Powder alkali-free accelerator as well as preparation method, use method and application thereof

A technology of quick-setting agent and powder, which is applied in the field of building materials, can solve the problems of uneven concrete quality, affecting the durability of concrete, and difficult control of water-cement ratio, so as to shorten the initial and final setting time, superior quick-setting effect, and production low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

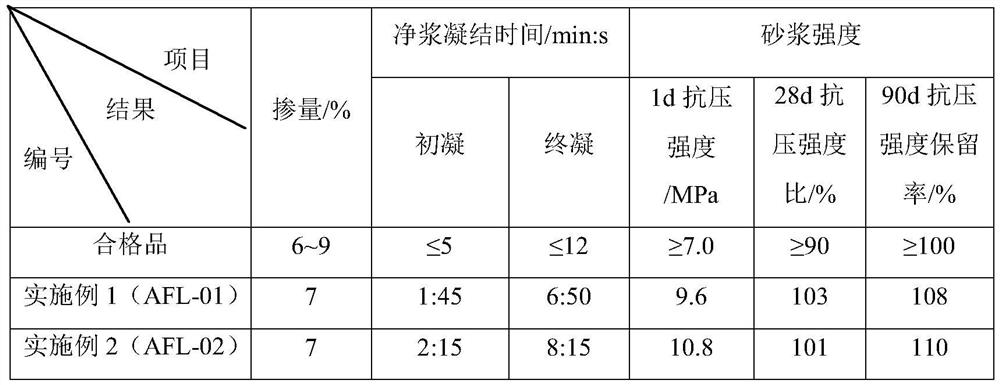

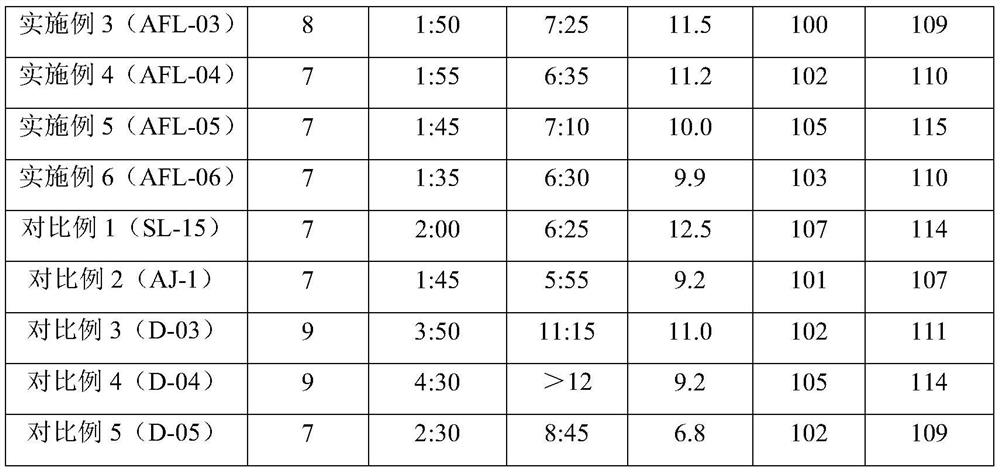

Examples

Embodiment 1

[0040] A powder alkali-free accelerator, 750 parts by weight of industrial aluminum sulfate, 40 parts by weight of magnesium fluorosilicate, 30 parts by weight of 3000 mesh zeolite powder, 70 parts by weight of diethanolamine, 15 parts by weight of triisopropanolamine, heptahydrate 65 parts by weight of magnesium sulfate, 20 parts by weight of aqueous organic bentonite, and 10 parts by weight of heavy magnesium oxide.

[0041] The preparation method of embodiment 1 powder alkali-free quick-setting agent comprises the steps:

[0042] (1) Add zeolite powder into the vertical double-helix conical mixer, slowly inject diethanolamine and triethanolamine solutions into the feeding port, and the feeding time is 30 minutes; then mix and stir the two materials for 30 minutes;

[0043] (2) Put aluminum sulfate, magnesium fluorosilicate, early strengthening agent, stabilizer and neutralizing agent into the mixer, mix and stir for 45 minutes, so that all materials are mixed evenly, and th...

Embodiment 2

[0046]A powder alkali-free accelerator, 800 parts by weight of industrial aluminum sulfate, 50 parts by weight of magnesium fluorosilicate, 20 parts by weight of 5000 mesh zeolite powder, 60 parts by weight of diethanolamine, 35 parts by weight of anhydrous magnesium sulfate, magnesium silicate 20 parts by weight of aluminum and 15 parts by weight of magnesium hydroxide. The preparation method is the same as in Example 1. A powder-free alkali-free setting accelerator is obtained. No water is added during the preparation process, and the water content is not more than 2wt%.

[0047] The method of using the powder non-alkali quick-setting agent: stir and dissolve the obtained powder non-alkali quick-setting agent and water according to the mass ratio of 650:350, and the code is AF-02.

Embodiment 3

[0049] A powder alkali-free accelerator, 780 parts by weight of industrial aluminum sulfate, 35 parts by weight of magnesium fluorosilicate, 30 parts by weight of 5000 mesh zeolite powder, 90 parts by weight of diethanolamine, 40 parts by weight of anhydrous magnesium sulfate, magnesium silicate 25 parts by weight of aluminum. The preparation method is the same as in Example 1. A powder-free alkali-free setting accelerator is obtained. No water is added during the preparation process, and the water content is not more than 2wt%.

[0050] The method of using the powder non-alkali quick-setting agent: stir and dissolve the obtained powder non-alkali quick-setting agent and water according to the mass ratio of 600:400, and the code is AF-03.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com