Patents

Literature

80 results about "N fertilizer" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

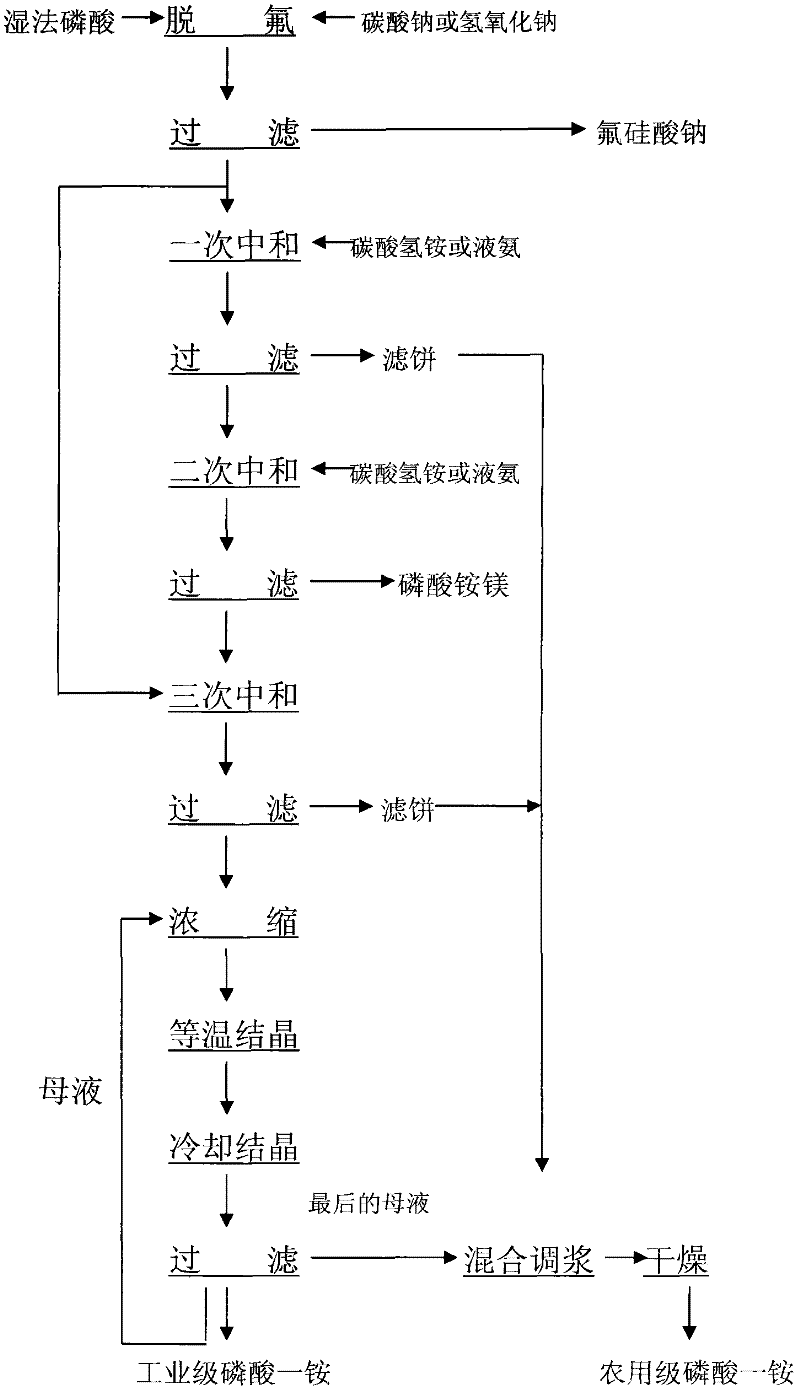

Method for producing industrial and agricultural monoammonium phosphate and magnesium ammonium phosphate with wet-process phosphoric acid

ActiveCN102020256AImprove purification effectTroubleshoot follow-up issuesPhosphatesO-Phosphoric AcidAgricultural engineering

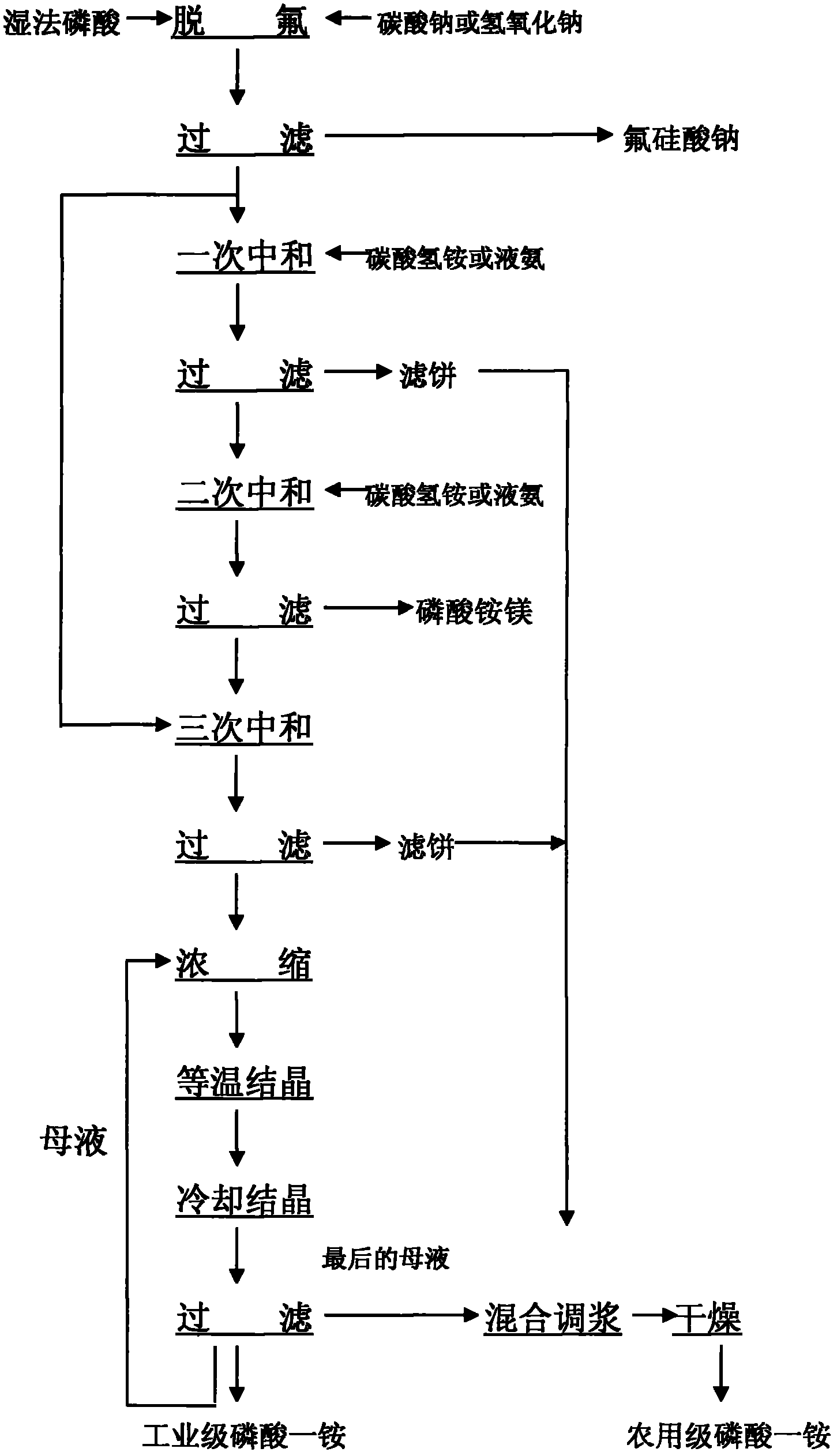

The invention provides a method for producing industrial and agricultural grade monoammonium phosphate and magnesium ammonium phosphate with wet-process phosphoric acid. The wet-process phosphoric acid is taken as a raw material. Sodium fluosilicate, monoammonium phosphate solution, monoammonium phosphate filter cakes and magnesium ammonium phosphate are respectively obtained through defluorination and a three-section substep neutralization process, wherein the monoammonium phosphate solution is concentrated and crystallized to obtain high-quality water soluble industrial monoammonium phosphate, and the monoammonium phosphate filter cakes and the monoammonium phosphate mother solution subjected to repeated crystallization are subjected to size mixed and dried to obtain qualified agricultural monoammonium phosphate. The magnesium ammonium phosphate is a good slow release nitrogenous fertilizer per se. The process has the advantages of little investment of equipment, good adaptability of raw material, low production cost and good product quality. The water soluble industrial monoammonium phosphate with low cost can provide a cheap and good water soluble phosphatic fertilizer for modern facility agriculture.

