Patents

Literature

51results about How to "Solve the problem of easy clogging" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

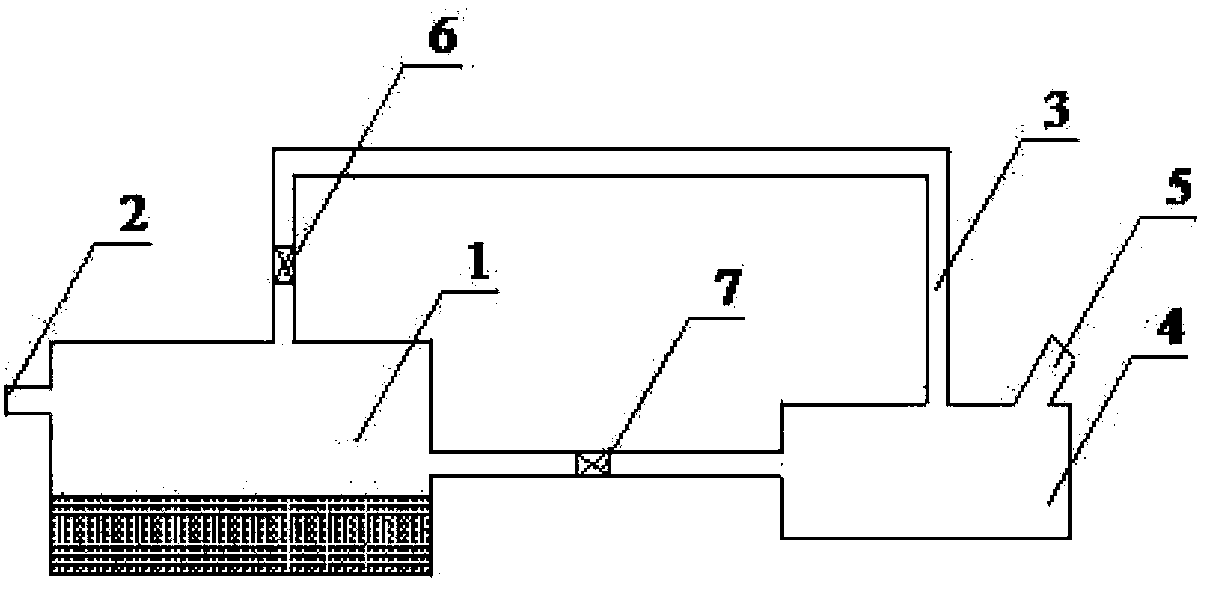

Anti-blocking method for artificial wetland

InactiveCN101723547ASolve the problem of easy cloggingMultistage water/sewage treatmentSustainable biological treatmentConstructed wetlandFiltration

