effectImprove adhesionConjugated diene hydrocarbon coatingsNatural rubber coatingsComposite constructionWater based

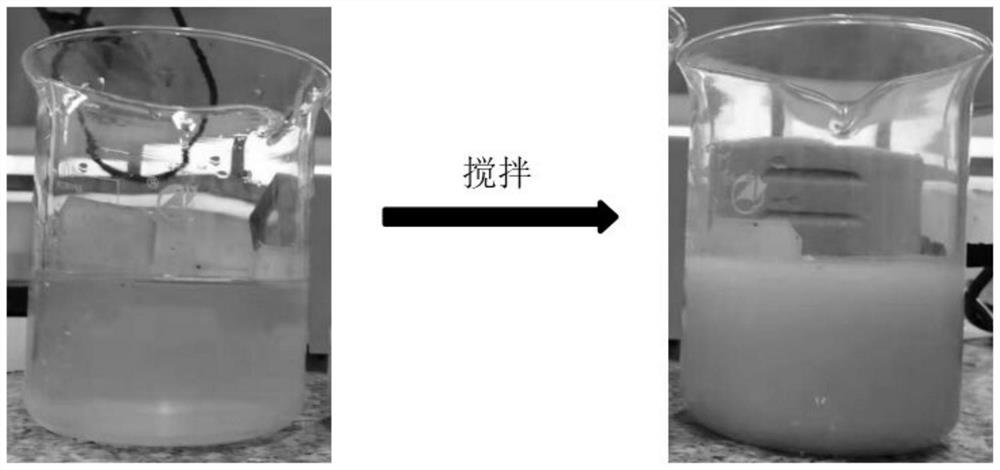

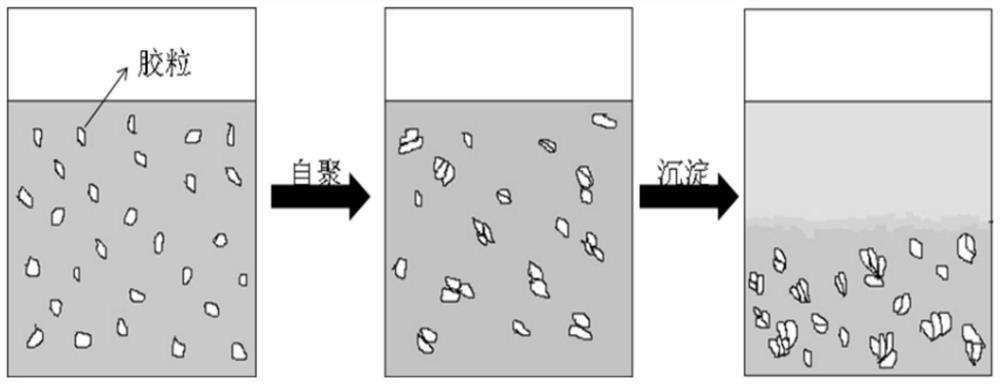

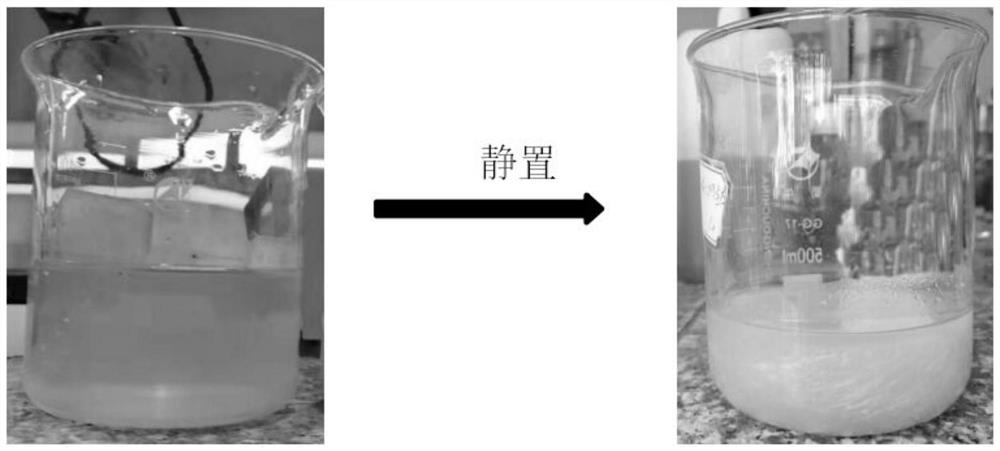

The invention relates to a spraying quick-setting rubber asphalt waterproof coating material. A special technology is adopted for preparation of the spraying quick-setting rubber asphalt waterproof coating material. The spraying quick-setting rubber asphalt waterproof coating material is a water-based spraying paint prepared according to a ratio, and a preparation method of the spraying quick-setting rubber asphalt waterproof coating material comprises following steps: a liquid rubber asphalt latex emulsion is prepared by mixing superfine, suspended and micro-emulsion modified emulsified asphalt with high-molecular polymer rubber latex; and the liquid rubber asphalt latex emulsion is mixed with a coagulant. Cold spraying construction is adopted for preparation of the spraying quick-setting rubber asphalt waterproof coating material; elastic coating film elongation is more than 1000%; restoration ratio is more than 95%. The spraying quick-setting rubber asphalt waterproof coating material possesses ultraviolet resistance, high construction efficiency, high bonding strength, excellent high-temperature resistance, excellent low temperature flexibility, and better quick setting effect; and is capable of forming films in 3 seconds. The spraying quick-setting rubber asphalt waterproof coating material is water based; is friendly to the environment; possesses no toxicity, and excellent endurance; is quick and convenient for construction; and is a novel environmental friendly waterproof paint with a wide application range. The spraying quick-setting rubber asphalt waterproof coating material is mainly used for various waterproof and anticorrosion projects. The spraying quick-setting rubber asphalt waterproof coating material is used for individual construction of waterproof projects, for composite construction of waterproof projects together with waterproof roll, and for individual construction of anticorrosion projects.

