Patents

Literature

89results about How to "Formula flexible" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Aqueous emulsion type electromagnetic wave shielded coating and preparation process thereof

InactiveCN1450137AGood performance in physical environmentNo sheddingPolyurea/polyurethane coatingsEpoxy resin coatingsAdjuvantEmulsion

The composition of water emulsion electromagnetic wave shielding paint is composed of (by weight portion) 20-60 portions of water soluble film-forming resin, 20-60 portions of conducting filler, 30-100 portions of pure clean water, 1-5 portions of thickening agent and 1-5 portions of film-forming adjuvant, and its preparation process includes the following steps: (1) drying conducting filler, controlling temp. at 50-80 deg.C until the conducting filler is become into powder; (2). mixing the dried conducting filler together with film-forming adjuvant, film-forming resin and pure clean water orclean running water and grinding by using grinding machine; and (3) adding thickening agent and regulating the paint to make it have a certain viscosity.

Owner:SICHUAN UNIV

Nutrient solution for soilless culture leaf vegetable and method for producing the same

InactiveCN101219914AReduce dosageReduce pollutionCalcareous fertilisersMagnesium fertilisersAgricultural scienceLeafy vegetables

The invention relates to a nutrient solution for soilless cultivating leafy vegetables and a preparation method thereof. Molar ratio of nutrient elements in the nutrient solution is: NO3<->: NH4<+>: H2PO4<->: K<+>: Ca<2+>: Mg<2+>: Fe<2+>: Cu<2+>: Zn<2+>: Mn<2+>: B<3+>: Mo<6+>, which is equal to (4 to 6): (3 to 6): (2 to 4): (5 to 8): (4 to 6): (2 to 3): 0.02: 0.0003: 0.001: 0.009: 0.05: 0.0004; the nitrogen is supplied in two forms: NO<3> and NH<4> with a proportion kept between (1 to 3): 1. The nutrient solution has flexible formulation, easy preparation and full nutrition, which can significantly improve nutrient quality of the leafy vegetables and reduce negative influence to environment and human health. The invention can meet the needs of soilless cultivation of the leafy vegetables of different kinds, which is convenient for industrial popularization.

Owner:INST OF SOIL & FERTILIZER SHANDONG ACAD OF AGRI SCI

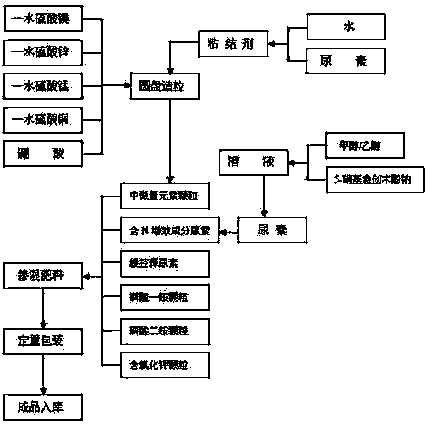

Slow-release compound fertilizer and production method thereof

InactiveCN103172453AAvoid secondary pollutionWide variety of sourcesFertilizer mixturesChemical industryMolecular materials

The invention relates to a slow-release compound fertilizer and a production method thereof. The slow-release compound fertilizer comprises a water-soluble granular fertilizer core and a coating layer, wherein the coating layer includes 2-3 coating layers; and the content of N, P2O5 and K2O which are contained in the slow-release compound fertilizer is respectively 4%-33%, 4%-30% and 0%-30% accounting for the total weight of the slow-release compound fertilizer. According to the invention, the coating layer of the slow-release compound fertilizer is not made from high-molecular materials or other organic polymers, the cost is reduced, and the secondary pollution of the organic polymer or the high-molecular materials on the soil is prevented; and a product formula is flexible, a production process is simplified by integrating the preparation process and compound (mixed) fertilizer production process of the slow-release compound fertilizer into a whole, the equipment investment is saved, the convenience for realizing large-scale industrial production is achieved, and no three wastes are discharged in the production process. Compared with the prior art, the slow-release compound fertilizer disclosed by the invention enhances the slow-release effect to a certain degree and meets the requirements of a chemical industry standard HG / T 4217-2011.