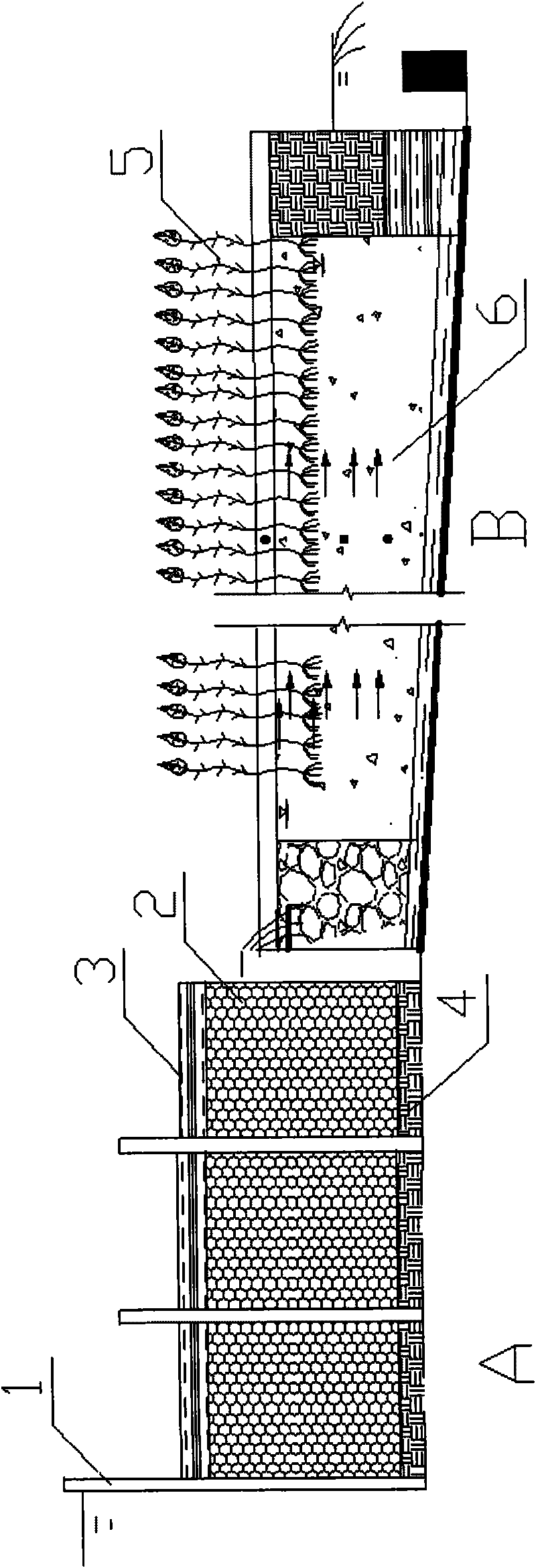

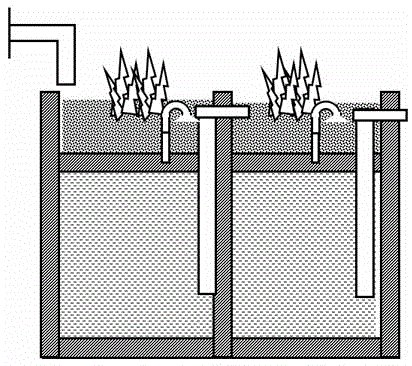

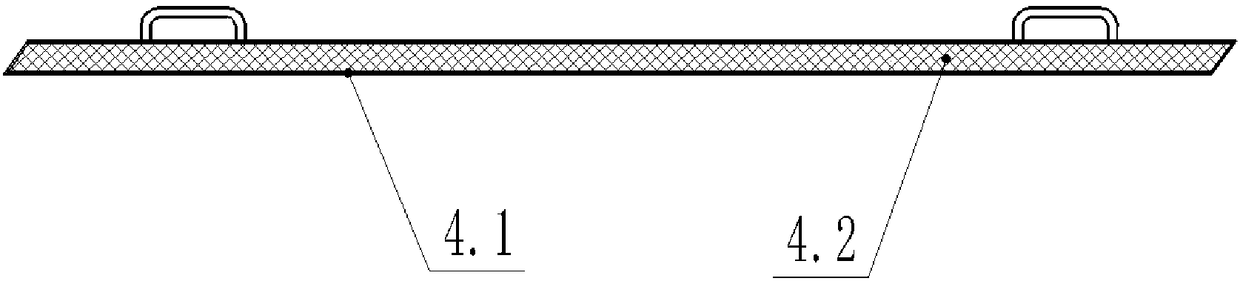

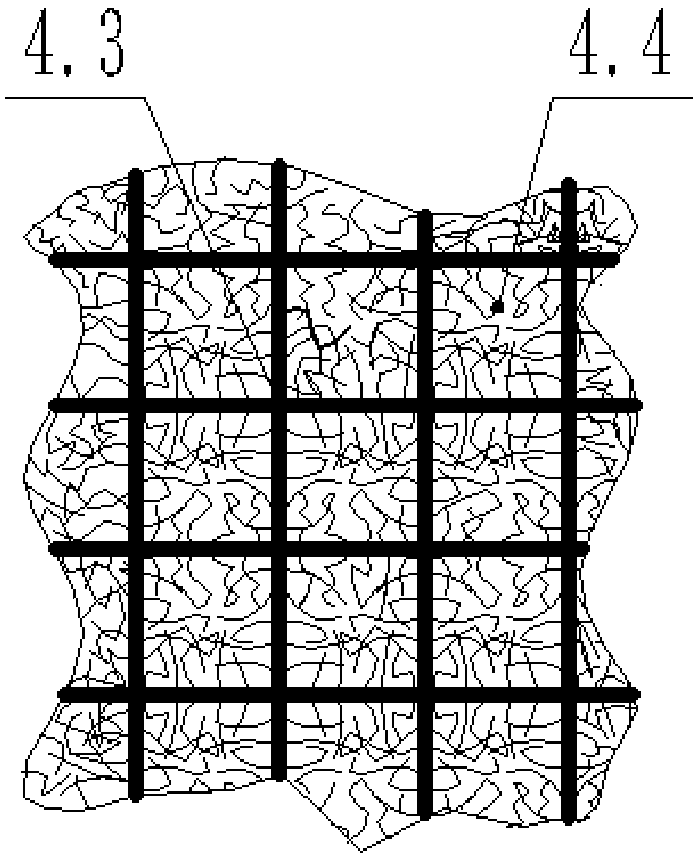

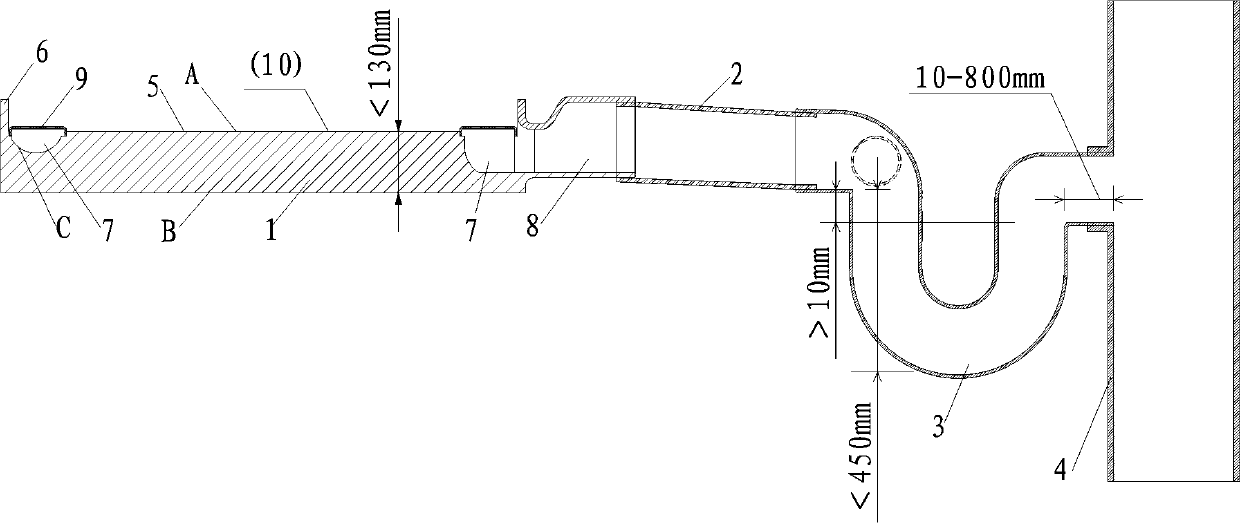

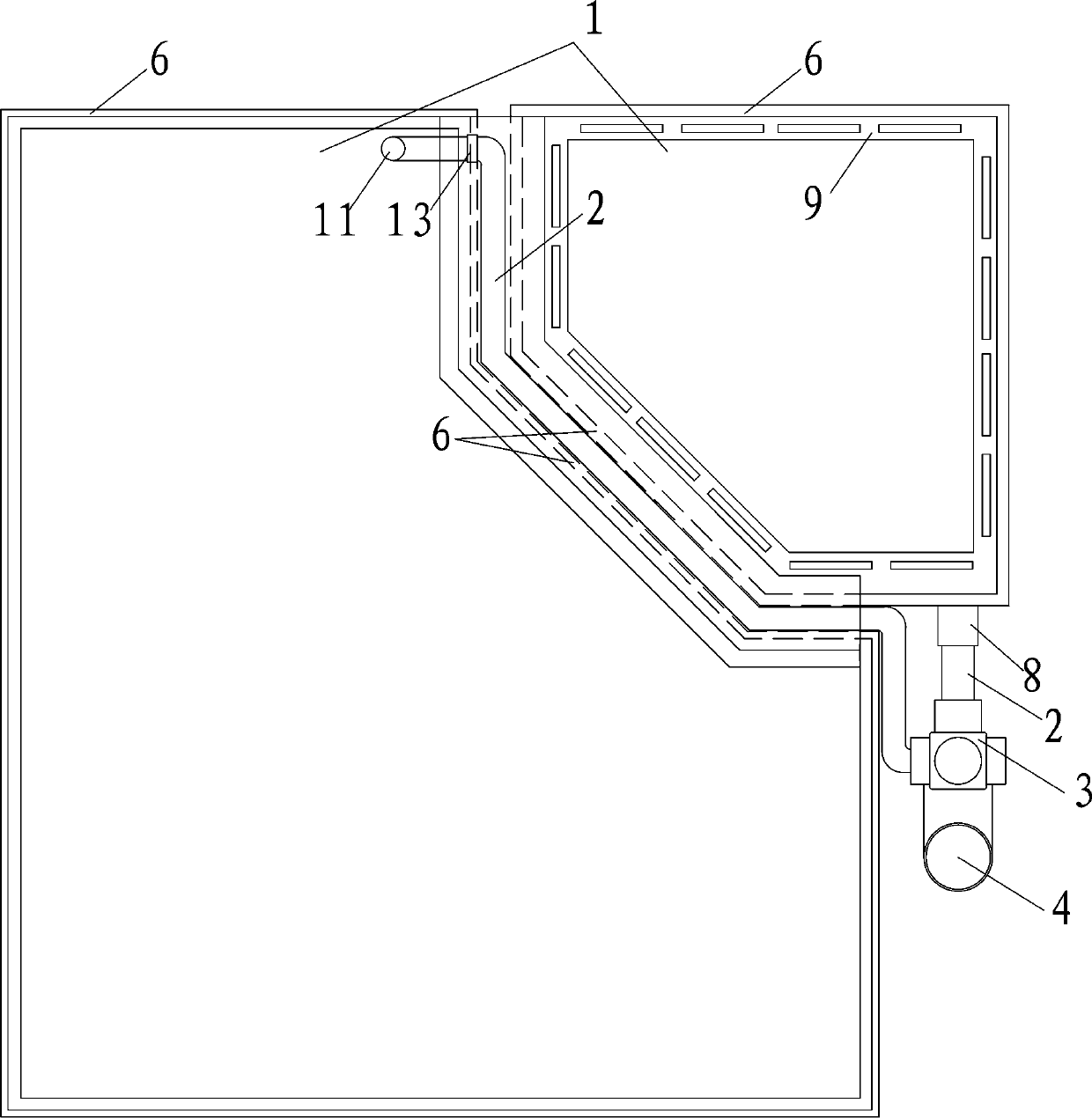

The invention belongs to the technical field of water treatment, and particularly discloses an anti-blocking method for an artificial wetland. The method is mainly to arrange a percolation dam A unit in front of a wetland system B unit, wherein the inside of the percolation dam A unit is provided with a filtering flashboard (1) made of textile material, a bio-packing filtration layer (2), an anti-permeability bottom (4) and a covering layer (3); and the wetland system B unit can be one or the series connection or the parallel connection of more of three wetlands such as a surface flow wetland, a subsurface flow wetland, a vertical flow wetland and the like. The treatment flow is that sewage is treated by the percolation dam A unit first, and then an effluent enters the wetland system B unit for further treatment. Compared with a conventional method, the method can conveniently solve the problem of easy blocking during the operation of wetland systems.

