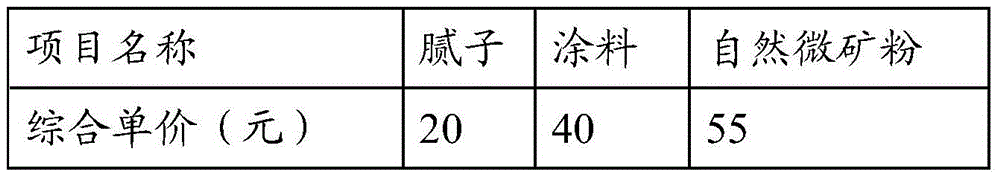

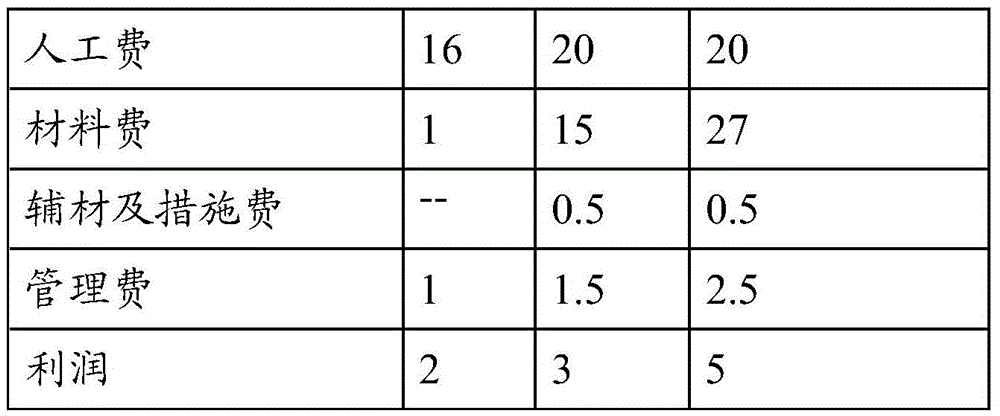

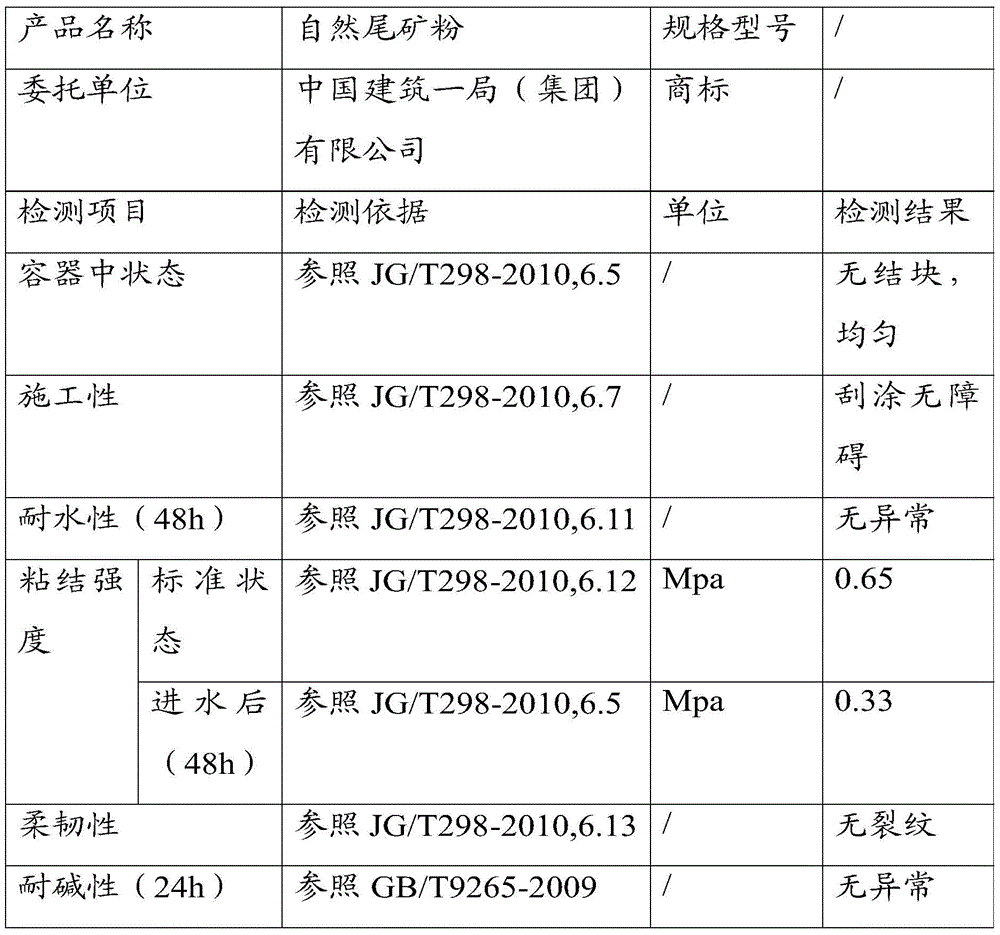

Natural micro-mineral powder

A technology of fine ore powder and natural ore powder, which is applied in the field of building materials, can solve the problems of poor water resistance and decoration, long processing time, slow hardening speed, etc., and achieve the effect of saving construction period, labor and cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] Natural Micro Mineral Powder:

[0041] White marble mineral powder 60kg, corundum 20kg, white cement 20kg, slaked lime 30kg, hydroxyethyl cellulose 2kg, ethylene-vinyl acetate copolymer 1.5kg, cross-linked starch 0.8kg and polysiloxane powder 1.5kg.

Embodiment 2

[0043] Natural Micro Mineral Powder:

[0044] White marble mineral powder 90kg, corundum 10kg, white cement 30kg, slaked lime 20kg, polypropylene fiber 5kg, ethylene-vinyl acetate copolymer 0.8kg, acid-modified starch 1.5kg and inorganic aluminum salt 0.8kg.

Embodiment 3

[0046] Natural Micro Mineral Powder:

[0047] White marble mineral powder 90kg, corundum 10kg, white cement 40kg, slaked lime 40kg, hydroxypropyl methylcellulose 2-5kg, vinyl acetate-vinyl tertiary carbonate copolymer 1.5kg, dialdehyde starch 1.5kg and polysiloxane powder 1.5kg.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com