Patents

Literature

85 results about "Magnesium fluorosilicate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Cement sealing and solidifying agent and construction technique thereof

InactiveCN104016714APlugging structural voidsImprove hardened wear resistanceSodium silicateMagnesium fluorosilicate

The invention relates to a construction paint, particularly a lithium-base permeable crystallization cement sealing and solidifying agent. The cement sealing and solidifying agent is composed of 15-20 parts of sodium silicate, 8-15 parts of lithium metasilicate, 3-5 parts of magnesium fluosilicate, 2-4 parts of sodium dihydrogen phosphate, 0-6 parts of water-based color paste for paint and 50-70 parts of water. The construction technique comprises the following steps: new ground: troweling the new ground, carrying out primary hardening, coating the solidifying agent, completely drying and curing, flushing the ground with clear water, naturally drying, and sanding and polishing with a sander; and old ground: sanding and cleaning the old ground, coating the solidifying agent, naturally drying, cleaning the ground, naturally drying, and sanding and polishing (or additionally coating solidifying agent, cleaning the ground, naturally drying, and sanding and polishing). By using the solidifying agent and construction technique, the strength, hardness and compactness of the concrete are greatly enhanced, and the durability and weathering resistance of the concrete are effectively improved.

Owner:HARBIN UNIV OF SCI & TECH

Compound soil remediator and preparation method thereof

ActiveCN104449753ADemeton clearReduce pollutionOrganic fertilisersSoil conditioning compositionsPolyethylene oxidePolypropylene

The invention belongs to the field of soil remediation and discloses a compound soil remediator and a preparation method thereof. The compound soil remediator comprises the following components in parts by weight: 13-24 parts of polyamide fibers, 5-13 parts of chitosan, 9-20 parts of sodium polyacrylate, 8-17 parts of polyethylene oxide, 5-14 parts of quicklime, 7-12 parts of magnesium fluosilicate and 4-10 parts of sodium bismuthate. The preparation method comprises the following steps: weighing the polyamide fibers, chitosan, sodium polyacrylate, polyethylene oxide, quicklime, magnesium fluosilicate and sodium bismuthate; and after uniformly mixing various components of the soil remediator, sealing to prepare the compound soil remediator.

Owner:JIANGSU GAIYA ENVIRONMENTAL SCI & TECH CO LTD

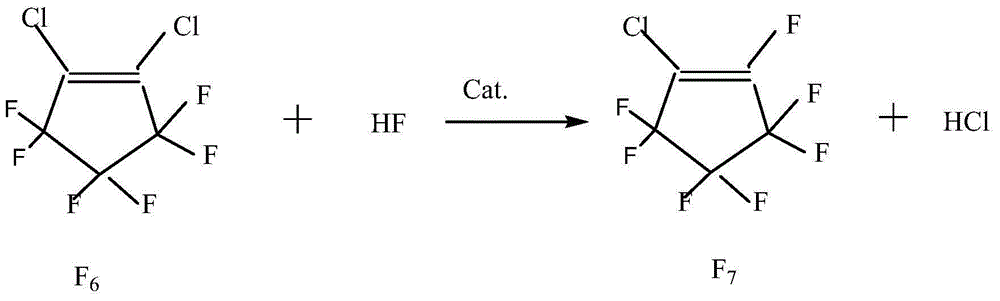

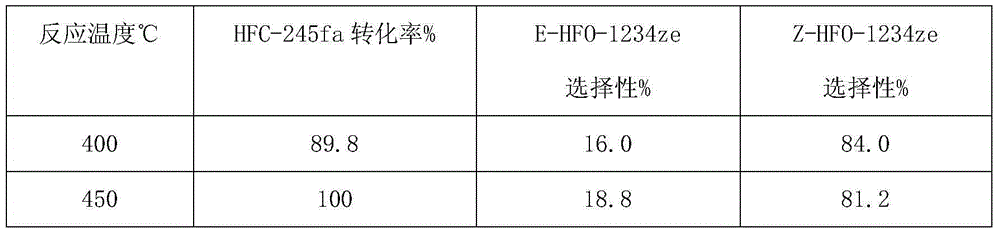

Chromium base catalyst, and preparation method and use thereof

InactiveCN104907063AInhibit carbon depositionCatalytic activity unchangedPreparation by hydrogen halide split-offPreparation by halogen replacementCalcium silicateChemical synthesis

The invention discloses a chromium base catalyst, and a preparation method and a use thereof, and belongs to the field of chemical synthesis. The precursor of the catalyst is composed of 90-99.9mass% of a trivalent chromium compound and 0.1-10mass% of a silicon-containing compound, wherein the trivalent chromium compound is chromic oxide or chromium hydroxide, and the silicon-containing compound can be zinc silicate, nickel silicate, magnesium silicate, aluminum silicate, zirconium silicate, barium silicate, bismuth silicate, ammonium fluorosilicate, nickel hexafluorosilicate, zinc fluorosilicate, magnesium fluorosilicate, aluminum fluorosilicate or calcium fluorosilicate The chromium base catalyst has the advantages of large specific surface area, effective inhibition of carbon formation, and long service life, is mainly used for gas phase catalysis of reactions for preparing hydrofluorocarbons or fluorinated alkenes from halogenated hydrocarbons or halogenated alkenes at a high temperature, and can also be used for gas phase catalysis of reactions for preparing hydrofluoroalkenes through hydrogen fluoride removal of hydrofluorocarbons at a high temperature.

Owner:BEIJING YUJI SCI & TECH

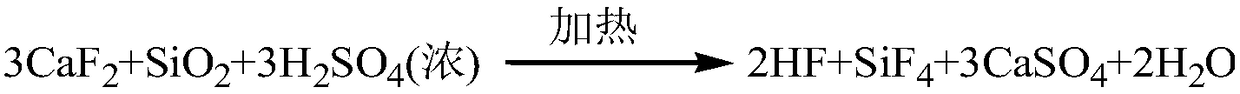

Method for producing hydrofluoric acid and waterless magnesium sulfate

The process of producing hydrofluoric acid and anhydrous magnesium sulfate with fluorosilicic acid and magnesia as material includes the following steps: 1. reacting fluorosilicic acid solution and magnesia for 10-60 min, filtering to obtain magnesium fluosilicate solution, and concentrating to obtain crystal magnesium fluosilicate hexahydrate; 2. decomposing magnesium fluorosilicate hexahydrate at 100-500 deg.c for 1-5 hr to produce solid magnesium fluoride, gaseous silicon tetrafluoride and water vapor; 3. absorbing gaseous silicon tetrafluoride and water vapor with water and hydrolyzing, and filtering to obtain fluorosilicic acid solution returned to the step 1 and silica, washing and drying to obtain carbon white; and 4. reacting the solid magnesium fluoride and 98 % over sulfuric acid, condensing the produced gas condensing and rectifying to obtain hydrofluoric acid, and obtaining anhydrous magnesium sulfate product.

Owner:DO FLUORIDE CHEM CO LTD

Method for producing hydrofluoric acid, waterless magnesium sulfate and sodium fluoride

The process of producing hydrofluoric acid, anhydrous magnesium sulfate and sodium fluoride with sodium fluorosilicate and magnesia as material includes the following steps: 1. decomposing sodium fluorosilicate to produce sodium fluoride product and silicon tetrafluoride gas; 2. absorbing the gas with water, filtering to prepare fluorosilicic acid solution for preparing magnesium tetrafluoride, washing silica and drying to obtain carbon white; 3. reacting fluorosilicic acid solution and magnesia, filtering to obtain magnesium fluorosilicate solution, and concentrating to obtain crystal magnesium fluorosilicate hexahydrate; 4. decomposing magnesium fluorosilicate hexahydrate to produce magnesium fluoride solid, silicon tetrafluoride gas and water vapor; 5. absorbing the gas with water and hydrolyzing, filtering to obtain fluorosilicic acid solution returned to the step 3, washing silica and drying to obtain carbon white; and 6. reacting magnesium fluoride and sulfuric acid, condensing and rectifying to obtain hydrofluoric acid, and obtaining anhydrous magnesium sulfate.