Owner:济南厚源化工有限公司

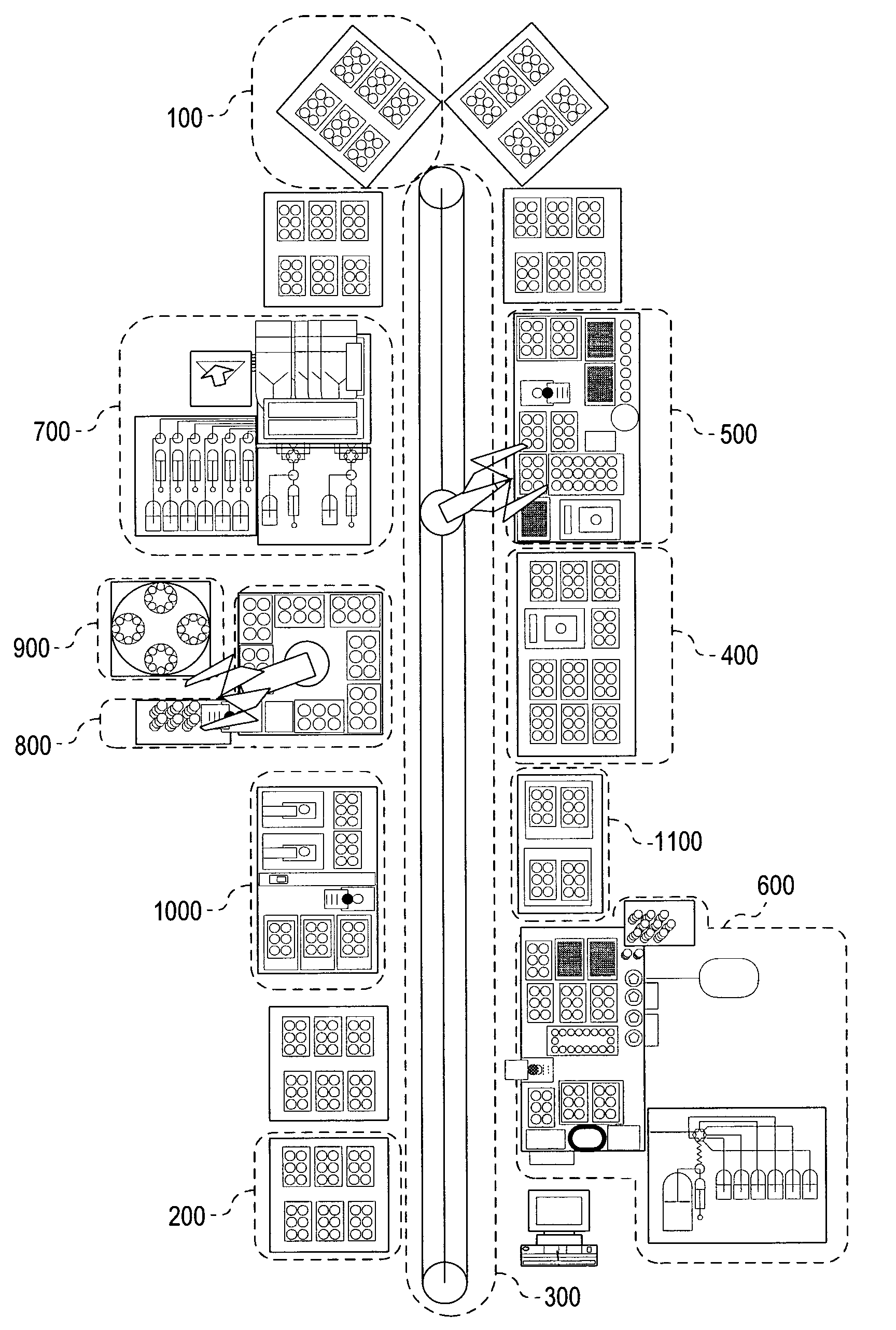

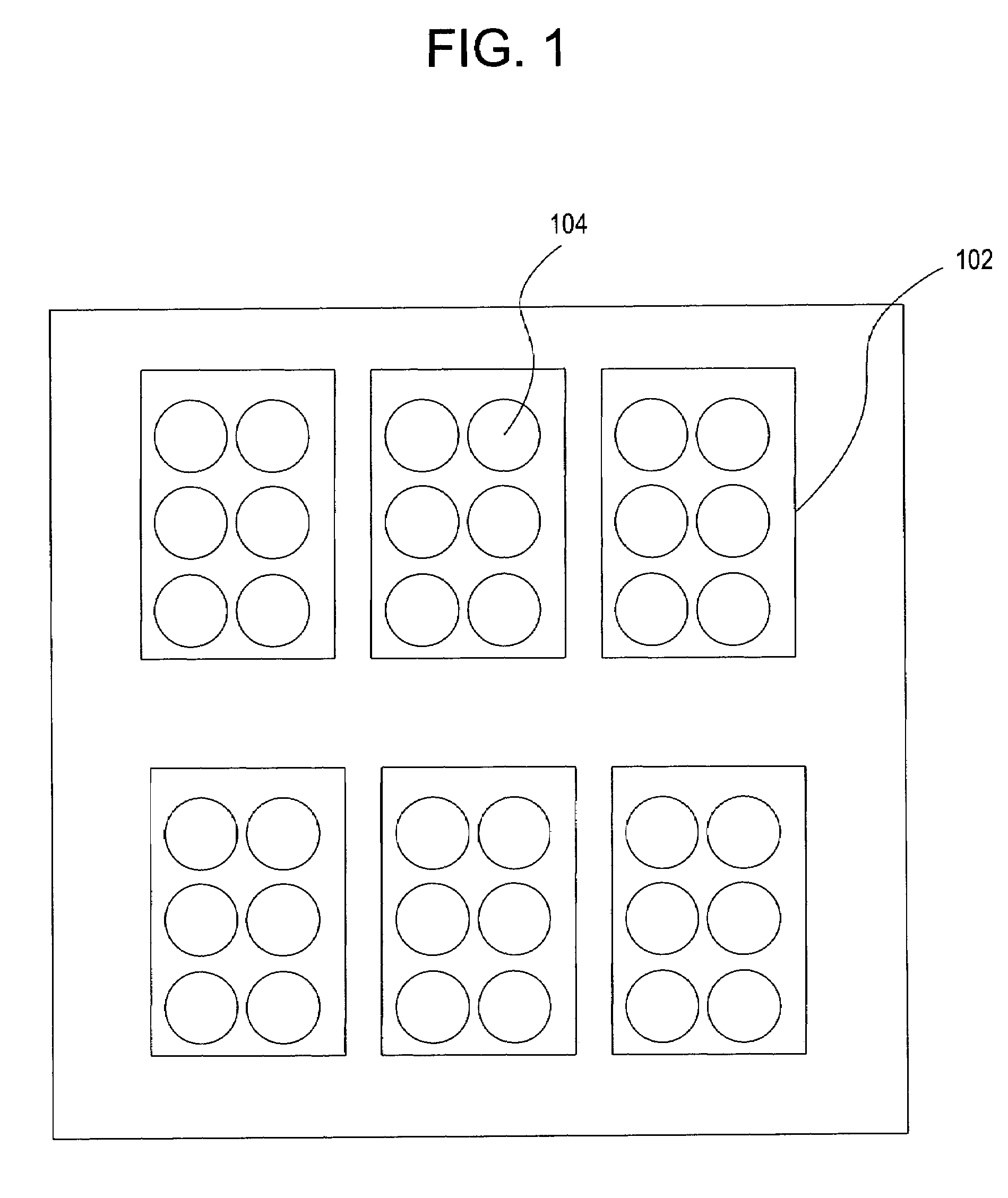

Preparation and characterization of formulations in a high throughput mode

ActiveUS7501094B2Improve throughputFormula flexibleLibrary tagsFlow propertiesSoftware systemAdditive ingredient

The invention is an automated robotic system for the production and testing of formulations at a very high throughput. It is an integrated system of hardware and software capable of preparing and evaluating hundreds of emulsions per day. The system can formulate aqueous solutions (SL), oil in water emulsions (EW), suspo-emulsions (SE), micro capsule suspensions (CS), micro-emulsions (ME), and suspension concentrates (SC) at the 1 ml to 25 ml scale. The system can process emulsions rapidly in an automated way and enable very flexible formulation recipes to be introduced.The system allows chemists to generate experimental samples of varying recipe and method to be conducted in parallel with projected throughput of up to 1200 formulations processed and characterized per day. Materials and consumables can be distributed from storage storage systems to the work stations where dispensing of ingredients in various states can be performed, including solids, liquids, gels, pastes, suspensions and waxes. The emulsions formed can be characterized using methods including phase diagnosis, turbidity analysis, viscosity and particle sizing using automated test equipment. An integrated module can also perform Tank Mix Compatibility testing in high throughput mode. The modular system allows future processes and tests to be added, either to a station, or as a new station. The software capability includes tracking of processes from start to finish and the integration of analytical data with the as-designed and as-formulated experimental results.

Owner:SYNGENTA LTD

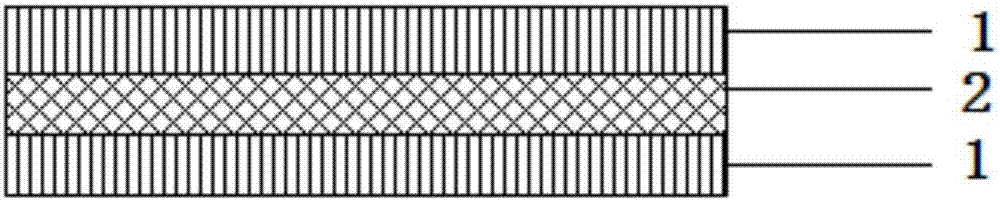

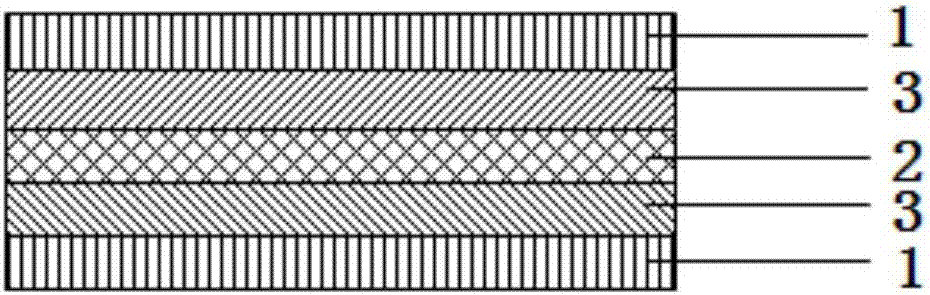

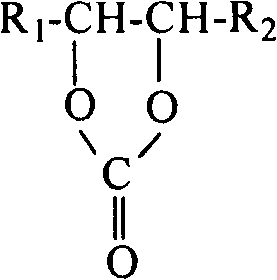

Biodegradable multilayer co-extrusion material and preparation method thereof

ActiveCN107031153APromote degradationWith natural propertiesSynthetic resin layered productsFlat articlesPolybutyleneMedical product

The invention provides a biodegradable multilayer co-extrusion material. The material is characterized by comprising two surface functional layers and a middle layer located between the two surface functional layers, components of the surface functional layers and the middle layer include biodegradable materials, and the biodegradable materials refer to one or more of polybutylene succinate, polylactic acid, polyhydroxyalkanoate and polybutylene adipate-polybutylene terephthalate. The invention further discloses a preparation method of the material. The biodegradablity of four selected master batches of the multilayer co-extrusion material is good, and adopted inorganic minerals are natural, so that the co-extrusion material has completely biodegradable properties and can be widely used in various types of food packages, medical products, environmental protection labels, advertisements and all kinds of environmental-protection products.

Owner:齐庆德

High solid share fluorine-containing polyurethane preparation method

The invention discloses a making method of high-solid fluorine polyurethane, which comprises the following steps: adding polyol, polyisocyanates, fluorine monomer, vinyl monomer, initiator, catalyst, solvent with weight rate at 5-20 2-80.5-5. 51-60.015-0.100.001-0.060-2 in the reactor; stirring to react at 20-100 deg. c for 10-300 min; obtaining the product A; using product A and hardener B with weight rate at 0.5- 50-5 to form fluoropolyurethane resin; solidifying the resin for 4-72h at 0-120 deg. c to obtain the product.

Owner:JIAXING HEXIN CHEM IND

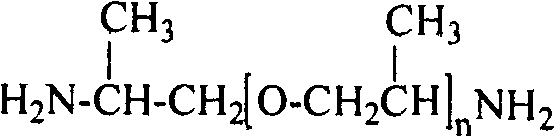

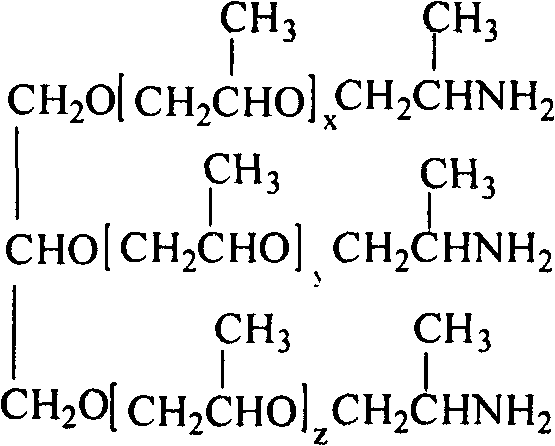

Novel shape memory spraying polyurethaneurea elastomer resin bathroom product and preparation method thereof

ActiveCN102504173ALow viscosityShort reaction timePretreated surfacesPolyurea/polyurethane coatingsPolyesterElastomer

The invention discloses a spraying elastomer raw material composition. The composition comprises an A component raw material and a B component raw material, wherein the A component raw material comprises one or more of polyester polyol having a number-average molecular weight of 400-3000, polyether polyol having a number-average molecular weight of 400-3000, vegetable oil polyol having a number-average molecular weight of 400-2000, amino-terminated polyether having a number-average molecular weight of 200-4000 and polyisocyanate; and the B component raw material comprises polyoxypropylene diamine having a number-average molecular weight of 200-4000, polyoxypropylene triamine having a number-average molecular weight of 400-5000, active aromatic diamine and aromatic diamine. The invention also discloses a prepolymer of a spraying elastomer, a raw material composition and a preparation method of the prepolymer as well as a bathroom product. The spraying elastomer disclosed by the invention is good in various comprehensive properties; and after pressed, the product can memory the original shape, thereby improving the whole comfortable sensation and broadening the use range of the spraying elastomer.

Owner:SHANGHAI MOERSHU CORP DEVING +1

Liquid fertilizer for drip irrigation for saline and alkaline inland, and preparation method of liquid fertilizer

ActiveCN104529632AImprove biological activityImprove effectivenessAlkali orthophosphate fertiliserAmmonium orthophosphate fertilisersAmmonium polyphosphateChemistry

The invention discloses a liquid fertilizer for drip irrigation for a saline and alkaline inland. The liquid fertilizer comprises the following components: 20 to 40 parts of fulvic acid extracted by microbial fermentation, 20 to 30 parts of urea, 5 to 10 parts of ammonium polyphosphate, 10 to 20 parts of potassium dihydrogen phosphate, 2 to 5 parts of an inorganic additive, 2 to 3 parts of ferrous sulfate, 2 to 3 parts of zinc sulfate, 2 to 3 parts of manganese sulfate, and 0.5 to 1 part of 15 to 20wt% plant growth regulator ethanol solution. The pH value of the fertilizer is 3.5 to 4.0. The liquid fertilizer for drip irrigation provided by the invention has the advantages of effectively reducing the pH value of crop rhizosphere soil, improving the bioavailability of soil nutrients, achieving the balanced supply of water and nutrients, and improving the water and fertilizer use efficiency.