Owner:昆明隆祥化工有限公司

Simultaneous desulfurization and denitrification method using aqueous ammonia

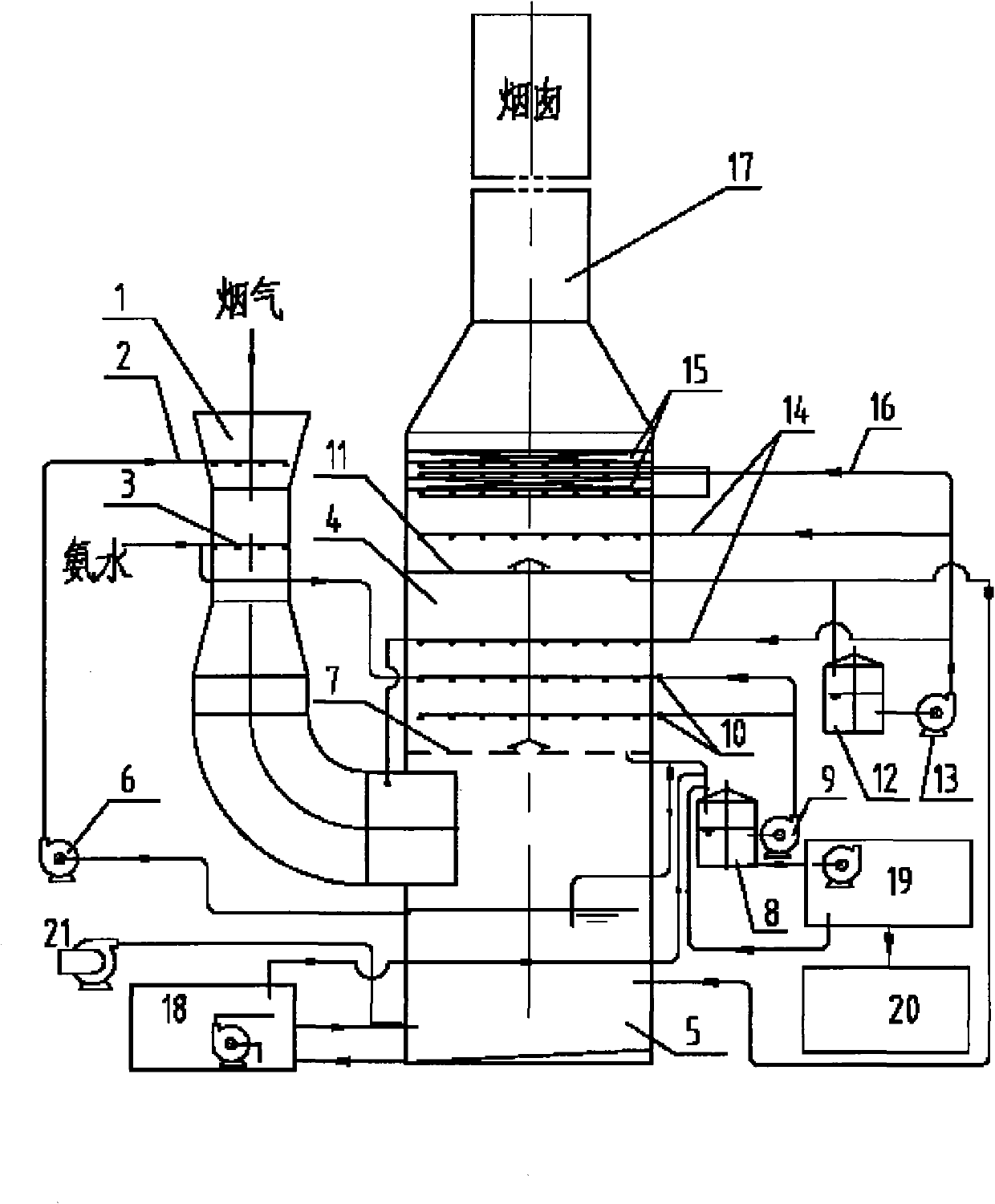

The invention relates to a method for simultaneously removing sulfur oxides and nitrogen oxides in flue gas by using aqueous ammonia. According to the method, the (NH4)2SO3, which is obtained from a desulfurization reaction for absorbing SO2 by aqueous ammonia, is used as an absorption solution for a denitrification reaction; and the (NH4)2SO3 has reducibility for reducing NOx in the flue gas to N2 to achieve the denitrification purpose. The method provided by the invention comprises the following steps that: the flue gas firstly enters into a denitrification spraying layer of a contraction segment in a venturi tower and is subjected to a downstream contact reaction with a circulating liquid from an oxidation pond on the tower bottom, an aqueous ammonia spraying layer is arranged at the throat part of the venturi tower to carry out the desulfurization reaction, the concentration of the (NH4)2SO3 is instantly increased due to the desulfurization reaction, the denitrification reaction is further carried out, the liquid after reaction and the flue gas transversely enter into the middle lower part of a cylindrical tower along the lower part of the venturi tower, the liquid flows downwards to the bottom of the cylindrical tower, the flue gas moves upwards after passing through a tower plate and is countercurrent contact with the circulating liquid to further generate a desulfurization reaction and a denitrification reaction, fine liquid drops and aerosol of the purified flue gas are captured when the purified flue gas passes through the water spraying layer and a folded plate type defroster, the purified flue gas is then directly exhausted from a direct exhaust chimney connected to the tower top, and simultaneously, a by-product of the system is ammonium sulfate, which is a raw material of an agricultural nitrogenous fertilizer or a compound fertilizer.

Owner:克莱斯克(北京)环境工程有限公司 +1

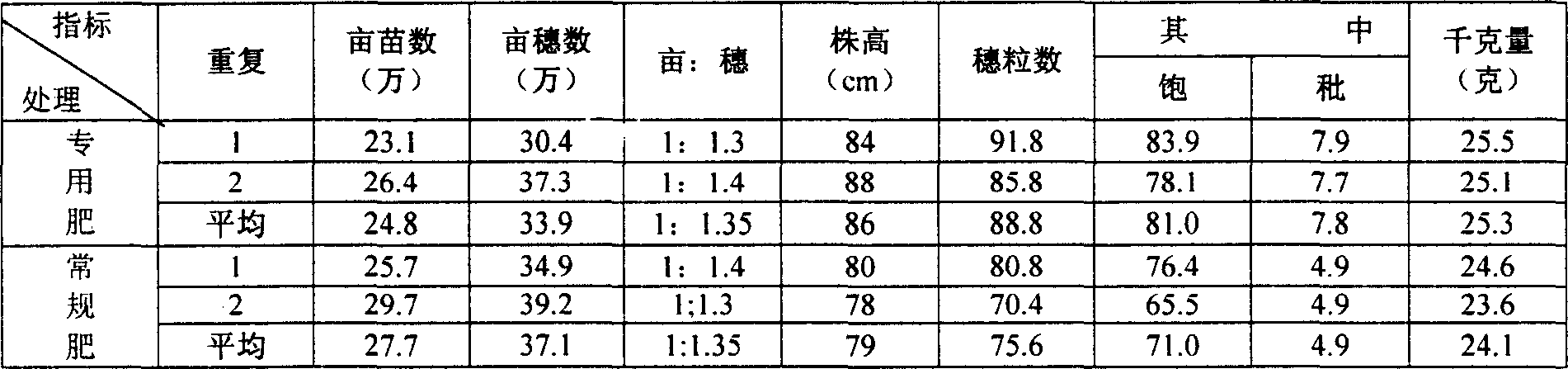

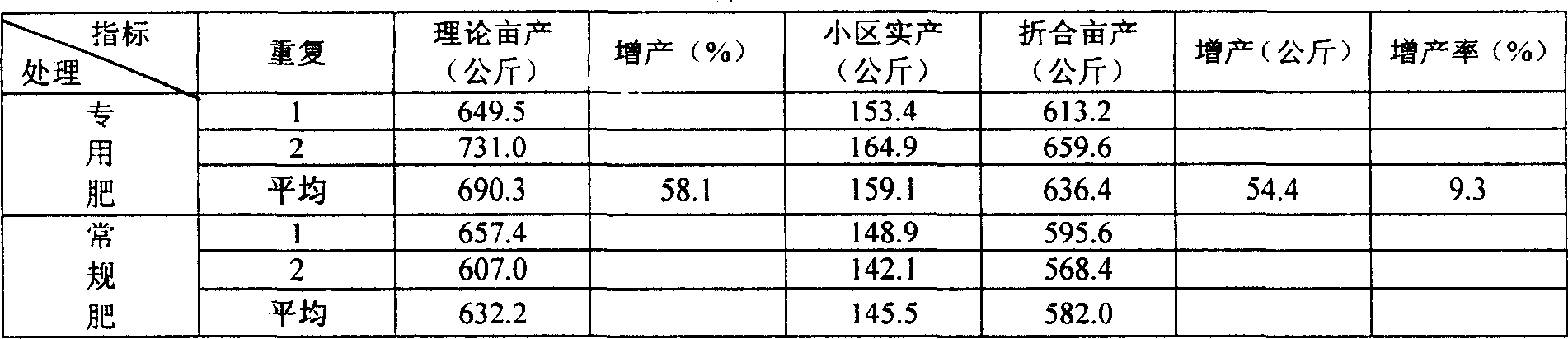

Special fertilizer for corn with water holding and soil improvement effects and preparation thereof

InactiveCN102093118AIncrease investmentImprove anti-retrogradeFertilizer mixturesPotassiumCross linker

The invention relates to a special fertilizer for corn, in particular to a special fertilizer for corn with water holding and soil improvement effects and preparation thereof. The special fertilizer comprises the following components in part by weight: 100 to 200 parts of organic substance, 200 to 300 parts of compound fertilizer, 0.2 to 3 parts of active covering agent, 150 to 200 parts of acrylamide, 50 to 100 parts of starch, 20 to 50 parts of attapulgite, 20 to 40 parts of porous inorganic substance, 30 to 60 parts of clay, 100 to 150 parts of acid liquid, 2 to 4 parts of initiator, 0.5 to 1 part of cross linker, and 0.03 to 0.1 part of compost leaven. The compound fertilizer mainly comprises the following components by weight based on effective content: 1 percent of nitrogen (N), 0.45 to 0.60 percent of phosphorus (P), 0.40 to 0.55 percent of potassium (K) and 0.10 to 0.25 percent of zinc (Zn); and hydroquinone and dicyandiamide are 2.0 to 3.0 percent of the consumption of N fertilizer. The special fertilizer for corn keeps certain advantage of a water holding agent; because proportional organic substance, porous inorganic substance, clay and the like are added, the special fertilizer plays a role in improving the structure, organic substances and pH value of the soil; because humic acid is added, the special fertilizer can play a role of urease inhibitor to certain degree; and by matching the urease inhibitor, the utilization efficiency of N in the compound fertilizer can be improved.