Owner:FUDAN UNIV

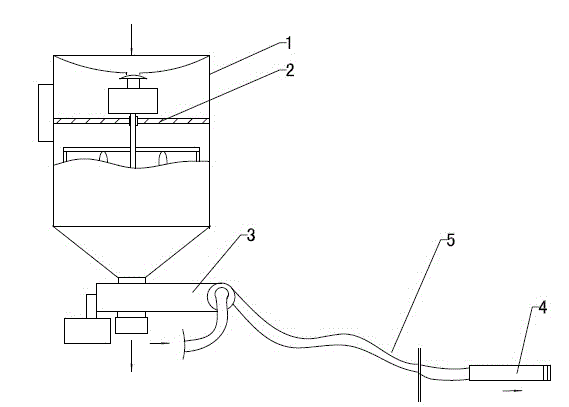

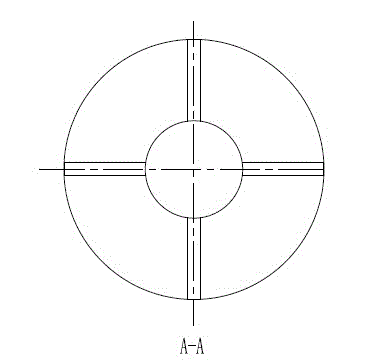

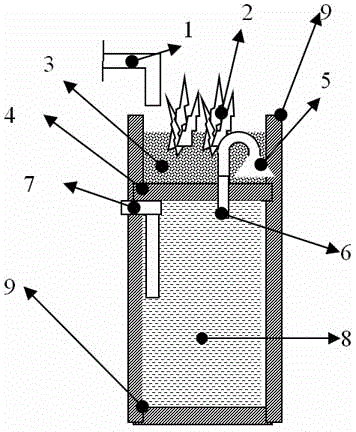

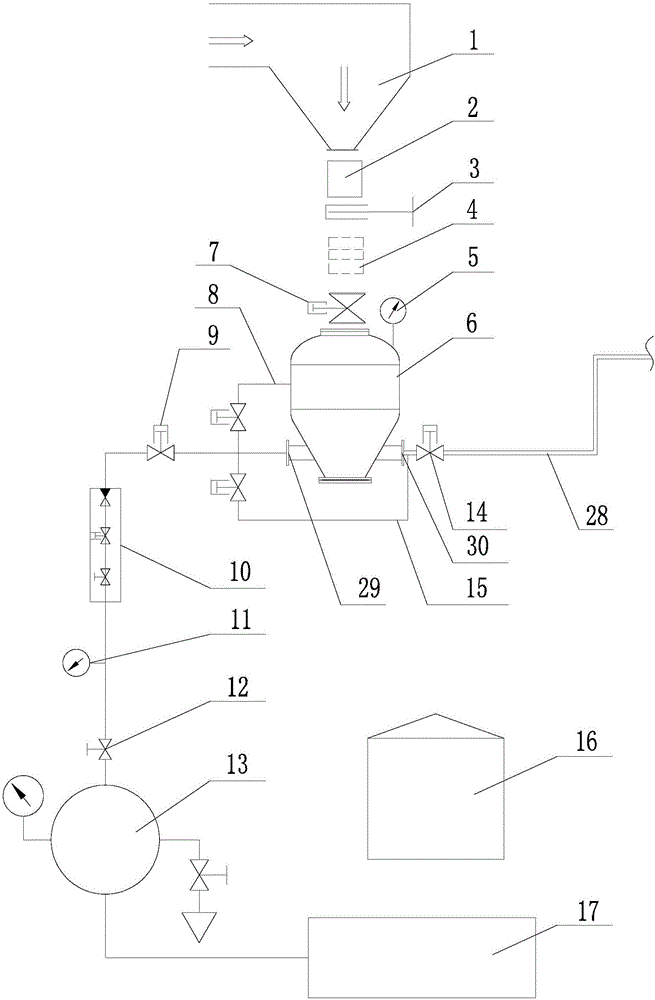

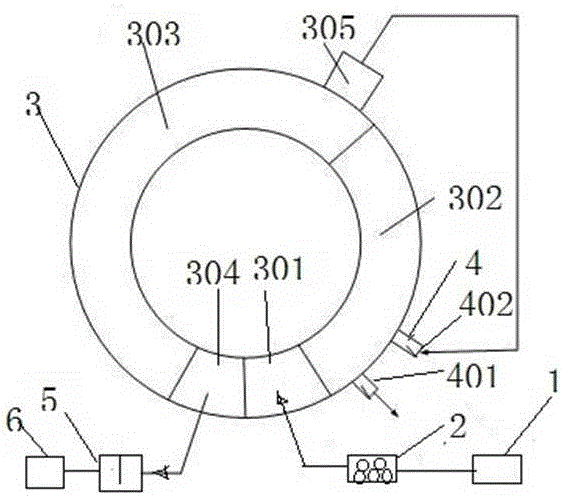

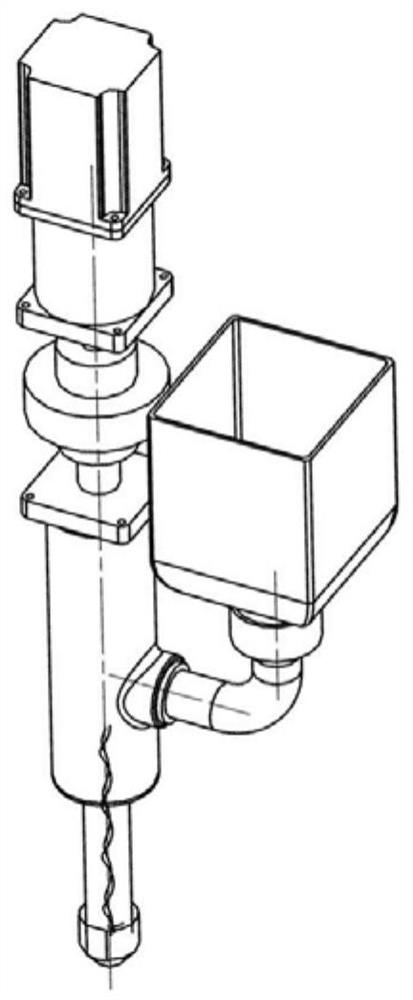

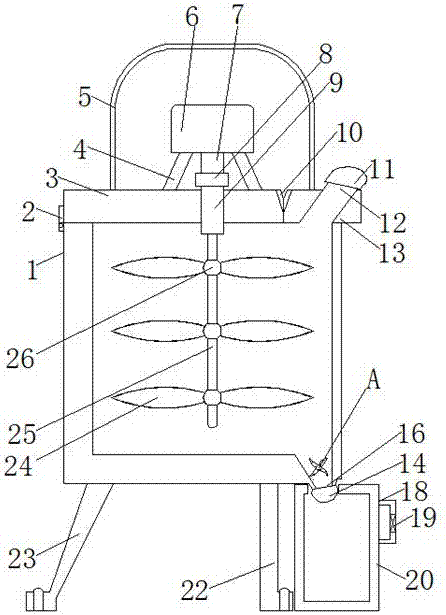

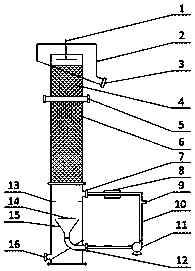

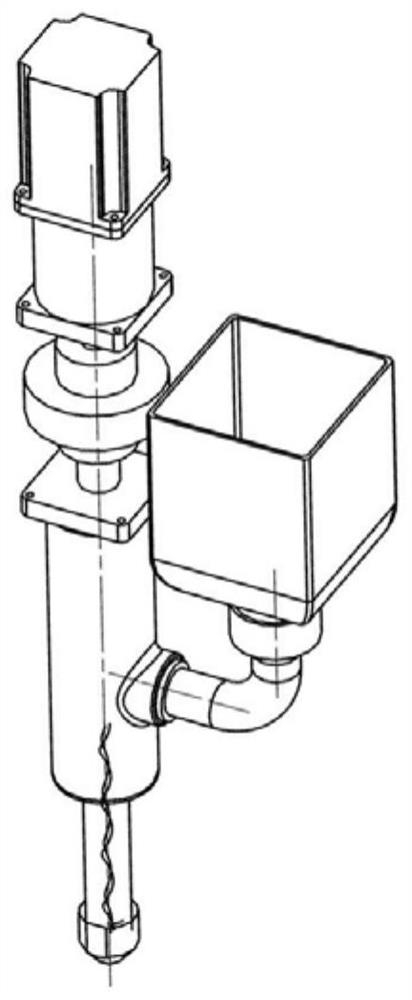

Novel flotation column

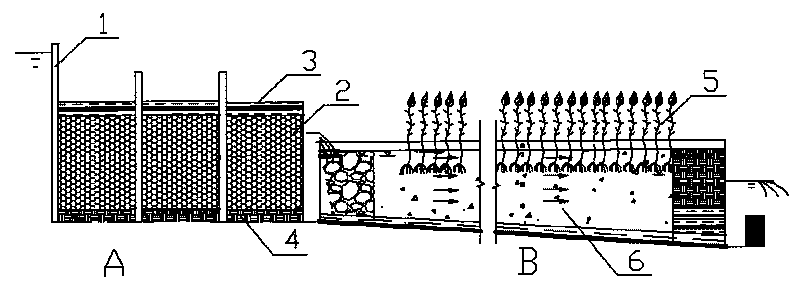

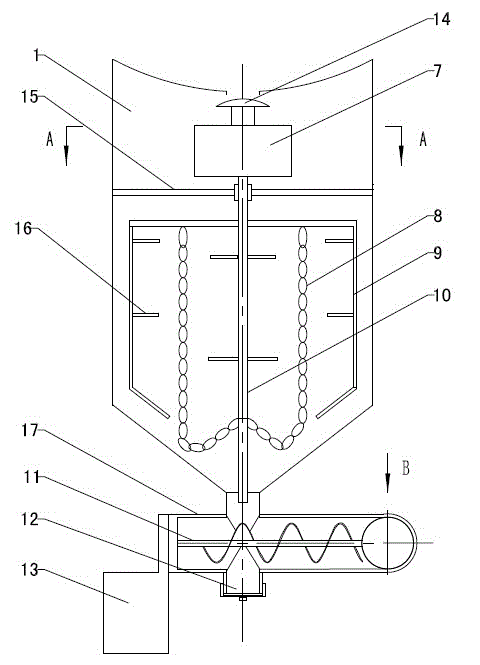

The invention relates to a novel flotation column. A main body of the novel flotation column is a column body; two-section type pore plate rolling padding is arranged in the column body; a middling circulating device is arranged on the lower portion of the column body and comprises an inverted-cone-shaped barrel, a circulating pump and an air bubble generator which are sequentially connected to one another through a pipe; the inverted-cone-shaped barrel is arranged in the column body; an opening of the inverted-cone-shaped barrel is upward; the circulating pump and the air bubble generator are arranged on the outside of the column body; the inverted-cone-shaped barrel is connected with the circulating pump through a liquid inlet pipe; and the air bubble generator is connected with the inside of the column body through a liquid outlet pipe. The novel flotation column is simple in structure and cannot be blocked easily; rising air bubbles are in contact with descending ore pulp sufficiently; and the flow state of the ore pulp is stable.