Owner:DO FLUORIDE CHEM CO LTD

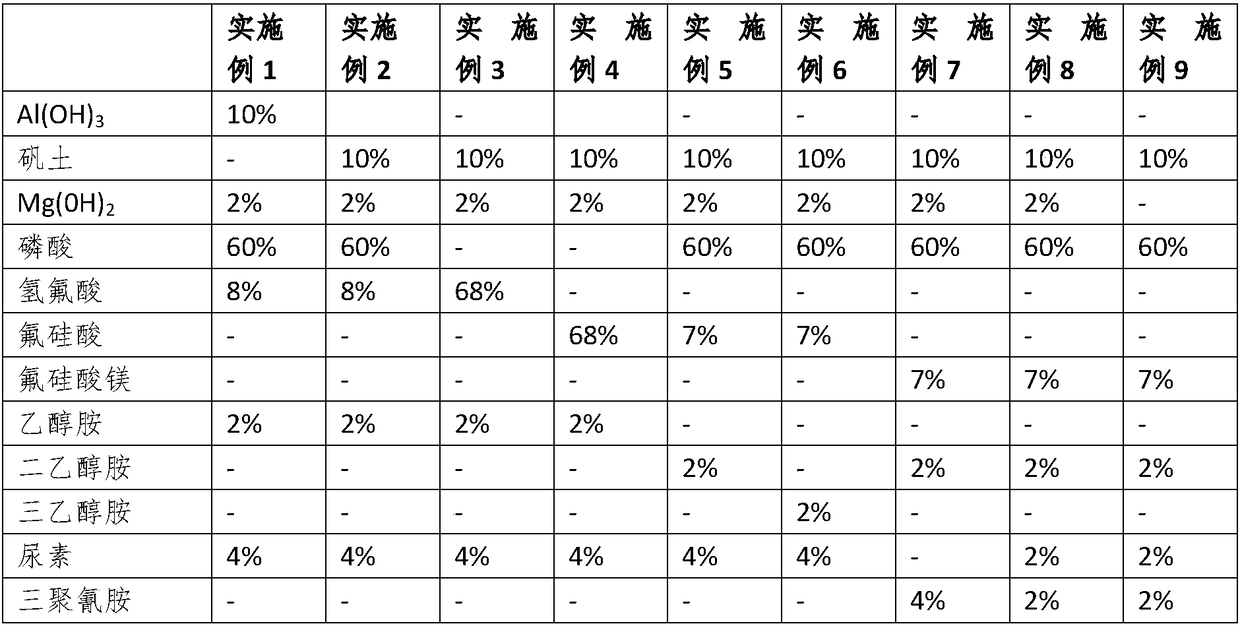

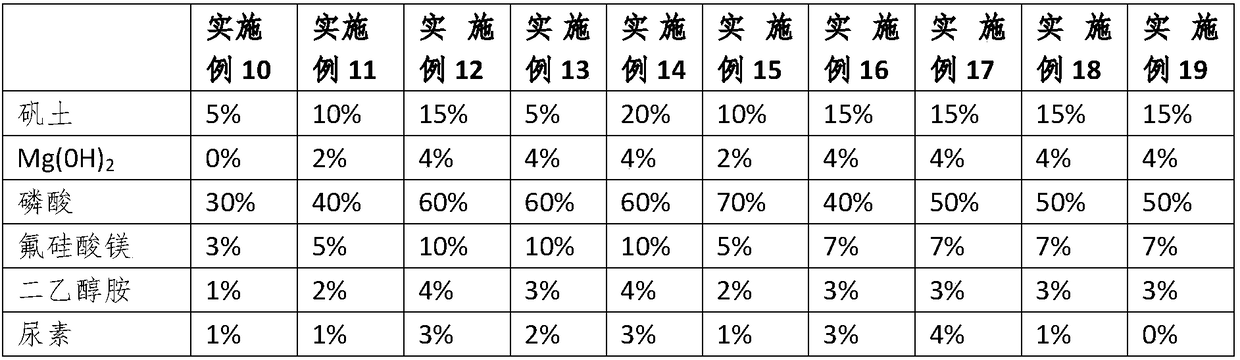

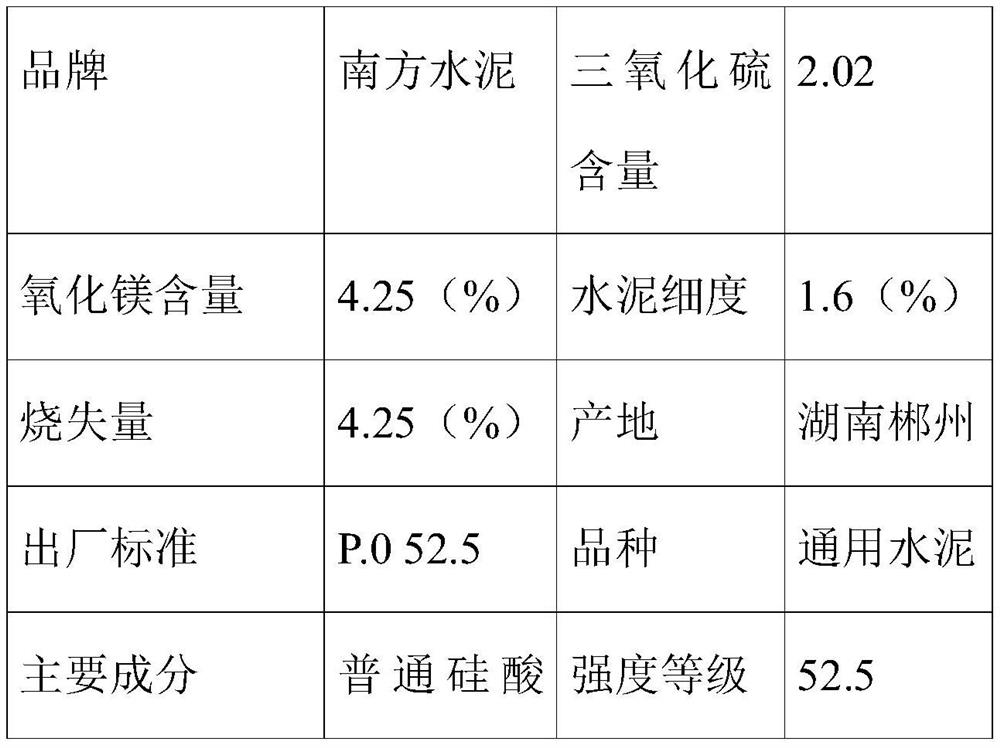

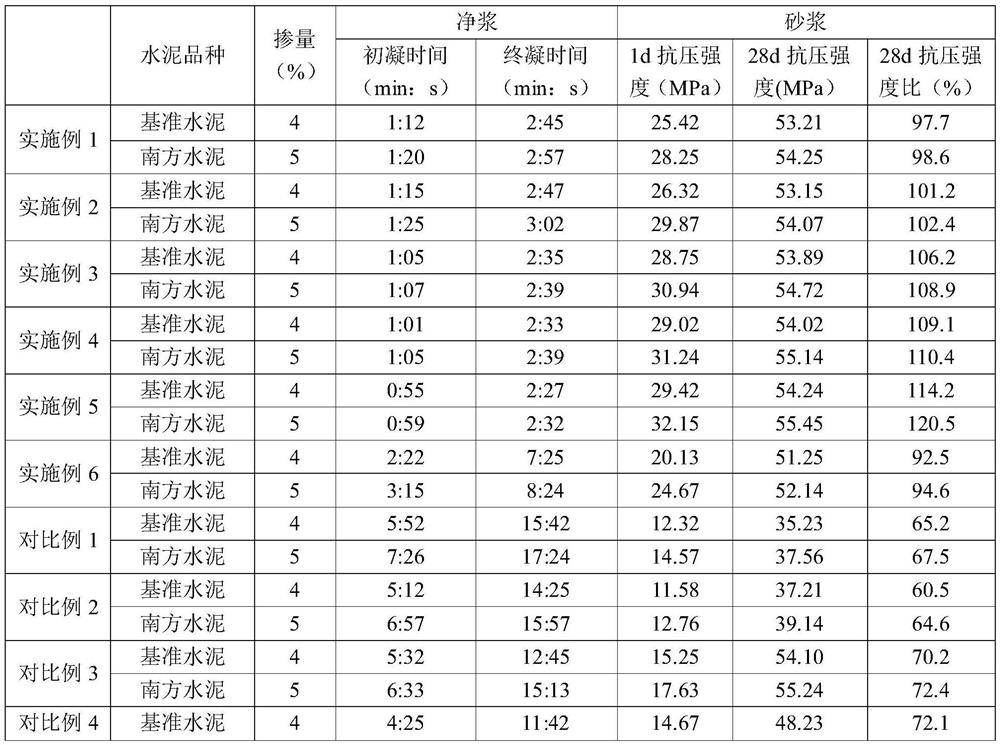

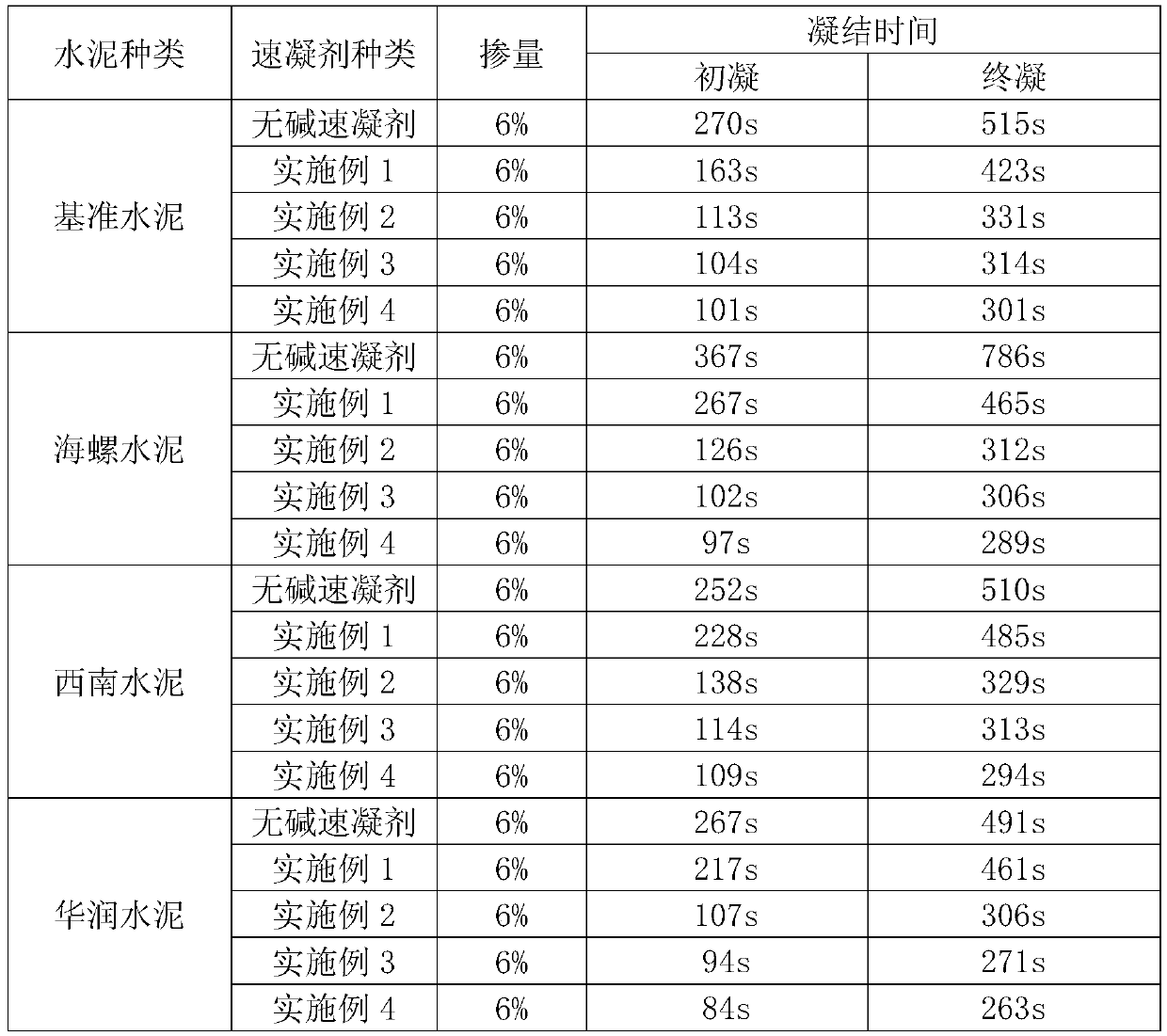

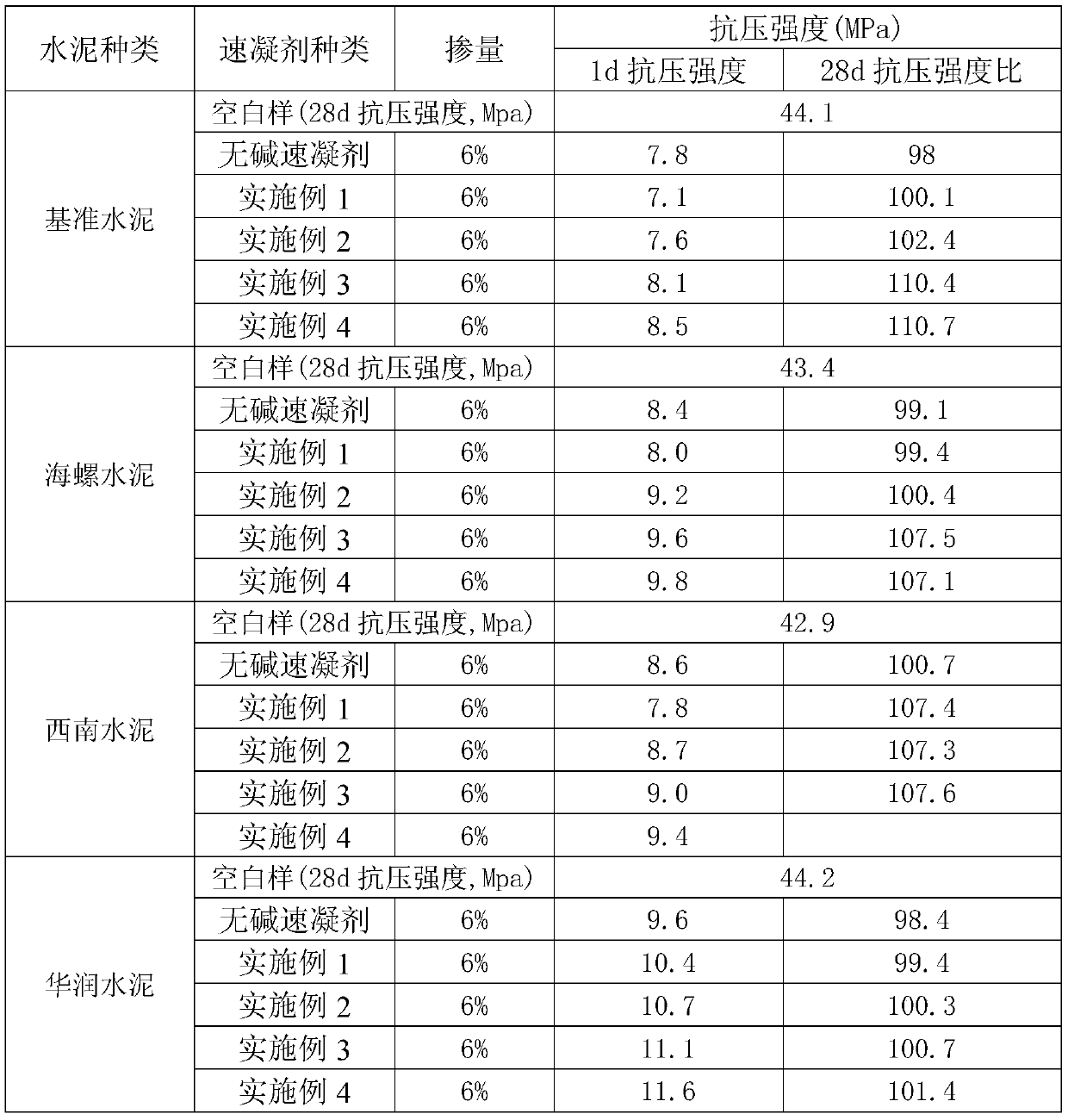

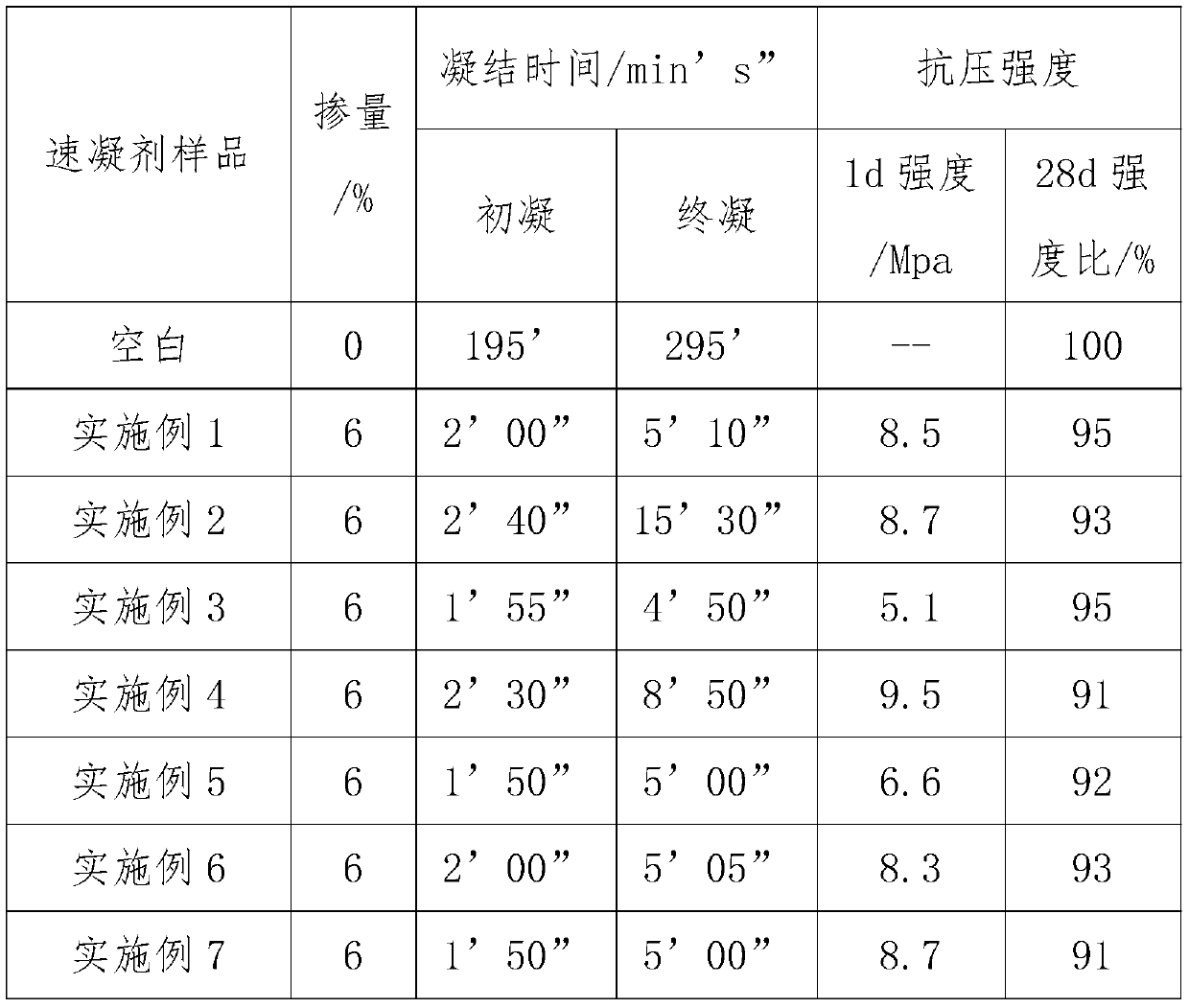

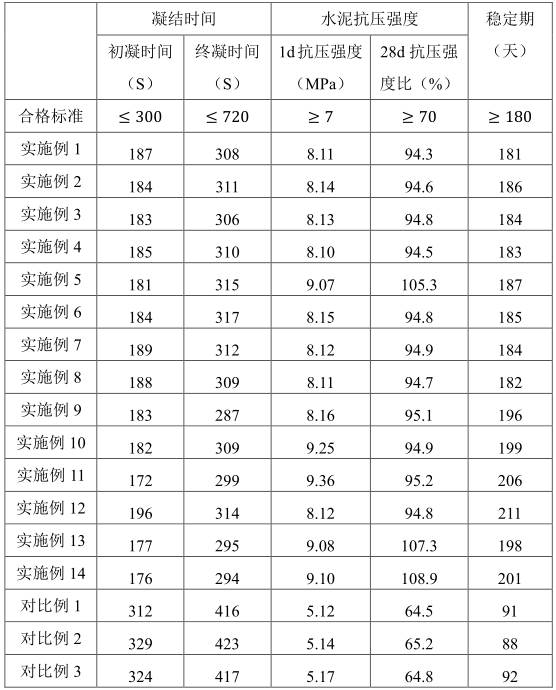

Polyaluminium phosphate-series chlorine-free sulfur-free liquid alkali-free accelerator and preparation method thereof

The invention discloses a polyaluminium phosphate-series chlorine-free sulfur-free liquid alkali-free accelerator and a preparation method thereof and relates to the technical field of alkali-free accelerators. The alkali-free accelerator comprises, by mass, 50-60% of phosphoric acid, 10-15% of alumina, 5-10% of magnesium fluorosilicate, 2-4% of magnesium hydroxide, 2-4% of diethanolamine, 2-6% ofa condensing agent and the balance of water. The accelerator is mainly used in shotcrete, and the use amount of the accelerator is 5 to 7% of