Owner:SHENYANG INST OF APPLIED ECOLOGY - CHINESE ACAD OF SCI

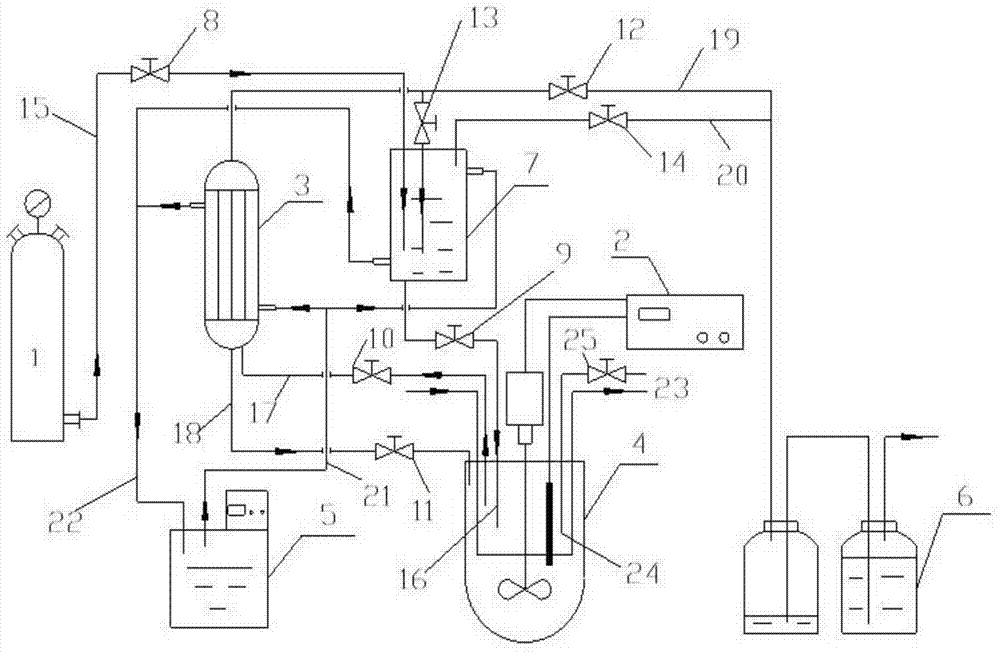

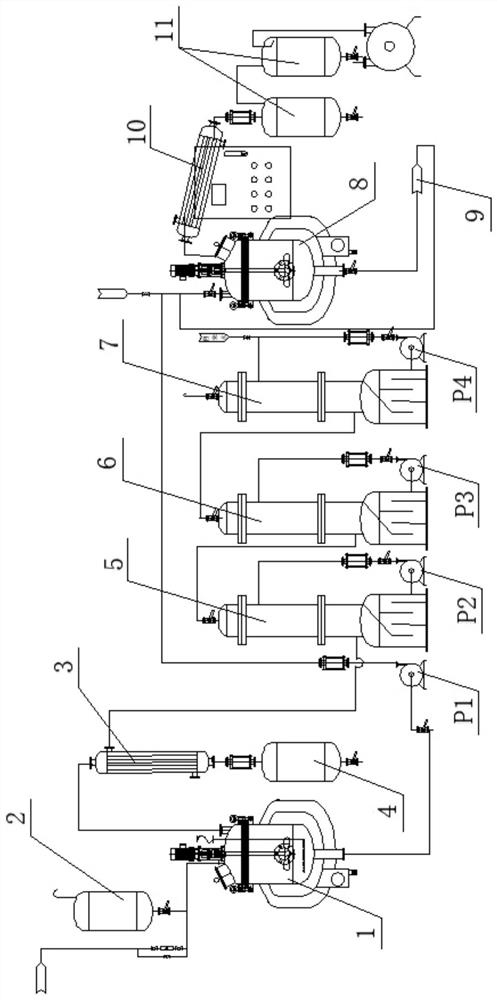

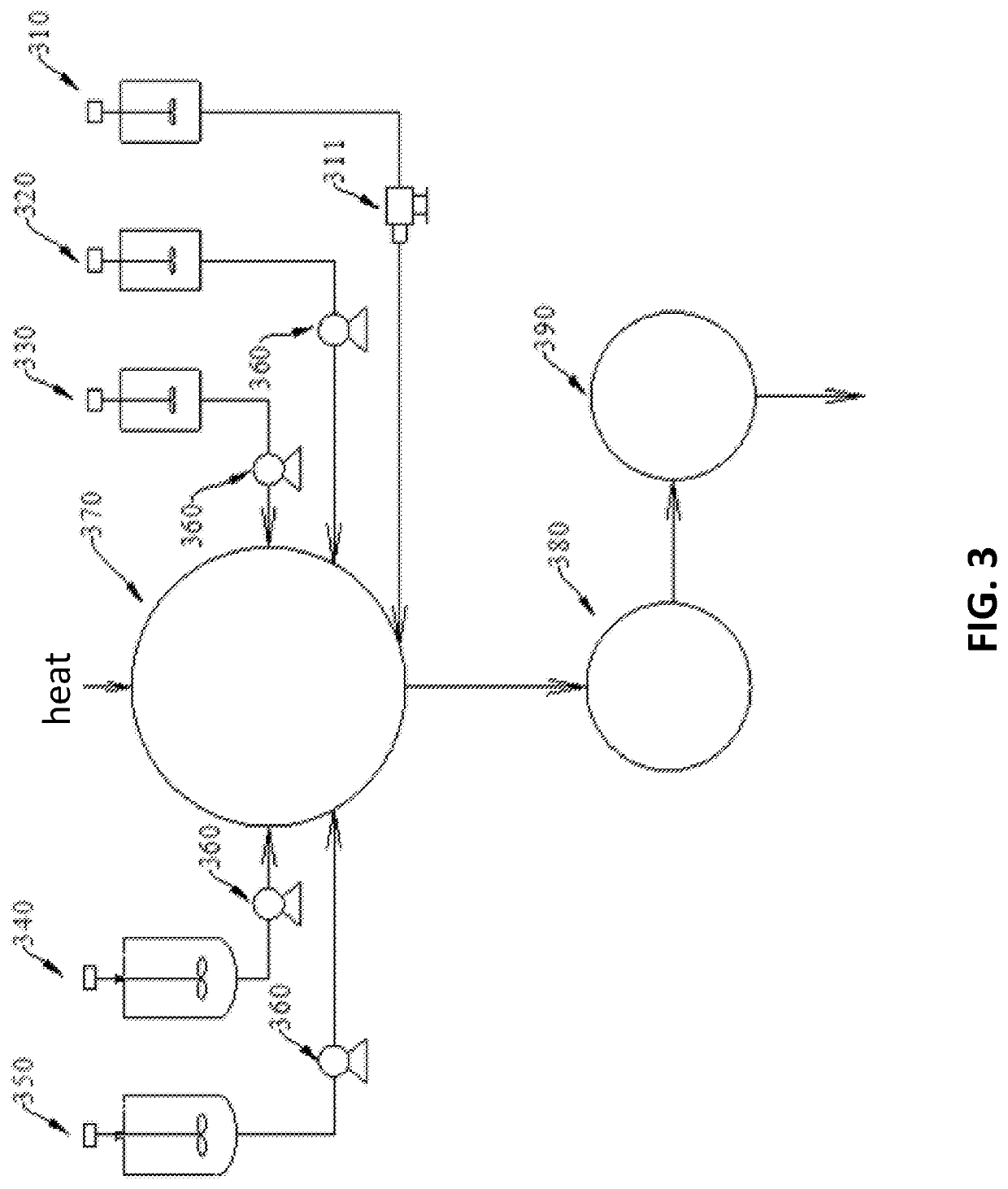

Method and device for directly synthesizing oxamide granules

InactiveCN103242188ASimple processEasy to operateOrganic compound preparationCarboxylic acid amides preparationTemperature controlProcess engineering

The invention relates to a method and a device for directly synthesizing oxamide granules. Dimethyl oxalate and ammonia serving as reaction raw materials and methanol serving as a reaction solvent are subjected to an ammonolysis reaction under normal pressure, a stirring system and a cooling system are arranged in the reactor, a jacket temperature control device is arranged at the outer side of the reactor, and a condenser is connected to the upper part of the reactor for regulation. A front ammonia absorption tank is arranged at the front end of the reactor, the front end of the reactor is provided with a cooling system, the outlet of the condenser is respectively connected with the front ammonia absorption tank and the tail gas absorption tank. The reaction process and the granule forming process can be performed in the same reactor, the methanol recycling and tail absorption device are equipped, and the ammonia gas is not discharged into atmosphere. The reaction investment and consumption can be greatly saved, the environmental pollution is reduced, and the product can be produced in a large scale until the product is industrially applied, so that the urea and ammonium bicarbonate are replaced, and the occupancy of oxamide in the nitrogenous fertilizer market is increased.

Owner:TIANJIN UNIV

Preparation method for nitrate urea-formaldehyde fertilizer

The invention discloses a preparation method for nitrate urea-formaldehyde fertilizer. The method comprises the following steps of: adding hot water in a kettle, rising temperature to 65 DEG C, adding urea, stirring and dissolving, adjusting PH value to 8.6 to 8.8 through 20% NaOH, adding formaldehyde with a weight ratio between formaldehyde and urea of 1:1.8, rising temperature to 85 DEG C, keeping temperature for 20 to 30 min, adding nitrate nitrogenous fertilizer in a backing material of a granulator according to a calculated formula NPK raw materials at a constant temperature about 80 DEG C, dehydrating to make grains, drying, cooling and screening to acquire the finished product. The nitrate urea-formaldehyde fertilizer contains urea, formaldehyde, monoammonium phosphate, potassium sulfate and ammonium nitrate. The invention has the advantages of convenient preparation, low cost, high nitrogen content, quick-acting and slow-acting functions of supplying nitrogen element, decreased pouring and volatilized loss, promoted use ratio, and the like.

Owner:山东史贝美肥料股份有限公司

Special lecithin-coated slow release fertilizer for cotton and production method of fertilizer

ActiveCN103102223ANo pollution in the processImprove fertilityAgriculture gas emission reductionFertilizer mixturesSoil sciencePhosphate

The invention discloses a special lecithin-coated slow release fertilizer for cotton. The slow release fertilizer is prepared from the following raw materials: urea, monoammonium phosphate, potassium chloride, ammonium chloride, superphosphate, zinc sulfate, borax, lecithin and amidinothiourea; and the production method of the slow release fertilizer comprises the steps of: firstly, granulating monoammonium phosphate, potassium chloride, ammonium chloride, superphosphate, zinc sulfate, borax and most part of urea (used after fusion) to form inner-layer particles; then spraying mixture of the rest of urea (used after fusion) and amidinothiourea on the inner-layer particles; and coating the outer layer with lecithin. As a sustained-release material (lecithin) and a controlled-release material which is amidinothiourea serving as a urease inhibitor and a nitrification inhibitor are selected and used in the slow release fertilizer, the effective period of a nitrogenous fertilizer is prolonged to 121 days from about 30 days, the effective period of the nitrogenous fertilizer is prolonged greatly, the utilization rate of the nitrogenous fertilizer for cotton is improved greatly, the utilization rate of the nitrogenous fertilizer in a cotton season is improved by 37%, the fixation and the loss of a phosphorus potassium fertilizer are reduced, and the utilization rate of the phosphorus potassium fertilizer in a cotton season is improved by 13% and 5% respectively.

Owner:新疆正易龙农资有限公司

Process for performing roofs virescence by using melastona dodecandrum bamboo straw

ActiveCN101116413AImprove insulation performanceWith cooling performanceCultivating equipmentsSoilless cultivationEcological environmentHeat resistance

The invention discloses a roof greening method by using callisia repens, in particular to a growing method for planting callisia repens on roof. The procedures of the method are as follows: first, a water-resistant system, a drainage system and a root resistant layer are arranged on the roof and a matrix layer is paved on the roof; second, grass seeds of the callisia repens is planted on the matrix layer by using any one method of offshoots, broadcasting sowing method, cottage or greensward transplanting and paving method; third, root fixing water is watered and N fertilizer is fertilized once every fifteen days, and lawn is formed within one to two months. As an effective measure for solving the influence of urban development on the entironment and raising the urban afforestation rate, the invention uses the callisia repens on the roof greening, which has a resultful effect on the heat resistance, virescence and disaster prevention of room surface.