Owner:INST OF AGRI ENVIRONMENT & RESOURCE SHANXI ACAD OF AGRI SCI

Preparation method of ardealite baked brick

InactiveCN101774797AGood effectGuaranteed compressive strengthCeramic materials productionClaywaresBrickAdhesive

The invention discloses a preparation method of an ardealite baked brick. The ardealite baked brick is prepared by the following steps of: taking ardealite, a shaping adhesive, a catalytic intensifier and a melting point depressing intensifier as raw materials, and crushing, mixing, shaping and drying and baking in a kiln according to a conventional process to obtain an ardealite baked brick, wherein the shaping adhesive is clay or shale, the catalytic intensifier is an iron-contained compound, and the melting point depressing intensifier is fluosilicate. The weight ratio of the ardealite to the shaping adhesive to the catalytic intensifier to the melting point depressing intensifier is 55-80:16-41:1-2:1-4, and the baking temperature is 700-870 DEG C. The invention not only solves the problem that sulfur dioxide generated in high-temperature sintering of the ardealite pollutes the environment but also can reduce the sintering temperature and reduce energy consumption.

Owner:TONGLING CHEM IND GRP

Anti-allergic traditional Chinese medicine handmade soap

ActiveCN106244357AFormula flexibleAvoid harmSoap detergents with organic compounding agentsSoap detergents with inorganic compounding agentsIrritationAllergic reaction

The invention relates to an anti-allergic traditional Chinese medicine handmade soap, wherein the problem that the industrial soap has irritation to the skin and can cause the allergic reaction can be effectively solved with the anti-allergic traditional Chinese medicine handmade soap. The technical scheme for solving the problem comprises that the anti-allergic traditional Chinese medicine handmade soap is prepared from the following raw materials by mass: 15-25% of olive oil, 5-15% of coconut oil, 10-15% of palm oil, 5-10% of rice bran oil, 5-10% of horse fat, 7-9% of sodium hydroxide, 15-20% of pure water, 2-4% of snake oil, 1-2% of dipotassium glycyrrhizinate, 1-2% of a radix cynanchi paniculati extract, 0.5-1% of a cortex phellodendri extract, 0.5-1% of a scutellaria baicalensis extract, 0.5-1% of a sophora flavescens ait extract, and 0-3% of an auxiliary material. According to the present invention, the formula is flexible, the grease content can be increased or reduced according to the skin type, the auxiliary material can be added according to the requirement, and the product is the pure natural product, has characteristics of no harm to the skin, effective antibacterial effect and effective anti-allergy effect, is used for people with allergy, and is the innovation in the traditional Chinese medicine handmade soap.

Owner:HENAN UNIV OF CHINESE MEDICINE

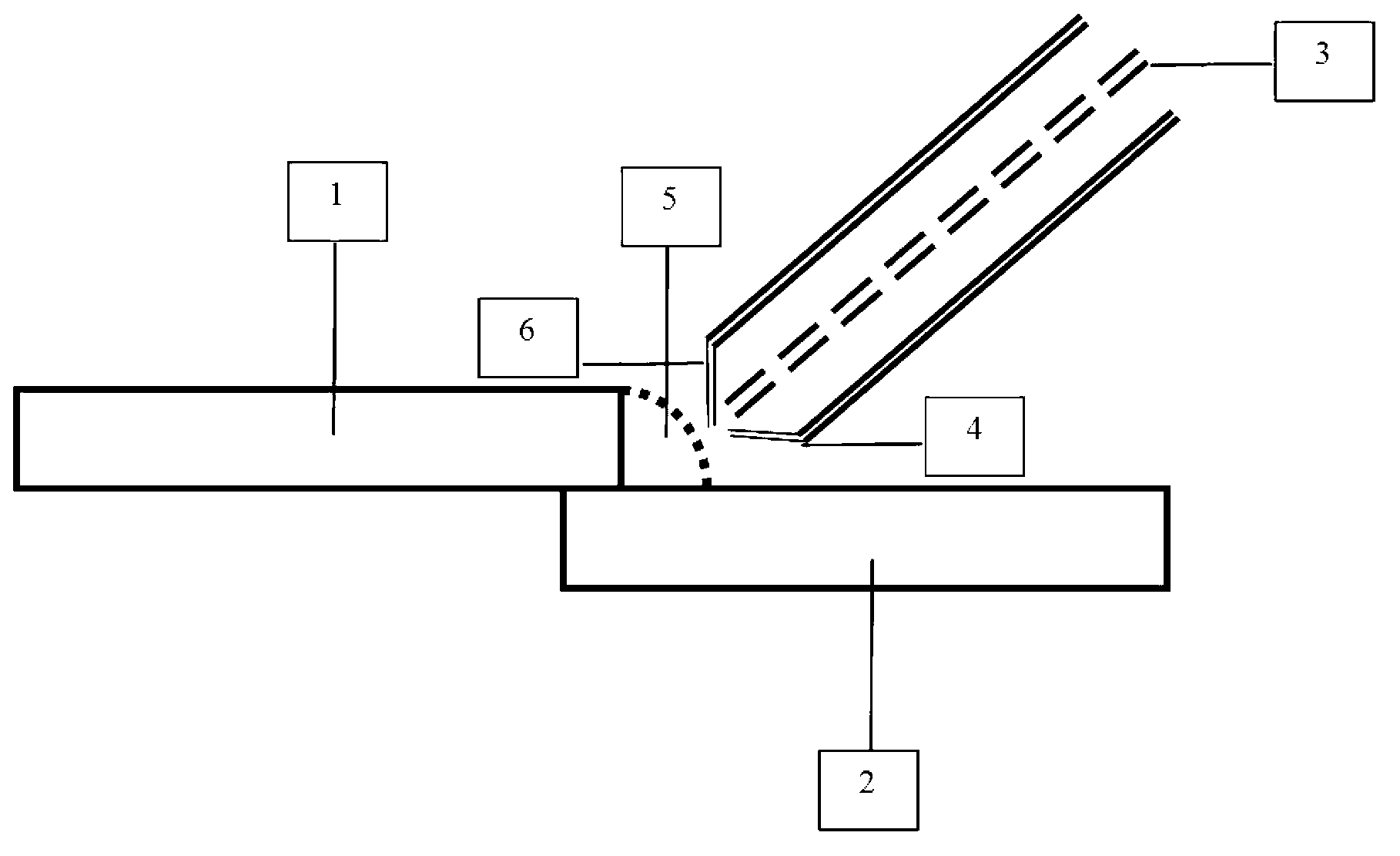

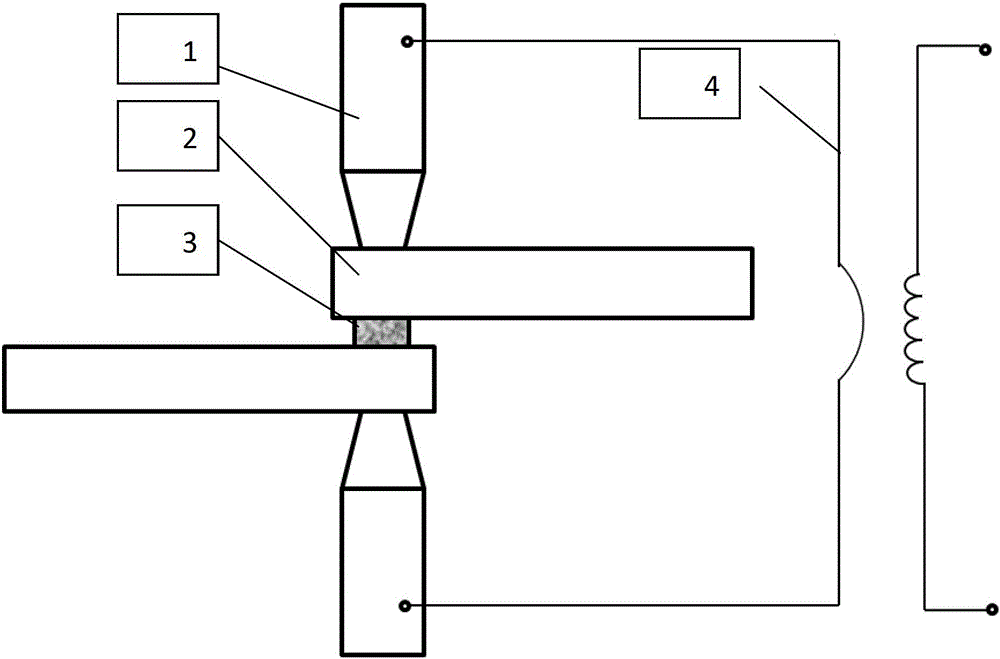

Alloy powder and method for synchronously sending powder and welding galvanized steel sheet and AZ91D magnesium alloy based on laser

InactiveCN103252581APrecise control ratioReduce burning lossLaser beam welding apparatusShielding gasMolten bath

The invention discloses an alloy powder and method for synchronously sending powder and welding a galvanized steel sheet and AZ91D magnesium alloy based on laser. A main component of the powder is AlMgxCuZn, wherein x is the mole ratio of Al and Mg, the ratio range is between 0 and 0.4, the size of the powder is 100 meshes to 300 meshes, and a process method which is matched with the alloy powder and method for synchronously sending the powder and welding the galvanized steel sheet and the AZ91D magnesium alloy based on the laser can improve wettability and compatibility between the galvanized steel sheet and AZ91D magnesium alloy. According to the alloy powder and method for synchronously sending the powder and welding the galvanized steel sheet and the AZ91D magnesium alloy based on the laser, the laser is taken as a welding hot source, under the protection of protective gas and the hot effect, a part of the surface of a material to be welded melts, through effective sending of the alloy powder, a stable weld pool is easily obtained, burning loss of alloying elements is reduced, the ratio of the alloying elements in a weld joint can be accurately controlled, a formula for filling the alloying powder is flexible, metallurgy action of weld metal can be remarkably improved, the weld joint without inclusions can be obtained especially aiming at the existence of Zn, a welding surface needs no special cleaning, welding efficiency is high, cost is low, the joint is reliable, and the alloy powder and method for synchronously sending the powder and welding the galvanized steel sheet and the AZ91D magnesium alloy based on the laser has relatively ideal engineering practical significance.