that of a gelling material. The accelerator has good stability and does not produce layering and precipitation crystallization and use effect change after being placed at the room temperature and a low temperature (5 DEG C) for 3 months. The accelerator does not contain alkali metal ions, chloride ions and sulfate ions so that the corrosion of the steel bars in the concrete and the alkali aggregate reaction are reduced and the durability of the shotcrete is improved. Through a compatibility of the condensing agent, the compressive strength ratio measured at 28th days is greater than 100% and satisfies the requirement on the one-grade product in JC477-2005.

Owner:贵州天威建材科技有限责任公司

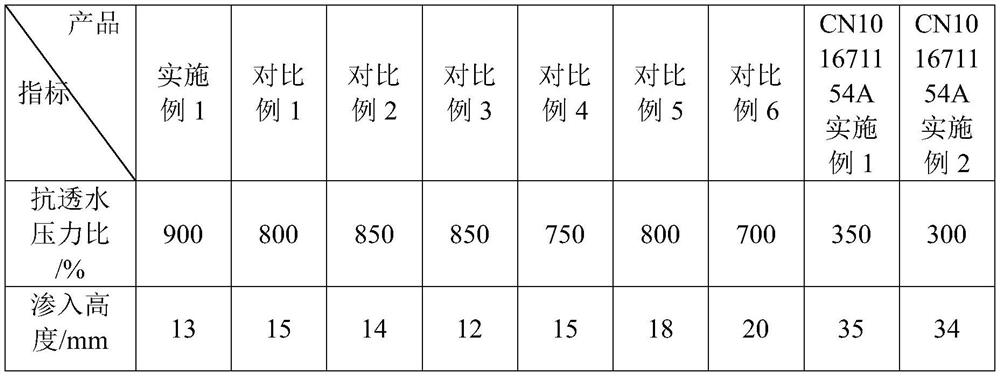

Self-healing backwater surface waterproof material capable of stopping open water, preparation method and application thereof

ActiveCN111825411AAchieve the effect of self-healing and self-repairingImprove self-waterproof performanceSolid waste managementProtective foundationAluminateAntiseptic Agent