Owner:广东如春生态集团有限公司

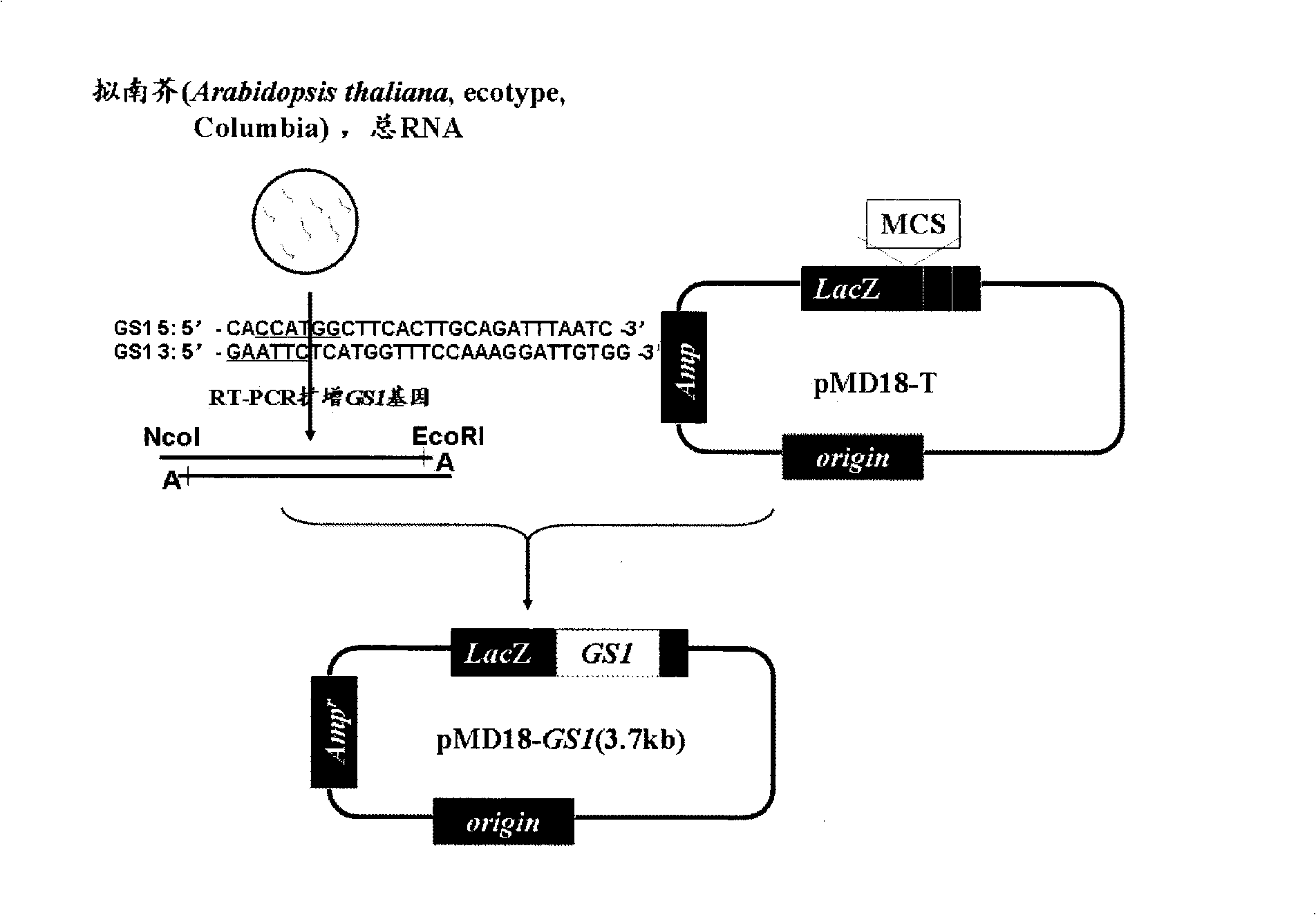

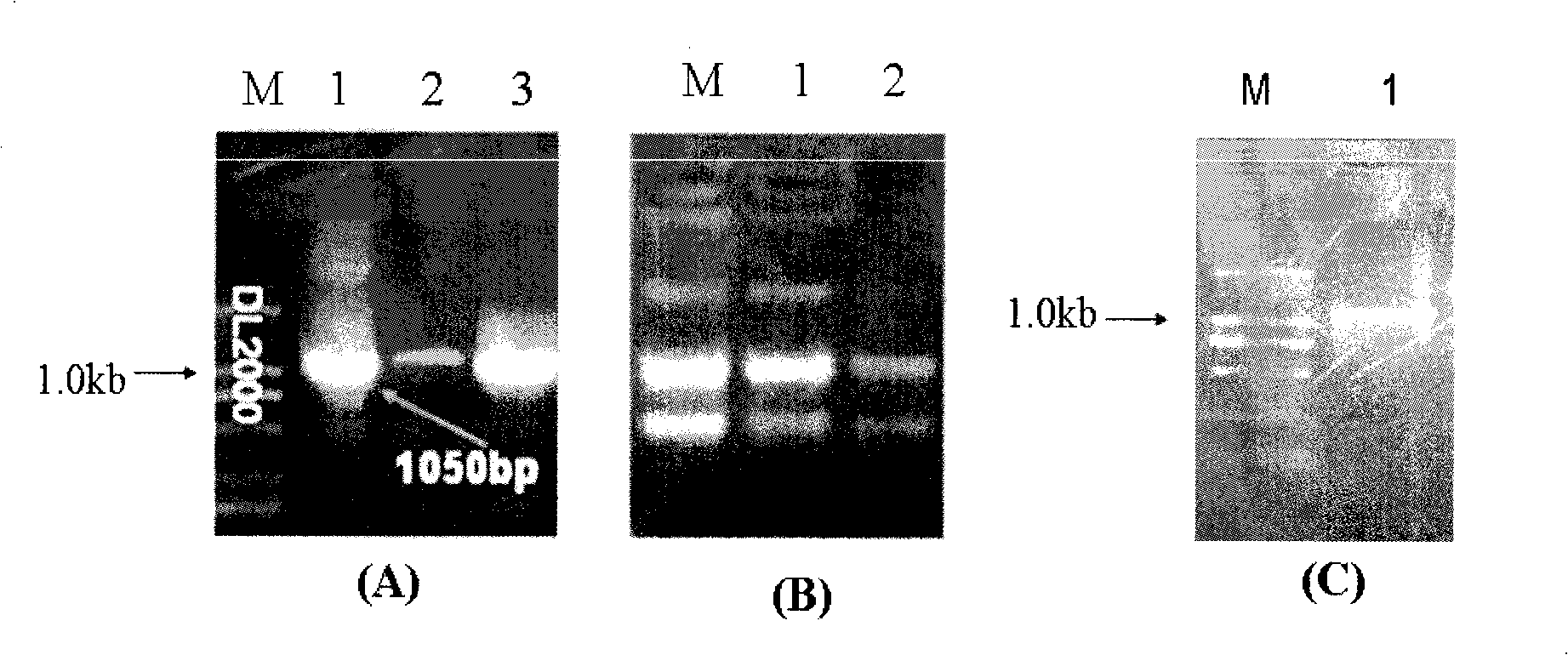

Construction and use of plant expression vector of Arabidopsis thaliana cytoplasm type glutamine synthetase gene

InactiveCN101407824AImprove nitrogen use efficiencyIncreased reassimilation capacityPlant tissue cultureHorticulture methodsNicotiana tabacumLow nitrogen

The invention relates to a special plant expression vector pH2-35S-PrbcS-GS1 which comprises an arabidopsis thaliana cytoplasm glutamine synthetase gene GS1 and can improve the utilization rate of a plant nitrogen element. A method of RT-PCR is used for cloning the GS1 gene from the arabidopsis thaliana of a model plant, a photoinduction type promotor (the promotor of a a small subunit Rubisco) is used for controlling the excessive expression of the GS1 gene in a plant leaf and a leaf disc conversion method is used for transferring the GS1 gene into a pPZP221-PrbcS-Dof1 type transgene tobacco. An experiment result shows that the GS1 gene can be normally transferred in the transgene tobacco; under the nutrition condition of low nitrogen and the growing conditions of indoor irradiation for 24 hours of 2000LUX and 25 DEG C, the growing situation of the plant transferred with the single gene of Dof1 is (the expression of the gene is controlled by the photoinduction type promotor Prbcs) is a little better than that of a contrast tobacco (a wild type without transgene); after being transferred under the natural growing condition of a green house, the growing situation of the tobacco which is simultaneously transferred with the GS1 gene and the Dof1 gene shows remarkable growing advantages than that of the contrast plant; and therefore, simultaneously and excessively expressing the GS1 gene and the Dof1 gene, can improve the efficiency of the GS / GOGAT (glutamine synthetase / glutamic acid synthetase) approaches in the leaf more extensively, thereby improving the utilization rate of the plant nitrogen element. The vector can be broadly applied to the molecule breeding of crops, improving the utilization rate of the plant nitrogen element thereof and the durability to the nutrition condition of low nitrogen and being capable of obtaining a higher yield under the conditions of applying less fertilizers and even not applying the fertilizers.

Owner:KUNMING UNIV OF SCI & TECH

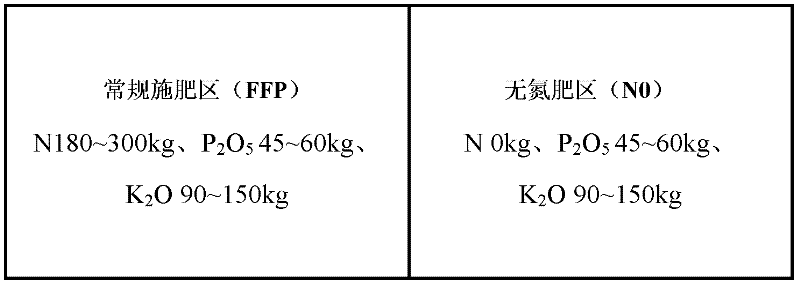

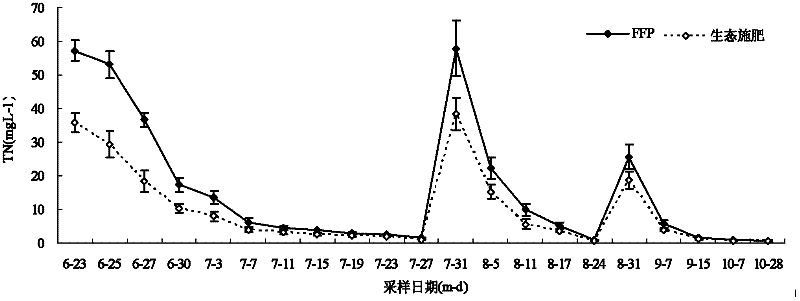

Ecological fertilization method based on nitrogen-saving high paddy rice yield and non-point source emission reduction

InactiveCN102440109AReduce investmentReduce non-point source pollutionFertilising methodsN fertilizerHigh yielding

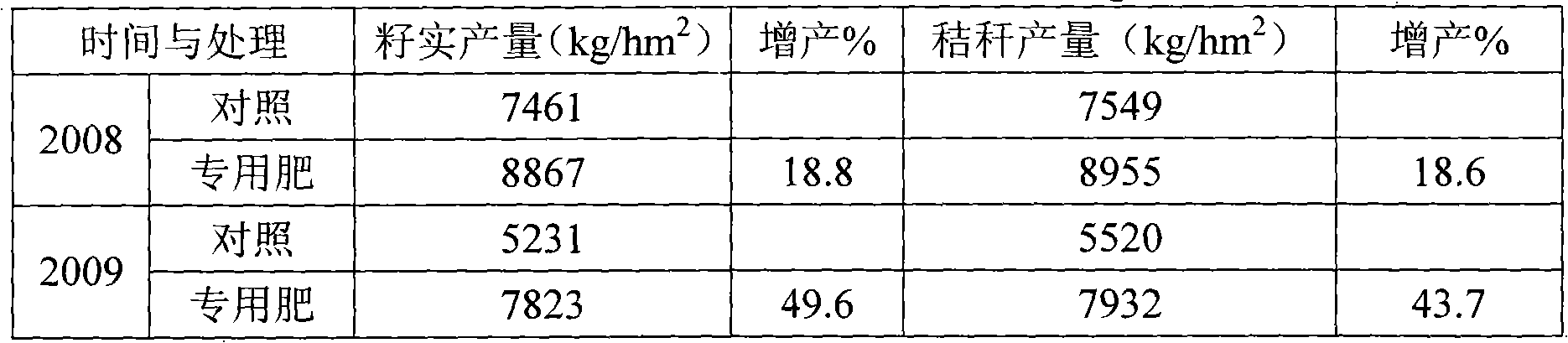

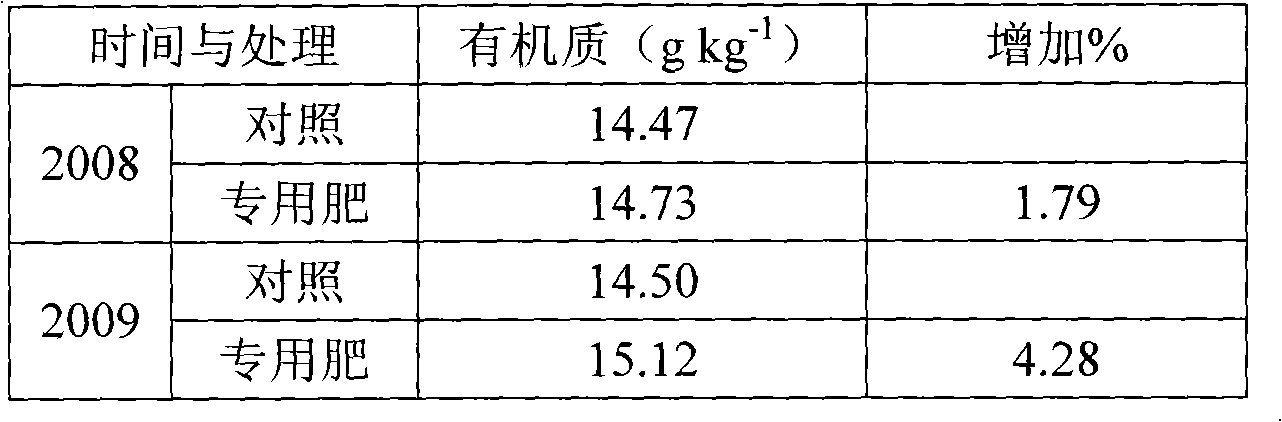

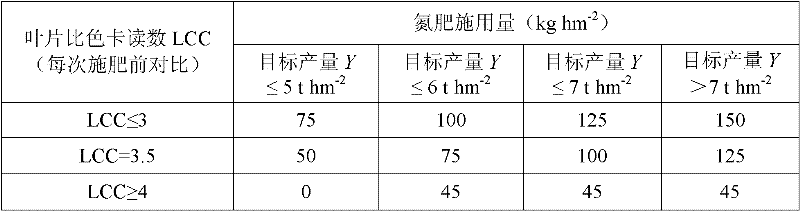

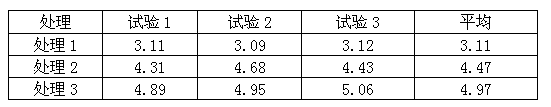

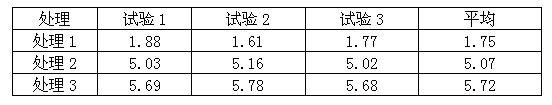

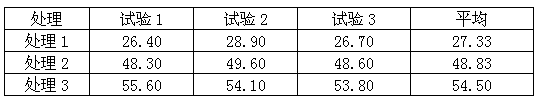

The invention discloses an ecological fertilization method based on nitrogen-saving high paddy rice yield and non-point source emission reduction, which includes the following steps: (1) determining target paddy rice yield Y(kg hm-2); (2) acquiring the potential nitrogen nutrient supply capability INS(kg hm-2) of soil: an N fertilizer-lacking fertilization area and a conventional fertilization area are established in advance; and the accumulated amount of the nitrogen of the overground part of paddy rice of the N fertilizer-lacking fertilization area is equal to INS; (3) measuring and calculating the amount RNR(kg hm-2) of demanded N nutrient under the target paddy rice yield: RNR is equal to Y multiplied by CGN plus (TB minus Y) multiplied by MCNS; (4) estimating the amount (FR, kg hm-2) of nitrogen fertilizer to be applied: FR is equal to (RNR minus INS) divided by (REN multiplied by NC); (5) dynamically regulating the amount of applied nitrogen fertilizer. Compared with the conventional fertilization management mode of farmers, the ecological fertilization mode based on the nitrogen-saving high yield and the non-point source emission reduction has the characteristics of accurate quantification, convenience in operation, low cost, high popularization and application value and the like.