Owner:WUHAN INSTITUTE OF TECHNOLOGY

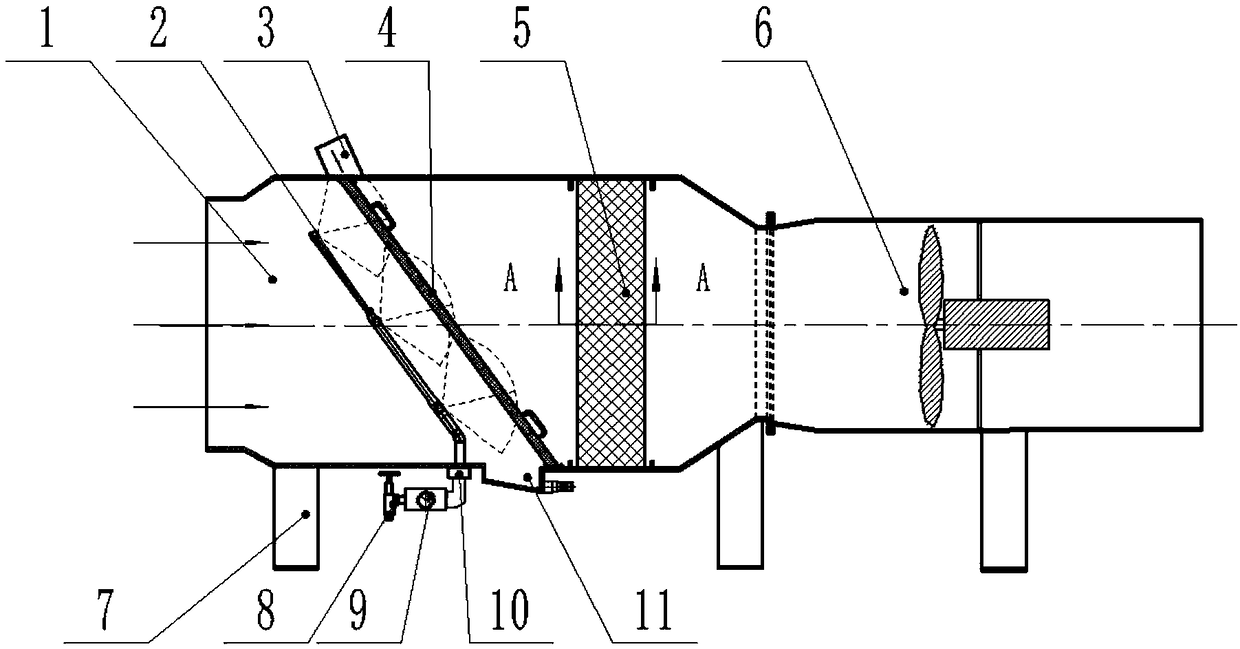

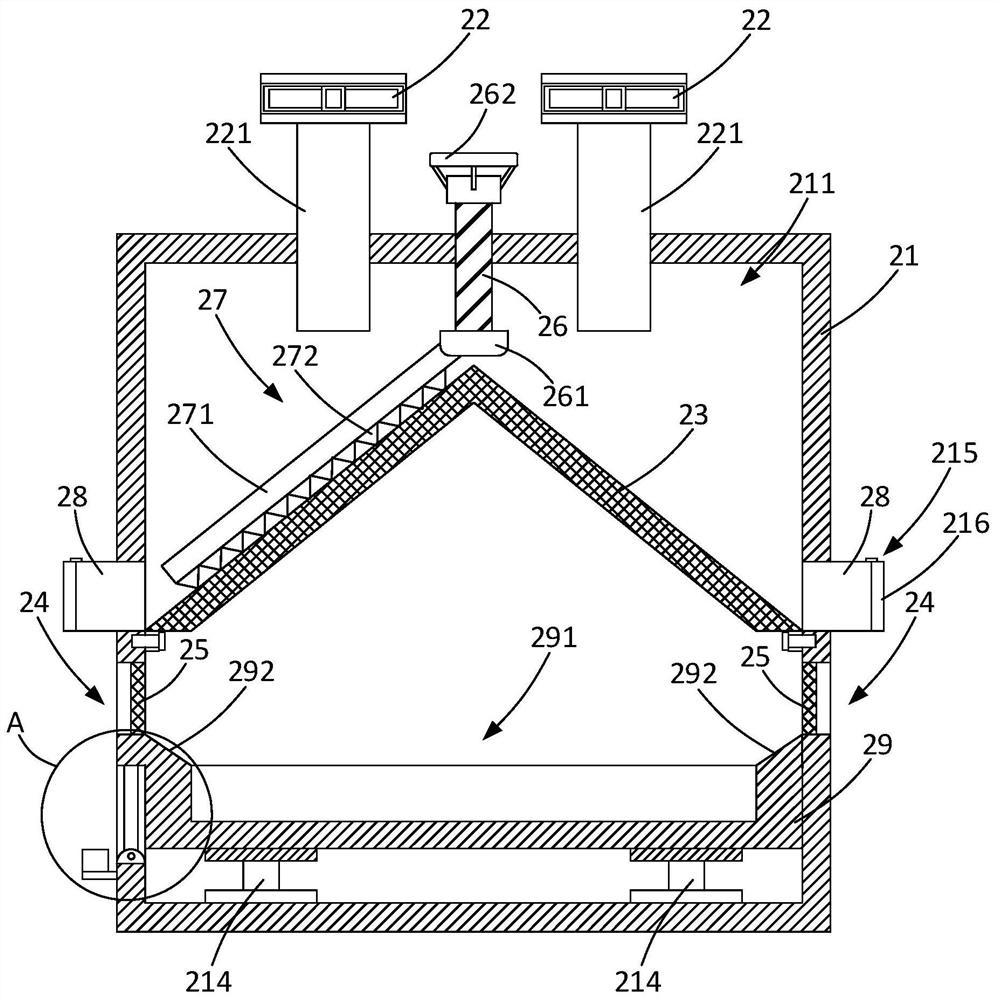

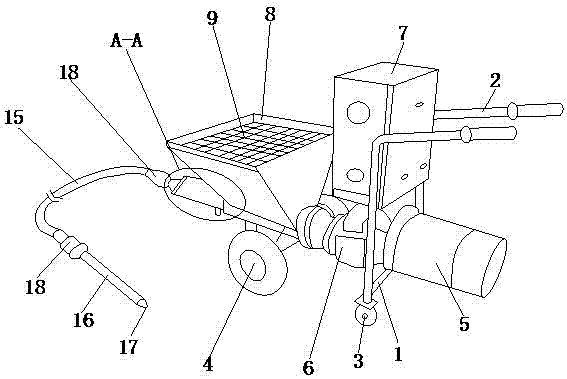

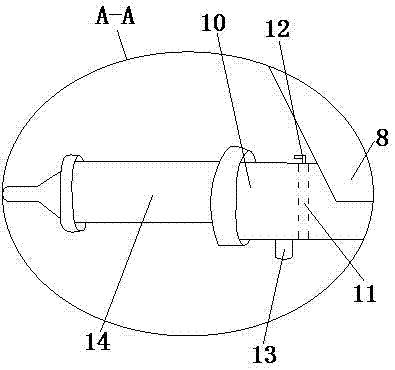

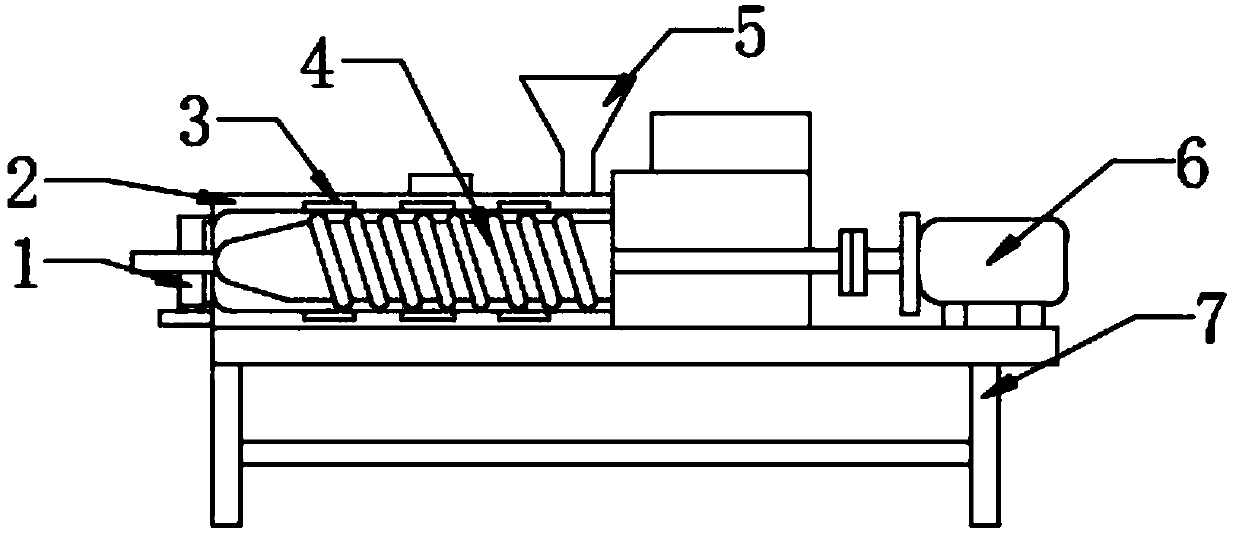

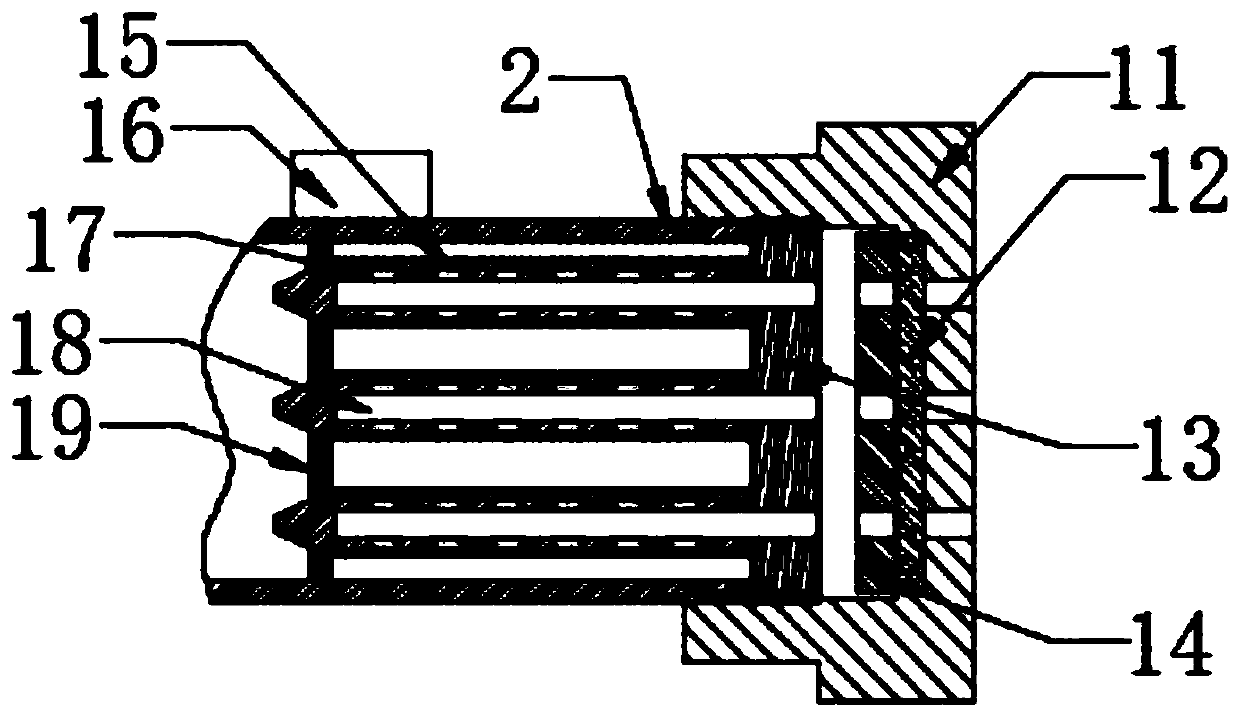

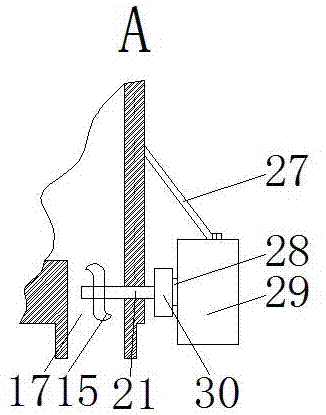

Special sponge grinding material spraying device

ActiveCN102744687ASimple structureOvercome the phenomenon of shed materialAbrasive blasting machinesSurface cleaningEngineering

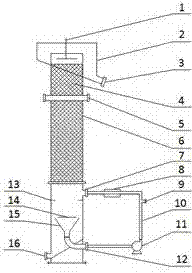

The invention discloses a special sponge grinding material spraying device, belongs to the field of surface