Owner:SHANDONG NORTH CHUANGXIN WATERPROOF SCI & TECH GRP CO LTD

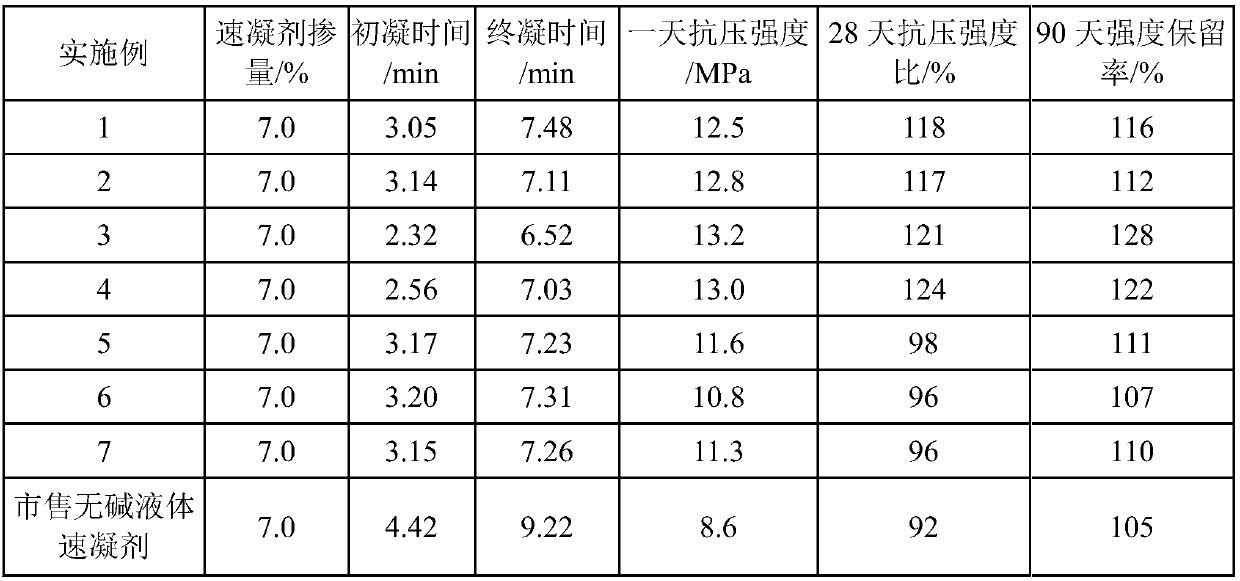

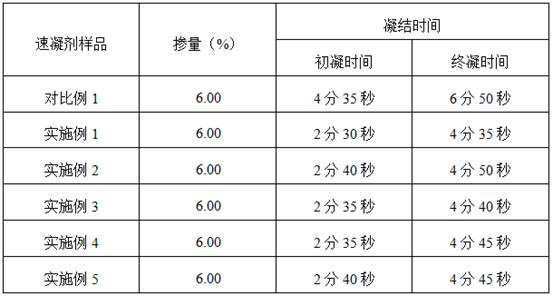

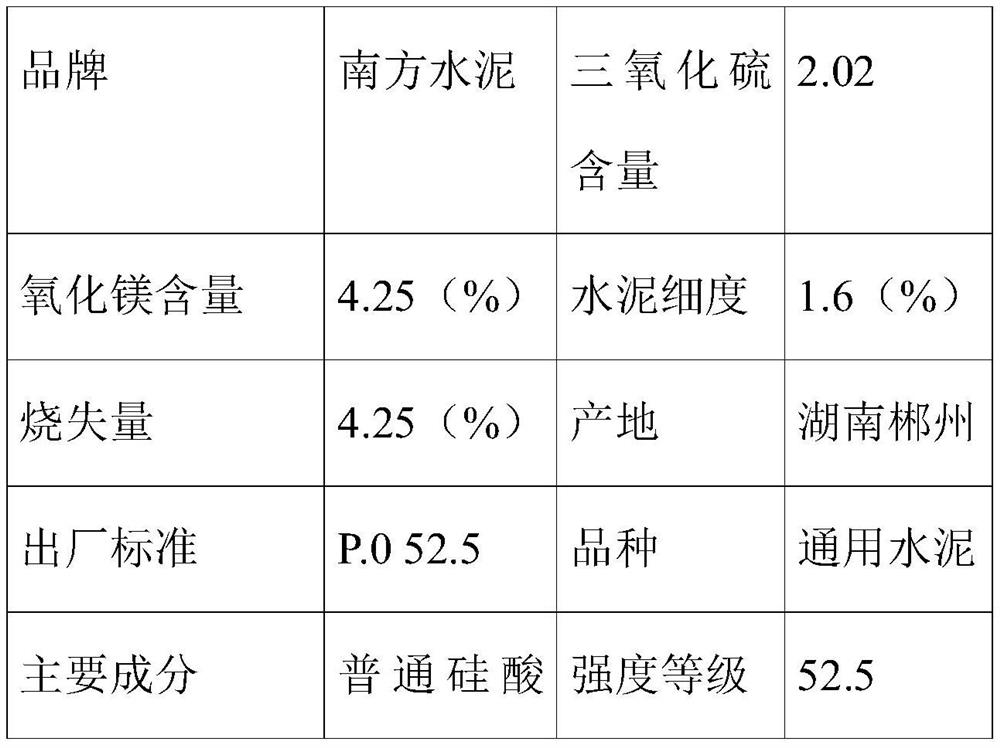

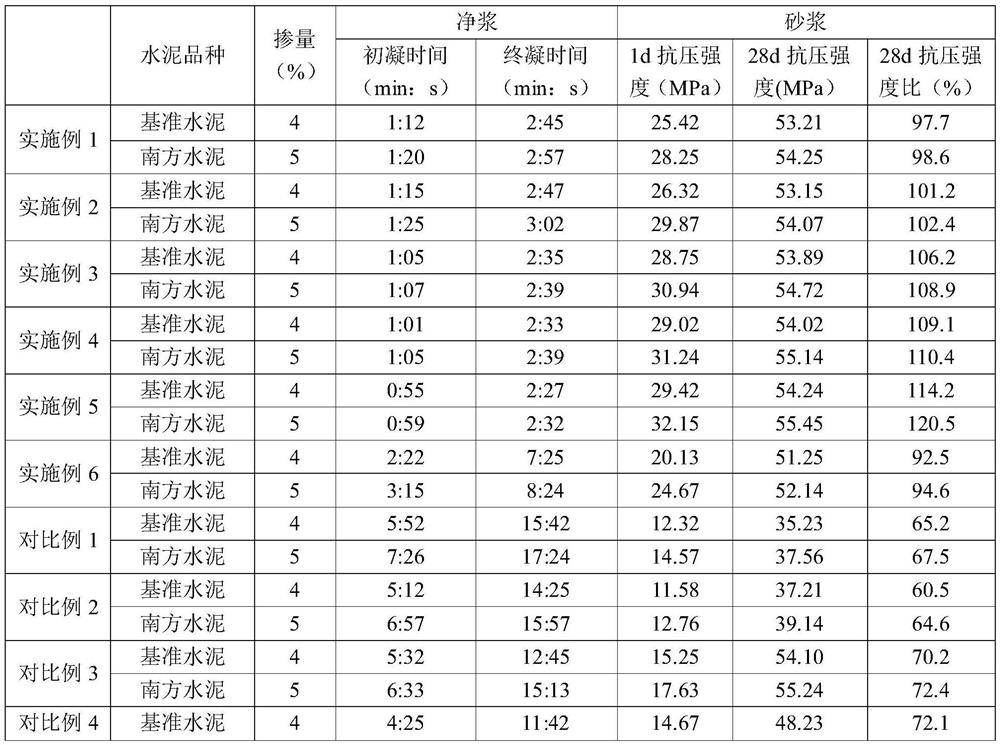

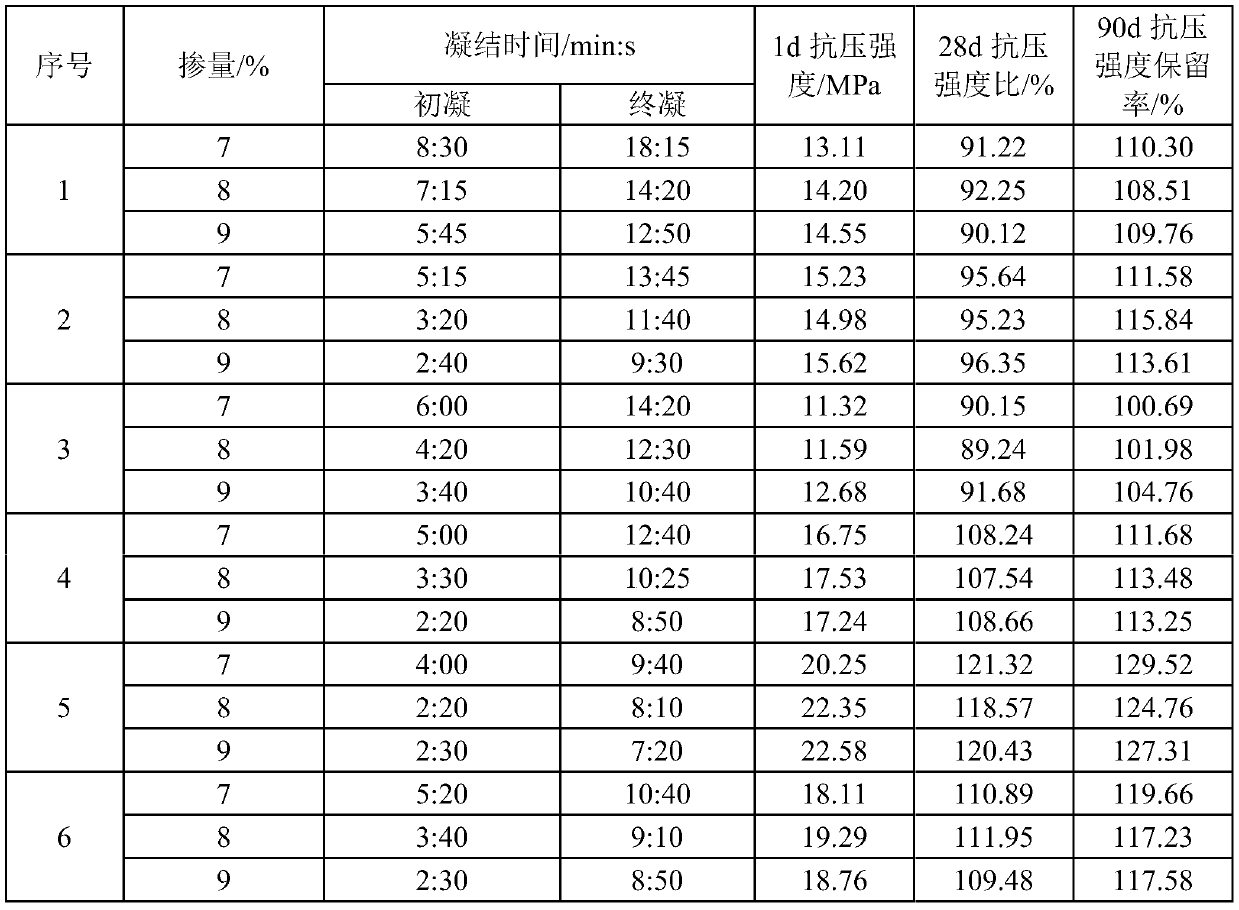

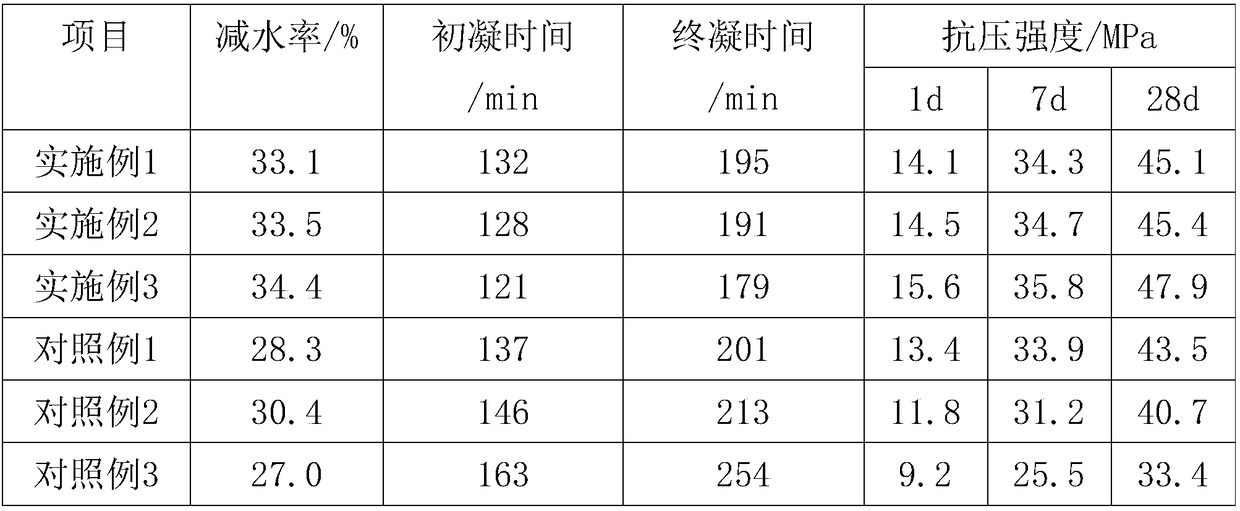

Preparation method of novel alkali-free liquid accelerator

The invention discloses a preparation method of a novel alkali-free liquid accelerator. The ingredients and the proportion of the accelerator are as follows: 30-50% of aluminum sulfate, 10-20% of aluminum citrate, 2-10% of hydroxycarboxylic acid, 5-10% of ammonium hydroxide at the concentration of 20%, 0.01-0.05% of polyacrylamide and the balance of water. The preparation method comprises the following technological production steps: feeding the raw materials into a reaction kettle according to different feeding sequences, heating and uniformly mixing the raw materials at 60-80 DEG C, and cooling the mixture to obtain a colorless or light green thick liquid. The preparation method disclosed by the invention has the following advantages that due to the introduction of multi-hydroxyl functional group molecules, the coordination crosslinking of an aluminum crosslinking system and polyacrylamide molecules is promoted, a composite aluminum citrate crosslinking system with high activity is prepared, the hydration rate of cement is obviously increased, and furthermore the action effect of the accelerator is enhanced. The setting time of the cement mortar doped with the accelerator is greatly shortened, the initial setting time is shorter than 2 minutes, the final setting time is shorter than 6 minutes, the 1d (Day) compressive strength is higher than 10MPa, and the 28d compressive strength rate is higher than 140%.

Owner:BEIJING ACAD OF BUILDING ENG

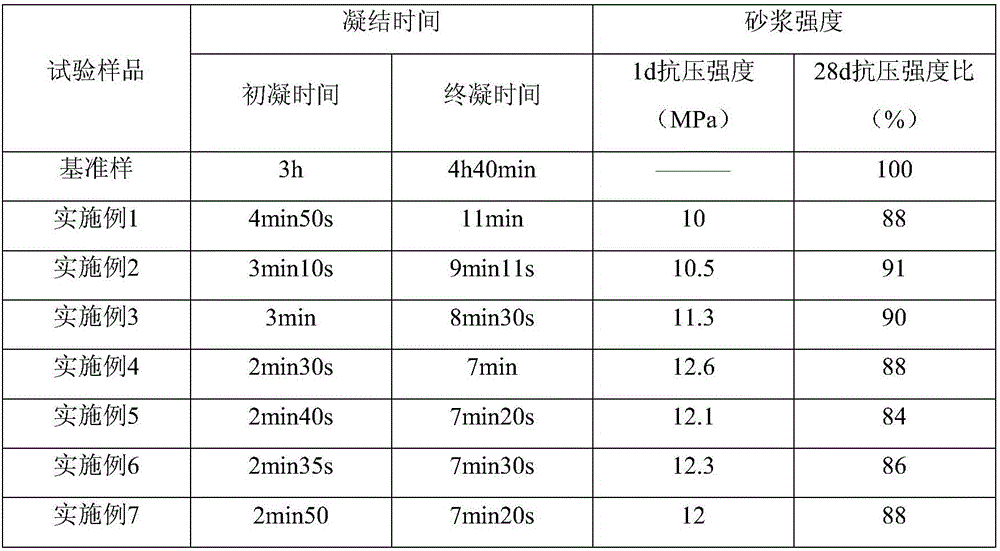

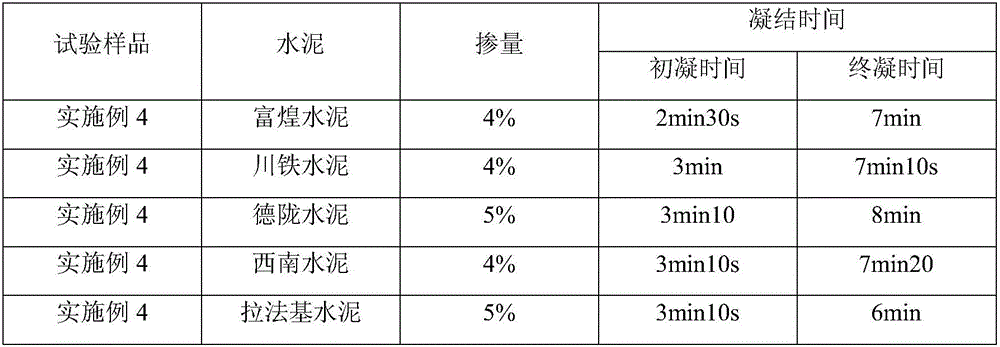

Alkali-free liquid accelerator and preparation method thereof

The invention provides an alkali-free liquid accelerator and a preparation method thereof and belongs to the technical field of concrete admixtures. The alkali-free liquid accelerator is prepared fromthe following raw materials: aluminum sulfate, ferrous sulfate, sodium fluoride, magnesium fluosilicate, precipitated hydrated magnesium silicate, diethanol amine and water. The alkali-free liquid accelerator has a good rapid hardening effect, can effectively shorten the coagulating and final setting time of concrete, and effectively improves the early strength and the later strength of concrete.The preparation method of the alkali-free liquid accelerator comprises the following steps: stirring water and precipitated hydrated magnesium silicate for 15-20 min at 40 DEG C; then adding ferroussulfate and sodium fluoride, and performing mixing and stirring for 8-15 min; after that, adding aluminum sulfate; performing heating up to 75-85 DEG C; after a reaction for 1 h, adding magnesium fluosilicate, and performing stirring for 20-40 min; and at last, adding diethanol amine, performing stirring for 18-25 min to prepare the alkali-free liquid accelerator. The preparation method is simple,the reaction is safe, and the prepared accelerator has good dispersibility.