Owner:SHANGHAI UNIV OF ENG SCI

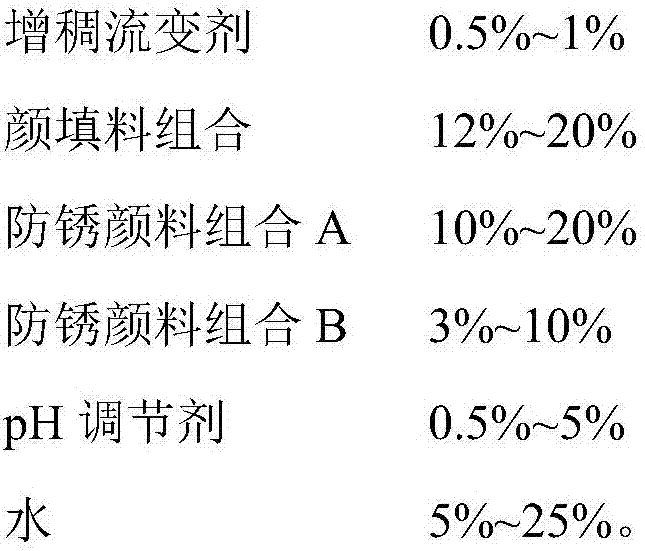

Two-component silicate coating

ActiveCN107446392ASolve instabilityImprove performanceAlkali metal silicate coatingsAnti-corrosive paintsPigmentMaterials science

The invention belongs to the field of coatings. Corresponding products can be applicable to industrial corrosion prevention and architectural ornament. The invention discloses a multifunctional environmental-friendly inorganic silicate coating which comprises a component A and a component B, wherein the component A comprises pigments; the component B comprises a silicate solution and a modifier. The coating is excellent in stability and excellent in film-forming effect.

Owner:珠海市威旗防腐科技股份有限公司

Method for producing high-macroelement liquid organic special fertilizer

InactiveCN104692847AFull of nutritionIncrease contentBio-organic fraction processingOrganic fertiliser preparationFiltrationSlag

The invention relates to a method for producing a high-macroelement liquid organic special fertilizer. The method comprises the following steps: selecting raw materials, pretreating the raw materials, performing anaerobic fermentation, performing slag-liquid separation, performing oxygen exposure filtration, mixing and blending and performing refined filtration filling. The content of the macroelement is improved to a high level, and the topdressing problem of organic cultivation is solved; and moreover, the production efficiency is high, the cost is low, and the problems that waste of biogas slurry and sewage is severe even the environment is polluted are solved.

Owner:王本明

Sustained or controlled release blending fertilizer containing N fertilizer synergistic component and medium trace element

ActiveCN104045470ASimple preparation processSimple equipmentFertilizer mixturesDiammonium phosphateAgricultural engineering

The invention discloses a sustained or controlled release blending fertilizer containing an N fertilizer synergistic component and a medium trace element. The sustained or controlled release blending fertilizer consists of the following components in parts by weight: 10 parts of N fertilizer synergistic component urea, 5 parts of medium trace element particles, 10-20 parts of sustained or controlled release urea, 0-50 parts of granular monoammonium phosphate, 0-50 parts of granular diammonium phosphate and 10-40 parts of granular potassium chloride or granular potassium nitrate or granular potassium sulphate. The sustained or controlled release blending fertilizer disclosed by the invention is simple in preparation process and low in production cost, does not need to be dried, can not generate three-waste emission, is high in product particle strength, strong in compatibility and flexible and diverse in product formula, can be flexibly configured as required, and can be used for improving the utilization rate of the fertilizer by virtue of double-channel, increasing both the production and income, and reducing the cost. The synergistic effect of large and medium trace elements can be used for promoting the improvement of the utilization rate, providing comprehensive and nutrient care for crops, and also reducing the labor intensity of farmers, thus enabling the fertilization process to become simple; the sustained or controlled release blending fertilizer can be used for performing soil testing and formulated fertilization according to different soil types and different crop strains, and can be used for avoiding the fertilizer from being excessively applied, protecting the environment, saving the energy and reducing the emission.

Owner:QINGDAO SANNONG FUKANG FERTILIZER

Method for restoring dimension discrepancy of bearing utilizing chemical plating nickel

InactiveCN1485460ALow costFix out-of-tolerance dimensionsLiquid/solution decomposition chemical coatingChemical platingWarm water

An application of chemically plating nickel, especially a method of repairing different sizes of bearing by chemically plating nickel. The method comprises : washing bearings with gasoline; washing bearings with methanol; washing bearings with warm water, the temperature of the warm water is 60 -70degree Cú¼washing for 2 min; washing bearings with chemicals, the temperature thereof is 60-70degreeCú”washing with cool water; immersing in an acid and activating for 1-2min, the concentration of the acid is 10í†5ú”washing with cool water; preheating bearings with hot water for 5-10min, the temperature thereof is 80-90 degree C;preparing the chemical plating nickel solution.

Owner:宁夏西北轴承石油机械轴承有限公司

Formula for producing high-heat-resistant plastic building formwork

InactiveCN106280153AHigh heat resistanceOvercome the disadvantages of thermal deformationWeather resistanceAging resistance

The invention relates to the technical field of PVC boards, in particular to a formula for producing a high-heat-resistant plastic building formwork. The formwork is prepared from, by weight, 100 parts of high-heat-resistant PVC, 1.5-3 parts of stabilizer, 0.4-1.6 parts of inner lubricant, 0.4-1.6 parts of outer lubricant, 2-8 parts of anti-impact modifier, 1-6 parts of processing modifier, 0.2-2 parts of anti-ageing agent and 5-40 parts of filler. The high-heat-resistant PVC is chloridized modified PVC or composed of chloridized modified PVC and common PVC. The defects that an existing plastic formwork is low in heat-resistant temperature, poor in weather resistance and poor in ageing resistance are overcome, the high-heat-resistant plastic building formwork produced according to the formula has the advantages of being high in heat-resistant temperature, high in weather resistance and good in ageing resistance, and building formworks used in different areas and under different weather conditions can be prepared according to client requirements.

Owner:XINJIANG CORPS MODERN GREEN CHLOR ALKALI CHEM ENG RES CENT LTD

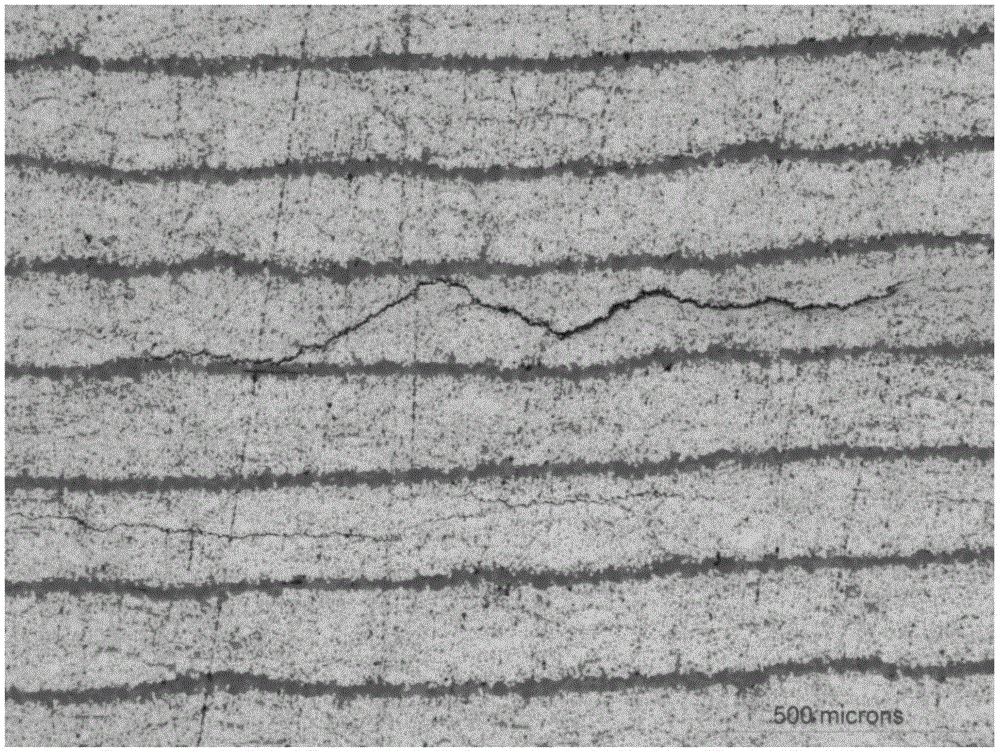

Epoxy resin composition suitable for being adopted at low temperature and preparation method thereof

ActiveCN105907040AExcellent resistance to microcracksGentle exothermic reactionChemistryCarbon fiber composite

The invention relates to an epoxy resin composition suitable for being adopted at low temperature. The composition comprises a polyfunctionality epoxy resin, biphenol A polyether epoxy resin, thermoplastic resin, a curing agent and an interfacial modification agent, wherein the composition is prepared from, by mass, 100 parts of polyfunctionality epoxy resin and biphenol A polyether epoxy resin, 20-40 parts of thermoplastic resin, 30-50 parts of the curing agent and 2-5 parts of the interfacial modification agent. The epoxy resin composition has the good manufacturability, the cured product has the advantage of being not likely to crack at low temperature, and the prepared carbon fiber composite material has the advantages of improving micro-crack resistance, being good in interface bonding force and the like, and is suitable for the fields of aircraft structural component manufacutirng, fuel storage tank and other military low temperature wind tunnels.