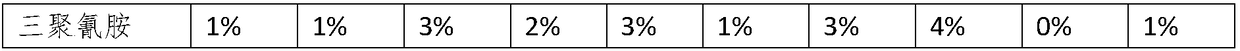

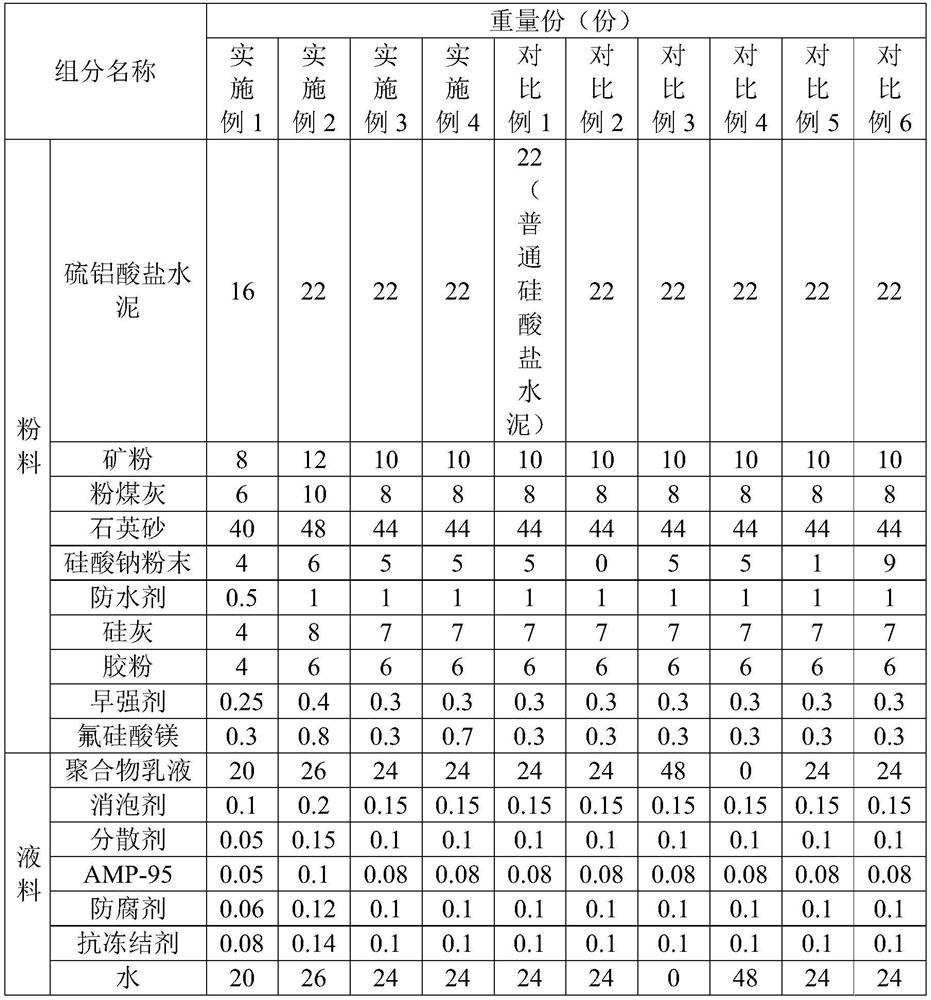

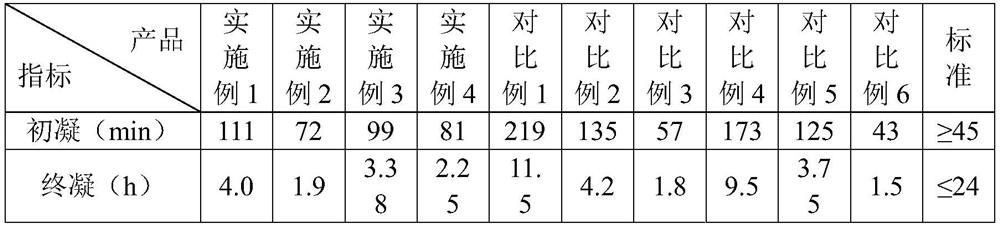

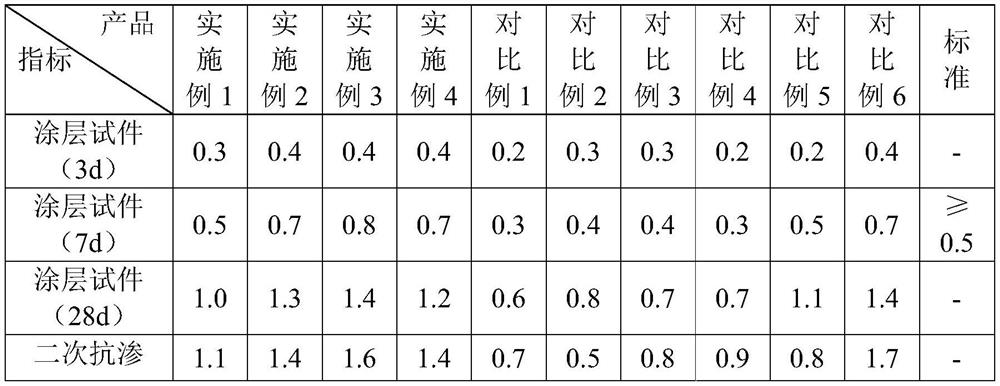

The invention discloses a self-healing backwater surface waterproof material capable of stopping open water, a preparation method and application thereof. The material comprises the following powder materials by weight: 16-22 parts of sulphoaluminate cement, 8-12 parts of mineral powder, 6-10 parts of fly ash, 40-48 parts of quartz sand, 4-6 parts of sodium silicate, 0.5-1 part of a waterproof agent, 4-8 parts of silica fume, 4-6 parts of rubber powder, 0.25-0.4 part of an early strength agent and 0.3-0.8 part of magnesium fluosilicate; and the liquid materials: 20-26 parts of a polymer emulsion, 0.1-0.2 part of an antifoaming agent, 0.05-0.15 part of a dispersant, 0.05-0.1 part of a multifunctional auxiliary agent, 0.06-0.12 part of an antiseptic, 0.08-0.14 part of an anti-freezing agentand 20-26 parts of water. The material disclosed by the invention is good in durability, impermeable, anti-cracking and anti-freezing; and the waterproof material is simple and convenient to manufacture and convenient to construct, has self-repairing and self-healing effects when leakage occurs again, and achieves an efficient and long-lasting waterproof effect.

Owner:SUZHOU GUARDEX NEW MATERIAL TECH CO LTD

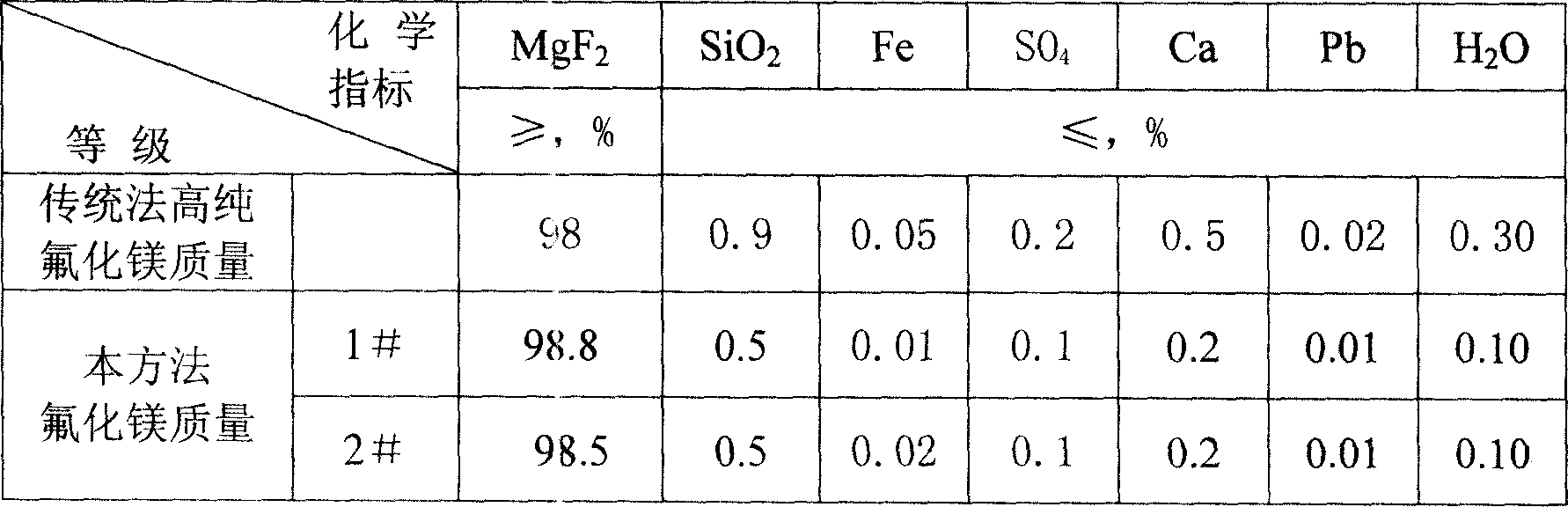

Preparation method of high-purity magnesium fluoride

InactiveCN101134585AReduce total usageReduce pollutionMagnesium fluoridesSilicon oxidesWater vaporPhysical chemistry

Owner:DO FLUORIDE CHEM CO LTD

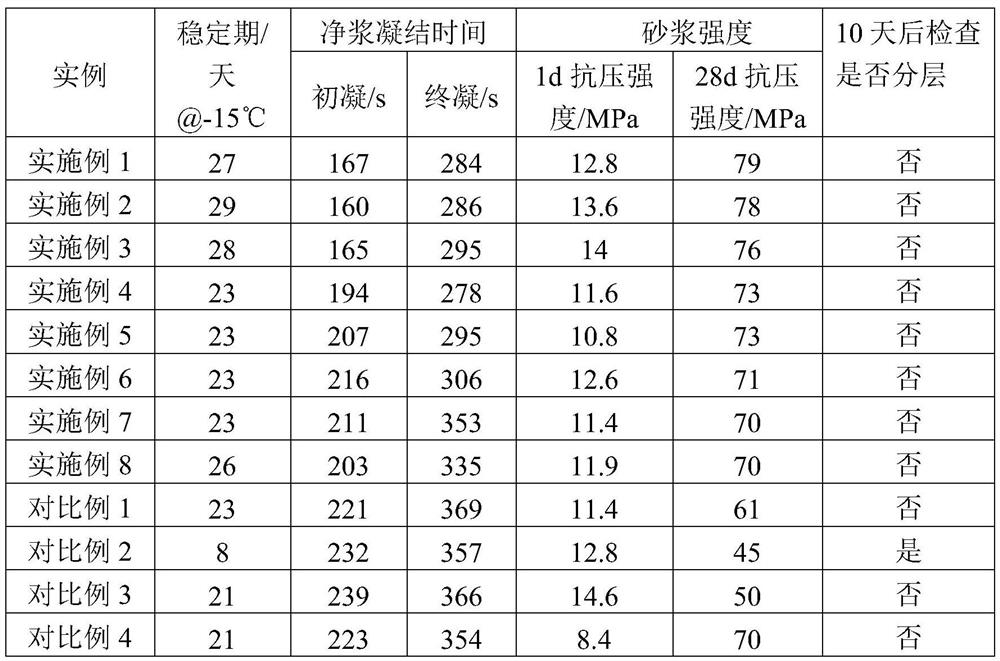

Concrete accelerator and preparation method thereof

The invention provides a concrete accelerator. The concrete accelerator is prepared from the following raw materials: aluminum sulfate, aluminum nitrate, phosphoric acid, ammonia water, a halloysite nanotube modified alkylol amine polymer grinding aid, a stabilizer, magnesium fluorosilicate, a tackifier and water. Various coagulation accelerating components are compounded, the coagulation time ofsprayed concrete can be further shortened, the comprehensive performance of cement is improved, a good coagulation accelerating effect is achieved on premixed concrete subjected to initial hydration,the coagulation time of the concrete can be obviously shortened, the early strength is improved, the stability, durability and safety of the concrete can be remarkably improved, and the cost is low. The concrete accelerator is particularly suitable for premixed concrete spraying construction of long-time and long-distance transportation.

Owner:海南佳益混凝土有限公司

Method for preparing aluminun fluoride, waterless magnesium sulfate and sodium fluoride

ActiveCN101134589AReduce total usageReduce pollutionMagnesium sulfatesSilicon oxidesAluminium hydroxideWater vapor

The process of preparing aluminum fluoride, anhydrous magnesium sulfate and sodium fluoride includes the following steps: 1. decomposing sodium fluorosilicate to produce sodium fluoride solid and silicon tetrafluoride gas; 2. absorbing silicon tetrafluoride gas with water and hydrolyzing, and washing and drying silica to obtain carbon white; 3. reacting fluorosilicic acid solution and magnesia, filtering and concentrating to obtain crystal magnesium fluorosilicate hexahydrate; 4. decomposing magnesium fluorosilicate hexahydrate to produce magnesium fluoride solid, silicon tetrafluoride gas and water vapor; 5. absorbing silicon tetrafluoride gas and water vapor with water and hydrolyzing, and washing and drying silica to obtain carbon white; 6. reacting magnesium fluoride and sulfuric acid to produce anhydrous magnesium sulfate, condensing and rectifying to obtain anhydrous hydrofluoric acid; and 7. reacting anhydrous hydrofluoric acid and aluminum hydroxide to produce aluminum fluoride.

