Preparation method of high-purity magnesium fluoride

A pure magnesium fluoride and magnesium oxide technology, applied in magnesium fluoride, magnesium halide, silicon oxide and other directions, can solve the problem of high production cost, achieve good economic value and social value, reduce production cost, and be easy to popularize and apply.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

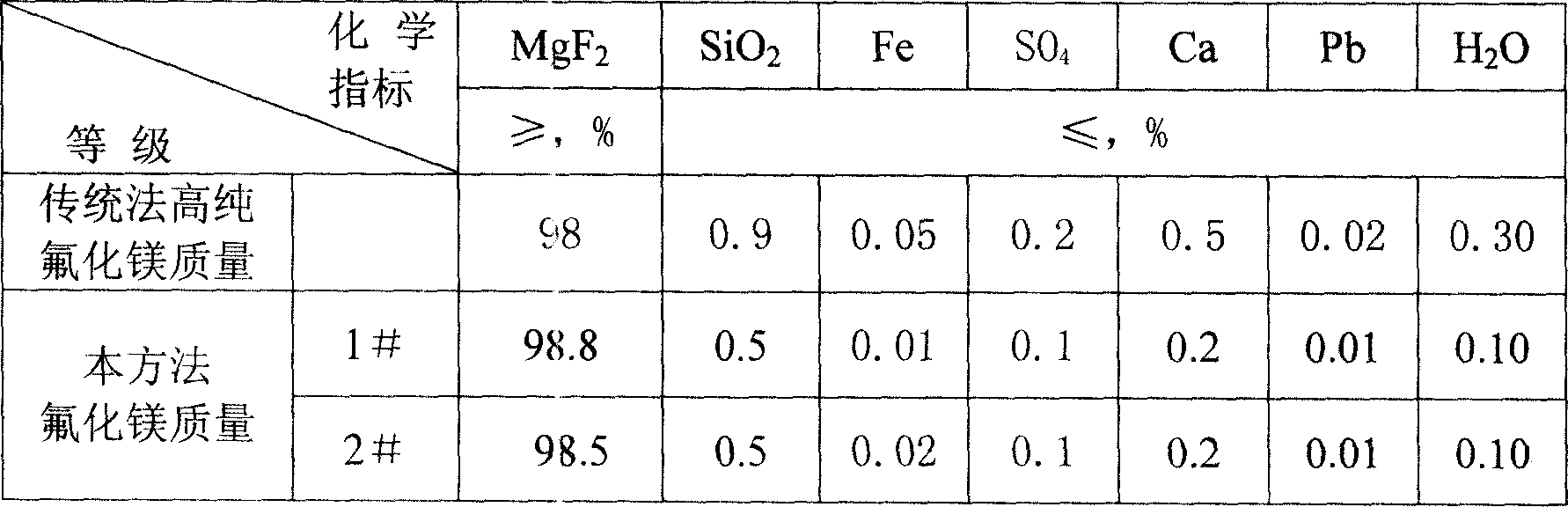

Examples

Embodiment 1

[0018] The preparation method of high-purity magnesium fluoride of the present invention, with fluosilicic acid and magnesium oxide as raw material, specifically comprises the following steps:

[0019] (1) reacting a fluorosilicate solution with a concentration of 15% and magnesium oxide solid for 40 minutes, filtering to obtain a magnesium fluorosilicate solution, concentrating and crystallizing to obtain magnesium fluorosilicate hexahydrate;

[0020] (2) decomposing magnesium fluorosilicate hexahydrate at a temperature of 200° C. for 4 hours to generate solid magnesium fluoride and silicon tetrafluoride gas and water vapor;

[0021] (3) Absorb and hydrolyze silicon tetrafluoride gas and water vapor with water, filter to obtain 15% fluorosilicic acid solution, return it to make magnesium fluorosilicate, wash and dry the silicon dioxide solid to obtain white carbon black.

Embodiment 2

[0023] The preparation method of high-purity magnesium fluoride of the present invention, with fluosilicic acid and magnesium oxide as raw material, specifically comprises the following steps:

[0024] (1) react 25% fluosilicic acid solution and 30% magnesium oxide slurry for 30 minutes, filter to obtain magnesium fluosilicate solution, concentrate and crystallize to obtain magnesium fluosilicate hexahydrate;

[0025] (2) Decompose magnesium fluorosilicate hexahydrate at a temperature of 300° C. for 3 hours to generate solid magnesium fluoride and silicon tetrafluoride gas and water vapor;

[0026] (3) Absorb and hydrolyze silicon tetrafluoride gas and water vapor with water, filter to obtain 25% fluorosilicic acid solution, return it to make magnesium fluorosilicate, wash and dry the silicon dioxide solid to obtain white carbon black.

Embodiment 3

[0028] The preparation method of high-purity magnesium fluoride of the present invention, with fluosilicic acid and magnesium oxide as raw material, specifically comprises the following steps:

[0029] (1) Reacting a 35% fluosilicic acid solution and a 20% magnesium oxide slurry for 20 minutes, filtering to obtain a magnesium fluosilicate solution, concentrating and crystallizing to obtain magnesium fluosilicate hexahydrate;

[0030] (2) Decompose magnesium fluorosilicate hexahydrate at a temperature of 400° C. for 2 hours to generate solid magnesium fluoride and silicon tetrafluoride gas and water vapor;

[0031] (3) Absorb and hydrolyze silicon tetrafluoride gas and water vapor with water, filter to obtain 35% fluorosilicic acid solution, return it to make magnesium fluorosilicate, wash and dry the silicon dioxide solid to obtain white carbon black.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com