Owner:ZHEJIANG UNIV

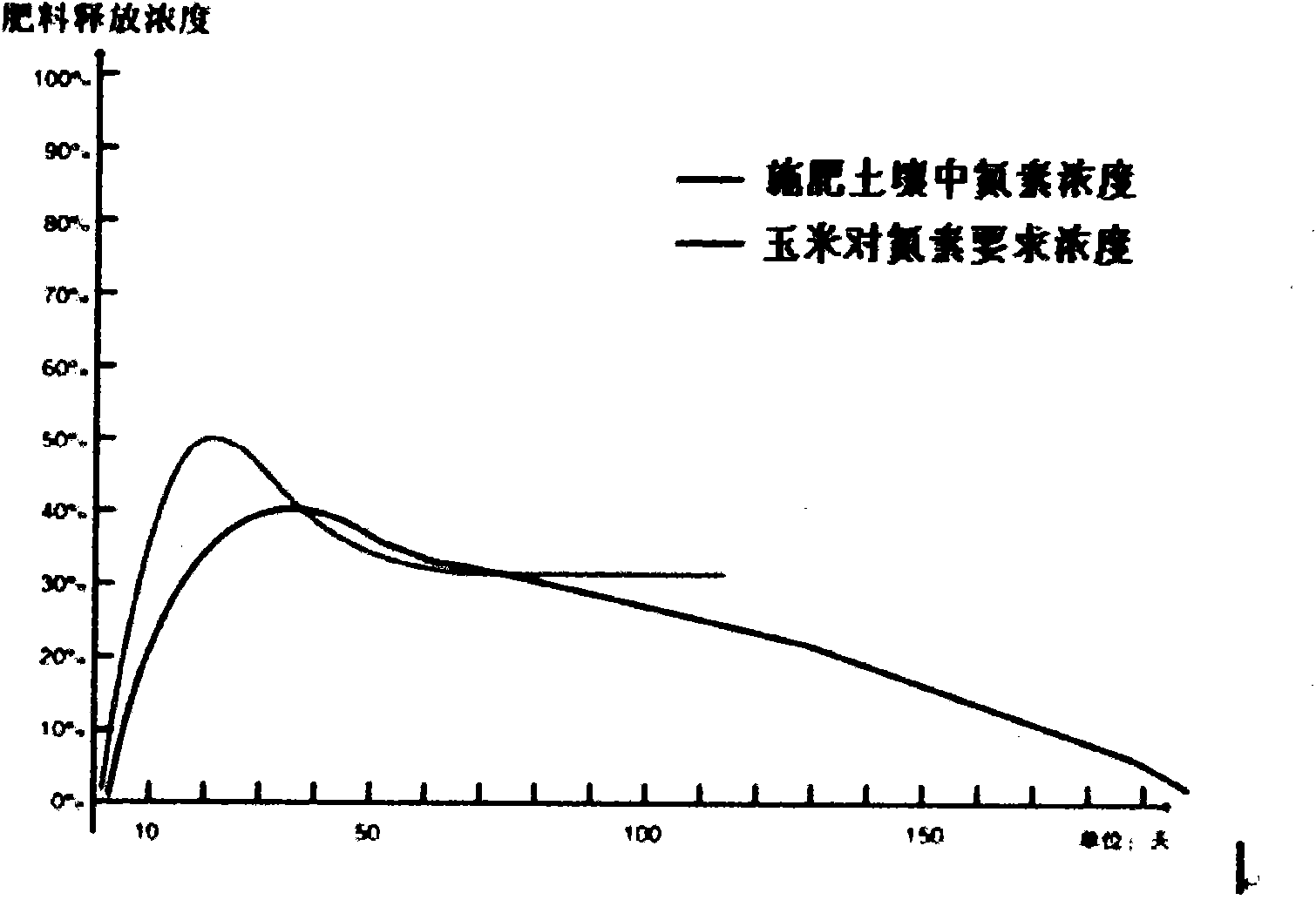

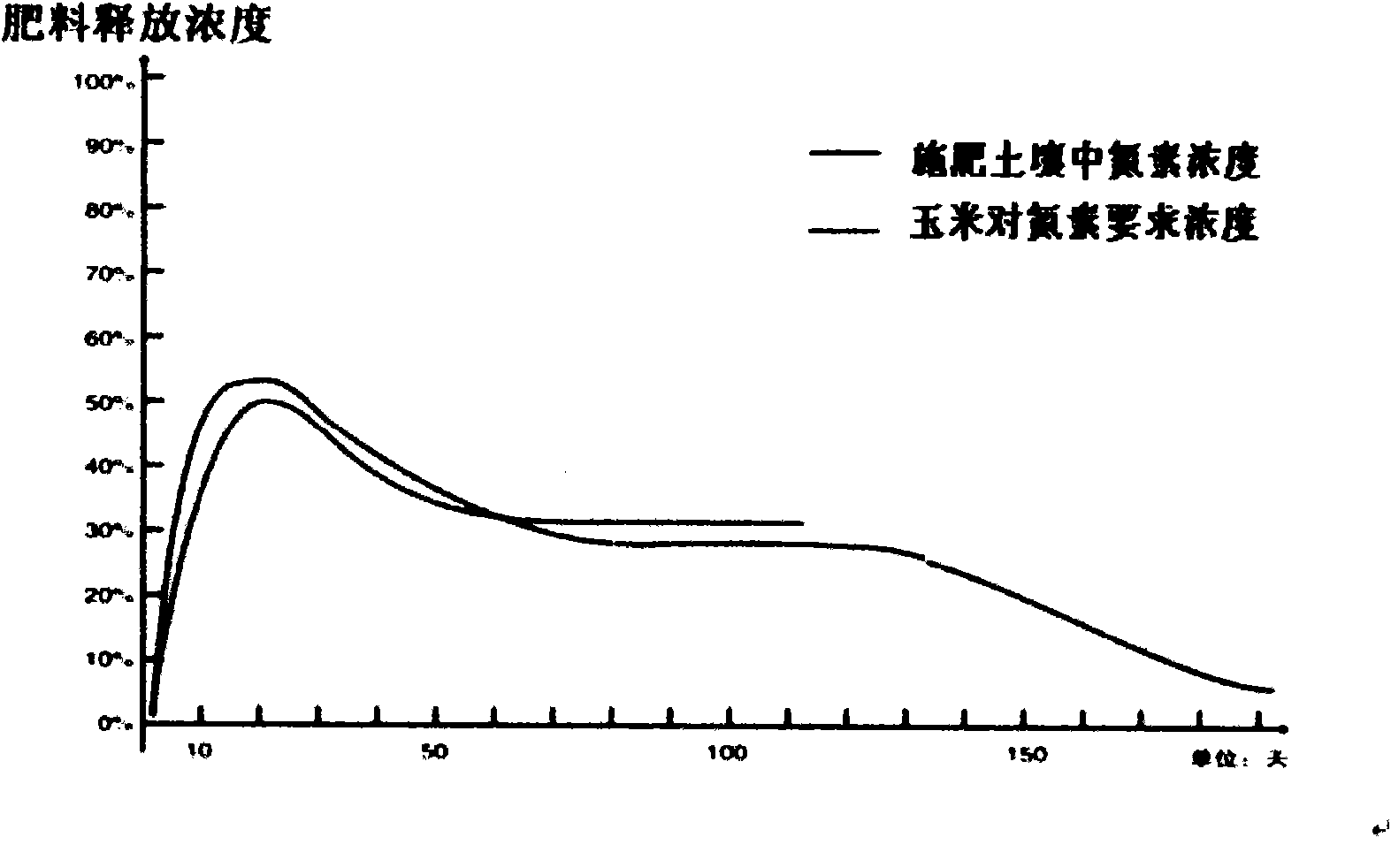

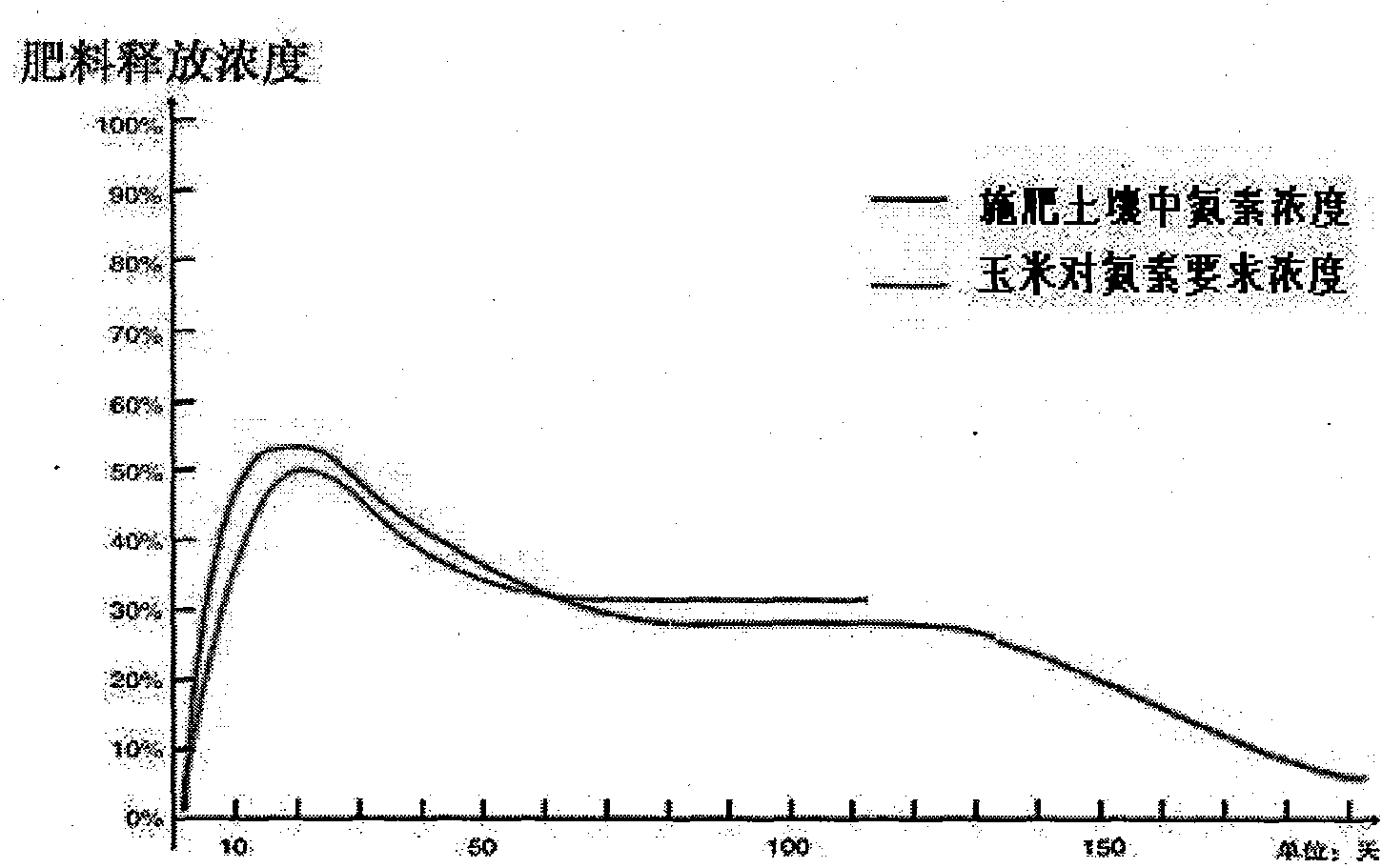

A controlled release fertilizer, a preparation method thereof and applications thereof

The invention belongs to the fertilizer field, particularly relates to a controlled release fertilizer, and further relates to a preparation method of the fertilizer and applications of the fertilizer. According to the invention, salts such as ferrous sulfate, etc. and a complexing agent are added into a gelatin solution that adopts formaldehyde as a cross-linking agent, thus preparing a composite colloidal solution containing chelated ferric salts. The composite colloidal solution is used to be coated on surfaces of fertilizer core (urea) particles, and heated to be dried and solidified to generate an envelope layer containing ureido complexing ferric salts. When the fertilizer is immersed in still water, the envelope layer absorbs water and swells to be a cystic structure, and therefore the fertilizer is called cyst urea and is a controlled release fertilizer. The controlled release period can be prolonged by repeating the above coating process. The controlled release fertilizer overcomes defects that traditional controlled release coating fertilizers contain degradation-resistant materials such as resin, etc., and reduces potential pollution to soil. The fertilizer provided by the invention has ecological safety, small usage amount, good film-forming property and good controlled release effects.

