Early strength agent and application thereof in concrete material

A technology of early strength agent and concrete, applied in the field of early strength agent and its application in concrete materials, can solve the problems of poor environmental adaptability, small increase in early strength, slow hardening time, etc., to meet service strength and durability Requirements, significant strength enhancement, accelerated hardening time effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

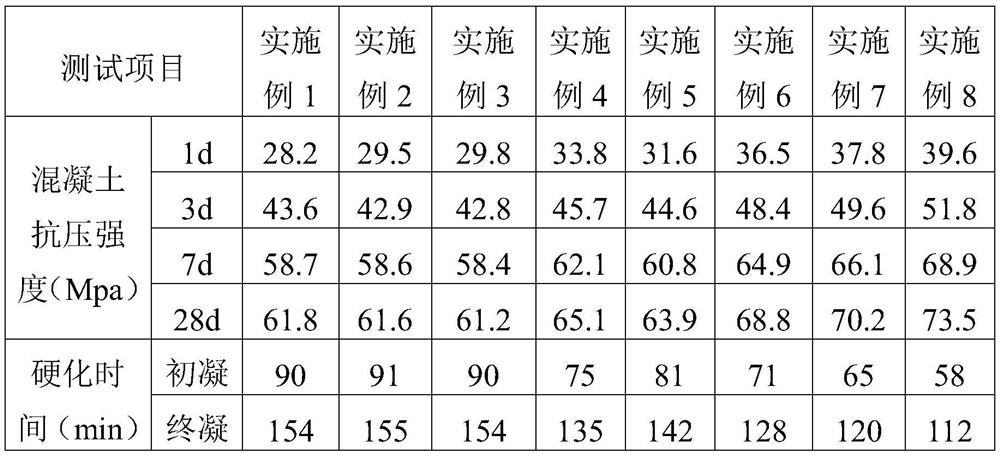

Examples

Embodiment 1

[0021] An early strength agent, comprising the following components:

[0022] 30kg of magnesium fluorosilicate, 14kg of lithium sulfate, 15kg of sodium sulfate, 15kg of sodium nitrite, 55kg of pre-hydrated cement particles;

[0023] The preparation method of the prehydrated cement granules is as follows: 80kg of cement and 20kg of water are stirred evenly, granulated and cured for 28 days, then ball milled, and sieved with 200 mesh to obtain the prehydrated cement granules.

Embodiment 2

[0025] An early strength agent, comprising the following components:

[0026] 50kg of magnesium fluorosilicate, 20kg of lithium sulfate, 25kg of sodium sulfate, 25kg of sodium nitrite, 75kg of pre-hydrated cement particles;

[0027] The preparation method of the pre-hydrated cement particles is as follows: uniformly stirring 120 kg of cement and 40 kg of water, granulating and curing for 30 days, then ball milling, and sieving through a 300-mesh sieve to obtain the pre-hydrated cement particles.

Embodiment 3

[0029] An early strength agent, comprising the following components:

[0030] 40kg of magnesium fluorosilicate, 16kg of lithium sulfate, 20kg of sodium sulfate, 20kg of sodium nitrite, 60kg of pre-hydrated cement particles;

[0031] The preparation method of the pre-hydrated cement particles is as follows: 100 kg of cement and 30 kg of water are uniformly stirred, granulated and then cured for 28 days, then ball-milled and screened with 300 mesh to obtain the pre-hydrated cement particles.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com