Oily wastewater treatment process

A wastewater treatment and process technology, applied in water/sewage treatment, neutralized water/sewage treatment, water/sewage multi-stage treatment, etc. It can solve the problems of complex materials, etc., to achieve the effect of small footprint, promotion of oil-water separation, and less tail sludge production.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039]Embodiment 1: the concrete structure of the present invention is as follows:

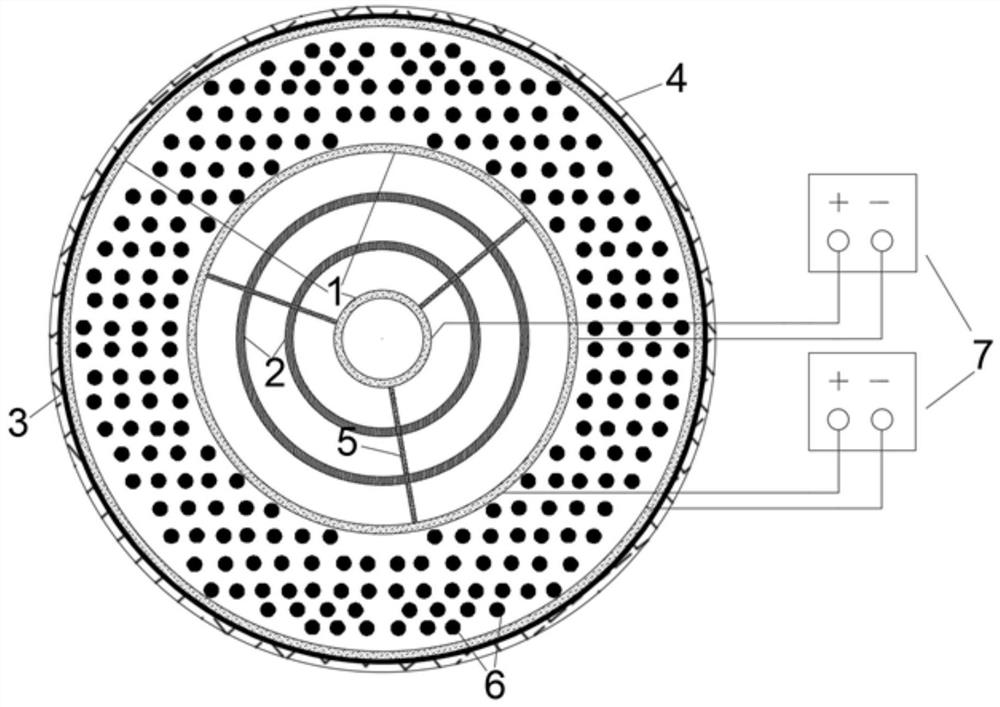

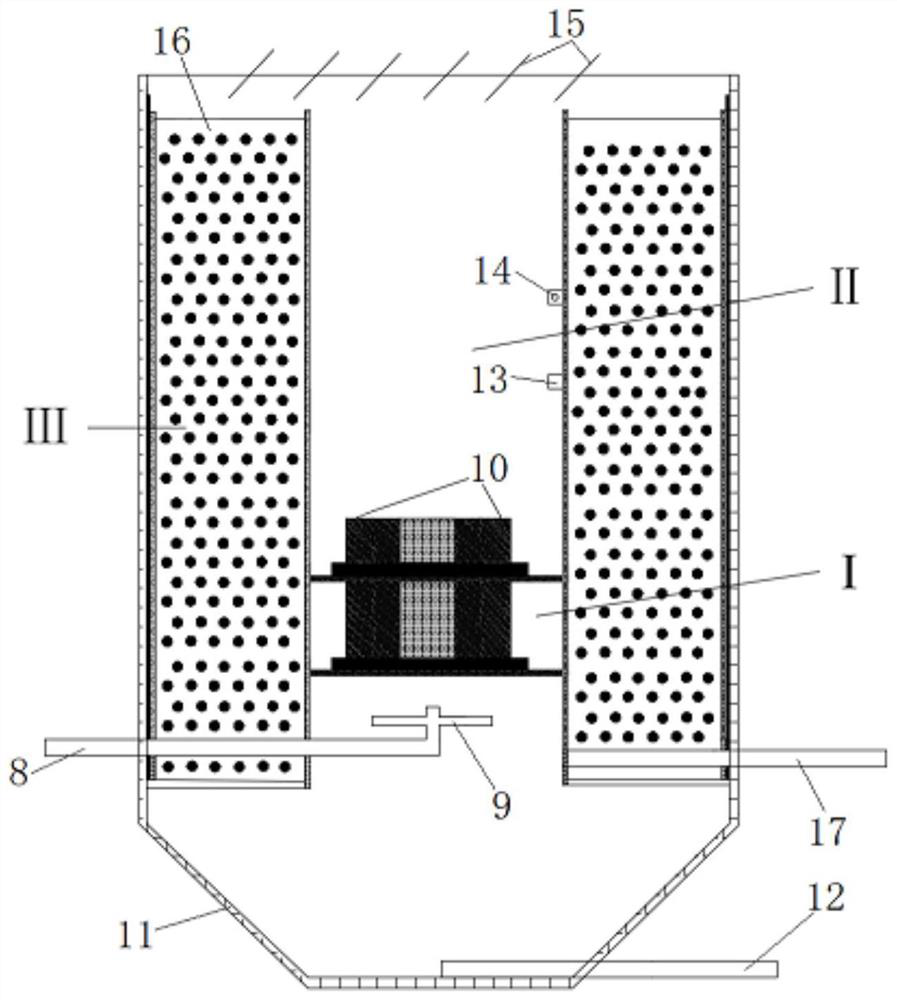

[0040] Please refer to attached Figure 1-2 , a kind of oily waste water treatment process of the present invention, this process comprises a waste water treatment device that is provided with water inlet pipe 8 and water outlet pipe 17, and this waste water treatment device comprises three metal rings 1 that form concentric circles from inside to outside, three A first electric field and a second electric field can be formed after a metal ring 1 is energized, and the process includes the following steps:

[0041] Step 1, performing demulsification treatment on the oily wastewater treated by the grease trap;

[0042] In step 2, the oily wastewater after demulsification treatment in step 1 enters the inner ring cavity in the wastewater treatment device through the water inlet pipe 8, and the lower part of the inner ring cavity is provided with an electrode reaction assembly and an electrode re...

Embodiment 2

[0060] The following is the working principle of the oily wastewater treatment process of an embodiment in this embodiment:

[0061] The oily wastewater enters the integrated treatment device from the water inlet pipe 8, and under the action of the swirl generator 9, the wastewater rotates up in the reactor.