Owner:AEROSPACE RES INST OF MATERIAL & PROCESSING TECH +1

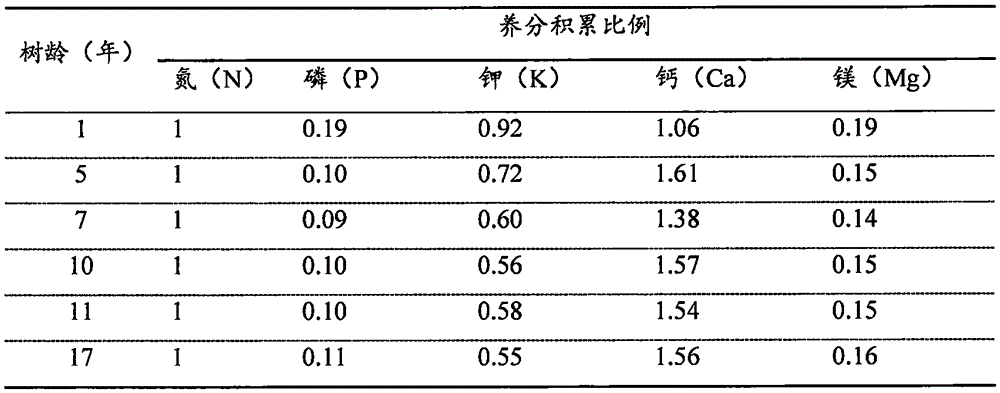

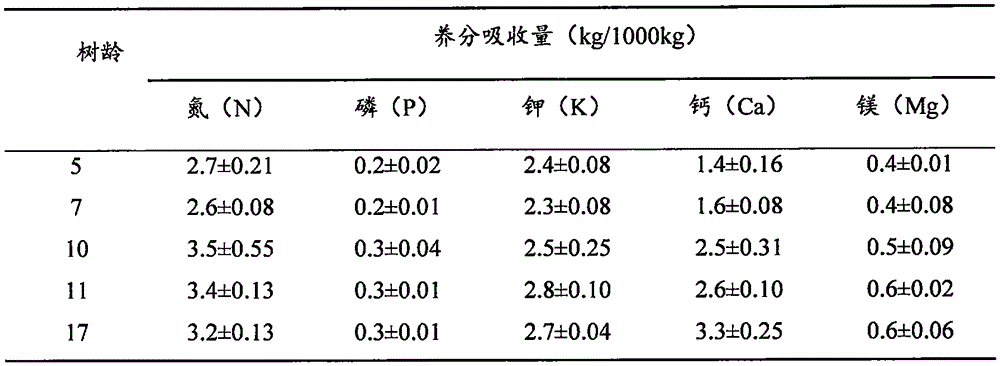

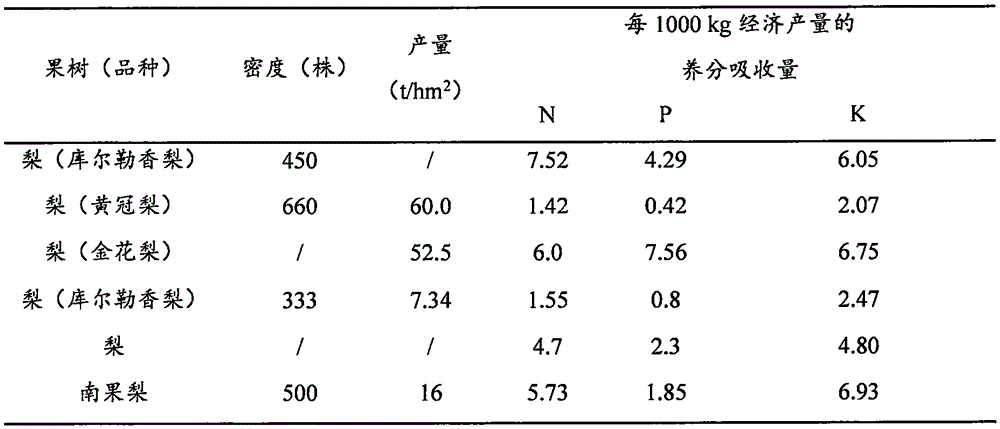

Formula fertilizer for production of green pear products as well as preparation method and application method of formula fertilizer

InactiveCN105523871APromote flowering and fruit settingStable outputAlkali orthophosphate fertiliserAmmonium orthophosphate fertilisersPEARPotassium

The invention provides formula fertilizer for production of green pear products. The formula fertilizer comprises nitrogenous fertilizer, phosphate fertilizer, potassium fertilizer as well as secondary element and microelement fertilizer containing Ca, Mg, B, Zn and Fe; in percentage by mass, the content of nitrogen in the formula fertilizer is 15%-18%, phosphorus pentoxide 6%-12%, potassium oxide 6%-18%, calcium oxide 0.5%-3%, magnesium oxide 0-2%, B 0.1%-0.5%, Zn 0.1%-0.2% and Fe 0.1%-1%. The formula fertilizer is mainly based on the soil fertility characteristic and the pear feature variety of pear orchards, the reasonable and accurate formula fertilizer is adopted, the fertilizer utilization rate is high, blooming and fruit setting of pears are facilitated, the product yield is stable, and the product quality is greatly improved.

Owner:辽宁省果树科学研究所

Traditional Chinese medicine anti-wrinkle handmade soap

InactiveCN106350312AAvoid harmFormula flexibleSoap detergents with organic compounding agentsShaping soapWrinkle skinAllergy

The invention relates to a traditional Chinese medicine anti-wrinkle handmade soap, which can effectively solve the problems that industrially manufactured anti-wrinkle products not only can not effectively resist wrinkles, but also easily injure skin, and cause allergy. The adopted technical scheme includes that the anti-wrinkle handmade soap is made of raw materials by weight percent: 5-8% of rice bran oil, 10-15% of camellia oil, 10-15% of sweet almond oil, 5-8% of grape seed oil, 8-12% of coconut oil, 8-12% of palm oil, 8-12% of olive oil, 8-12% of sodium hydroxide, 15-20% of pure water, 1-3% of vitamin E, 0.5-1% of eucommia extract, 0.5-1% of extract of angelica sinensis, 0.5-1% of extract of herba leonuri, 0.5-1% of extract of papermulberry fruit, 0.5-1% of extract of rosa rugose and 0-3% of auxiliary material. The traditional Chinese medicine anti-wrinkle handmade soap is flexible in formula, can increase and decrease oil content according to skin types, and also can add the auxiliary material according to needs. The traditional Chinese medicine anti-wrinkle handmade soap is a pure natural product, can not injure the skin, is applicable to people of allergic constitution, and is an innovation of handmade soaps.