Owner:山东鲁虹智慧农业研究院

Green Chinese onion planting method

InactiveCN103766098AGuarantee the safety of growthImprove yield per muHorticultureSoil scienceN fertilizer

The invention discloses a green Chinese onion planting method. The method comprises the steps of 1) making preparations before seeding; 2) making ridges with the row spacing between 65cm and 80cm and the plant distance ranging from 5cm to 8cm, wherein the seeding rate is 4kg / mu; 3) performing topdressing and row shoveling during the 2 to 3 days after watering after seeding, topdressing, mainly N fertilizers, for 2 to 3 times after the rear row shoveling, performing combined application of K and P fertilizers in the late periods, wherein the fertilizers are applied at the position of 5cm to 7cm away from seedling holes; 4) managing the seedling bed: b, dipping roots with 600-800-times dipterex after weeds are removed; c, performing topdressing watering once, topdressing 10kg of urea, performing topdressing once after a while, wherein urea of 25kg / ridge is topdressed; d, performing watering with a kelpak 100-time diluents; e, spraying the liquor uniformly on green Chinese onion leaves. According to the method, reasonable usage of soil space of green Chinese onions is achieved, resources are used furthest, labor is saved, rust diseases can be effectively controller, guarantees are provided for the safe growth of the green Chinese onions, and the yield per mu of the green Chinese onions is improved.

Owner:吴燕

Plant composite foliar fertilizer and preparation method thereof

ActiveCN102746057AMeet the needs of all stages of growth and developmentGood application effectFertilizer mixturesN fertilizerNaphthaleneacetic Acids

Owner:SHANXI AGRI UNIV

Synergism and lost control fertilizer and preparation method thereof

ActiveCN103664369AIncrease profitIncrease contentFertilizer mixturesAgricultural scienceAgricultural engineering

The invention discloses a synergism and lost control fertilizer and a preparation method thereof, comprising the following raw material components by weight: 150-500 parts of urea and 500-850 parts of functional nitrogenous fertilizer. The synergism and lost control fertilizer provided by the invention has advantages of high fertilizer utilization rate, prolonged fertilizer efficiency period, high yield of crop, quality improvement of agricultural product, soil improvement and fertility betterment, easy identification product color, excellent appearance quality, convenient mechanical fertilization, low production cost, simple technology, safety usage and high benefit.

Owner:CNSG ANHUI HONG SIFANG FERTILIZER IND CO LTD

Manufacture method of synergic type nitrogenous fertilizer with slow release and loss control effect

InactiveCN103011972AImprove adsorption capacityImprove stabilityFertilizer mixturesOrganic acidAgricultural engineering

The invention discloses a manufacture method of a synergic type nitrogenous fertilizer with a slow release and loss control effect. The manufacture method comprises the following steps in sequence: preparing a modified oyster shell powder adsorbent by modifying through chitosan under the assistance of the microwave; preparing a water swelling and conservation agent by humic acid, polyacrylamide and an initiator; compounding the modified oyster shell powder adsorbent with the water swelling and conservation agent to obtain a fertilizer nutritional ingredient slow release and loss control material which contains oyster shell powder, chitosan, humic acid, polyacrylamide, organic acid chelate titanium and urea peroxide (based on weight ratio of 100: 0.5 to 3.0: 3.0 to 5.0: 2.5 to 4.0: 0.05 to 0.15: 0.05 to 0.15); and compounding the fertilizer nutritional ingredient slow release and loss control material with conventional nitrogenous fertilizer based on the weight ratio of 1: 5.0 to 6.5, so as to obtain the synergic type nitrogenous fertilizer which contains the slow release and loss control material and a plurality of synergists and has the slow release and loss control effect.

Owner:FUJIAN CHAODA GROUP

High-strength urea formaldehyde slow release fertilizer and preparation method thereof

InactiveCN103819278AReduce decompositionRestore activityFertilising methodsFertilizer mixturesSoil scienceN fertilizer

The invention provides particles and tablets of a high-strength urea formaldehyde slow release fertilizer produced through dry-process granulation. The urea formaldehyde slow release fertilizer is prepared from urea formaldehyde, nitrogenous fertilizer, phosphatic fertilizer, potassic fertilizer and packing through pressing. In addition, the invention also provides a preparation method, an application and the like of the urea formaldehyde slow release fertilizer.

Owner:GUILIN JIQI BIOCHEM +2

Slow-release liquid compound fertilizer

The invention provides slow-release liquid compound fertilizer, and belongs to the technical field of compound fertilizer preparation. The slow-release liquid compound fertilizer is prepared from, by weight, 15-65 parts of phosphatic fertilizer, 10-50 parts of calcium fertilizer, 15-60 parts of nitrogenous fertilizer, 1-5 parts of magnesium fertilizer, 1-5 parts of potash fertilizer, 40-200 parts of slow-release fertilizer, 5-10 parts of biological agents, 1-3 parts of emulsifying agents, 2-6 parts of thickening agents, 0.5-5 parts of cosolvent, 1-3 parts of stabilizers and 60-160 parts of water. The slow-release liquid compound fertilizer is rich in nutrition and reasonable in match, particularly the biological agents are added to have the efficient coordinating effect, efficient utilization of the slow-release fertilizer is ensured, and the slow-release liquid compound fertilizer is more suitable for large-area fertilizer application.

Owner:张彦优

Organic-selenium-enriched slow release fertilizer specially used for strawberries

ActiveCN103772051AMeet the needs of selenium fertilizerPromote growthFertilizer mixturesFragariaCellulose

The invention relates to an organic-selenium-enriched slow release fertilizer special for strawberries. The organic-selenium-enriched slow release fertilizer is prepared from the following raw materials in parts by weight: 2-5 parts of selenium source (based on the content of selenium), 20-30 parts of attapulgite, 25-40 parts of sodium humate, 0.5-1.5 parts of sodium carboxymethylcellulose, 19 parts of nitrogenous fertilizer (based on the content of nitrogen), 10 parts of phosphate fertilizer (based on the content of phosphorus), 19 parts of potassium fertilizer (based on the content of potassium) and 20 parts of water. The organic-selenium-enriched slow release fertilizer can meet the requirement of the strawberries for selenium fertilizer; moreover, due to the addition of nitrogen phosphorus and potassium fertilizers, the nitrogen phosphorus and potassium fertilizers can promote strawberry growth and quality after the slow release fertilizer is applied.

Owner:NINGBO ZHONGJING BIOLOGICAL TECH

Building and planting method of evergreen lawn

ActiveCN105009889AShort growing seasonMake up for the defects of winter yellowPlant cultivationCultivating equipmentsInsect diseaseEvergreen

The invention discloses a building and planting method of an evergreen lawn. The method comprises the following steps: 1, carrying out grass thinning on warm-season type grass in a cross direction for two times, and scarifying the withered grass layer of a warm-season type lawn; 2, carrying out low trimming on the warm-season type lawn two to three days earlier when roegneria kamoji seeds are reseeded; 3, reseeding the roegneria kamoji seeds, wherein the seeding rate is 5-10 grams / square meter; 4, immediately performing sand covering after sawing, wherein the sand covering thickness is 1-3mm; 5, performing flattening after the sand covering; and 6, carrying out irrigation to keep soil moist until seedling emergence and lawn formation. The method provided by the invention has the following advantages: the quality of the lawn in four seasons is good, the grass does not have obvious insect diseases, the maintenance is simple, more ecological and safer, the maintenance cost is low, and compared to conventional rye grass commonly used in a climate transition region, the workload is lower, and roegneria kamoji dies more quickly through application of an N fertilizer.

Owner:JIANGSU POLYTECHNIC COLLEGE OF AGRI & FORESTRY

Controlled release nitrogeneous fertilizer composition system

A controlled release nitrogeneous fertilizer composition system, comprising (a) a tannin selected from the group consisting of purified tannins, purified modified tannins, condensate tannins, and mixtures thereof; (b) a nitrogeneous fertilizer component selected from the group consisting of an ammonia fertilizer, an ammonium fertilizer, a urea fertilizer, a nitrogen containing fertilizer, a natural nitrogen containing organic fertilizer, a nitrogen containing waste product fertilizer, a slow and control release fertilizer, and mixtures thereof; and optionally (c) a carrier. Also disclosed is a method for making such fertilizer composition systems.

Owner:MITANIC

Environment-friendly composite series fertilizer and its preparation method

The invention relates to a composite fertilizer whose formulation (by mass percent) includes, zeolite 5-25%, sepiolite 2.0-15%, reactive addition agent 0.5-5.0%, nitric rare earth 0.03-0.1%, traditional fertilizer 70-85%. The process for preparing the fertilizer consists of preparing 0.04-0.23% of nitric rare earth aqueous solution, charging by proportion, mixing uniformly and drying.

Owner:HEBEI UNIV OF TECH +1

Winter-late-autumn-potato early-marketed planting method

InactiveCN109566313AEarly reproductive processPromote expansionClimate change adaptationFertilising methodsN fertilizerBrown patch

The invention relates to a winter-late-autumn-potato early-marketed planting method, and belongs to the field of planting. The method includes the steps of selecting a potato variety, accelerating germination of potato seeds, coating the potato seeds, determining the sowing date, preparing soil, early applying N-and-P base fertilizers, sowing ridging potato seed with buds, covering a film, erecting small sheds on ridges, controlling overgrowth to promote tuber expansion and controlling potato epidemic diseases. According to the winter-late-autumn-potato early-marketed planting method, early seedling emergence and early potato forming are effectively promoted, the large potato rate of tubers is increased, the defect that as a N fertilizer is applied after potatoes are sowed, potato formingis delayed is overcome, the problems that the large potato rate is low, hollow heart and brown patch disease are easy to occur are solved, epidemic disease is controlled through a leaf fertilizer anda trichoderma-strain biological bacterium agent, and the mode is a green, ecological and no-residue control measure. Potatoes are early marketed, and the aims of increasing production and increasing income are effectively achieved; the method is a planting technology that winter-late-autumn potatoes early enter fresh vegetable markets of outer country in extremely-deficient season, and meanwhile it can be promoted that the income of potato farmers is increased, and the winter-late-autumn-potato early-marketed planting method is suitable for application and popularization in the lower and middle elevations of the southwest.

Owner:云南省农业科学院经济作物研究所

Solvent free N-alkyl thiosphoric triamide formulations for use in the stabilization of nitrogen fertilizer

ActiveUS9090516B2Improve abilitiesReduce eliminateFertilising methodsHorticulture methodsActive agentAgricultural engineering

The invention relates to a composition containing a concentrate of at least one N-alkyl thiophosphoric triamide and at least one surfactant. The invention also relates to methods of using the composition.