Owner:PANZHIHUA CITY JIYUAN TECH

Low-resilience liquid accelerator for shotcrete and preparation method thereof

The invention discloses a low-resilience liquid accelerator for shotcrete and a preparation method thereof. The accelerator is prepared from the following raw materials in percent by mass: 20%-40% of sodium hydroxide, 25%-40% of aluminium hydroxide, 3%-10% of a synergist, 0.5%-2% of a setting accelerator, 0.003%-0.02% of a viscosity adjusting agent, and the balance water, wherein, the synergist is sodium silicate, the setting accelerator is an alcohol amine substance, and the viscosity adjusting agent is potassium chromate or sodium nitrite. The preparation method comprises the following technical steps: adding sodium hydroxide and the synergist into a reaction kettle, adding water, and starting an agitator and a heater; keeping the temperature after the temperature reaches a set temperature, adding aluminium hydroxide, and reacting with the constant temperature; adding the viscosity adjusting agent, stirring, heating, reacting with a constant temperature, then stopping heating, and naturally cooling; and adding the setting accelerator after the reaction system is cooled, and cooling to room temperature, so as to obtain the accelerator. The accelerator is short in setting time, low in resilience and moderate in viscosity, generates a little sediment, has good cement adaptability, and the preparation method for the accelerator is simple, practicable and energy-saving.

Owner:SHIJIAZHUANG CHANGAN YUCAI BUILDING MATERIALS

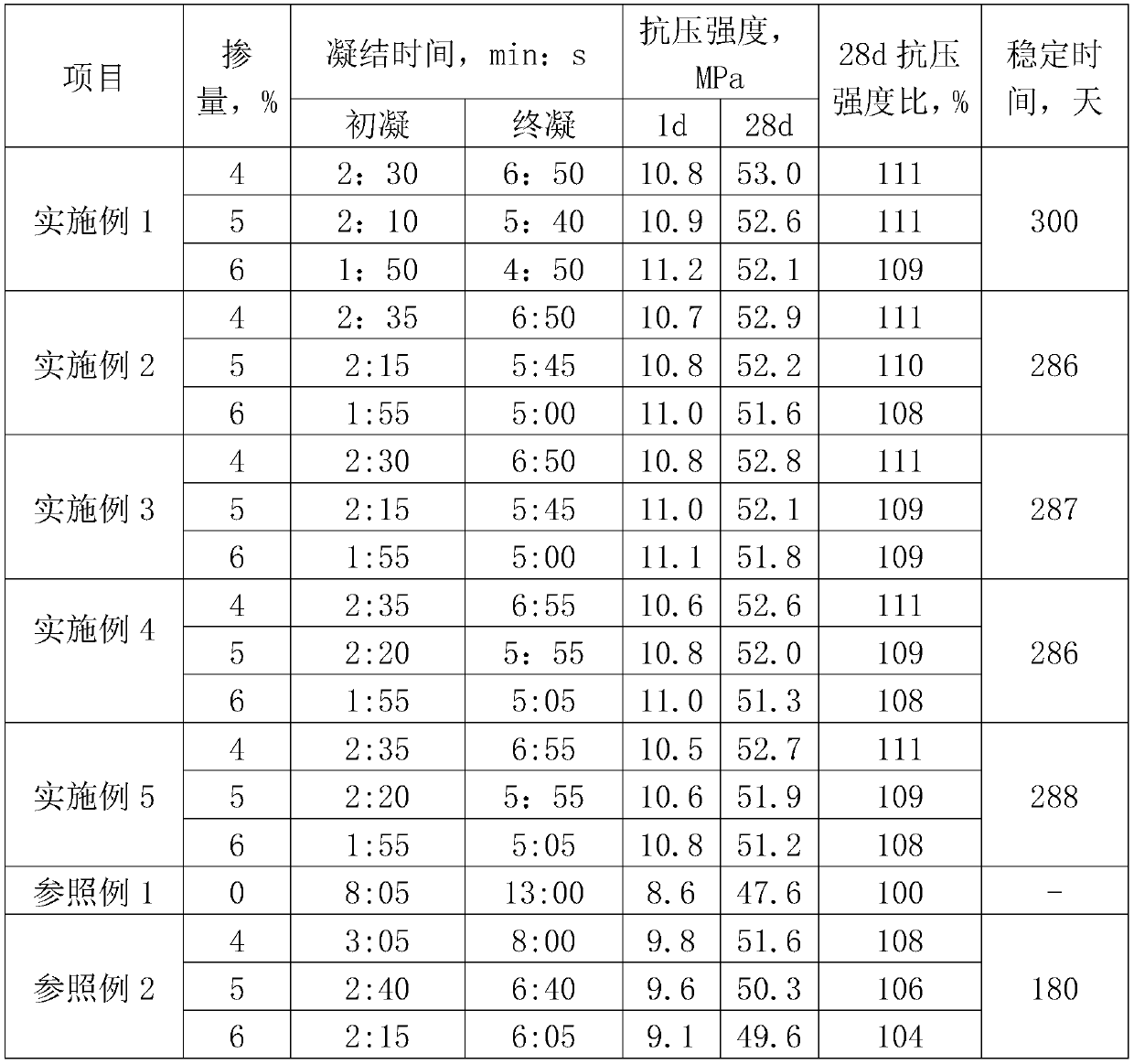

Preparation method of low-alkali polymer high-efficient liquid setting-accelerator for sprayed concrete

The invention discloses a preparation method of a low-alkali polymer high-efficient liquid setting-accelerator for sprayed concrete. The preparation method comprises the following steps: (1) preparing an aluminate mother solution; (2) preparing a modifying agent; (3) preparing a low-alkali polymer high-efficient liquid setting-accelerator. The disclosed low-alkali polymer high-efficient liquid setting-accelerator has a uniform and stable property and strong adaptability; the mixing amount is 2 to 4% of the cement mass, the initial setting time is within 2 minutes, the final setting time is within 5 minutes, the strength loss in the later stage of concrete is within 10%; furthermore, the liquid setting-accelerator can efficiently reduce the dust amount and resilience value during the sprayed concrete construction and improves the strength of sprayed concrete.

Owner:SHANDONG UNIV

Liquid quick-setting agent and preparation method thereof

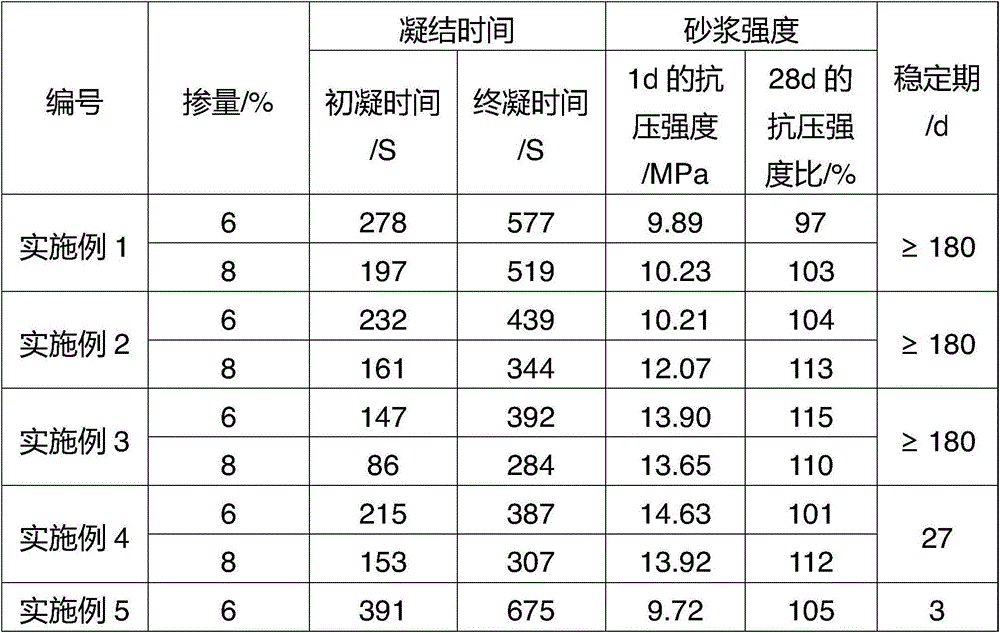

The invention provides a liquid quick-setting agent and a preparation method thereof. The liquid quick-setting agent adopts aluminum sulfate as a main material, and is low in alkaline content, good in quick-setting effect and high in stability. The preparation method comprises the following steps of: uniformly mixing the following materials in percent by weight: 45%-60% of aluminium sulfate, 5%-15% of alcohol amine, 0.5%-5% of solubilizing agent, 0-5% of setting accelerator and the balance of water, thus obtaining the liquid quick-setting agent; the content of Al2O3 of the aluminium sulfate is 14%-17%; the solubilizing agent is phosphoric acid and / or hydroxy carboxylic acid with the number of carbon atoms being not more than 6; the setting accelerator is at least one of water-soluble nitrate, nitrite, sulfate, fluoride salt, carbonate and carboxylate-sulfonate-nonionic terpolymer. The liquid quick-setting agent obtained by the preparation method is used for jetting concrete, the doping amount is generally 5%-8% of the mass of cement, the quick setting effect is good, the stability is high and the stable period reaches more than 180 days.