Owner:HENAN UNIV OF CHINESE MEDICINE

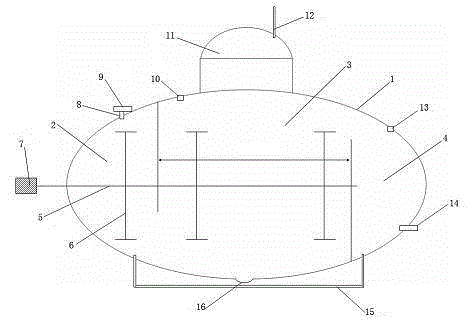

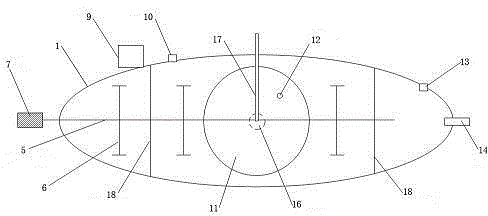

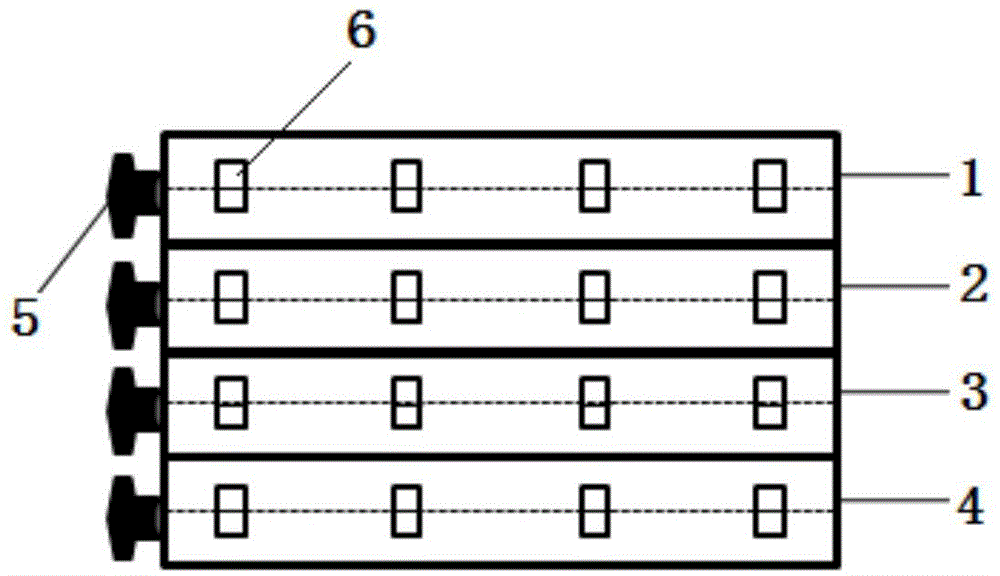

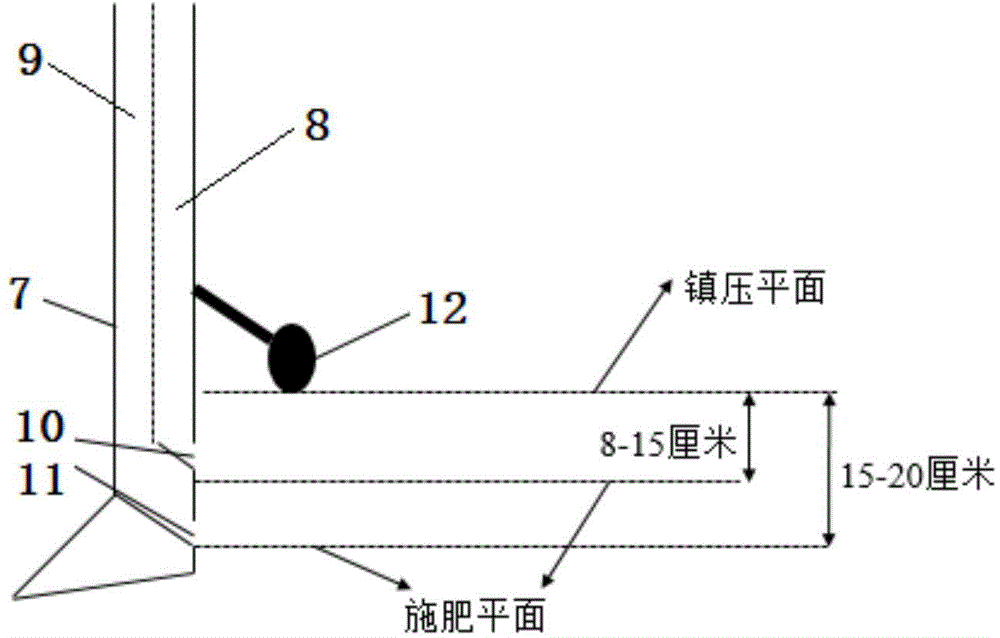

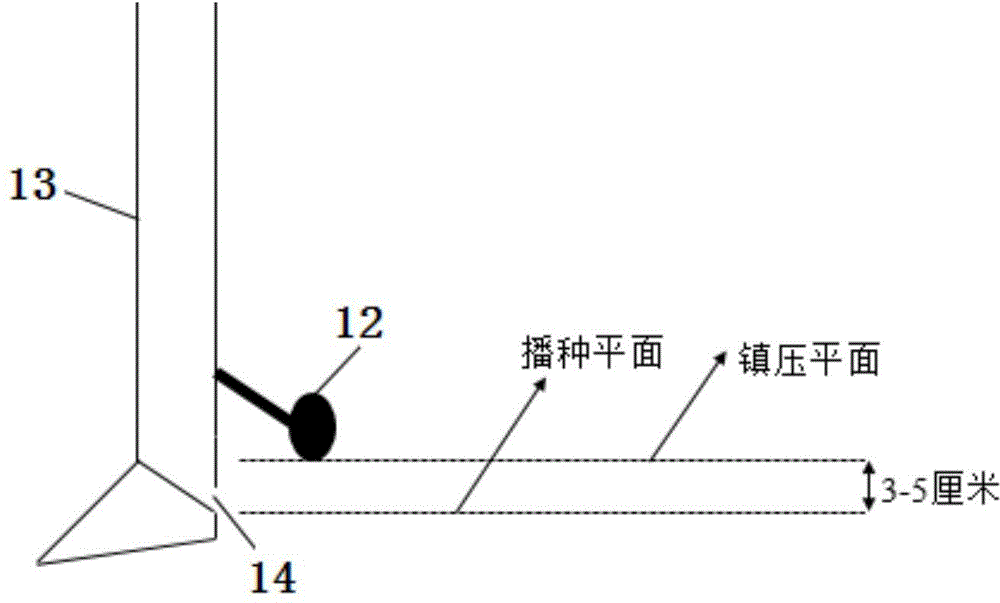

Corn seed manure simultaneous-application prescription fertilizer applicator and fertilizer application method

InactiveCN104521383AFormula flexibleLow costSaving energy measuresFertilising methodsNutrientFertilizer

The invention belongs to the technical field of agricultural fertilizer application and particularly relates to a corn seed manure simultaneous-application prescription fertilizer applicator and a fertilizer application method. A fertilizer box of the fertilizer applicator consists of secondary fertilizer boxes which are arranged side by side from front to back; each row of fertilizer outlets of the secondary fertilizer box respectively correspond to fertilizer application shoves; the bottom of each fertilizer application shovel is provided with a shallow-layer fertilizer outlet and a deep-layer fertilizer outlet which are arranged up and down; a shallow-layer fertilizer passage and a deep-layer fertilizer passage are arranged inside each fertilizer application shovel; each fertilizer outlet of the secondary fertilizer boxes is connected with each shallow-layer fertilizer passage or each deep-layer fertilizer passage; during fertilizer application, fertilizers are respectively fed into each secondary fertilizer box according to the requirements on shallow-layer fertilizer application and deep-layer fertilizer application by automatically making a prescription so as to realize layered composite fertilizer application. According to the required prescription of crops, the fertilizer application cost is effectively lowered, the utilization efficiency of nutrients is improved and ecological environment is protected; fertilizer application is flexibly performed according to the prescription and is not limited by agricultural acreage; the fertilizer application method is high in flexibility and high in multiplicity with a soil measurement prescription.

Owner:CHINA AGRI UNIV

Big rounded-grain nitrogen potassium chlorine based binary compound fertilizer and preparation method

ActiveCN102898231AReduce manufacturing costFertilizer formula flexibleFertilizer mixturesFertilizerNutrient

The invention relates to a big rounded-grain nitrogen potassium chlorine based binary compound fertilizer and a preparation method of the compound fertilizer. Main raw materials of the nitrogen potassium chlorine based binary compound fertilizer are powdery ammonium chloride and powdery potassium chloride, a disk or a drum serve as prilling equipment, a prilling assistant is used for forming the big rounded-grain binary compound fertilizer. The big rounded-grain nitrogen potassium chlorine based binary compound fertilizer is produced, as the prilling and the production are difficult, no similar raw material-shaped nitrogen potassium fertilizer exist in the market at present, and in addition, the fertilizer can meet special requirements for nitrogen and potassium nutrient of region soil containing phosphorus. Compared with an existing manufacture process of the compound fertilizer, the compound fertilizer has the advantages of (1) being low in fertilizer production, (2) being flexible in fertilizer formula, capable of arbitrarily adjusting proportion of the ammonium chloride and the potassium chloride and capable of effectively prilling under effects of the prilling assistant; (3) enabling prilling fertilizers to be high in particle strength and enabling average smashing resisting pressure to be 20-40N; (4) having a wide market; and (5) promoting an additional value of the ammonium chloride and having big profits.

Owner:武汉禾大科技有限公司

Preparation method of standardized sample for X-ray fluorescence analysis

InactiveCN104677701AShort production cycleFormula flexibleMaterial analysis using wave/particle radiationPreparing sample for investigationMetallic NickelHigh frequency

The invention discloses a preparation method of a standardized sample for X-ray fluorescence analysis. The method comprises the following steps: carrying out high frequency melting centrifuge casting on a single substance material and / or an alloy material and a mixed flux in a mold by using a crucible to obtain an alloy piece, wherein the total mass of the simple substance material and / or the alloy material and a pure iron flux is 40-60g, a mass ratio of the simple substance material and / or the alloy material to the pure iron flux is 1:1-1:5, and metallic chromium and / or metallic nickel introduced to the mixed flux account(s) for 8-14% of the total mass of the alloy pieces; and grinding and polishing the surface of the alloy piece to obtain the mirror standardized sample. The method has the advantages of short preparation period of the standardized sample, flexible formula and low cost, and the sample prepared in the invention has strong pertinence, stable physical and chemical properties, accords with analysis precision requirements, meets daily analysis demands, and guarantees the determination accuracy and stability of the content of all elements in the X-ray fluorescence analysis.

Owner:SHANGHAI BAOSTEEL IND TECHNOLOGICAL SERVICE

Arnebia root handmade soap and production method thereof

InactiveCN105296232AAvoid harmFlexible preparation methodSkin careDermatological disorderCoconut oilTemperature difference

The invention relates to an arnebia root handmade soap and a production method thereof. The invention is characterized in that: main raw materials contain soak oil, coconut oil, palm oil, sodium hydroxide and pure water, and the water is used as a water phase. The production method comprises the following steps: arnebia roots are placed in the soak oil and sealed, the immersion time is longer than 3 months, during the immersion time, bottles are frequently shaken for ensuring uniform contact; after immersion, the arnebia roots are filtered, the soak oil, the coconut oil and the palm oil are uniformly mixed at 40-50 DEG C, sodium hydroxide is dissolved by alkaline hydrolysis and is added into the mixed oil, and the temperature difference does not exceed 10 DEG C; an eggbeater is used for uniformly stirring to a dense state, and the materials are poured into a soap die, after moulding, the materials are taken out, the maturity period is 4-8 weeks, and after maturation, the soap can be used. The soap does not contain any additives and does not irritate skin; the arnebia roots have substantial efficacies for removing acne and diminishing inflammation; the soap can improve skin tension and prevent skin roughness, and has a certain effect for eczema. The production method is flexible, and the soap can be produced at home.