Owner:HELENA HLDG

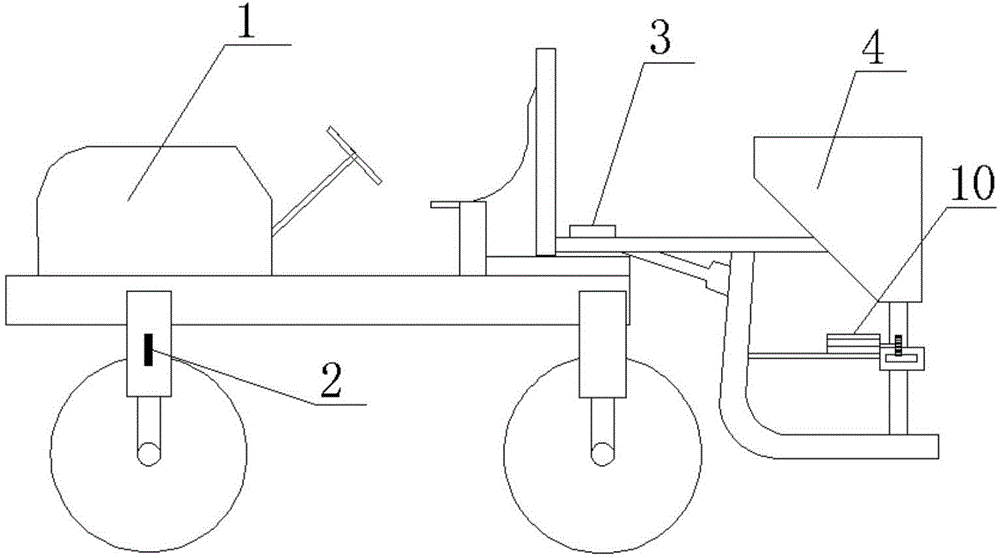

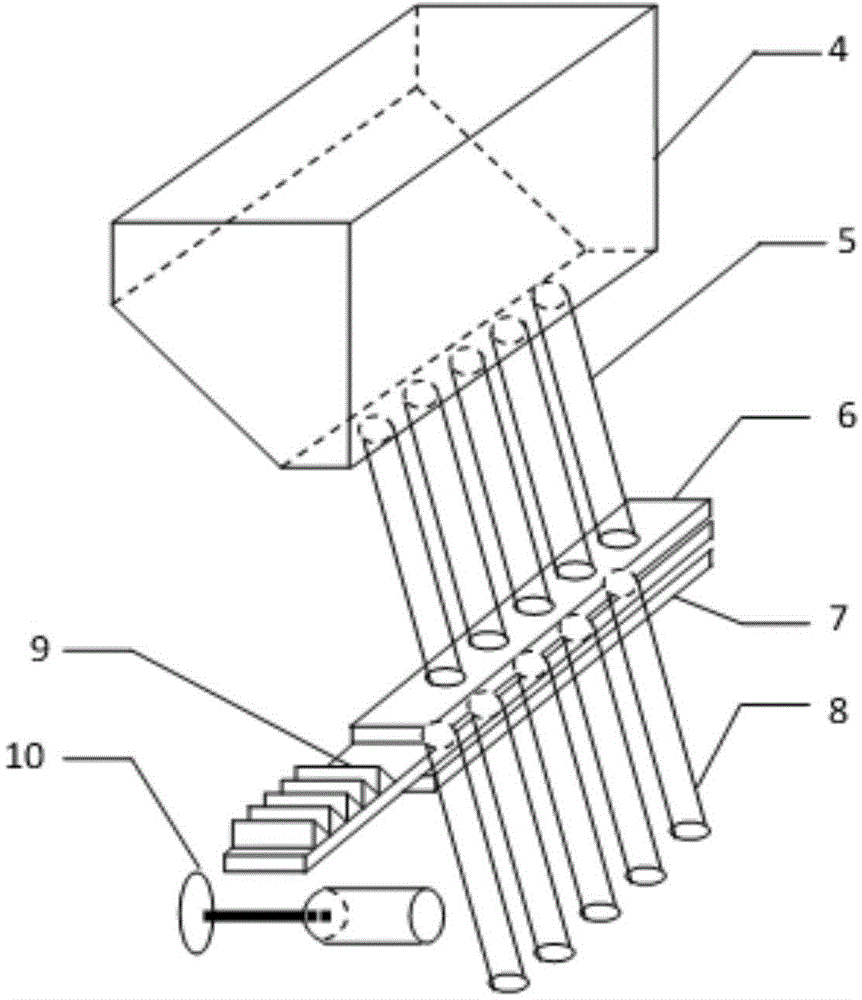

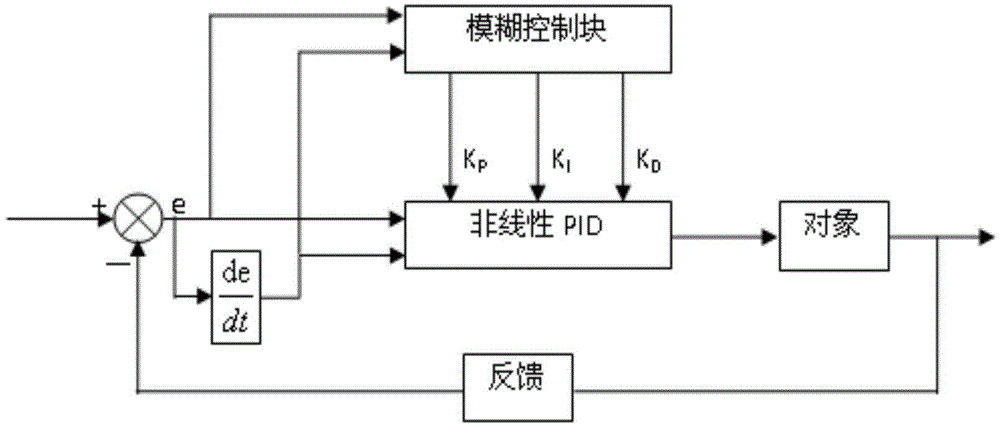

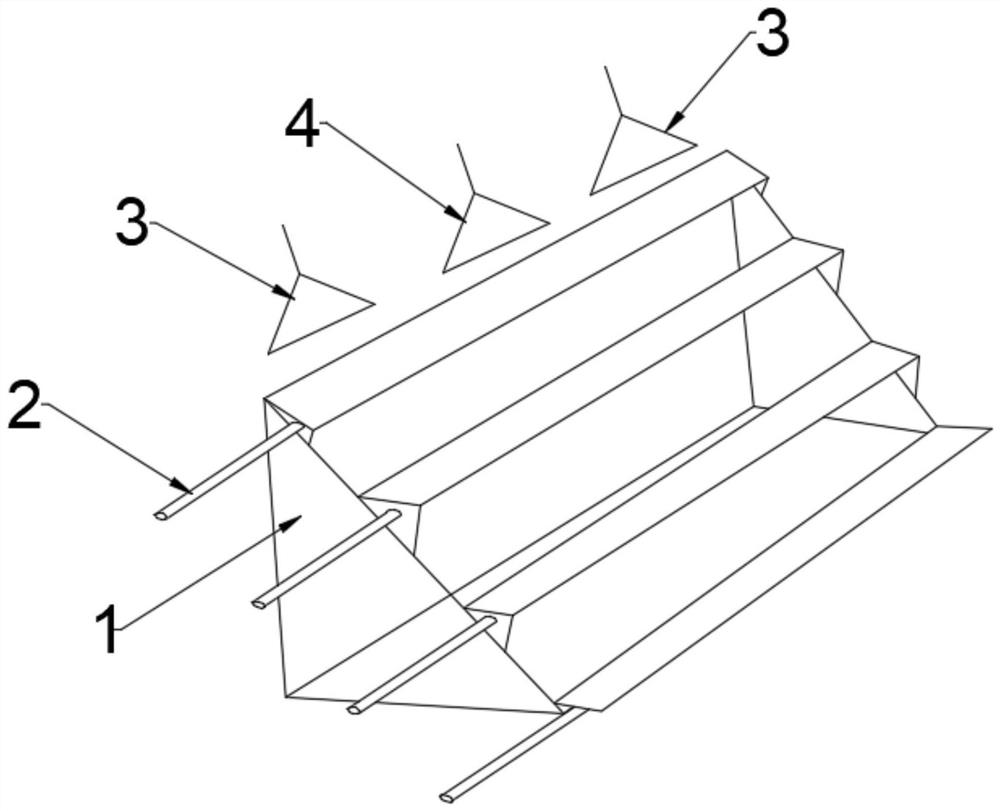

Automatic variable rate fertilization device based on stepping motor and control method of automatic variable rate fertilization device

ActiveCN104081921AReduce the impactControl the amount of fertilizerFertiliser distributersAgriculture gas emission reductionEcological environmentN fertilizer

The invention discloses an automatic variable rate fertilization device based on a stepping motor and a control method of the automatic variable rate fertilization device. The automatic variable rate fertilization device comprises a traction device, a material box and a discharge adjusting device, wherein the discharge adjusting device is provided with N fertilizer discharging holes; the upper end of each fertilizer discharging hole is communicated with the material box through a fertilizer guiding pipe; the lower end of each fertilizer discharging hole is connected with a fertilizing pipe; an adjusting plate is further inserted into the discharge adjusting device; the adjusting plate is provided with N material passing holes adapted to the N fertilizer discharging holes; the adjusting plate is engaged with a gear on a rotary shaft of the stepping motor through a rack on one side; the adjusting plate is driven by the stepping motor to move left and right to change the apertures of the fertilizer discharging holes so as to realize variable rate fertilization. The automatic variable rate fertilization device has the obvious effects that the structure is simple; the stepping motor is controlled in real time according to fertilizing information of each land to adjust the fertilizing amount of the automatic variable rate fertilization device; the utilization rate of fertilizer is improved, the influences on an ecological environment are reduced and the popularization cost is low.

Owner:重庆帝勒金驰通用机械股份有限公司

Effect improved compound fertilizer

ActiveCN104003809AIncrease profitInhibition of specific enzyme - urease activityFertilizer mixturesPhosphateN fertilizer

The invention discloses effect improved compound fertilizer. The effect improved compound fertilizer comprises, by part, 35-65.2 parts of urea with 46 percent of N, 8-40 parts of monoammonium phosphate with 10 percent of N and 50 percent of P2O5, 6.7-30 parts of potassium chloride with 60 percent of K2O or 8-30 parts of potassium sulphate with 50 percent of K2O, 0-15 parts of ammonium sulfate with 21 percent of N and 0.1-1 part of nitrogen controlled synergist (AHE). According to the AHE, the proportion of sodium tetraphenylborate, copper sulfate, zinc oxide, ammonium citrate and potassium thiosulfate is 3: 2: 2: 1: 2-3. The effect improved compound fertilizer reduces the hydrolysis rate of urea in the fertilizer, restrains the activity of nitrobacteria in soil, the 6-8 millesimal of AHE is added into the effect improved compound fertilizer, the nitrogen use efficiency reaches to 44 percent, the nitrogen use efficiency is improved by 23 percent, the nitrogen loss is reduced by 22.6 percent, and the crop is increased by 8-16 percent. One-time fertilize application is carried out in spring, and labor cost is saved.

Owner:赤峰杰翔复合肥有限公司

Recovery treatment method and recovery treatment device for glass etching waste liquid

PendingCN112456443ASolve pollutionSolve wasteHydrogen fluorideNitrogenous fertilisersHydrofluoric acidN fertilizer

The invention discloses a recovery treatment method and recovery treatment device for glass etching waste liquid. Hydrofluoric acid in the glass etching waste liquid is recovered by adopting a defluorination reaction kettle and a falling film absorption system; residual waste liquid is neutralized and crystallized to prepare nitrogen-containing salt which can be sold as a by-product of a compositenitrogen fertilizer. With the recovery treatment method and recovery treatment device for glass etching waste liquid adopted, the problems of environmental pollution and waste of the glass etching waste liquid can be solved, the purpose of clean production can be achieved for enterprises; the generation of three wastes can be reduced; the effect of circular economy can be realized; and energy-saving and environment-friendly production support can be created for enterprises.