Owner:BAIYIN ZHONGTIAN CHEM

Film-forming permeable waterproof material, preparation method and application thereof

The invention discloses a film-forming permeable waterproof material, and a preparation method and application thereof. The waterproof material comprises a component A and a component B. The componentA comprises sodium silicate, a surfactant, a reaction retarder, a reducing agent, a reaction promoter, an anti-freezing agent, a metal ion blocking agent, a surface enhancer, an antirust agent, a photoinitiator, a cross-linking agent, water and an acrylate emulsion. The component B comprises white cement, gypsum, silica fume, mineral powder, fly ash, citric acid, magnesium fluosilicate, magnesiumoxide, sodium silicate, a reinforcing component and fumed silica. The film-forming permeable waterproof material is suitable for various environments, can achieve a good waterproof effect on buildingstructures in any environment, and can form a seamless complete high-strength waterproof coating film to prevent leakage; large-scale machining is not needed, the production efficiency is high, the investment is small, the construction is convenient, heating and boiling are not needed, environmental protection and no pollution are realized, and the labor cost is greatly reduced.

Owner:苏州佳固士新材料科技有限公司

Chemical fastening method for arenoso

InactiveCN1614153ASuitable for protectionTo achieve the purpose of reinforcementOther chemical processesSoil preservationMagnesium fluorosilicateOrganic chemistry

A chemical stabilization method for arenoso rock features that after the solution of magnesium fluorosilicate is sprayed, the organosilicone consolidating agent WD-WO2 is sprayed.

Owner:INST OF ROCK & SOIL MECHANICS CHINESE ACAD OF SCI

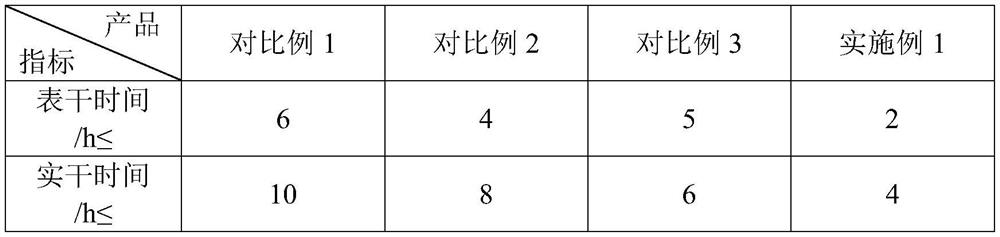

Low-alkali setting accelerator, and preparation method and application thereof

The invention discloses a low-alkali setting accelerator and a preparation method thereof. The low-alkali setting accelerator is prepared from aluminum sulfate, sodium metaaluminate, magnesium fluosilicate, hydrofluoric acid, triethanolamine, a stabilizer, an inorganic modified material and water. The preparation method comprises the following steps: 1, mixing aluminum sulfate I, sodium metaaluminate and water I to obtain a solution I; 2, sequentially adding magnesium fluosilicate and hydrofluoric acid into the solution I to obtain a solution II; 3, mixing aluminum sulfate II, water II and thesolution II to obtain a solution III; and 4, mixing aluminum sulfate III, triethanolamine, a stabilizer, an inorganic modified material and the solution III. The low-alkali setting accelerator provided by the invention has good low-temperature stability, and still has short setting and hardening time and good strength at a low temperature.

Owner:SHANXI SUNWAY INTION TRADE CO LTD

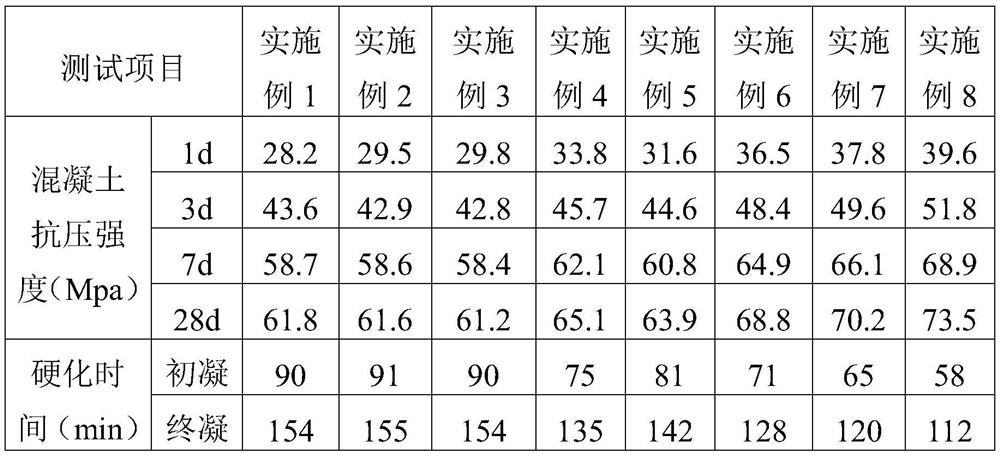

Early strength agent and application thereof in concrete material

ActiveCN111960709AImprove performanceMeet strength requirementsLithium sulphateStructural engineering

The invention discloses an early strength agent and application thereof in a concrete material. The early strength agent comprises the following components in parts by weight: 30-50 parts of magnesiumfluosilicate, 14-20 parts of lithium sulfate, 15-25 parts of sodium sulfate, 15-25 parts of sodium nitrite and 55-75 parts of pre-hydrated cement particles. The preparation method of the pre-hydratedcement particles comprises the following steps: uniformly stirring 80-120 parts by weight of cement and 20-40 parts by weight of water, granulating, maintaining for 28-30 days, carrying out ball milling, and screening with a 200-300-mesh sieve to obtain the pre-hydrated cement particles. The performance of the early strength agent can be remarkably improved and the hardening time can be shortenedby the self-making pre-hydrated cement particles and combining the pre-hydrated cement particles with other components, and the early strength agent has a remarkable effect of enhancing the later strength of a cement base material, does not shrink and meets the requirements on the service strength and durability of concrete.

Owner:绵阳市安州区荣盛建材有限公司

Liquid alkali-free accelerator and room-temperature synthesis process thereof

The invention discloses a liquid alkali-free accelerator and a room-temperature synthesis process thereof. The accelerator includes, by weight, 48 to 50 parts of aluminum sulfate, 4.5 to 5.5 parts ofmagnesium fluosilicate, 1.5 to 2.5 parts of ferrous sulfate, 3.5 to 5.5 parts of urea, 2 to 3 parts of organosilicon sol, 4.5 to 5.5 parts of glycerol, 1 to 2 parts of AMP-95 (amine neutralizer) and 24.5 to 35.5 parts of water. The problem that a solution is too thick is solved by reducing the proportion of the aluminum sulfate and the magnesium fluosilicate in the whole system. The pH value of the accelerator is adjusted by using the AMP-95 (amine neutralizer), so that the pH value of the accelerator can be effectively increased while the setting time of the accelerator is not influenced, andalkali metal ions are not introduced. The use of the glycerol can effectively shorten the final setting time, so that the final setting time is closer to the initial setting time. Moreover, no inorganic acid is introduced in the accelerator, so that the corrosion of the accelerator to spraying equipment is very small. The accelerator has the advantages of low corrosivity, low cost, small consistency, good comprehensive performance and the like.

Owner:GUIZHOU DR SHI TECH

Two-component crack repairing agent

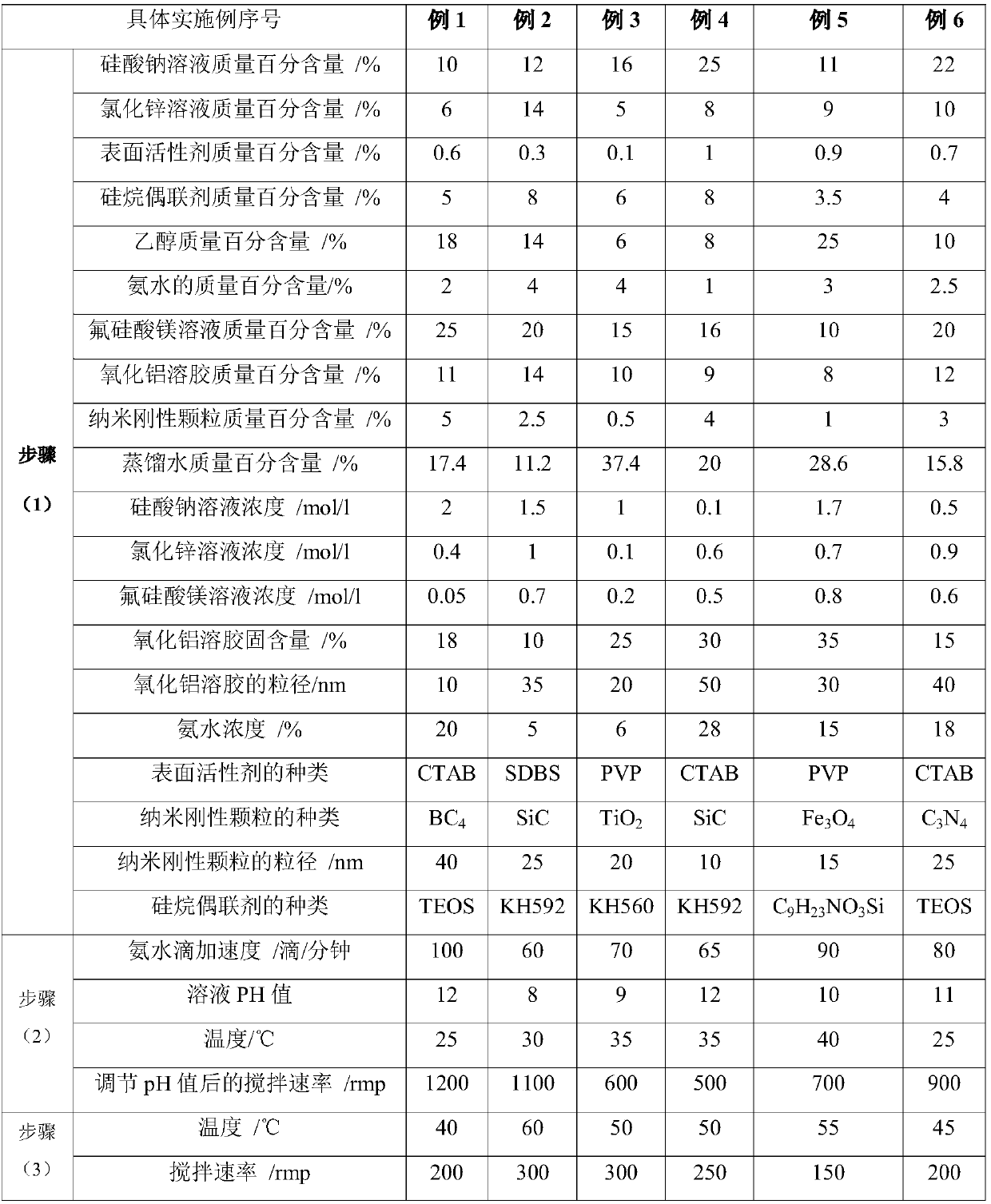

The invention relates to the technical field of building materials, and aims to provide a two-component crack repairing agent which comprises, by mass, 10% to 25% of sodium silicate solution, 5% to 14% of zinc chloride solution, 0.1% to 1% of surfactant, 3 .5% to 8% of silane coupling agent, 6% to 25% of ethanol, 1% to 4% of ammonia water, 10% to 25% of magnesium fluorosilicate solution, 8% to 14%of aluminium oxide sol, 0.5% to 5 % of nano-rigid particles and the balance being distilled water. According to the principle of dual system reaction reinforcement, that is, alkaline system reacts with acidic system to further strengthen the matrix material, the material at the repair site is more firmly combined with the surrounding matrix material; as reaction products of aluminum oxide oil canharden and reinforce concrete and rigid nanoparticles can also improve hardness of concrete, the overall performance is improved. The two-component crack repairing agent has simple preparation process, can be directly rolled or sprayed to the surface of concrete in large area for construction, has no pollution to the environment, needs simple raw materials and low cost, and is especially suitablefor large-scale industrial production.