Owner:王晓伟

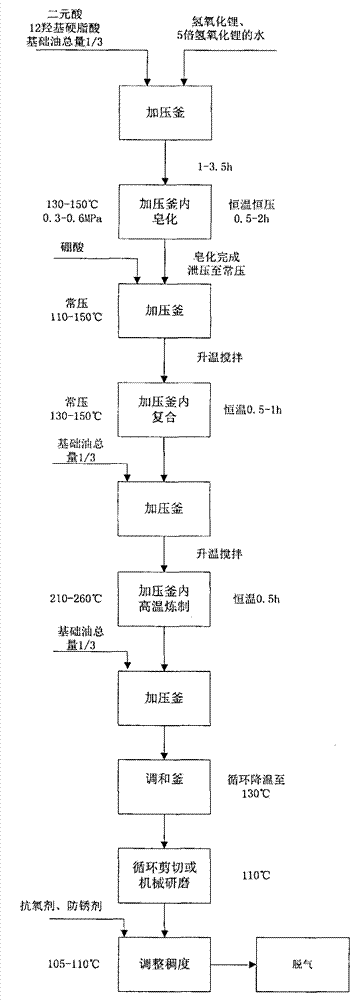

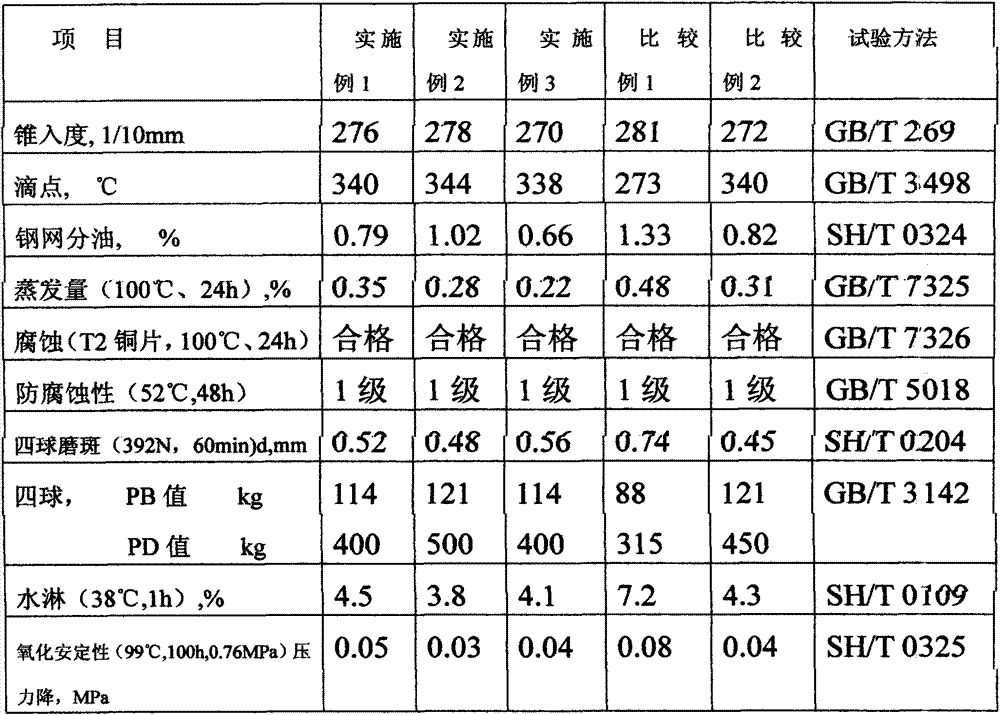

Preparation method of complex lithium grease

ActiveCN103773580AImproved dropping point and anti-friction and anti-wear propertiesFormula flexibleThickenersOperating temperatureCalcium hydroxide

The invention relates to a preparation method of complex lithium grease. The preparation method comprises the following steps: adding one third of total base oil or synthetic oil, 12 hydroxy stearic acid, binary acid, lithium hydroxide and water to an autoclave, sealing, stirring, heating and pressurizing the materials to carry out saponification; after saponification is completed, relieving the pressure, adding boric acid and stirring the materials; adding one third of total base oil or synthetic oil and stirring and heating the materials to carry out constant temperature refining; adding the remaining base oil or synthetic oil, reducing the temperature, adjusting the consistency, adding an antioxidant and antirust agents and obtaining the finished product after cyclic shearing or mechanical grinding. The preparation method has the beneficial effects that the problems that the dropping point of the complex lithium grease is low and additives are needed for achieving antifriction and antiwear properties in traditional preparation processes are solved; under the condition of not adding antifriction antiwear agents, the dropping point and antifriction and antiwear properties of the complex lithium grease are increased by changing the addition process of the boric acid, so that the complex lithium grease can meet the lubricating requirement under the severe conditions that the operating temperature is higher than 260 DEG C and the PB value is more than 980N.

Owner:北京雅士科莱恩石油化工有限公司

Environment-friendly catalyst and preparation method thereof

The invention discloses a preparation method of an environment-friendly catalyst. The method includes: reacting isocaprylic acid, bismuth oxide and solvent oil to obtain a solution, reacting isocaprylic acid, zinc oxide and solvent oil to obtain a solution, and mixing the obtained solutions to obtain a finished product. On the other hand, the invention also provides an environment-friendly catalyst, which comprises the following effective components: 20% of bismuth isocaprylate and 10% of zinc isocaprylate. The catalyst provided by the invention is environment-friendly, can completely replace lead mercury and tin catalysts that are currently abolished by legislation, has fast reaction speed when applied to polyurethane elastomers, and can significantly reduce bubbles of the product, combined use of bismuth and zinc can reach a synergistic effect, so that the formula and production can be more flexible, energy consumption is reduced, the profit can be increased, and therefore the environment-friendly catalyst provided by the invention is very suitable for application as a drier in polyurethane coating, medical polyurethane elastomer, polyurethane leather, polyurethane adhesive, polyurethane rubber, PU resin slurry, water-based paint industries and other fields.

Owner:赵洪枝

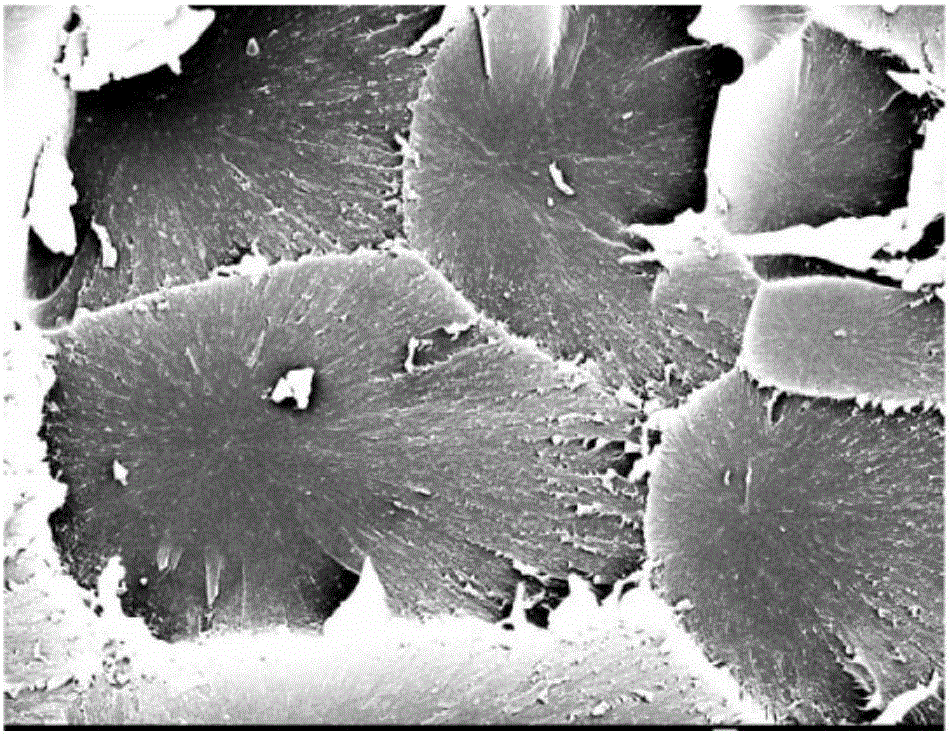

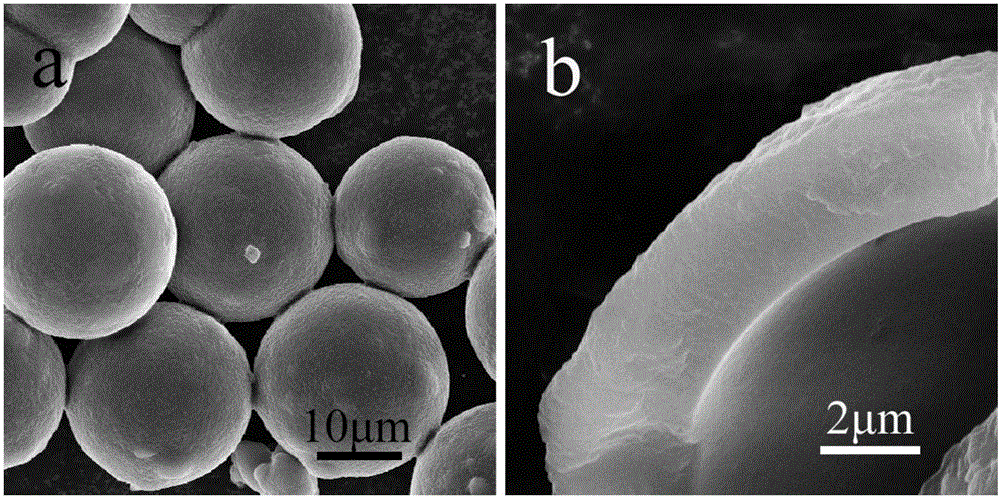

Preparation method of single-component photo-initiation self-healing silicon dioxide-based microcapsule

