Two-component crack repairing agent

A crack repair, two-component technology, applied in the field of building materials, can solve the problems of gloss loss, gloss durability and weather resistance, low content of active ingredients, etc., and achieve the effect of firm combination, overall performance improvement, and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

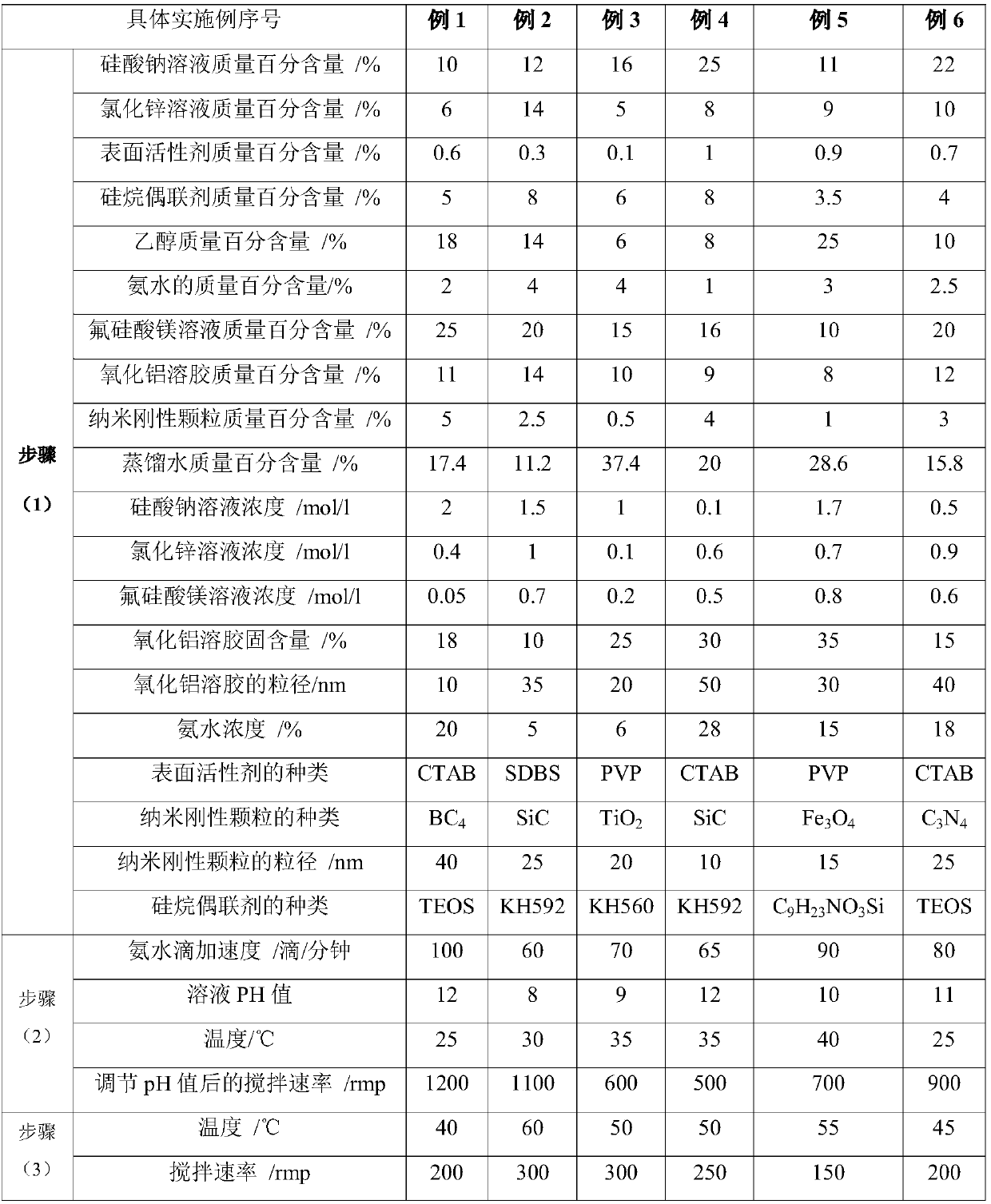

[0022] The present invention will be described in further detail below in conjunction with the examples, but those skilled in the art will understand that the following examples are only used to illustrate the present invention, and should not be considered as limiting the scope of the present invention.

[0023] The two-component crack repairing agent of the present invention is made up of each raw material component of following mass percentage relation:

[0024] Sodium silicate solution 10%~25%, zinc chloride solution 5%~14%, surfactant 0.1%~1%, silane coupling agent 3.5%~8%, ethanol 6%~25%, ammonia water 1%~ 4%; magnesium fluorosilicate solution 10% to 25%; alumina sol 8% to 14%, nano rigid particles 0.5% to 5%; the balance is distilled water;

[0025] The two-component crack repair agent is divided into two parts, A component and B component; among them, sodium silicate solution, zinc chloride solution, surfactant, silane coupling agent, ammonia water, and half the amount...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com