Owner:ZIGONG INNOVATION CENT OF ZHEJIANG UNIV

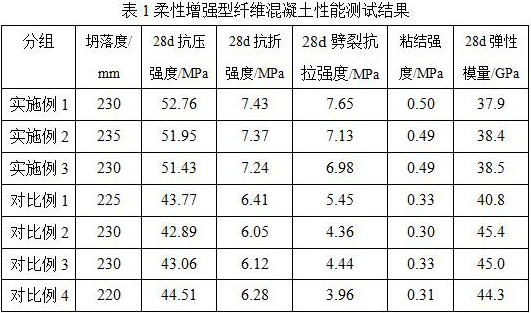

Flexible reinforced fiber concrete and preparation method thereof

The invention discloses a flexible reinforced fiber concrete. The concrete is prepared from the following raw materials in parts by weight: 110-130 parts of ordinary Portland cement, 10-15 parts of high-iron aluminophosphate cement, 25-30 parts of modified waste rubber particles, 5-10 parts of polyolefin elastomer, 3-6 parts of flotation deinking slag fibers, 3-5 parts of modified sepiolite fibers, 10-20 parts of silicon carbide powder, 5-10 parts of bamboo fiber powder, 10-15 parts of a polycarboxylate superplasticizer, 3-5 parts of magnesium fluosilicate, 10-15 parts of slag powder, 3-7 parts of coal ash, 160-170 parts of sand, 460-480 parts of pebbles and 50-60 parts of water. The invention also discloses a preparation method of the flexible reinforced fiber concrete. The flexible reinforced fiber concrete disclosed by the invention has the characteristics of good deformability, high toughness, high strength and good adhesive property, and the expansion stress of the concrete is absorbed by utilizing the elastic characteristics of the modified waste rubber particles and the polyolefin elastomer, so that the overall volume stability of the concrete is good; and the concrete is matched with other materials, so that the overall flexibility of the concrete is remarkably improved.

Owner:泰安市同达建材有限公司

Addition combination agent of rapid powder repairing material and application of addition combination agent in cement concrete

ActiveCN114180874AProlong initial setting timeHigh compressive strengthSolid waste managementIron sulfateLithium sulphate

The invention discloses an addition combination agent of a rapid powder repairing material and application of the addition combination agent in cement concrete. The addition combination agent is prepared from 260-300 parts of aluminum sulfate, 30-40 parts of ferric sulfate, 15-20 parts of lithium sulfate, 15-20 parts of magnesium oxide, 20-30 parts of magnesium fluosilicate and 80-150 parts of modified nano silicon dioxide. The materials are placed in a ball milling tank, the ball-to-material ratio is (20-30): 1, ball milling is conducted for 1-2 h at 300-500 rpm under the protection of argon, the particle size of ground powder is 200-300 meshes, and the additive combination agent of the rapid powder repairing material is obtained; the method comprises the following steps: mixing the additive combination agent of the powder rapid repairing material with water and diethanol amine according to a mass ratio of (400-600): (200-300): (20-30), and then mixing the mixture with cement according to a mass ratio of (6-8): 100. According to the invention, aluminum sulfate is taken as a main component and is combined with other components, and a nano silicon dioxide material with a huge specific surface area can provide crystallization nucleation points for hydration products of cement, has an effect of promoting early hydration, can fill nano-scale pores of a cement material, improves the compactness of an internal structure and meets the requirements of strength and durability of the cement.

Owner:绵阳市安州区荣盛建材有限公司

Hazardous chemical substance-free magnesium-aluminum fluoride system alkali-free setting accelerator without hazardous chemical substances and preparation method thereof

The invention provides a hazardous chemical substance-free magnesium-aluminum fluoride system alkali-free accelerator which comprises the following components in parts by weight: 40-55 parts of aluminum sulfate, 0-15 parts of magnesium sulfate, 3-8 parts of magnesium fluosilicate, 0.5-1.5 parts of magnesium hydroxide, 0-8 parts of cryolite, 1-14 parts of amine compounds and 20-30 parts of water. According to the hazardous chemical substance-free magnesium-aluminum fluoride system alkali-free setting accelerator provided by the invention, the reaction system reaction can achieve the dissolutionreaction, and the prepared accelerator does not contain hydrofluoric acid and fluosilicic acid, so that harmful gas cannot be generated during the construction process, the influence of the harmful gas on the health of the construction personnel is avoided, the pollution of the harmful gas on the air is avoided, and the safety and the environmental protection are provided.

Owner:PANZHIHUA CITY JIYUAN TECH

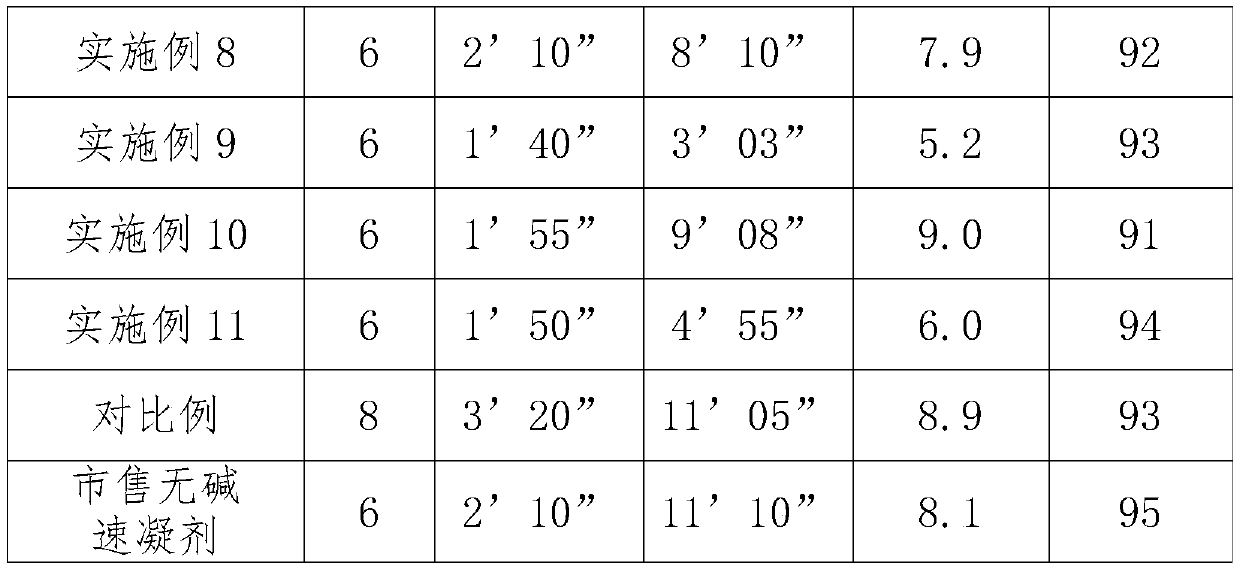

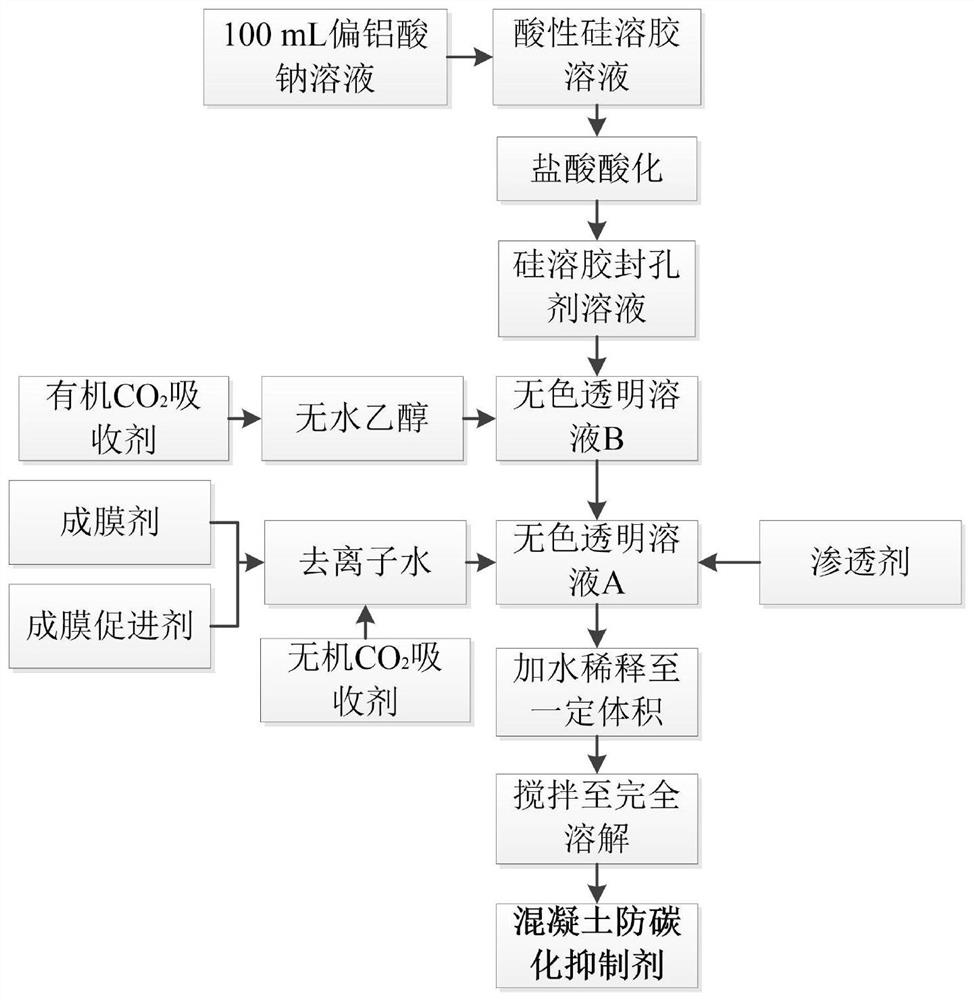

Concrete anti-carbonization inhibitor and preparation method thereof

The invention discloses a concrete anti-carbonization inhibitor and a preparation method thereof, and relates to the technical field of concrete surface protection. The anti-carbonization inhibitor comprises a film-forming agent, a film-forming accelerant, a CO2 absorbent, a hole sealing agent and a penetrating agent; wherein the film forming agent is one or more of magnesium fluosilicate, sodium fluosilicate and gamma-(2, 3-epoxypropoxy) propyl trimethoxy silane; the film-forming accelerant is one or more of lithium silicate, sodium silicate and potassium silicate; the CO2 absorbent is one or more of potassium carbonate, sodium carbonate, triethanolamine and 2, 2-dihydroxydiethylamine; the hole sealing agent is modified silica sol; and the penetrating agent is one or more of hexadecyl trimethyl ammonium bromide, hexadecanol polyoxyethylene ether dimethyl octyl ammonium chloride and octadecyl dimethyl benzyl ammonium chloride. According to the concrete anti-carbonization inhibitor, the raw materials are easy to obtain, the preparation process is simple, CO2 can be physically isolated, CO2 diffused to the surface of concrete can be absorbed, and concrete carbonization inhibition dual protection is achieved.