Owner:BENGBU COLLEGE +1

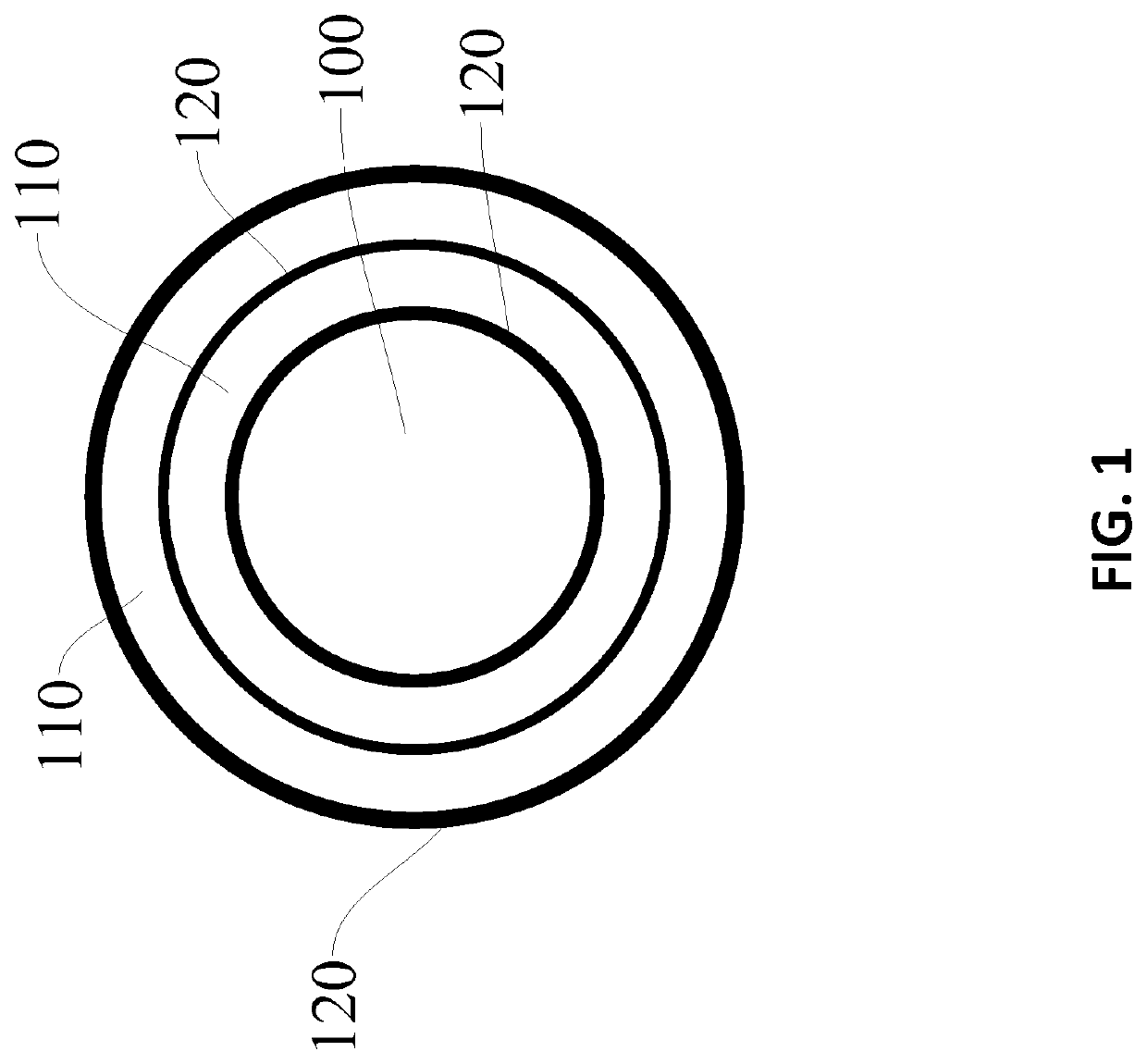

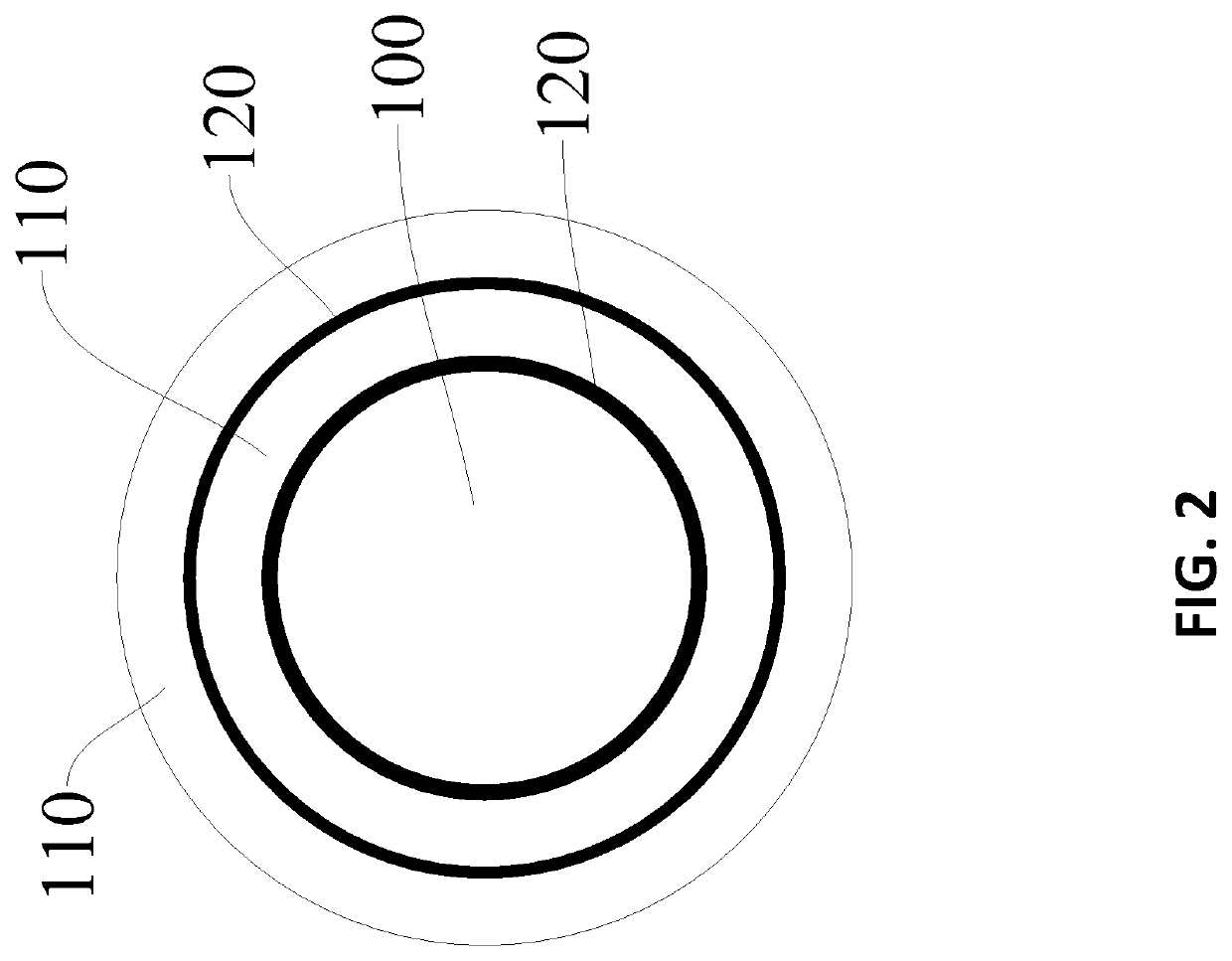

Multi-layered fertilizer and preparation method thereof

InactiveUS20210380502A1Slowly and timely releasedMeet the requirementsAlkali orthophosphate fertiliserAmmonium orthophosphate fertilisersSoil scienceN fertilizer

In one aspect, a multi-layered fertilizer includes a layer-by-layer coated fertilizer layer and a coating layer, wherein the fertilizer layer is separated from the coating layer, and one of the fertilizer layers is a fertilizer core; the fertilizer layer contains at least one of nitrogen fertilizer, phosphate fertilizer and potassium fertilizer, the coating layer is polyurea formaldehyde, which includes at least a polyurea formaldehyde having two to five carbon atoms. It can better control the release of nitrogen, phosphorus, potassium, calcium, magnesium and zinc in the fertilizer to meet the different nutrient requirements of different crops at different growth stages. The fertilizer can be prepared by a reactor, a slurry tank, a powdering tank and supporting facilities, which can control the amount of each layer of fertilizer and its position in the entire fertilizer granules according to a design procedure.

Owner:ZHENGZHOU GAOFU FERTILIZER CO LTD

Indoor multi-generation peanut hybridization method

PendingCN113598043AOvercoming tough problemsProlong flowering timeFabaceae cultivationGrowth substratesEmamectin benzoateN fertilizer

The invention relates to an indoor multi-generation peanut hybridization method. The method specifically comprises the following steps: preparing a male parent planting room and a female parent planting room; preparing a culture medium; performing parent planting: respectively planting male parents and female parents in the male parent planting room and the female parent planting room, planting the male parents in a film covering manner, and performing plant culture in different photoperiod stages; performing management in each period: applying 28% N fertilizer to all parent materials in a seedling stage, and spraying 3% emamectin benzoate, indoxacarb and imidacloprid in a 3-4 leaf stage and an initial flowering stage to prevent and treat insect pests, so that plants grow robustly; spraying 8% of phosphate fertilizer in the flowering stage to promote flowering; spraying 18% of potash fertilizer in a pod bearing period to strengthen fruits; and hybridizing immediately after castration. The method has the advantages that the peanuts can normally bloom and bear fruits indoors, the hybridization time can be shortened, the timeliness and effective utilization rate of valuable and rare materials can be increased, the peanuts can be planted in batches at any time according to needs, and multiple hybridization in one year is achieved.

Owner:四川省农业科学院经济作物育种栽培研究所

Straw utilization method capable of relieving soil salinization

ActiveCN109757147APromote decompositionPromote the growth of putrefying bacteriaSoil-working methodsPorphyridiumGreenhouse

The invention discloses a straw utilization method capable of relieving soil salinization in the technical field of agricultural (vegetable) cultivation. The method is characterized by comprising thefollowing steps: as for a greenhouse with soil salinization due to excessive application of N fertilizer, upright growth type hygrophilous crops suitable for surface soil sufficient wet cultivation are planted in the greenhouse; herbal crop straw with high carbon content are selected and the straw is spread in bed furrows; bed surfaces are fully wet by furrow irrigation or spraying, and water is held in the bed furrows in a short time; straw in the bed furrows is stepped during agricultural operation such as fertilization, pesticide spraying and harvesting; when the straw in the bed furrows iscompletely decomposed and time permits, if porphyridium or green moss still exist on soil surfaces of the bed furrows, straw is added continuously to the bed furrows; if porphyridium or green moss isnot discovered in the bed furrows, the soil salinization is indicated to be relieved. Extra NO3<-> ions in soil can be consumed and decomposed and soil salinization can be relieved.

Owner:YANGZHOU UNIV

Method for producing industrial and agricultural monoammonium phosphate and magnesium ammonium phosphate with wet-process phosphoric acid

ActiveCN102020256BImprove purification effectTroubleshoot follow-up issuesPhosphatesO-Phosphoric AcidAgricultural engineering

The invention provides a method for producing industrial and agricultural grade monoammonium phosphate and magnesium ammonium phosphate with wet-process phosphoric acid. The wet-process phosphoric acid is taken as a raw material. Sodium fluosilicate, monoammonium phosphate solution, monoammonium phosphate filter cakes and magnesium ammonium phosphate are respectively obtained through defluorination and a three-section substep neutralization process, wherein the monoammonium phosphate solution is concentrated and crystallized to obtain high-quality water soluble industrial monoammonium phosphate, and the monoammonium phosphate filter cakes and the monoammonium phosphate mother solution subjected to repeated crystallization are subjected to size mixed and dried to obtain qualified agricultural monoammonium phosphate. The magnesium ammonium phosphate is a good slow release nitrogenous fertilizer per se. The process has the advantages of little investment of equipment, good adaptability of raw material, low production cost and good product quality. The water soluble industrial monoammonium phosphate with low cost can provide a cheap and good water soluble phosphatic fertilizer for modern facility agriculture.

Owner:昆明隆祥化工有限公司

Fertilizer special for paddy rice

InactiveCN1151100CSufficient nutritionExtend the fertilization timeRice cultivationFertilizer mixturesSulfate zincSoil science

A special fertilizer for paddy rice is prepared from N fertilizer, P fertilizer and zinc sulfate through mixing and granulating. It contains N (17-20%), P2O5 (7-10%) and Zn (0.22-1.1%). Its advantages are durable fertility, and high utilization rate.

Owner:王鸿庆

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com