High-temperature resistant single-component epoxy structure glue, preparation method and using method thereof

An epoxy structural adhesive, one-component technology, applied in the direction of epoxy resin adhesive, non-polymer adhesive additive, novolac epoxy resin adhesive, etc., can solve the problem of bonding epoxy adhesive to non-metal Surface overheating, small thermal expansion coefficient, affecting product quality, etc., to achieve the effect of adjustable viscosity range, high viscosity, and elimination of interfacial stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] Calculated by the total weight of epoxy resin in units of 100

[0020] Epoxy resin E-51 50g, F-51 50g and toughening agent KH-07A 2.5g, KH-07B 2.5g, KH-07C 2.5g, KH-07D 2.5g, γ-aminopropyl triethoxy Add 1g of silane into the mixing kettle, stir for 1h~2h at room temperature, and rotate at 100r~180rpm; add 5g of alumina powder, 10g of spherical aluminum powder, 5g of silicon micropowder, stir at 1000r~1200rpm for 20min~40min, mix well and then reduce to At room temperature, add 3g of dicyandiamide, 2g of toluene-2,4-di[N,N-dimethylamino]propionurea, stir at 100r~180rpm for 30min, finally add 3g of fumed silicon, stir for 20min~40min, adjust the viscosity to 200~ 400Pa·s, the epoxy structural adhesive is obtained from the discharge.

[0021]

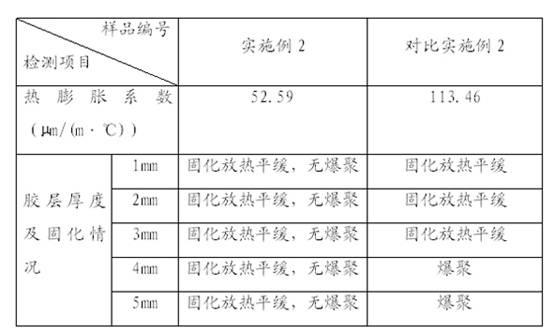

Embodiment 2

[0032] Calculated by the total weight of epoxy resin in units of 100

[0033] Add 70g of epoxy resin E-51, 30g of F-51, 5g of toughening agent KH-07C, 20g of KH-07D, 5g of γ-aminopropyltriethoxysilane into the mixing tank, stir at room temperature for 1h~2h, and rotate at 100r~180rpm; add 10g of alumina powder, 20g of spherical aluminum powder, 10g of silicon micropowder, stir at 1000r~1200rpm for 20min~40min, mix well and lower to room temperature, add 6g of dicyandiamide, toluene-2,4- 4g of di[N,N-dimethylamino]propaneurea, stirred at 100r~180rpm for 30min, finally added 8g of fumed silicon and stirred for 20min~40min, adjusted the viscosity to 200~400Pa·s and discharged to obtain epoxy structural adhesive.

[0034]

Embodiment 3

[0047] Calculated by the total weight of epoxy resin in units of 100

[0048] Add 20g of epoxy resin E-51, 80g of F-51, 18g of toughening agent KH-07C, 3g of silane coupling agent γ-aminopropyltriethoxysilane into the mixing kettle, stir at room temperature for 1 h~2h, and rotate at 100r~180rpm; add 5g of alumina powder, 15g of spherical aluminum powder, 10g of silicon micropowder, stir at 1000r~1200rpm for 20min~40min, mix well and cool down to room temperature, add 6g of dicyandiamide, toluene-2,4- Di[N,N-dimethylamino]propaneurea 1g, stirred at 100r~180rpm for 30min, finally added 5g of fumed silicon and stirred for 20min~40min, adjusted the viscosity to 200~400Pa·s and discharged to obtain epoxy structural adhesive.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com