Owner:XINJIANG UNIVERSITY

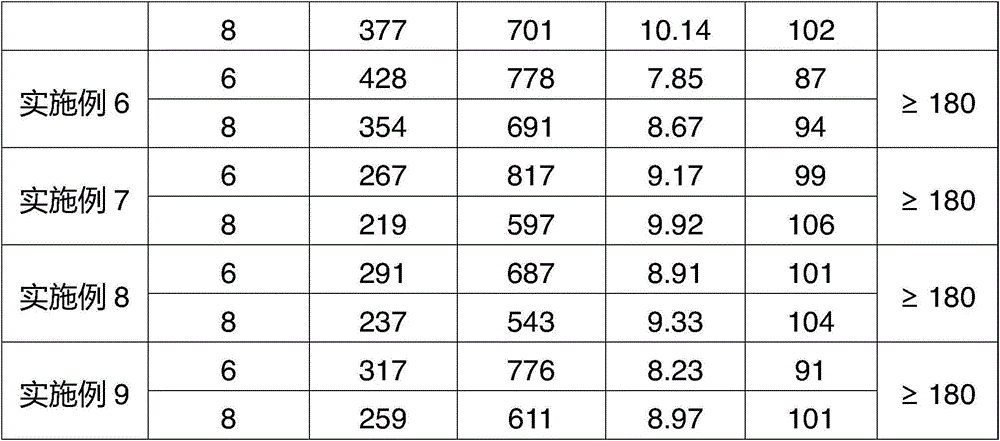

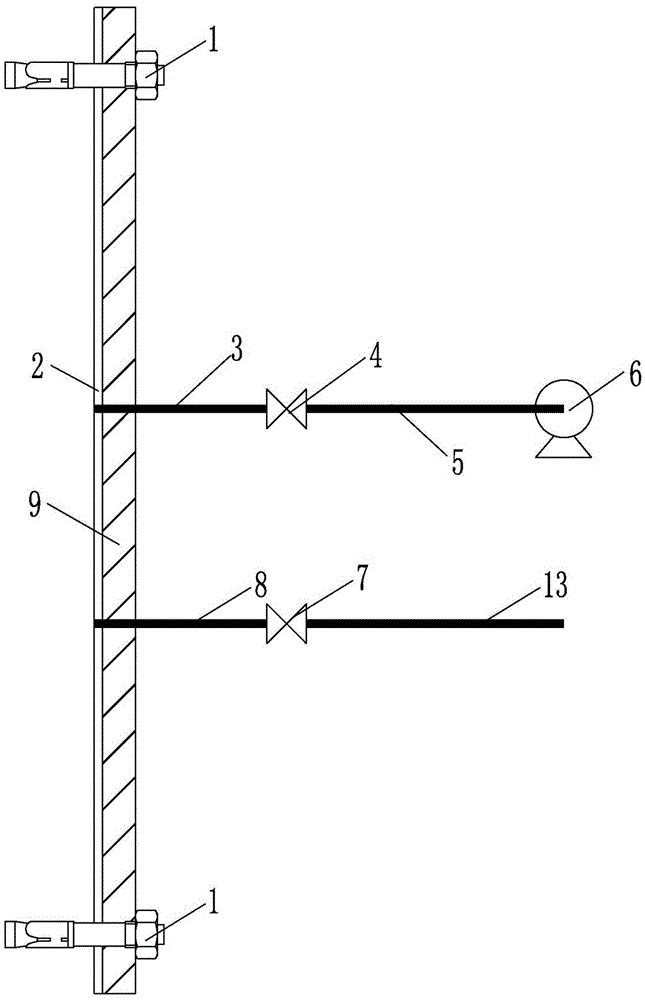

Leakage repairing device for pressure-bearing reinforced concrete structure and construction method thereof

ActiveCN104088254AFacilitate communicationImprove sealingMarine site engineeringReinforced concreteRebar

A leakage repairing device for a pressure-bearing reinforced concrete structure comprises a double-layer sealing and reinforcing plate and a crack grouting and draining device, wherein the outer wall surface of a seepage crack portion is fixedly covered with the double-layer sealing and reinforcing plate. The double-layer sealing and reinforcing plate is composed of a rubber sealing backing plate on the inner side and a reinforcing steel plate on the outer side and is anchored to structure concrete around the seepage crack portion through expansion bolts around a plate body. The crack grouting and draining device is separately arranged on the upper side and the lower side of the seepage crack portion and comprises a grouting pipe at the upper portion and a first draining pipe at the lower portion. The outer wall surface of the seepage crack portion is provided with a flow guide groove through which a plurality of cracks are communicated. The grouting pipe, the flow guide groove and the first draining pipe are communicated. The leakage repairing device can be quickly manufactured at the construction site, the whole structure repairing process only takes several minutes, the leakage repairing device can be conveniently disassembled in the later stage without influencing the appearance of the concrete structure, and the solution method high in efficiency and fast to implement in a limited construction period is achieved.

Owner:泛华建设集团有限公司

Quick-setting high-strength alkali-free liquid accelerator

The invention relates to a quick-setting high-strength alkali-free liquid accelerator. Raw materials comprise aluminum sulfate, hydrofluoric acid, aluminum hydroxide, a pre-dispersion reinforcing component, a suspension component, a complexing component, organic acid and water. The accelerator has great adaptability on cement-based materials and dual technical effects of quick setting and high strength are achieved, and the sprayed concrete applying the cement-based material is high in setting speed, high in early strength, low in rebound rate, small in dust amount, good in bonding effect, environmentally friendly and free of corrosion.

Owner:CNBM ZHONGYAN TECH

Special spraying and quick-setting rubber waterproof coating for sewage treatment plant

InactiveCN102993968AAvoid breedingHigh elongation at breakConjugated diene hydrocarbon coatingsNatural rubber coatingsBitumen emulsionSewage

The invention relates to a special spraying and quick-setting rubber asphalt waterproof coating for a sewage treatment plant, which is a special spraying and quick-setting rubber asphalt waterproof coating for the waterproofness of a sewage treatment plant. The special spraying and quick-setting rubber asphalt waterproof coating is prepared from modified emulsified asphalt and high-molecular polymer rubber latex, and particularly is a water-based spraying material prepared by adding a mildew preventive in a liquid rubber asphalt latex constituent, mixing with a coagulant constituent, and then preparing in a ratio. With the adoption of cold construction, the special spraying and quick-setting rubber asphalt waterproof coating disclosed by the invention has the advantages of being high in the elongation at break (not less than 1000%) of a waterproof film, high in bonding strength, strong in acid-base-resistant capacity, capable of preventing microbe multiplication, long in service life and the like; and the special spraying and quick-setting rubber asphalt waterproof coating can be widely applied to the waterproofness of environments with harsh requirements on waterproof materials such as sewage treatment plants and refuse landfills.

Owner:SHANDONG NORTH CHUANGXIN WATERPROOF SCI & TECH GRP CO LTD

High-performance alkali-free liquid accelerator and preparation method thereof

The invention relates to a high-performance alkali-free liquid accelerator and a preparation method thereof. The high-performance alkali-free liquid accelerator comprises the following components: 30-45% of active aluminum hydroxide, 3-15% of a fluorine-aluminum complex, 0.5-8% of an early strength coagulation accelerating component, 2-8% of an alcohol amine substance, 5-15% of a nano silica sol,0.5-2% of a dispersing agent and water. The high-performance alkali-free liquid accelerator disclosed by the invention can weaken adverse effects on later mechanical strength and durability of concrete while achieving a good accelerating effect, can effectively inhibit expansion cracking of the concrete, improves early strength and cement adaptability, and is low in dosage. The preparation methodis simple to operate and mild in condition.

Owner:湖南加美乐素新材料股份有限公司

Chloride-free and low-alkaline powder accelerator

The invention discloses a chloride-free and low-alkaline powder accelerator and application thereof. The powder accelerator comprises aluminum sulfate and sodium metaaluminate and / or sodium fluoride, and the low-alkaline type refers to that the accelerator does not contain additional alkaline. The compound accelerator integrates the advantages of good accelerated setting effect of an alkaline-containing accelerator and strength loss prevention of an alkaline-free accelerator, meanwhile, the preparation cost is reduced, and the cost performance is improved. Therefore, the low-alkaline efficient accelerator is prepared, and the harm of the accelerator to the human body is reduced at the same time. The accelerator is suitable for sprayed concrete requiring accelerated setting; and by using the compound accelerator, the performance of cement concrete is improved, the solidification time of the cement concrete is regulated, the later strength of the cement concrete is not affected, and the production cost is reduced.

Owner:HENAN POLYTECHNIC UNIV

Concrete accelerator and preparation method thereof

The invention provides a concrete accelerator. The concrete accelerator is prepared from the following raw materials: aluminum sulfate, aluminum nitrate, phosphoric acid, ammonia water, a halloysite nanotube modified alkylol amine polymer grinding aid, a stabilizer, magnesium fluorosilicate, a tackifier and water. Various coagulation accelerating components are compounded, the coagulation time ofsprayed concrete can be further shortened, the comprehensive performance of cement is improved, a good coagulation accelerating effect is achieved on premixed concrete subjected to initial hydration,the coagulation time of the concrete can be obviously shortened, the early strength is improved, the stability, durability and safety of the concrete can be remarkably improved, and the cost is low. The concrete accelerator is particularly suitable for premixed concrete spraying construction of long-time and long-distance transportation.

Owner:海南佳益混凝土有限公司

Liquid accelerating agent and preparing method and application thereof

The invention relates to the field of building materials, in particular to a liquid accelerating agent and a preparing method and application thereof. The liquid accelerating agent is a chloride-free,fluoride-free, alkali-free and low-cost liquid accelerating agent, and is prepared from, by mass, 50%-70% of aluminum sulfate, 1%-7% of phosphoric acid, 1%-5% of amide, 1%-10% of aluminum hydroxide,1%-8% of alkylol amine, 1%-5% of silicate and the balance water. The chloride-free and alkali-free liquid accelerating agent is white thick liquid, the density is 1.30 g / cm<3> to 1.55 g / cm<3>, the pHvalue is 2.5 to 4.5, and the solid content is 30% to 50%. The liquid accelerating agent has the advantages of being low in cost, capable of being prepared at the room temperature, simple in productiontechnology and the like, and is suitable for industrial mass production, a finished product of the liquid accelerating agent is non-corrosive, and the liquid accelerating agent can be safely appliedto construction.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

