Method and device for directly synthesizing oxamide granules

A technology of oxamide and granules, which is applied in the preparation of carboxylic acid amide, chemical instruments and methods, and the preparation of organic compounds, etc., which can solve the problem that there is no integrated equipment for ammonolysis reaction and granule forming, and the key technology has not been directly disclosed and has not been industrialized. Application and other issues, to achieve the effect of saving equipment investment and energy consumption, large economic benefits and application prospects, and expanding market share

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

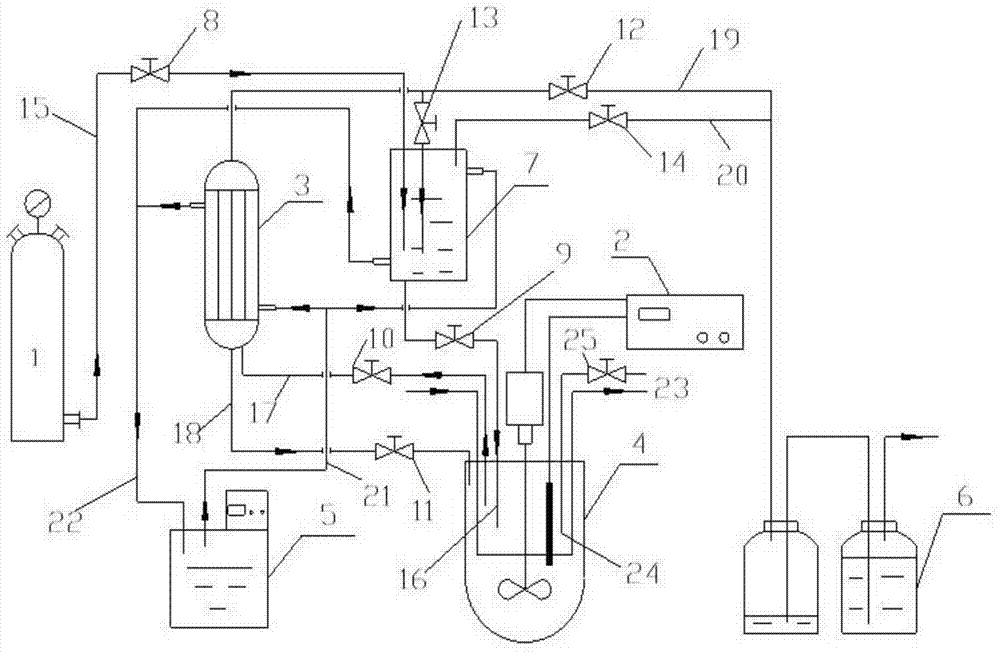

[0045] As shown in the accompanying drawings of the description, first configure a certain concentration of ammonia methanol solution according to the first step of the implementation mode, control the temperature of the front ammonia absorption tank 7 to 5°C, and start to pass ammonia, and the ammonia flow rate should not be too high quick. Add raw material dimethyl oxalate in the reaction kettle 4 in the process of feeding ammonia gas, after the ammonia gas is passed into, open the pre-ammonia gas absorption tank infusion regulating valve 9, open the refrigeration unit 5 of the reaction kettle simultaneously, the ammonia gas During the addition of the methanol solution, no stirring was performed. Select the mass ratio of methanol to dimethyl oxalate to be 4:1 for addition, and the ammonia gas is excessive. After the addition was completed, the temperature began to rise, and the reaction kettle temperature regulating device 2 was opened to set the reaction temperature to 50°...

example 2

[0047] The operation steps of the whole reaction process are the same as Example 1, and the conditions of the reaction process are changed as follows: the mass ratio of methanol to dimethyl oxalate is 2:1, the reaction temperature is 20°C, the reaction time is 1h, and the yield of oxamide is 13.23 %, the purity is 49.33%, and the total organic nitrogen content is 15.69%. Due to the low yield and purity of the obtained product, no particle molding treatment is carried out.

example 3

[0049] The operation steps of the whole reaction process are the same as in Example 1, and the conditions for changing the reaction process are: the mass ratio of methanol to dimethyl oxalate is 2:1, the reaction temperature is 60°C, and the reaction time is 1h. The particle forming process and conditions are the same as in Example 1 Described, the yield that finally obtains oxamide is 97.49%, and purity is 98.34%, and total organic nitrogen content is 31.27%, and the average particle diameter of oxamide solid particle is 3.89mm, and crushing strength is 2.8Kg / particle, in water two No collapse phenomenon was found in the week, and it has good stability in water.

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com