Owner:CHONGQING IND POLYTECHNIC COLLEGE

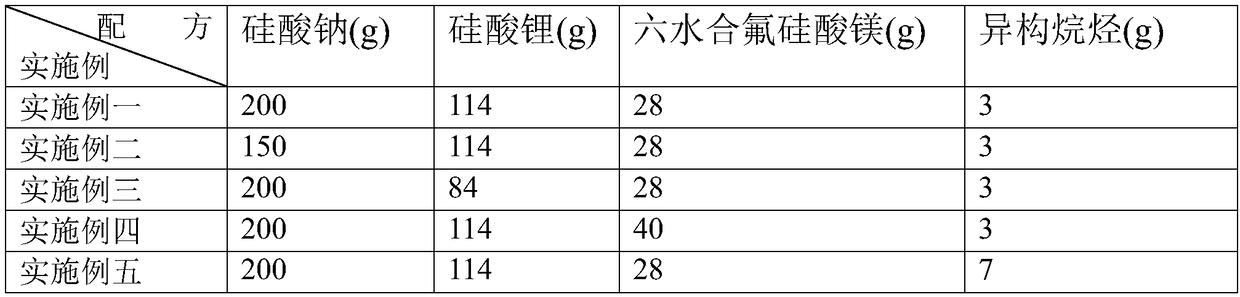

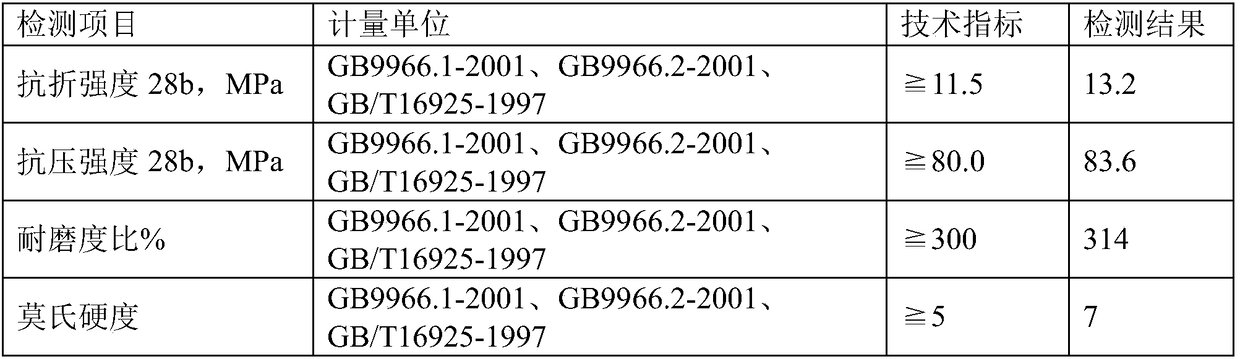

Special curing agent for indoor corundum ground, and construction process thereof

The invention discloses a special curing agent for indoor corundum ground, and a construction process thereof, wherein the special curing agent is dry powder and contains sodium silicate, lithium silicate, magnesium fluorosilicate hexahydrate and IP Clean HX. The construction process comprises: S1, substrate treatment; S2, grinding sheet selective test; S3, ground rough grinding; S4, treatment ofspecial curing agent; S5, primary soaking; S6, middle grinding of the ground; S7, watering curing; S8, secondary soaking; S9, ground surface polishing; and S10, cleaning with felt and clear water, wherein the ground is used after the ground is dried. According to the present invention, the special curing agent is used based on the corundum ground, and the professional construction process is supplemented, such that the special curing agent and the ground concrete completely react, and the obtained corundum ground has advantages of good wear resistance and high density.

Owner:深圳市金铸固化剂地坪有限公司

Anti-crack, anti-permeation and high-durability concrete and preparation method thereof

InactiveCN113135695ASmall particle size and low contentHigh apparent densitySolid waste managementCrack resistanceCalcium formate

The invention discloses anti-crack anti-permeation high-durability concrete and a preparation method thereof, relates to the field of concrete, and aims to solve the problem that durability indexes such as crack resistance and permeation resistance of concrete in the prior art are difficult to realize. The concrete is prepared from the following components in parts by weight: 500 to 750 parts of cement, 70 to 85 parts of water, 600 to 680 parts of sand, 1200 to 1450 parts of gravel, 750 to 800 parts of recycled coarse aggregate, 500 to 575 parts of fine aggregate, 25 to 30 parts of silicon powder, 15 to 20 parts of boron nitride powder, 35 to 40 parts of fly ash, 25 to 30 parts of aluminum oxide, 15 to 30 parts of calcium chloride, 45 to 50 parts of silicate, 15 to 20 parts of additive, 60 to 75 parts of sodium silicate, 20 to 25 parts of sodium fluosilicate, 20 to 25 parts of magnesium fluosilicate, 20 to 50 parts of accelerant, 35 to 50 parts of polypropylene fiber, 25 to 40 parts of calcium formate and 50 to 75 parts of sealing curing agent; wherein the additives comprise a water reducing agent, an air entraining agent, a retarder, an early strength agent, an anti-freezing agent and an expanding agent.

Owner:南通固盛建材有限公司

Alkali-free accelerator as well as preparation method and application thereof

The invention relates to the field of accelerators, and particularly discloses an alkali-free accelerator which is prepared from the following raw materials in parts by mass: 360-380 parts of aluminum sulfate; 30 to 50 parts of magnesium fluosilicate; 15-20 parts of phosphoric acid; 65-80 parts of sodium sulfate; 38 to 46 parts of alcohol amine; 55 to 70 parts of a coagulation accelerator; 1-5 parts of xanthan gum; and 180 to 220 parts of water. The invention also discloses a preparation method of the alkali-free accelerator, which comprises the following steps: (1) adding water, sodium sulfate and the accelerator according to the formula to obtain a premix; (2) heating the reaction kettle to 48-52 DEG C, and adding magnesium fluosilicate, aluminum sulfate and xanthan gum into the premix; (3) heating the reaction kettle to 65-70 DEG C, and dropwise adding phosphoric acid and alkylol amine into the reaction kettle; and (4) cooling to normal temperature to obtain the alkali-free accelerator. The alkali-free accelerator provided by the invention can be applied to concrete. The accelerator has the effect of improving the stability of the accelerator.

Owner:GUANGZHOU JIANSHENG BUILDING MATERIALS CO LTD

Glass etching solution and method for imitating ceramic furnace transmutation ice flower glass by adopting etching solution

ActiveCN112321170AMeet special needsAchieve harmonyDecorative surface effectsSpecial ornamental structuresAcid etchingSodium phosphates

The invention belongs to the technical field of chemical etching, and particularly relates to a glass etching solution and a method for imitating ceramic furnace transmutation ice flower effect glassby adopting the etching solution. The glass etching solution comprises the following raw materials in percentage by weight: 18-25% of ammonium fluoride, 6-10% of ammonium fluosilicate, 2-6% of magnesium fluosilicate, 15-20% of sulfuric acid, 3-8% of acetic acid, 5-10% of sodium chloride, 3-8% of lead nitrate, 1-3% of sodium pyrophosphate, 1-3% of copper sulfate, 0.5-2% of sodium gluconate, 0.5-2.5% of lauryl sodium sulfate, 0.2-0.5% of polyacrylamide, 0.1-0.3% of maltodextrin and the balance of water. According to the etching solution, acid etching treatment is carried out on the surface of the glass so that ice flower-shaped crystals which are different in shape and ever-changing are formed on the surface of the glass.

Owner:ZHENGZHOU HIHO OPTICAL TECH CO LTD

Alkali-free concrete accelerator and processing method thereof

The invention discloses an alkali-free concrete accelerator and a processing method thereof. The alkali-free concrete accelerator comprises the following raw materials in parts by weight: 30-65 partsof aluminum sulfate, 2-8 parts of an organic amine, 1-3% of a stabilizer, 1-5 parts of a suspending agent, 20-35 parts of water, 2-5 parts of bentonite and 4-6% of magnesium fluosilicate. In the present invention, the caulking agent for building decoration of prefabricated parts is simple in preparation method, low in cost, is liquid after preparation, can be uniformly mixed with concrete conveniently, contains no alkali or chlorine or pungent smell, is high in safety, is harmless to human body, is excellent in cohesiveness; adding of a stabilizing agent can prolong the storage time, preventdeterioration; magnesium fluosilicate and aluminum sulfate are adopted for cooperative using, so that the resilience value is low, later strength retention rate is high, and impermeability grade is high; adding of the alkali-free concrete accelerator in sprayed concrete is capable of achieving a preferable working environment and considerable market value.

Owner:湖南加美乐素新材料股份有限公司

Special curing agent for indoor cement ground, and use method thereof

The invention discloses a special curing agent for indoor cement ground, and a use method thereof. In the prior art, the general cement curing agent is not suitable for different grounds with different active ingredients, and the reaction is insufficient. A purpose of the present invention is to solve the problems in the prior art. The technical scheme of the present invention is that the specialcuring agent is dry powder, and contains sodium silicate, lithium silicate, magnesium fluorosilicate hexahydrate and isoparaffin. According to the present invention, the special curing agent is the dry powder, does not contain water, and can be added with water according to a certain ratio before the use, such that the ratio of various components can be easily and flexibly adjusted according to the ground conditions; the dry powder has advantages of light mass, convenient carrying, convenient transportation, easy sealing during the transportation and less leakage; and the special curing agenthas the long shelf life, and various components of the special curing agent are not easily subjected to coordinating and other reactions.

Owner:深圳市金铸固化剂地坪有限公司

Concrete structure self-compacting waterproofing agent as well as preparation method and application thereof

InactiveCN112341034AEfficient pressure resistance and water retention performanceStrong waterproof sealing effect appearsStructural engineeringStearic acid

The invention discloses a concrete structure self-compacting waterproofing agent as well as a preparation method and application thereof. The concrete structure self-compacting waterproofing agent isprepared from the following components in parts by weight: 10-12 parts of magnesium fluosilicate, 5-8 parts of a dispersing agent, 6-7 parts of ammonia water, 0.6-0.8 part of a preservative, 110-120 parts of water, 3-5 parts of molten aluminum, 3-5 parts of a defoaming agent and 4-6 parts of stearic acid. When the concrete structure self-compacting waterproof agent is applied, the concrete structure self-compacting waterproof agent only needs to be sprayed on the surface of concrete, the spraying amount is 0.2-0.4 kg / m <2>, with wetting kept for 0.3-0.4 h; the surface of the concrete fully absorbs the concrete hardening waterproof agent, and the concrete hardening waterproof agent can permeate by 0.8-1.2 cm; and still standing is conducted for 14-16 h, and a strength waterproof sealing effect can be shown.