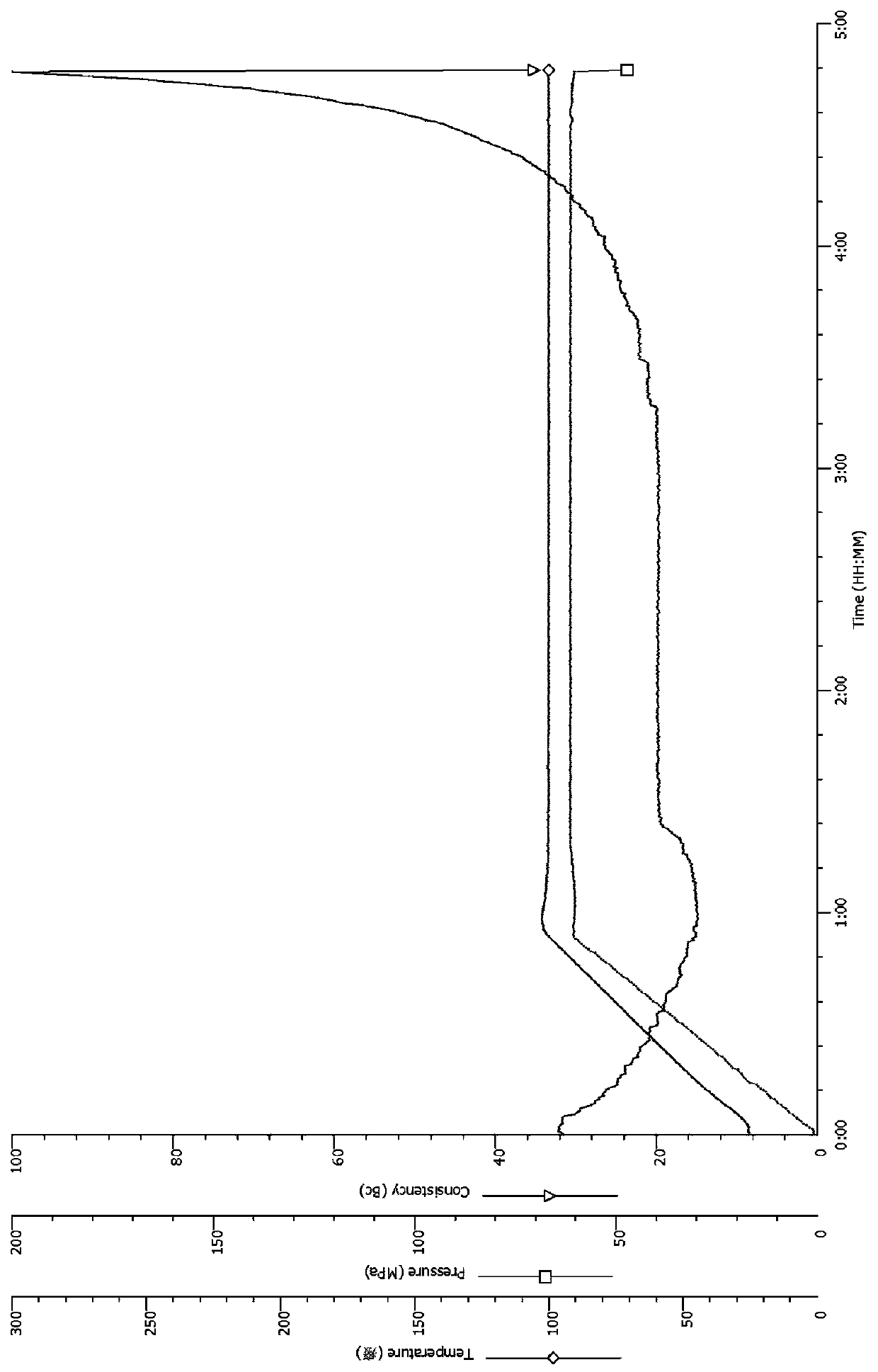

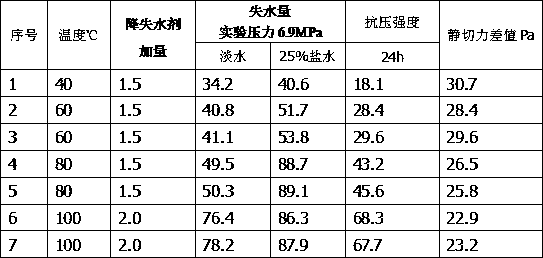

Modified fluid loss agent

InactiveCN110305641AExpansive realizationIncreased dispersionDrilling compositionAluminium sulfateSulfonate

The invention discloses a modified fluid loss agent, and relates to the technical field of cement paste admixtures. The modified fluid loss agent is prepared from the following components in percentage by weight: 40-65% of a polyamide polymer, 0-20% of bentonite, 20-45% of super-fine calcium carbonate, and 5-10% of aluminum sulfate; and the polyamide polymer is a copolymer of 2-acrylamide-2-methylpropane sulfonate and acrylamide (AMPS / AM). By using the fluid loss agent, cement paste with low water loss, high strength, good anti-salt performance and rheological property, high static shear forceand good thixotropic property is easily prepared.

Owner:JIAHUA SPECIAL CEMENT

Technology for preparing quick-setting agent by utilizing industrial waste phosphoric acid

InactiveCN108483965AGood quick setting effectShorten the setting timeChemical treatmentAluminium hydroxide

The invention discloses a technology for preparing a quick-setting agent by utilizing industrial waste phosphoric acid. The technology adopts the following raw materials in parts by weight: 50-200 parts of deionized water, 50-200 parts of aluminum hydroxide, 80-150 parts of industrial waste phosphoric acid, 20-50 parts of hydrofluoric acid, 5-15 parts of boric acid, 15-50 parts of triethanolamine,and 200-350 parts of aluminum sulfate hydrate. The technology directly utilizes waste phosphoric acid without any physical or chemical treatment, belongs to the hazardous wastes reuse, not only accords with the country's concept of promoting green production conformed with, but also reduces the cost of waste liquid disposal of enterprises, can also realize recycling of wastes and generate incomefor the enterprises to get three results with one action, and is suitable for promotion.

Owner:萧县沃德化工科技有限公司 +1

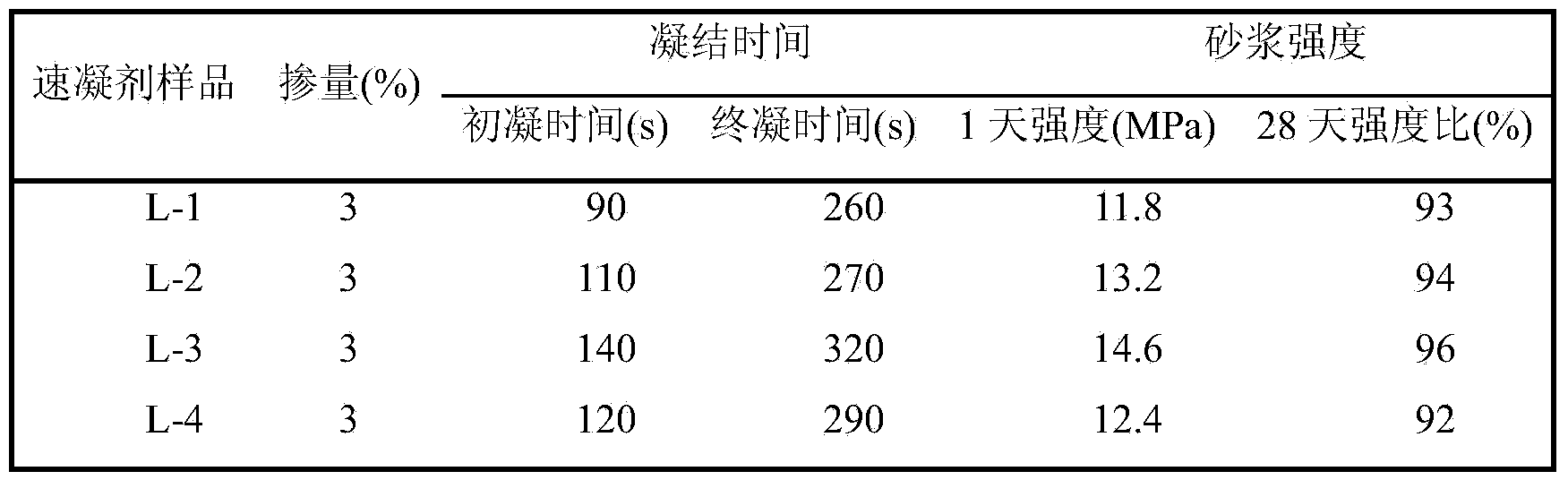

Liquid accelerator for sprayed concrete and application thereof

The invention discloses liquid accelerator for sprayed concrete and application thereof. The liquid accelerator for sprayed concrete comprises, by weight percent, 30-50% of aluminum sulfate, 0.5-1.5% of triethanolamine, 10-30% of aluminate, 1.0-5.0% of cellulose, 5-10% of efficient water reducer, and the balance of water. In construction of the sprayed concrete, the accelerator 2-5% of cement is dosed. The accelerator is effective in setting acceleration, initial setting time is 2min-4min, final setting time is 4min-8min, early strength attains fast, 28d compressive strength ratio is over 95%, and the accelerator is high in cohesiveness and low in resilience. In addition, the accelerator is chloride-free and low in alkali and is capable of lowering the risk of concrete alkali-aggregate reaction and erosion of reinforced concrete.

Owner:JIANGSU SOUTH PORCELAIN INSULATOR CO LTD

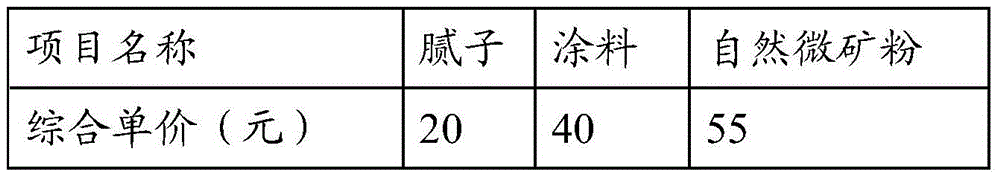

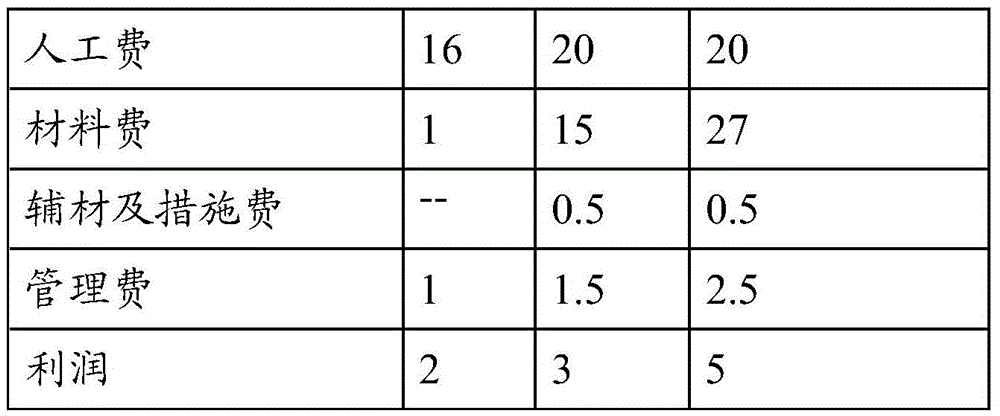

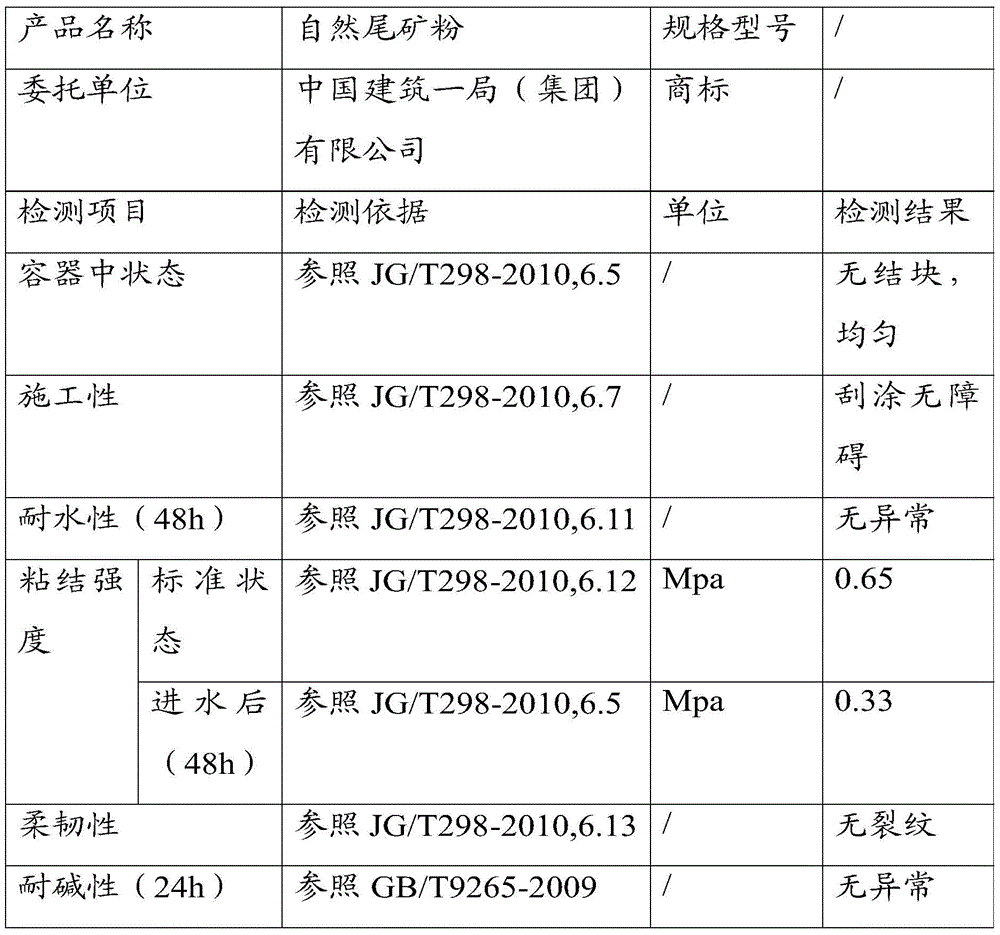

Natural micro-mineral powder

The invention provides natural micro-mineral powder. The natural micro-mineral powder is mainly prepared from, by weight, 60-90 parts of natural mineral powder with calcium carbonate content of 97% or higher, 20-40 parts of white cement, 20-40 parts of slaked lime, 2-5 parts of cellulose and 2-5 parts of other modifiers selected from one or more of emulsion powder, modified starch, water repellent and pigments. The natural micro-mineral powder can replace traditional paint and putty powder, the aim of decorating a wall surface through raw materials is achieved, and the natural micro-mineral powder has the advantages of being firm, resistant to fire, water and dampness, strong in adhesion force, breathable, easy to clean, free of chemical and radiation pollution, free of peculiar smell, static electricity, color fading and aging and the like and particularly has the advantages of being rapid in hardening and high in strength.