ActiveCN106237945AAvoid contact with the mixing processImprove stabilitySilicaMicroballoon preparationEpoxyMixed materials

The invention discloses a preparation method of a single-component photo-initiation self-healing silicon dioxide-based microcapsule. The preparation method comprises following steps: epoxy resin, a cationic photoinitiator, and tetraethyl orthosilicate are uniformly mixed at a mass ratio of 2:0.4-1:1-2 as an oil phase; the oil phase mixture is mixed with an aqueous solution of a nonionic surfactant, and an obtained mixed material is subjected to stirring for 15min using a high-speed homogenizer at a speed of 8000rpm so as to obtain an O / W emulsion; the O / W emulsion is delivered into a container, diluted hydrochloric acid is added dropwise, the container is delivered into an oil bath pan, the temperature is increased to 50 DEG C, and reaction is carried out at a revolving speed of 300rpm; 3h later, tetraethoxysilane is added, a hydrochloric acid solution is added every 4h for three times, continuous reaction is carried out for 12h, an obtained product is washed with deionized water for a plurality of times until an obtained supernatant liquid is colorless and transparent, and then the product is delivered into a drying oven for drying. The single-component photo-initiation self-healing silicon dioxide-based microcapsule possesses monodispersity, high coating rate, and excellent thermal stability; and stability and repair rate are increased at a certain degree.

Owner:湖北金伟新材料有限公司

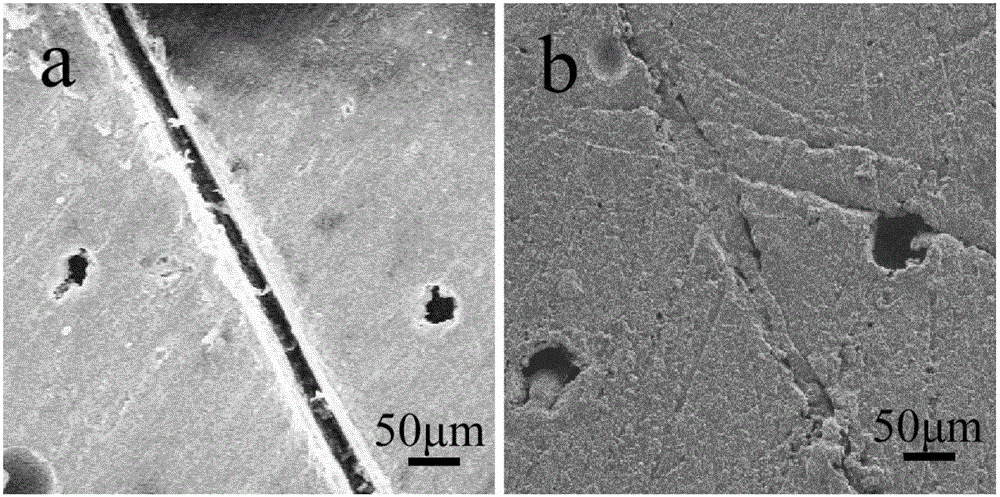

A kind of process method for filling spot welding stainless steel high-entropy alloy powder and a kind of high-entropy alloy powder filling spot welding stainless steel

InactiveCN103252568BIncrease contact resistanceGood welding performanceResistance welding apparatusElectrical resistance and conductanceHigh entropy alloys

The invention discloses a technique method for filling spot welding stainless steel high-entropy alloy powder and for filling spot welding stainless steel with high-entropy alloy powder. According to the technique method for filling the spot welding stainless steel high-entropy alloy powder and for filling the spot welding stainless steel with the high-entropy alloy powder, the high-entropy alloy powder is mainly composed of AlFeCuCoNiTiCrx, wherein the x is molar ratio of the Al to the Cr and is between 0 to 0.3, and the size of the powder is 100-300 meshes. When high-entropy alloy powder media are used as a filling layer, the contact resistance of a stainless steel material which are different to weld at the early welding stage is improved, resistance heat is used as a welding heat source, partial melting of the surface of the material to be welded is achieved under the protection of protective air and under the action of the resistance heat, an oxidation film can be broken under the impact effect of proper electrode pressure, refining of the high-entropy alloy powder media can be achieved on the interface of the material to be welded, a molten core and a single face-centered cubic tissue are formed on the interface, and then the strength and the corrosion resistance of a connector are improved. The technique method for filling the spot welding stainless steel high-entropy alloy powder and for filling the spot welding stainless steel with the high-entropy alloy powder has the advantages that welding can be achieved under the thermal compensation condition, the flexibility is strong, and ideal engineering significance is achieved.

Owner:SHANGHAI UNIV OF ENG SCI

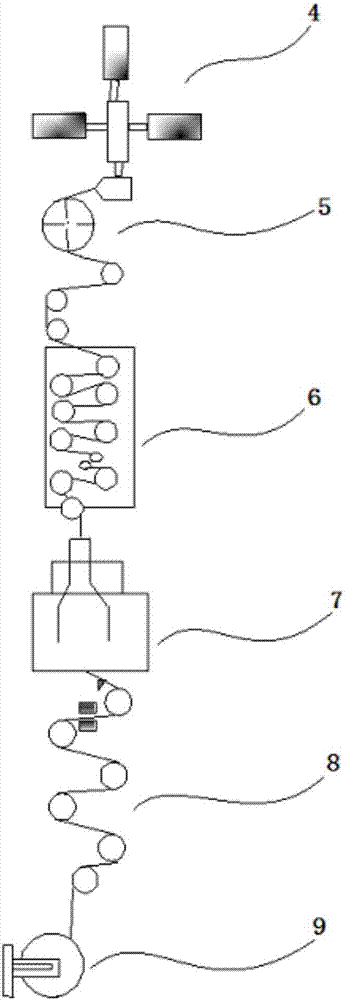

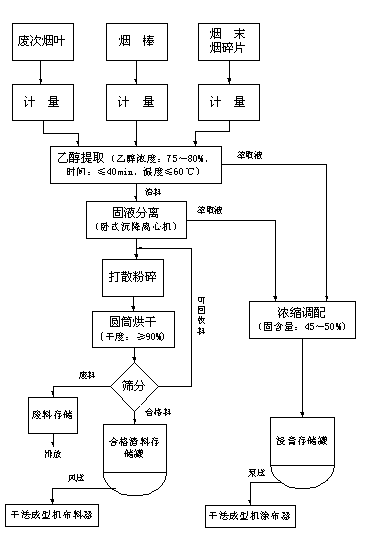

Raw material preparation method of dry method reconstituted tobacco

The invention provides a raw material preparation method of dry method reconstituted tobacco. An ethanol extraction method is adopted, lipid utmost fragrant substances in tobacco residuals such as tobacco powder, broken stalks and fragments are extracted out through a reverse alcohol extraction method and are used for preparing extracta, then, solid-liquid separation is carried out on slag charge, residual ethanol is extracted, remaining moisture is discharged out, and then the slag charge is screened and scattered, and dry method reconstituted tobacco raw materials are manufactured after being dried by a rotary drum dryer. Not only can intrinsic frangrance of natural tobacco be reserved to the maximum degree, but also the pollution of waste water to environment is reduced. The raw material preparation method of the dry method reconstituted tobacco is especially beneficial to accurate measuring of dry method paper-making process reconstituted tobacco equipment to raw materials in the process of manufacturing paper with pulp, and conducive to improving the filling value of the reconstituted tobacco.

Owner:GUANGDONG JINKE REFORGING TOBACCO LEAF CO LTD

Chinese herbal sunscreen handmade soap

InactiveCN106336971AAvoid harmFormula flexibleSkin careAlkali/ammonium soap compositionsHypersensitive responseRice bran oil

The invention relates to Chinese herbal sunscreen handmade soap. The problem that most industrial sunscreen products are irritating to the skin and can cause anaphylaxis can be effectively solved. According to the technical scheme, the sunscreen handmade soap is prepared from the following raw materials (by weight): 8-12% of rice bran oil, 10-20% of rose hip seed oil, 8-12% of canola oil, 10-20% of coconut oil, 5-10% of palm oil, 5-10% of olive oil, 8-12% of sodium hydroxide, 15-20% of pure water, 1-3% of natural indigo powder, 0.5-2% of a phellodendron extract, 0.5-2% of a garden burnet extract, 0.5-2% of a folium isatidis extract and 0-3% of an auxiliary material. The formula is flexible, and the auxiliary material can be added according to needs. The product is a pure natural product, is nonirritating to the skin, is suitable for people with allergic physique, and is an innovation of Chinese herbal handmade soap.

Owner:HENAN UNIV OF CHINESE MEDICINE

Ready mixed dry mortar and preparation method thereof

InactiveCN102408209AFormula flexibleTechnical requirements to meet different needsCellulosePolymer science

The invention discloses a ready mixed dry mortar and a preparation method thereof. The ready mixed dry mortar is prepared by the following components in percentage by weight: 18-50% of cement, 48-80% of medium fine sand and 0.1-2% of cellulose ether high molecular polymer. The preparation method comprises the following steps of: A, drying the medium fine sand, screening to remove particles of more than 4.75mm and weighing for use; B, weighing the cellulose ether high molecular polymer and the cement, and uniformly stirring in advance for use; and C, adding the medium fine sand screened in the step A and the mixture of the cellulose ether high molecular polymer and the cement in the step B to a stirrer for uniformly stirring to obtain the product. The aim of the invention is to overcome the defects in the prior art and provide a high-quality ready mixed dry mortar containing high molecular polymer component. The other aim of the invention is to provide a method for preparing the ready mixed dry mortar.

Owner:中山建华墙体材料有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com