Epoxy resin composition suitable for being adopted at low temperature and preparation method thereof

A technology of epoxy resin and composition, which is applied in the field of epoxy resin composition for ultra-low temperature and its preparation, can solve the problems that resin is difficult to completely infiltrate fiber, difficult to obtain uniform adhesive film, resin accumulation and poor adhesive, etc. The effect of micro-cracking ability, mild reaction exotherm, and high cross-linking density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0050] The preparation method of the epoxy resin composition that the present invention is suitable for low temperature use comprises the steps:

[0051] (1) Mix multifunctional epoxy resin and bisphenol A polyether epoxy resin evenly, add thermoplastic resin at a temperature of 120°C to 130°C, stir and dissolve to obtain a transparent and uniform hot-melt mixture;

[0052] (2) Cool the hot-melt mixture to 80°C-100°C, mix it with curing agent and interface modifier evenly in a high-speed stirring disperser, the stirring speed is 1000-3000r / min, and after thorough mixing, it is suitable for low-temperature environment The epoxy resin composition used.

[0053] In the epoxy resin composition prepared by the above method, the D component, that is, the solid curing agent is fully and uniformly dispersed rather than being dissolved in the epoxy resin, so the composition has a long shelf life at room temperature, and for the composition Viscosity control is very beneficial. In add...

Embodiment 1

[0055] The components and proportioning of the epoxy resin composition are listed in Table 1:

[0056] Table 1

[0057]

[0058] The preparation method of epoxy resin composition is as follows:

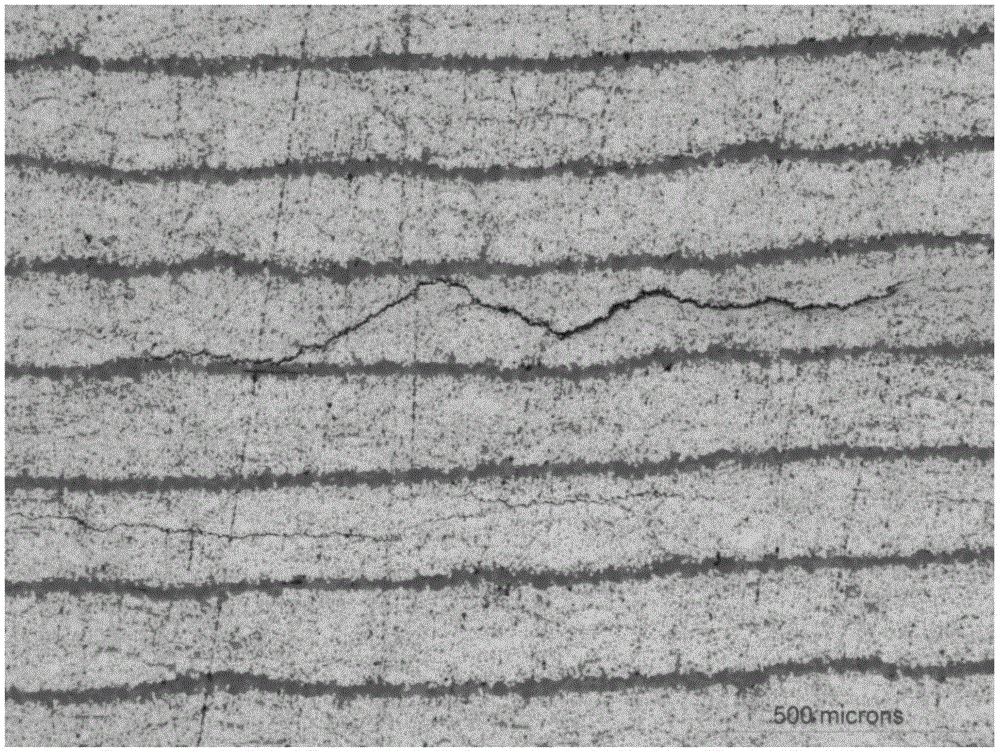

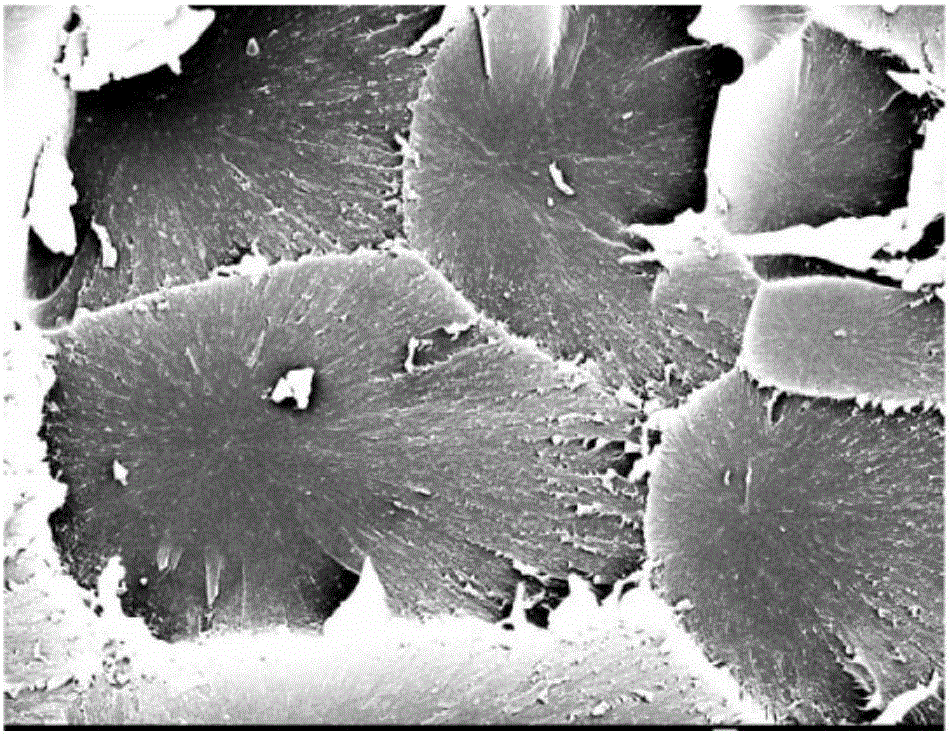

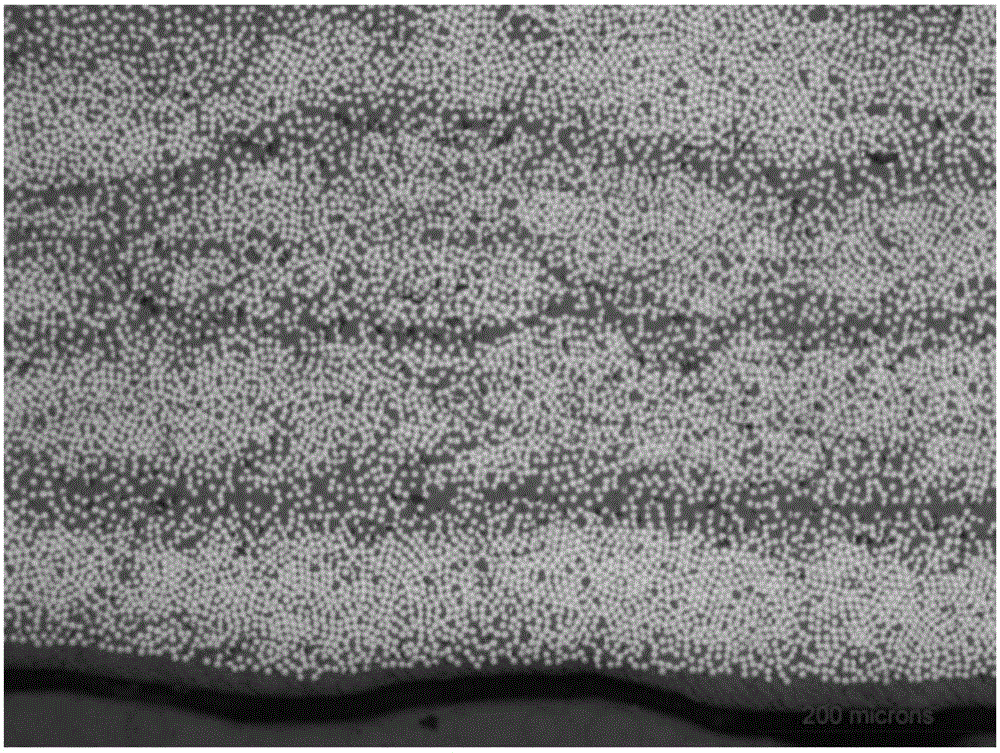

[0059] According to the ratio shown in Table 1, mix m-aminophenol triglycidyl epoxy resin and bisphenol A polyether epoxy resin evenly, add polyethersulfone at 120°C, stir and dissolve; then cool down to 80°C, Add 3,3'-diaminodiphenylsulfone, 4,4'-diaminodiphenylsulfone and core-shell structure polymer P52, and mix evenly in a high-speed stirring disperser at a stirring speed of 2000r / min to obtain epoxy resin composition. Such as figure 2 Shown is the microscopic morphology of the fractured resin cast body in Example 1 of the present invention. It can be seen from the figure that the P52 core-shell polymer exists in the form of dispersed particles, and is torn into an anchor-like microscopic morphology when fractured.

[0060] Performance Testing:

[0061] (1), the mechanica...

Embodiment 2

[0074] Components and proportioning of epoxy resin composition are listed in table 3:

[0075] table 3

[0076]

[0077] The preparation method of epoxy resin composition is as follows:

[0078] Mix m-aminophenol triglycidyl epoxy resin and bisphenol A polyether epoxy resin evenly according to the ratio shown in Table 3, add polyethersulfone at 130°C, stir and dissolve; then cool down to 90°C, Add 3,3'-diaminodiphenylsulfone, 4,4'-diaminodiphenylsulfone and core-shell structure polymer P52, and mix evenly in a high-speed stirring disperser at a stirring speed of 1500r / min to obtain epoxy resin composition.

[0079] Performance Testing:

[0080] (1), the mechanical properties of the cured product of the low temperature epoxy resin composition in this embodiment are as follows:

[0081] The impact strength is 28.5±3.2KJ / m 2 (liquid nitrogen temperature); elongation at break 2.7% (liquid nitrogen temperature);

[0082] (2) The cured resin / casting body did not produce mic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Interlayer strength | aaaaa | aaaaa |

| Interlayer strength | aaaaa | aaaaa |

| Interlayer strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com