Owner:江苏黑莓自动化科技有限公司

Alkali-free chloride-free liquid accelerating agent as well as preparation method thereof and application thereof

The invention relates to an alkali-free chloride-free liquid accelerating agent as well as a preparation method thereof and application thereof. The liquid accelerating agent is an aqueous solution comprising 5-15 parts of a poly(aluminum carboxylate) liquid dispersing agent and 30-50 parts of aluminum sulfate. The liquid accelerating agent can be widely applied to tunnels, maritime work, support of subway, repairing, leakage prevention, water sealing and the like. Concrete using the accelerating agent is remarkable in accelerating effect, is low in rebound ratio and is high in early strength. The alkali-free chloride-free liquid accelerating agent is non-toxic and harmless, is low in comprehensive cost, and is free of pollution during production, transportation and use.

Owner:BEIJING UNIVERSITY OF CIVIL ENGINEERING AND ARCHITECTURE

Mineral additive for shotcrete as well as preparation method and application of mineral additive

PendingCN112321187AIncrease the solid-to-liquid ratioIntensity lastsFoundation engineeringBuilding material handlingMineralogyCorrosion

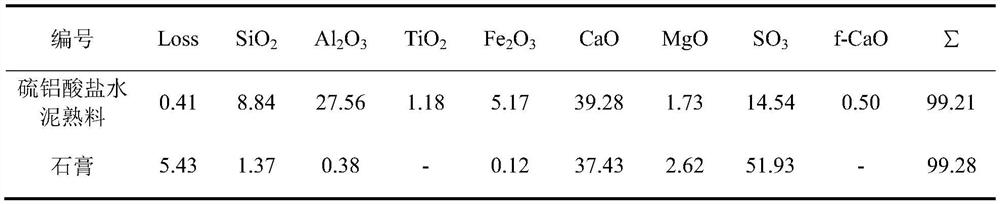

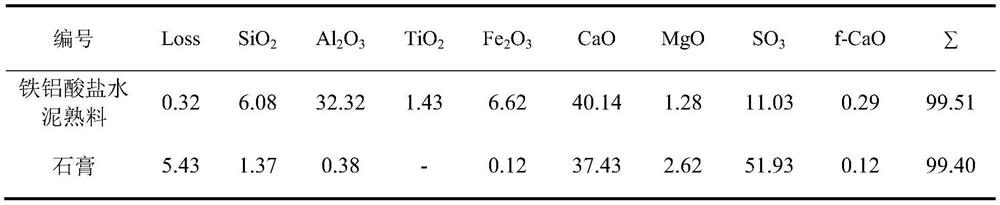

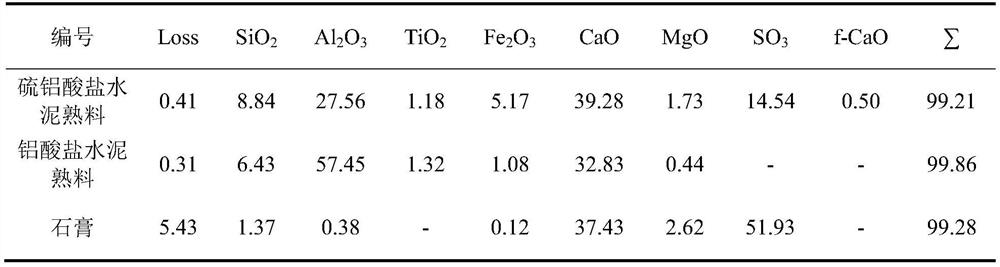

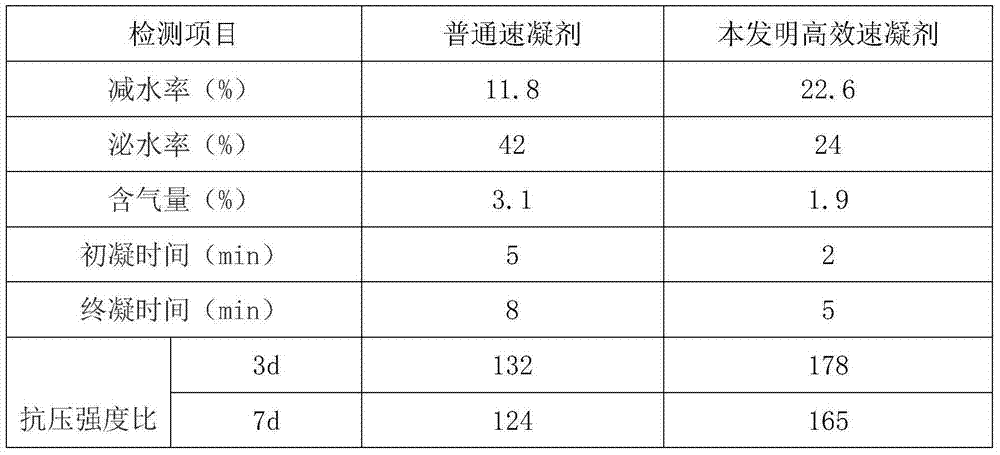

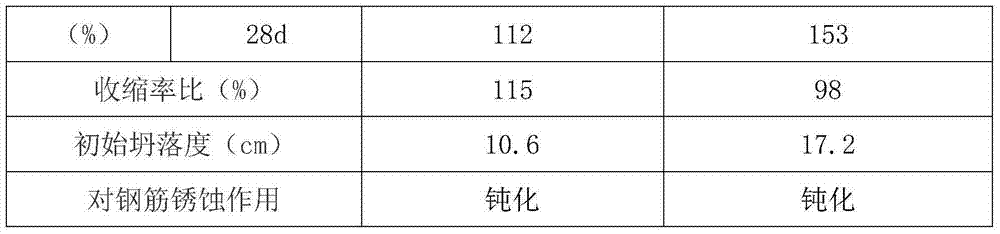

The invention relates to a mineral additive for shotcrete as well as a preparation method and application of the shotcrete. The mineral additive comprises the following components in percentage by weight: 60%-90% of clinker containing aluminum active minerals, 10%-35% of gypsum and 0-5% of chemical additive. A concrete accelerator comprises a liquid accelerator and the shotcrete mineral additive which are respectively added into concrete at different moments. According to the invention, when the wet-spraying concrete is sprayed out, the reaction can be quickly generated, the solid-to-liquid ratio is quickly increased, the concrete is quickly tackified and quickly coagulated and hardened, hydrated minerals generating strength are continuously increased, the strength is continuously improved, hydrated slurry is more compact, the durability such as later strength, sulfuric acid corrosion resistance and the like is greatly improved, and therefore, the common problem of wet shotcrete is fundamentally solved.

Owner:北京中研国信检测技术服务有限公司 +1

High-efficiency setting accelerator

The invention discloses a high-efficiency setting accelerator. The high-efficiency setting accelerator is prepared by mixing the following raw materials in parts by weight: 20-30 parts of alum clay, 10-15 parts of sodium aluminate, 2-4 parts of manganese naphthenate, 5-10 parts of 1,4-butynediol, 15-25 parts of HSA (high streace ammonia), 12-18 parts of poly (diallyldimethylammonium chloride), 10-15 parts of polysilicate ferric sulfate, 28-36 parts of SN-II high-efficiency water reducing agent, 2.5-4.5 parts of zinc dialkyl dithiophosphate, 4-6 parts of ethyl cyanoacrylate, 5-10 parts of modified soybean phospholipid, 10-15 parts of quicklime, 7-14 parts of ulexite powder, 5-10 parts of carbomer, 4-8 parts of diglycol dioleate and 3-5 parts of aid. The high-efficiency setting accelerator disclosed by the invention is good in setting acceleration effect and quick in setting, can enable concrete to be initially set within 3min and finally set within 6min and is low in construction water consumption, the water reducing rate of the setting accelerator can reach over 20%, and the setting accelerator can be used for accelerating the setting of the concrete, improving the early strength, reducing resilience and collapse and shortening the construction period, so that the setting accelerator is suitable for underground engineering sprayed concrete and ground concrete.

