Simultaneous desulfurization and denitrification method using aqueous ammonia

A desulfurization, denitrification, and denitration technology, applied in the field of flue gas purification, can solve the problems of high price, dependence on imported catalysts, complex process system, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

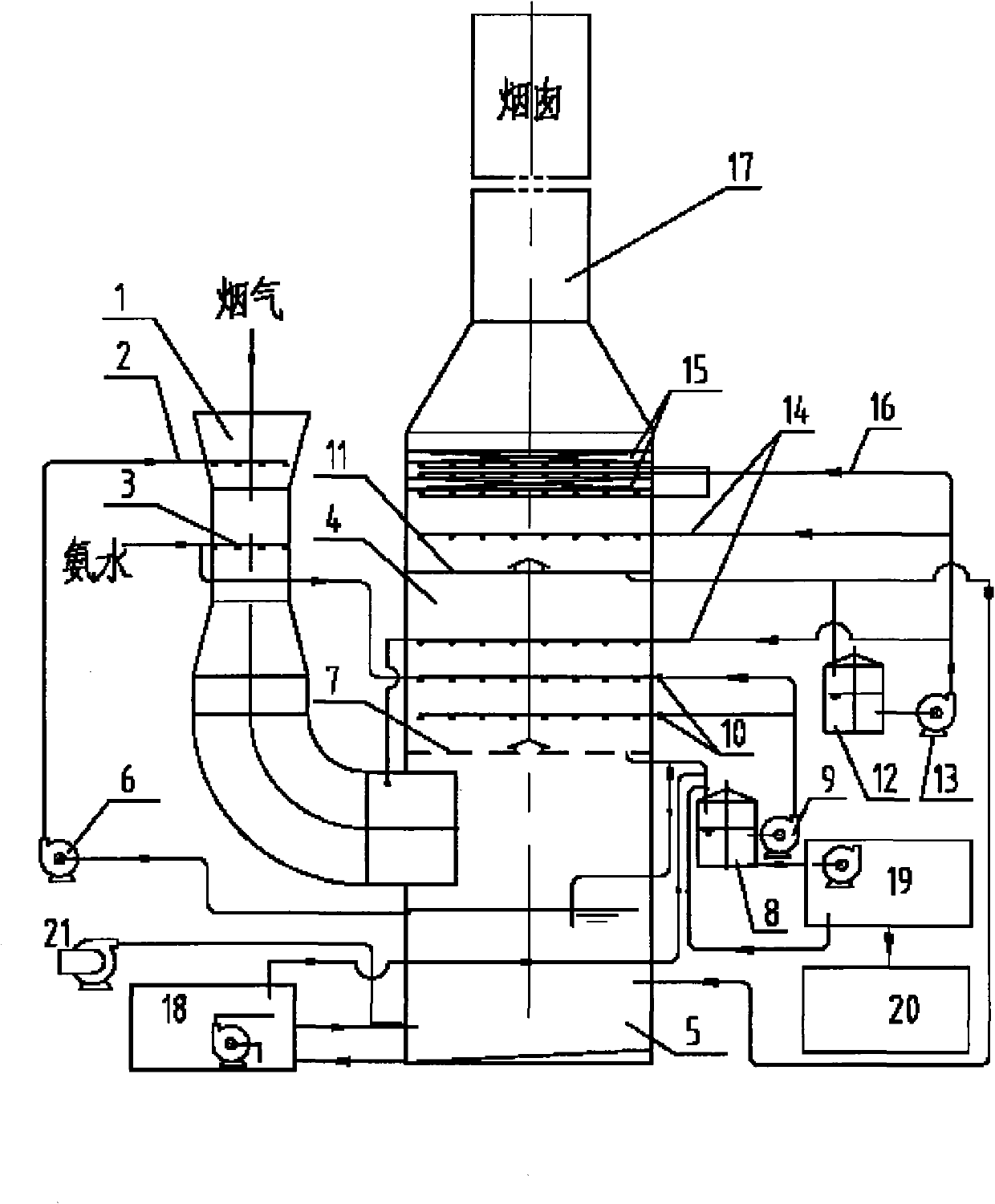

[0014] As shown in Figure 1, the flue gas does not need heat exchange, and first enters the Venturi tower (1) at a relatively high temperature of 100°C to 150°C, and the Venturi tower (1) is respectively equipped with denitrification spray layers ( 2), the ammonia water spray layer (3), the denitrification spray layer is connected with the oxidation pool (5) at the bottom of the cylindrical tower (4) through the dilute liquid circulation pump (6), and the denitrification spray layer (2) generates 2(NH 4 ) 2 SO 3 +2NOx=2x(NH 4 ) 2 SO 4 +N 2 The denitrification reaction, the flue gas after denitrification and the ammonia water in the ammonia water spray layer (3) produce SO 2 +2NH 3 ·H 2 O=(NH 4 ) 2 SO 3 +H 2 The desulfurization reaction of O makes the liquid phase (NH 4 ) 2 SO 3 The concentration increases instantaneously, which is favorable for 2(NH 4 ) 2 SO 3 +2NOx=2x(NH 4 ) 2 SO 4 +N 2 As the reaction proceeds, further denitrification reactions occur. T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com