[0062] The waste water enters the electrolysis reaction zone Ⅰ, where two stainless steel rings connected to the DC power supply 7 are placed. The distance between the middle ring and the inner ring is 40-60 cm. There are aluminum or iron sensing electrodes, and the distance between the aluminum or iron sensing electrodes is 5-10cm.

[0063] Turn on the DC power supply and adjust the current density of the stainless steel electrode to 10A / m 2 ~100A / m 2 , at this time, a second electric field is generated between the stainless steel rings, so the surfaces of the aluminum or iron electrodes form cathodes and anodes respectively. On the surface of the anode, the aluminum...

Embodiment 3

[0069] The following is an oily wastewater treatment process of an embodiment in this embodiment, which specifically includes the following steps:

[0070] Step 1: Demulsify the oily wastewater treated in the grease trap, and then enter the integrated electrochemical treatment device through the water inlet pipe 8;

[0071] Step 2, the oily wastewater enters the electrolysis reaction zone I through the swirl generator 9, inserts aluminum rings into the electrode slot 2, the distance between each aluminum ring is 5cm, and adjusts the current density to 10A / m 2 , electrolysis for 10min;

[0072] Step 3, the electrolyzed wastewater enters the contact zone II, and the pH is adjusted to 7, and a 2 mg / L polyacrylamide solution is added;

[0073] Step 4, under the action of swirling flow, aluminum hydroxide colloid, polymer flocculant, suspended particles, oil droplets and micro-bubbles are fully contacted, and rise to the water surface to form scum, which is scraped out by the scra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com