Owner:WUHU SANXING CONCRETE ADMIXTURE

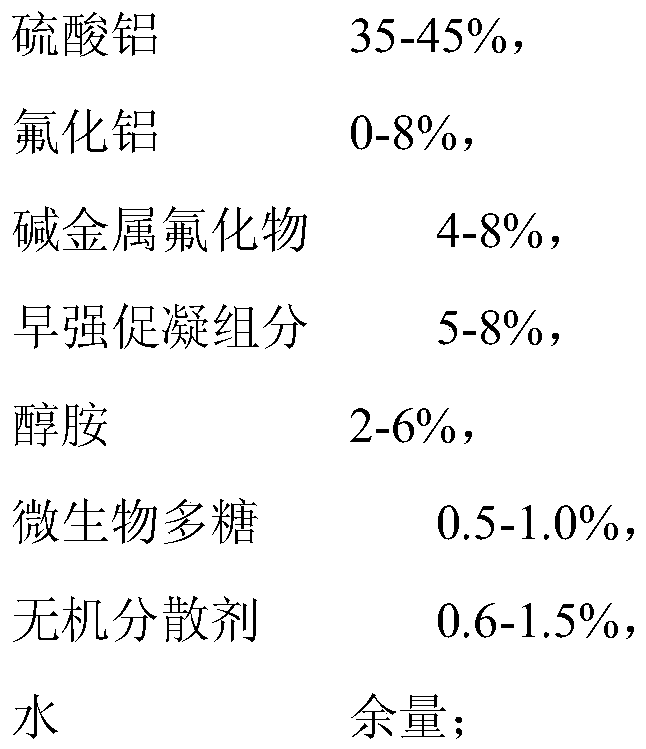

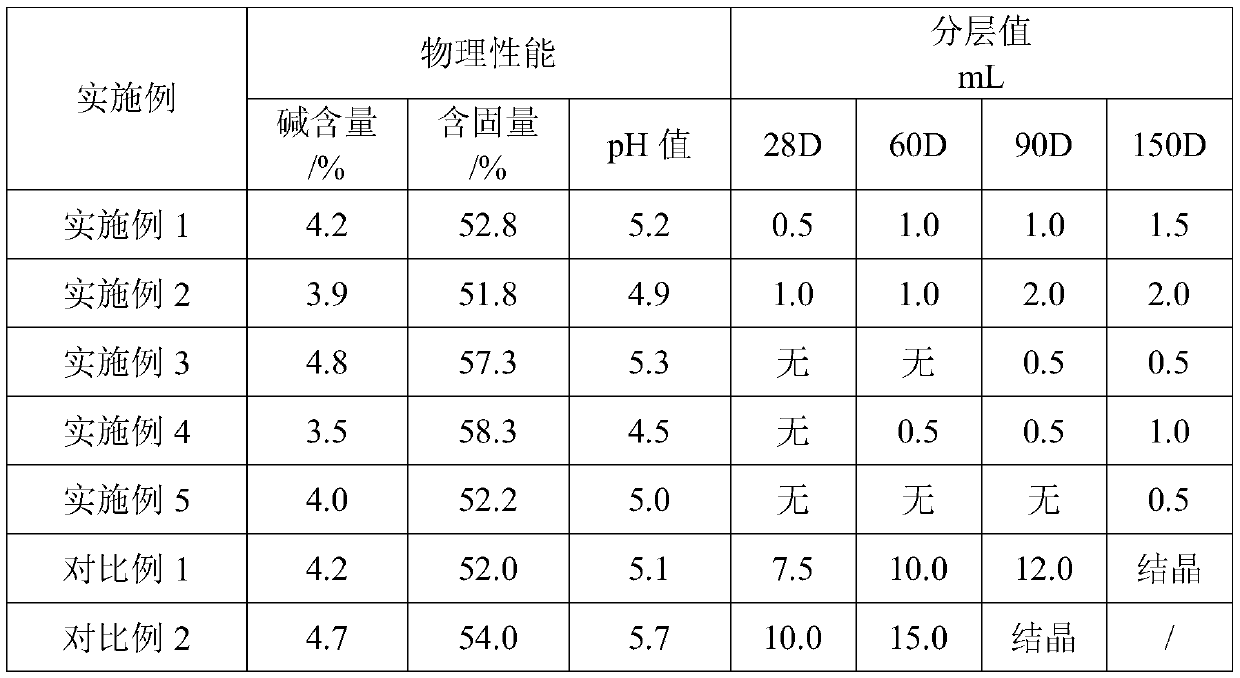

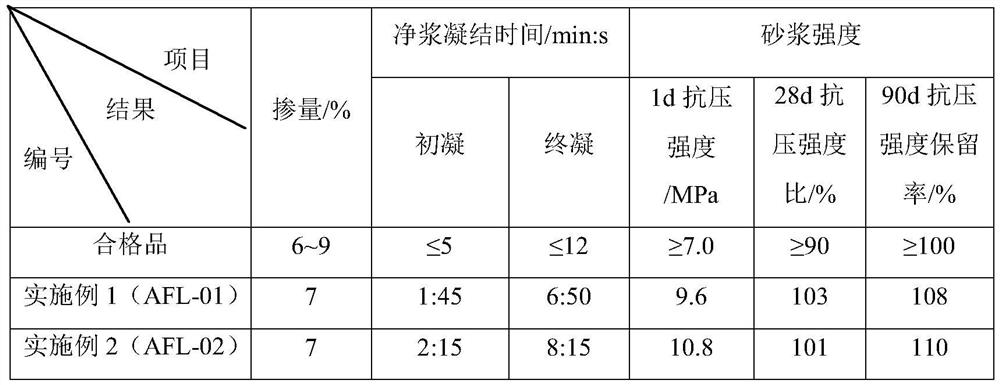

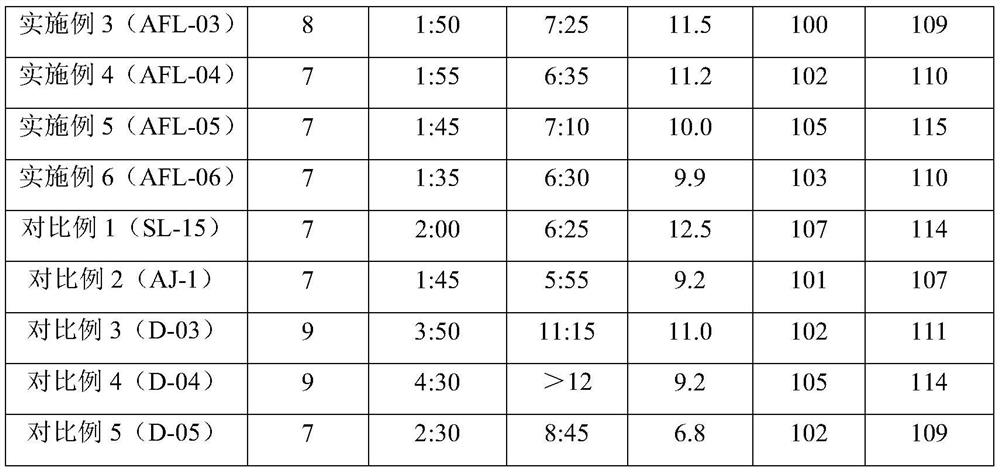

Low-alkali liquid accelerator containing microbial polysaccharide and preparation method thereof

The invention discloses a low-alkali liquid accelerator containing microbial polysaccharide and a preparation method of the low-alkali liquid accelerator. The low-alkali liquid accelerator is preparedfrom the following components in percentage by mass: 35 to 45 percent of aluminum sulfate, 0 to 8 percent of aluminum fluoride, 4 to 8 percent of alkali metal fluoride, 5 to 8 percent of early-strength coagulant component, 2 to 6 percent of alkylol amine, 0.5 to 1.0 percent of microbial polysaccharide, 0.6 to 1.5 percent of inorganic dispersant and the balance of water, wherein the sum of the mass percentages of the components is 100 percent. The low-alkali liquid accelerator disclosed by the invention has a good accelerating effect, has less harm to later-stage mechanical properties and durability of concrete, and can improve the adaptability of the accelerator and promote early-stage strength development by being supplemented with a plurality of early-strength accelerating components; by utilizing the synergistic thickening and dispersing effects between the microbial polysaccharide organic macromolecules and the inorganic dispersing agent, the prepared low-alkali setting accelerator is good in long-term stability, the 28d layering rate is less than or equal to 1.0%, and the normal-temperature storage stability is more than or equal to 6 months.

Owner:JIANGSU SOBUTE NEW MATERIALS +2

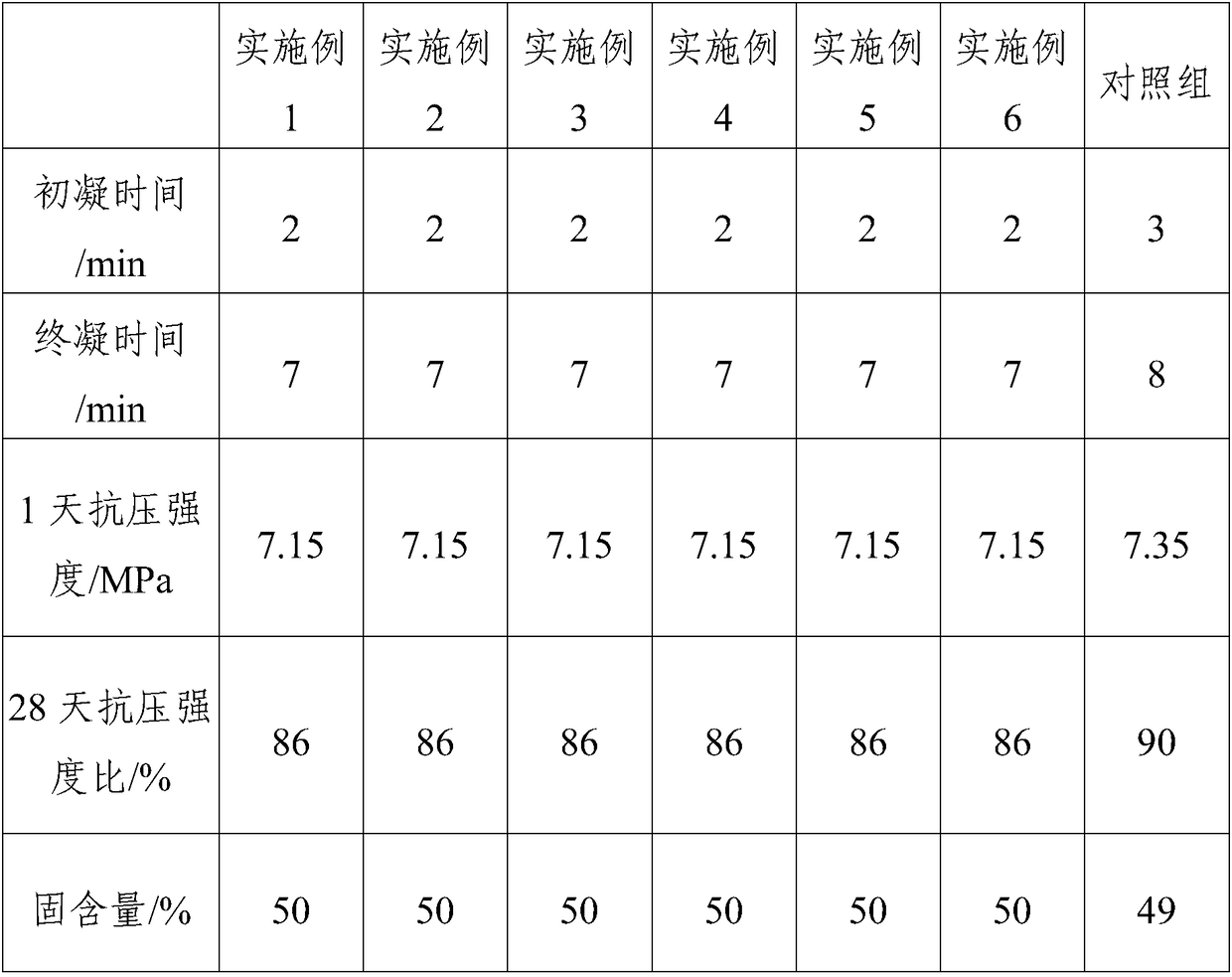

Powder alkali-free accelerator as well as preparation method, use method and application thereof

PendingCN113264711ASolve the transportation of susceptible crystalsSolve problems such as storage difficultiesAlkali freeAluminum sulphate

The invention discloses a powder alkali-free accelerator as well as a preparation method, a use method and application thereof. The powder alkali-free accelerator comprises the following raw materials: aluminum sulfate, magnesium fluosilicate, an adsorbent, alkylol amine, an early strength agent, a stabilizer and an optional neutralizer, and the water content of the powder alkali-free accelerator is not greater than 2wt%. The powder alkali-free accelerator can reduce the storage and transportation cost in a severe environment and a long-distance transportation process, is convenient to use and has a good effect, and the liquid alkali-free accelerator prepared by mixing and dissolving the powder alkali-free accelerator and water has the characteristics of low mixing amount, high setting speed, high retention rate of early strength and later strength and the like.

Owner:SHANXI SUNWAY INTION TRADE CO LTD

Alkali-free accelerator and preparation method thereof

The invention provides an alkali-free accelerator and a preparation method thereof, and the alkali-free accelerator comprises the following materials in percentage by mass: 30-38% of water; 50%-65% of aluminum sulfate; 3%-3.3% of alcohol amine; 0.7%-0.9% of white carbon black; and 0.35%-0.45% of a pH regulator. The preparation method of the alkali-free accelerator comprises the following steps: step S10, placing the alkylol amine, the white carbon black and the distilled water into a flask, and uniformly stirring; s20, raising the temperature to 60-65 DEG C, and adding aluminum sulfate; s30, stopping heating, performing stirring for 4.5- 5.5 h, and forming a uniform emulsion; and S40, adding a pH regulator to regulate the pH value to 2-4, and standing to obtain the alkali-free accelerator. The alkali-free accelerator provided by the invention has the advantages of high solubility of aluminum sulfate, good rapid setting effect, low material cost, high cost performance and excellent and stable performance.

