Concrete accelerator and preparation method thereof

A quick-setting agent and concrete technology, which is applied in the field of concrete, can solve the problems of poor comprehensive performance, few types of products, and high prices, and achieve the effects of increasing compressive strength, improving grinding efficiency, and improving cement performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

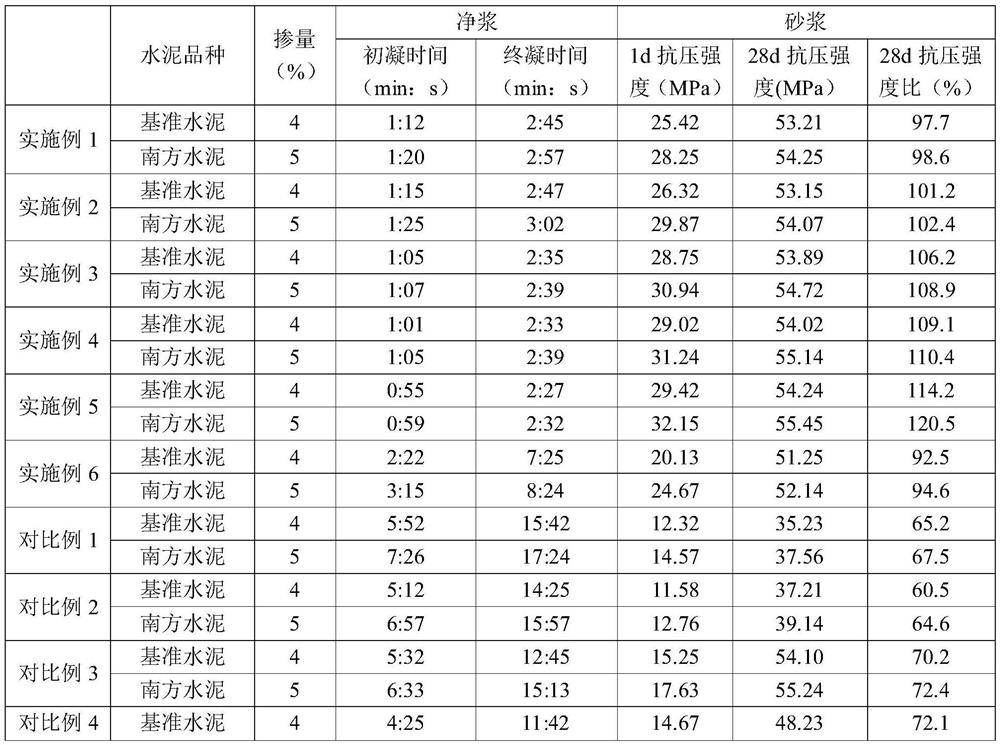

Examples

preparation example 1

[0035] Preparation Example 1 Preparation of Modified Alcoholamine Polymer Grinding Aid

[0036] Composition of raw materials (parts by weight): 12 parts of 2-methacrylic anhydride, 1 part of halloysite nanotube, 20 parts of triethanolamine, 0.5 part of sodium p-toluenesulfonate, 1 part of silane coupling agent, 5 parts of methacrylic acid, 0.1 parts of ammonium persulfate. The silane coupling agent is the compound of KH570 and KH560 according to the mass ratio of 1:1.

[0037] Preparation:

[0038] Put 2-methacrylic anhydride, halloysite nanotubes and triethanolamine into the reactor, add catalyst sodium p-toluenesulfonate and silane coupling agent, react at 100°C for 1 hour, add an equal volume of ethanol, filter to obtain Angstrom Triethanolamine acrylate is modified by rockite nanotubes, and an aqueous solution with a concentration of 30% is prepared, then an aqueous solution containing 15wt% methacrylic acid is added, after stirring and mixing evenly, the initiator ammon...

preparation example 2

[0039] Preparation Example 2 Preparation of Modified Alcoholamine Polymer Grinding Aid

[0040] Composition of raw materials (parts by weight): 35 parts of 2-methacrylic anhydride, 3 parts of halloysite nanotubes, 40 parts of triethanolamine, 1.5 parts of sodium p-toluenesulfonate, 3 parts of silane coupling agent, 10 parts of methacrylic acid, 0.5 parts of ammonium persulfate. The silane coupling agent is a compound of KH570 and bis(2-hydroxyethyl)-3-aminopropyltriethoxysilane in a mass ratio of 1:3.

[0041] Preparation:

[0042] Put 2-methacrylic anhydride, halloysite nanotubes and triethanolamine into the reactor, add catalyst sodium p-toluenesulfonate and silane coupling agent, react at 120°C for 2 hours, add an equal volume of ethanol, filter to obtain Angstrom Triethanolamine acrylate is modified by rockite nanotubes, and an aqueous solution with a concentration of 50% is prepared, then an aqueous solution containing 25wt% methacrylic acid is added, after stirring and...

preparation example 3

[0043] The preparation of preparation example 3 tackifier

[0044] Prepared by:

[0045] S1. Grinding the asbestos finely and performing ultrafine pulverization to obtain asbestos fine powder below 1000 mesh;

[0046] S2. Evenly disperse 5 g of the asbestos fine powder obtained in step S1 in 100 g of an ethanol solution containing 15 wt % sodium ethylate, heat to 40° C. and stir for 30 minutes, then filter with suction to obtain surface-treated asbestos fine powder;

[0047] S3. Add 15g of asbestos fine powder surface-treated in step S2 to 30g of ethanol containing 0.5wt% silane coupling agent KH550, heat to 50°C, and react for 1h, add 10g of sodium carboxymethylcellulose, and react while stirring After 30 minutes, filter with suction and dry to remove ethanol to obtain a thickener.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com