Owner:上海尼索建材科技有限公司

Slow-release disinfection gel, preparation method and application thereof

PendingCN114028326AHigh purityImprove securityCosmetic preparationsSenses disorderSodium acetateBiocompatibility

The invention discloses slow-release disinfection gel, a preparation method and application thereof, and belongs to the technical field of biomedical materials. High-purity hypochlorous acid water is prepared by imitating a generation mode of hypochlorous acid in human neutrophil, and the hypochlorous acid hydrogel is prepared by taking the hypochlorous acid water as a main raw material, taking a mixture of sodium magnesium fluosilicate and magnesium fluosilicate as gel, taking hydrochloric acid or alkaline electrolyzed water as a pH regulator and taking acetic acid and sodium acetate as pH buffering agents. If necessary, sodium chloride can be added as an isotonic agent, sodium hyaluronate can be added as a humectant, and poloxamer can be added as a hemostatic. According to the gel disclosed by the invention, the high-purity hypochlorous acid water is taken as a main raw material, particularly the mixture of the sodium magnesium fluosilicate and the magnesium fluosilicate is taken as the gel agent, and the invention has good tissue adhesion, biocompatibility and swelling property and has the advantages of long-acting slow-release bacterium killing, adjustable formula and wide application range.

Owner:杭州易沃科信息科技有限公司

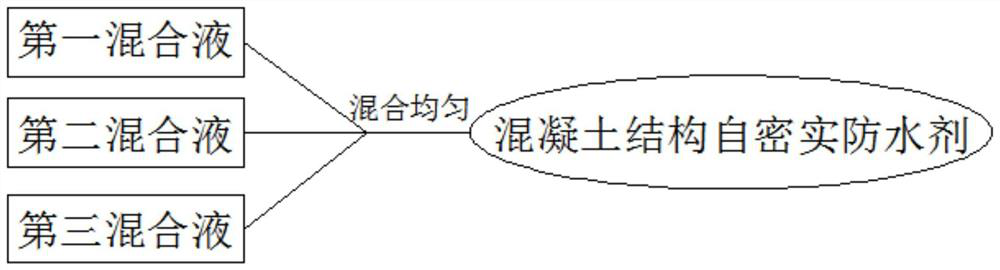

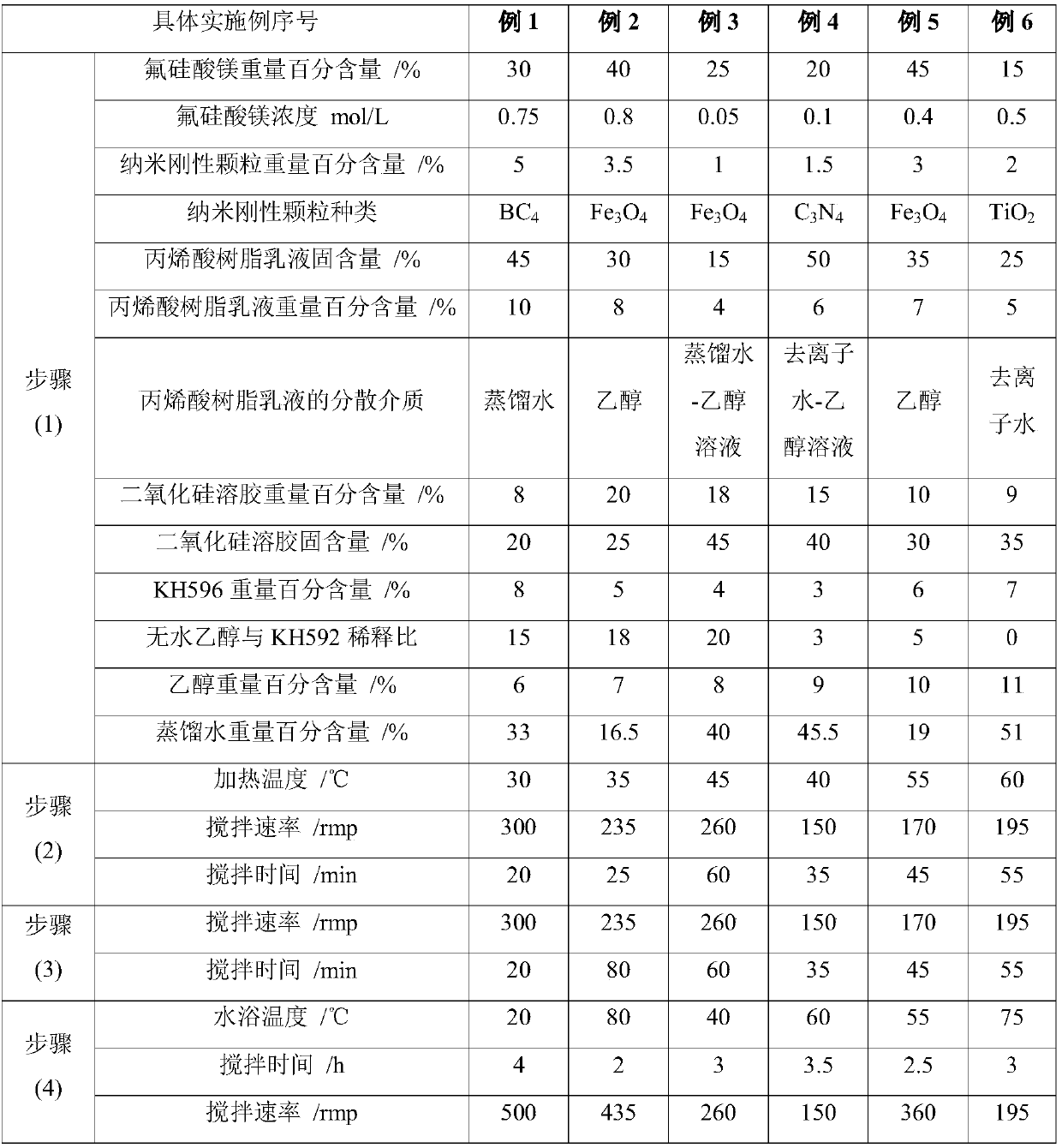

Preparation method of anti-skidding agent for floor

The invention relates to the technical field of building materials, aiming at providing a preparation method of an anti-skidding agent for floor. The preparation method comprises the following steps:weighing all the raw material components according to a weight ratio: 15-45% of a magnesium fluorosilicate solution, 1-5% of nano-rigid particles, 4-10% of acrylic resin emulsion, 8-20% of silica sol,3-8% of a silane coupling agent, 6-11% of ethanol and the balance of distilled water; taking half of the weighed ethanol and half of the weighed distilled water, evenly stirring, then adding the magnesium fluorosilicate solution and the silica sol, heating, and mixing; taking the rest ethanol and the rest distilled water, evenly stirring, then sequentially adding the acrylic resin emulsion and the nano-rigid particles, and mixing at the room temperature; merging the mixed liquid obtained in the previous two steps, then adding the silane coupling agent, stirring and then carrying out ultrasonic treatment; then, heating and stirring; cooling to the room temperature to obtain the anti-skidding agent for concrete. The product can form a great deal of hard wear-resistant microbeads on a concrete surface layer, thus enhancing the contact friction force; the problem that different people have diversified requirements for skid resistance, durability and the like of the floor is solved.

Owner:ZIGONG INNOVATION CENT OF ZHEJIANG UNIV

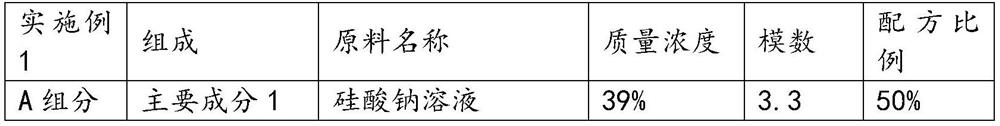

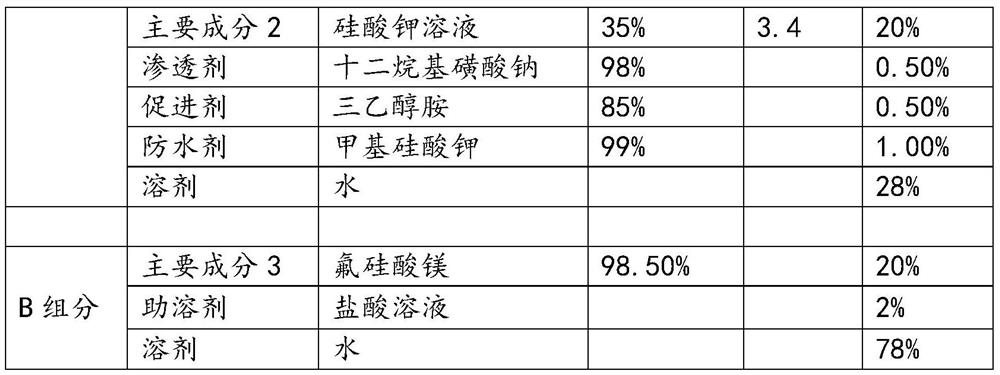

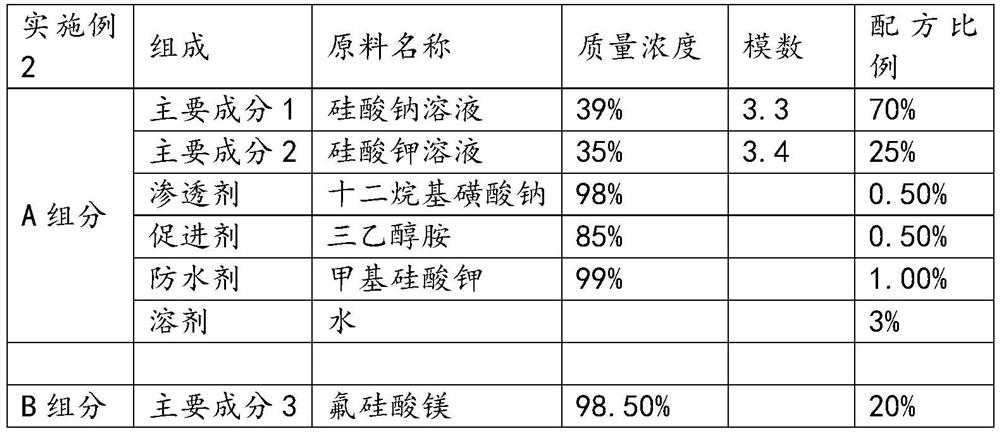

Water-based two-component concrete sealing curing agent

The invention relates to a water-based two-component concrete sealing curing agent, and solves the problem that the performance of the existing curing agent needs to be further improved. According to the technical scheme, the coating comprises a component A and a component B, the component A comprises a sodium silicate solution, a potassium silicate solution, a penetrating agent, an accelerant, a waterproof agent and water, and the component B comprises magnesium fluosilicate, a hydrochloric acid solution and water. The curing agent is low in cost, good in stability, high in cost performance, high in strength and high in wear resistance.

Owner:WUHAN DELIGU MATERIAL CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com