Owner:厦门路桥翔通建材科技有限公司

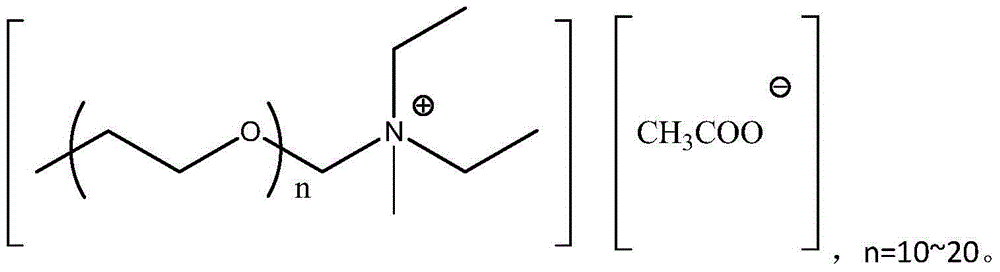

Low temperature oil well early strength well cementing agent

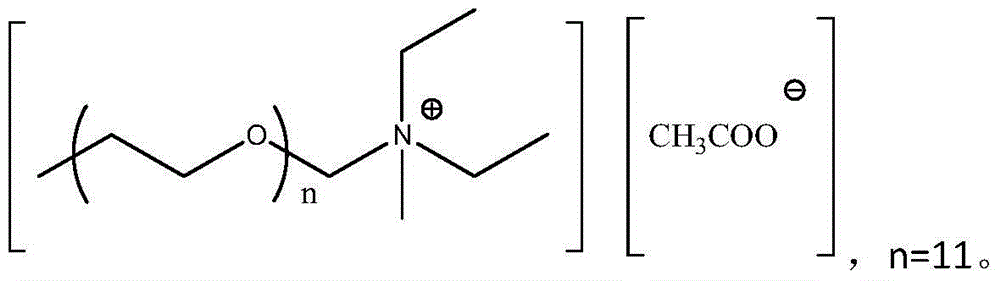

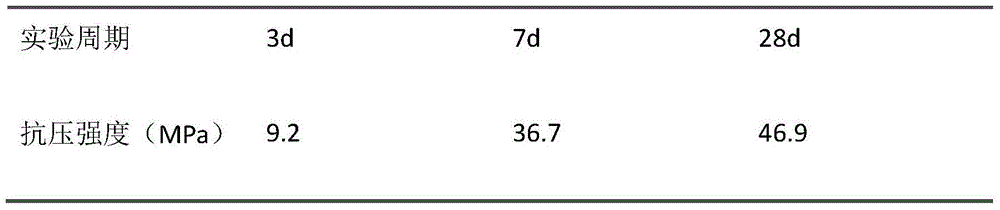

ActiveCN104099072AAvoid healthImprove convenienceDrilling compositionSuperplasticizerCarboxylic acid

The invention relates to an oil field chemical, in particular to a low temperature oil well early strength well cementing agent, which is characterized by being prepared by mixing of the following raw materials by weight: 85-95% of an ionic liquid and 5-15% of a polycarboxylate superplasticizer. The polycarboxylate superplasticizer is obtained by polymerization of polymaleic anhydride and methoxypolyethylene glycol, the functional group mole ratio of methoxypolyethylene glycol to polymaleic anhydride is 0.8-1:15. With the dual efficacy of early strength and freezing prevention, the well cementing agent provided by the invention has a high promoting effect on early strength improvement of a well cementing liquid, and has no unfavorable influence on 28d strength. Sodium chloride able to cause negative effects on cement slurry later strength and sodium nitrite are not adopted by the well cementing agent provided by the invention, thus avoiding environment and construction personnel health problems caused thereby.

Owner:山东聚鑫新材料有限公司

High stability concrete accelerator

The invention provides a high stability concrete accelerator and relates to the technical field of building material preparation. A technical flow is concise; a raw material proportion is reasonable;the accelerator is prepared from nontoxic and innocuous chemical substances; raw materials are low in price; and the prepared high stability concrete accelerator is good in accelerating effect, high in stability, strong in applicability, obvious in use effect, high in market value and convenient to popularize and use.

Owner:安徽恒远管桩有限公司

Novel environment-friendly liquid alkali-free cement accelerator

The invention belongs to the field of building materials, and particularly relates to a novel environment-friendly liquid alkali-free cement accelerator which comprises basic raw materials and additives; the basic raw materials comprise aluminum sulfate, magnesium sulfate, an early strength agent, a stabilizer, a regulator and water; and the additive is modified fumed silica. According to the cement accelerator, an existing formula is improved, and the additive modified fumed silica is added, so that the setting time of a cementing material is shortened, the compressive strength is improved, the rebound rate is low, the cementing material is free of alkali, fluorine and chlorine, adverse effects on a human body and the environment are avoided, and all technical requirements in the existing railway standard Q / CR807-2020 are met.

Owner:CHINA RAILWAY DESIGN GRP CO LTD +3

Novel mine filling quick-setting enhanced additive

The invention provides a novel mine filling quick-setting enhanced additive and belongs to the technical field of underground filling of metal mines. The novel mine filling quick-setting enhanced additive comprises the following components in percentage by weight: 10-40wt% of a slurry rheological agent, 20-35wt% of an alkaline activator, 15-35wt% of an accelerator and 15-30wt% of an early strengthagent. According to the invention, the function of mine filling slurry is studied, the slurry rheological agent, the alkaline activator, the accelerator and the early strength agent are selected as raw materials, the ratio of the raw materials is adaptively researched, and finally, the novel mine filling quick-setting enhanced additive which enables mine filling slurry to have good flowing property, quick setting time and high early strength is obtained. And under the condition that the additive is used, the performance of a filling material can be effectively improved, it is guaranteed thatthe filling slurry can keep good rheological property, rapid hardening effect, high strength, good volume stability, low settling shrinkage rate and other characteristics under large-volume and different-concentration conditions, and all the properties are excellent.

Owner:HEBEI JINTAICHENG BUILDING MATERIAL

Alkali-free liquid accelerator and production process thereof

The invention provides an alkali-free liquid accelerator and a production process thereof. In the prior art, the performance of concrete is influenced by a large mixing amount of an alkali-free liquidaccelerator. A purpose of the invention is to solve the technical problem in the prior art. The alkali-free liquid accelerator is prepared from the following raw materials in parts by weight: 50-70 parts of polyaluminum sulfate, 3-6 parts of sodium fluoride, 8-12 parts of aluminum alkoxide, 1-2 parts of triethanolamine, 1-2 parts of diethanol amine, 0.5-1.0 part of magnesium silicate, 1-3 parts of glycerol, 1-3 parts of a thickening agent, 1-5 parts of an inorganic acid, and 30-40 parts of deionized water. According to the alkali-free liquid accelerator provided by the invention, the accelerator prepared by taking polyaluminum sulfate as a main raw material has good accelerating effect, and the mixing amount of the accelerator can be reduced, namely, the introduction of sulfate ions is reduced, so that the damage of the accelerator to the later strength of concrete is reduced, and the stability of the accelerator is improved while the mixing amount is reduced.

Owner:四川恒泽建材有限公司

Preparation method of cement setting accelerator

The invention relates to a preparation method of a cement setting accelerator, and belongs to the technical field of building materials. Starch is modified with beta-cyclodextrin, the beta-cyclodextrin is formed by polymerizing seven molecules of D-glucopyranose, and has a cone-like pore cavity, straws are modified with maleic anhydride to introduce a double bond and a carboxylic acid group to themolecular chain of the straws, the modified straws are mixed with water absorbent resin containing a carboxyl group, a hydroxyl group, an amido group a sulfonic acid group, the maleic anhydride-modified straws are mixed with diatomite, the diatomite has an orderly micro-porous structure with a large porosity, micro-pores have large sizes and can adsorb a large amount of the modified straw particles, and the modified straw particles contain the carboxyl group introduced by the maleic anhydride in order to avoid the agglomeration phenomenon of organic molecules and increase the contact area between the molecules and the outside, so moisture in the cement can be sufficiently and efficiently absorbed, the quick-setting effect is enhanced, and the cement setting accelerator has a broad application prospect.

Owner:FOSHAN LINGCHAO NEW MATERIAL CO LTD

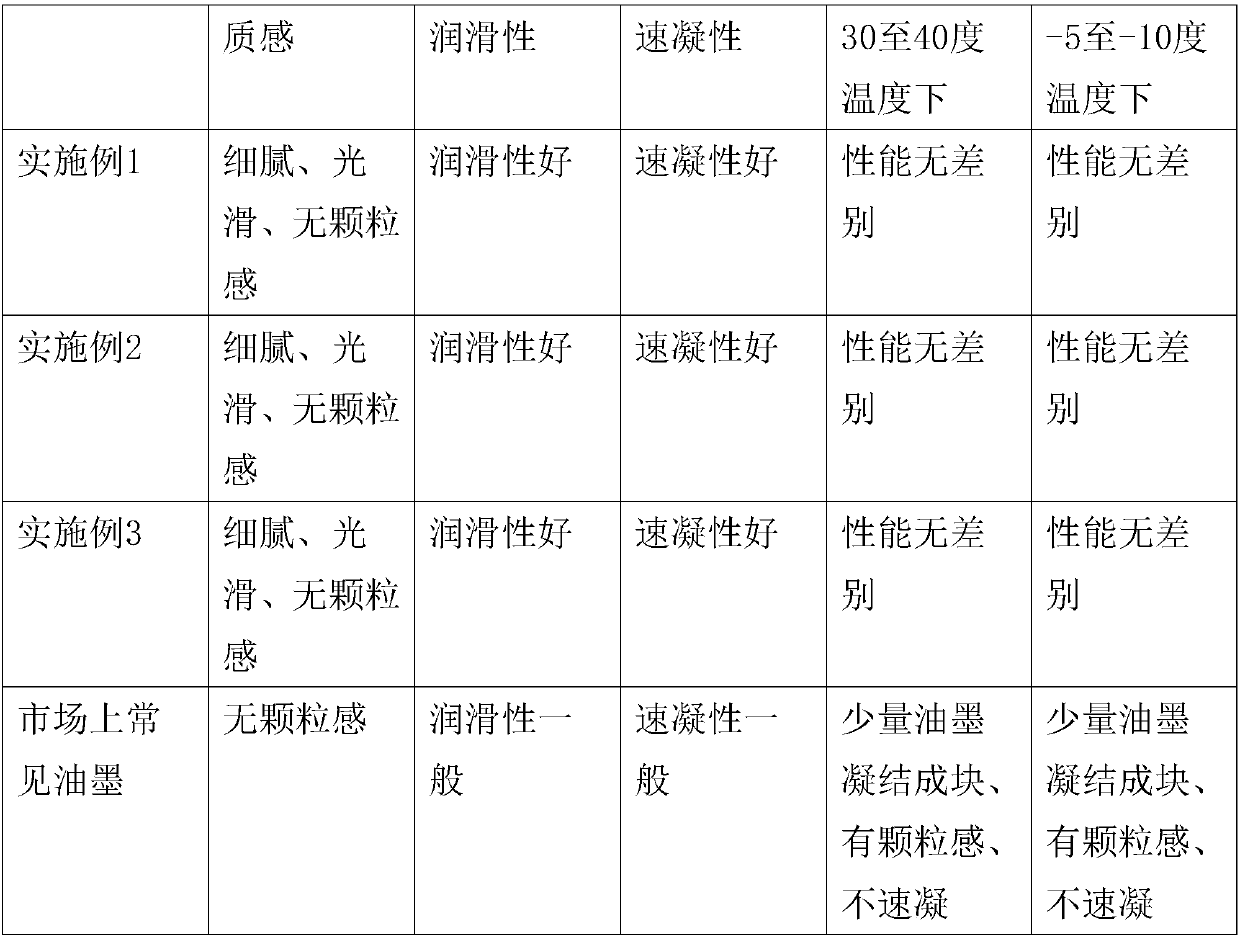

Accelerating agent for printing ink

The invention provides an accelerating agent for printing ink, and relates to the technical field of printing. A production technology is simple, and raw materials are green and safe and have no toxicaction; the produced ink has a good setting accelerating property; a modifying agent is added and a preparation technology is improved, so that the accelerating agent has optimized performance including oxidization resistance, ageing resistance, lubricating property and the like.

Owner:BENGBU KUNLUN COLOR PRINTING PACKAGING CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com