cleaning equipment, and particularly relates to a special sponge grinding material spraying device which comprises a material storage pressure tank (1) and a nozzle (4). The special sponge grinding material spraying device is characterized in that a stirring device (2) is vertically and fixedly mounted in the material storage pressure tank (1) by a center shaft (10), an opening switch (14) used for controlling a feed inlet on the top of the material storage pressure tank (1) is disposed on the top of the stirring device (2), a feed inlet of a spiral feeding device (3) is connected to an outlet at the bottom of the material storage pressure tank (1), a discharge outlet of the spiral feeding device (3) is connected with a material inlet hole of the nozzle (4) by a pipeline, and a compressed air power system (5) is connected to one side of an air inlet hole of the nozzle (4). The special sponge grinding material spraying device has the advantages that the special sponge grinding material spraying device is simple in structure, convenient to use, fine in fluidity and high in efficiency, is not blocked easily, and the like.

Owner:淄博大亚金属科技股份有限公司

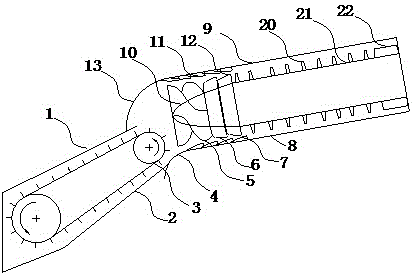

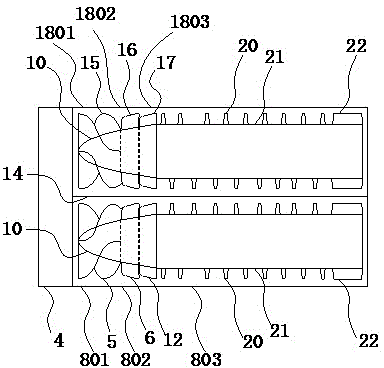

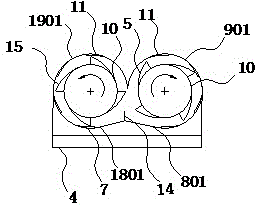

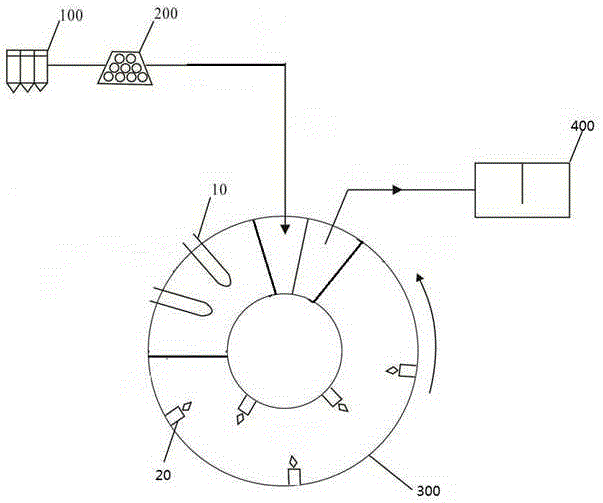

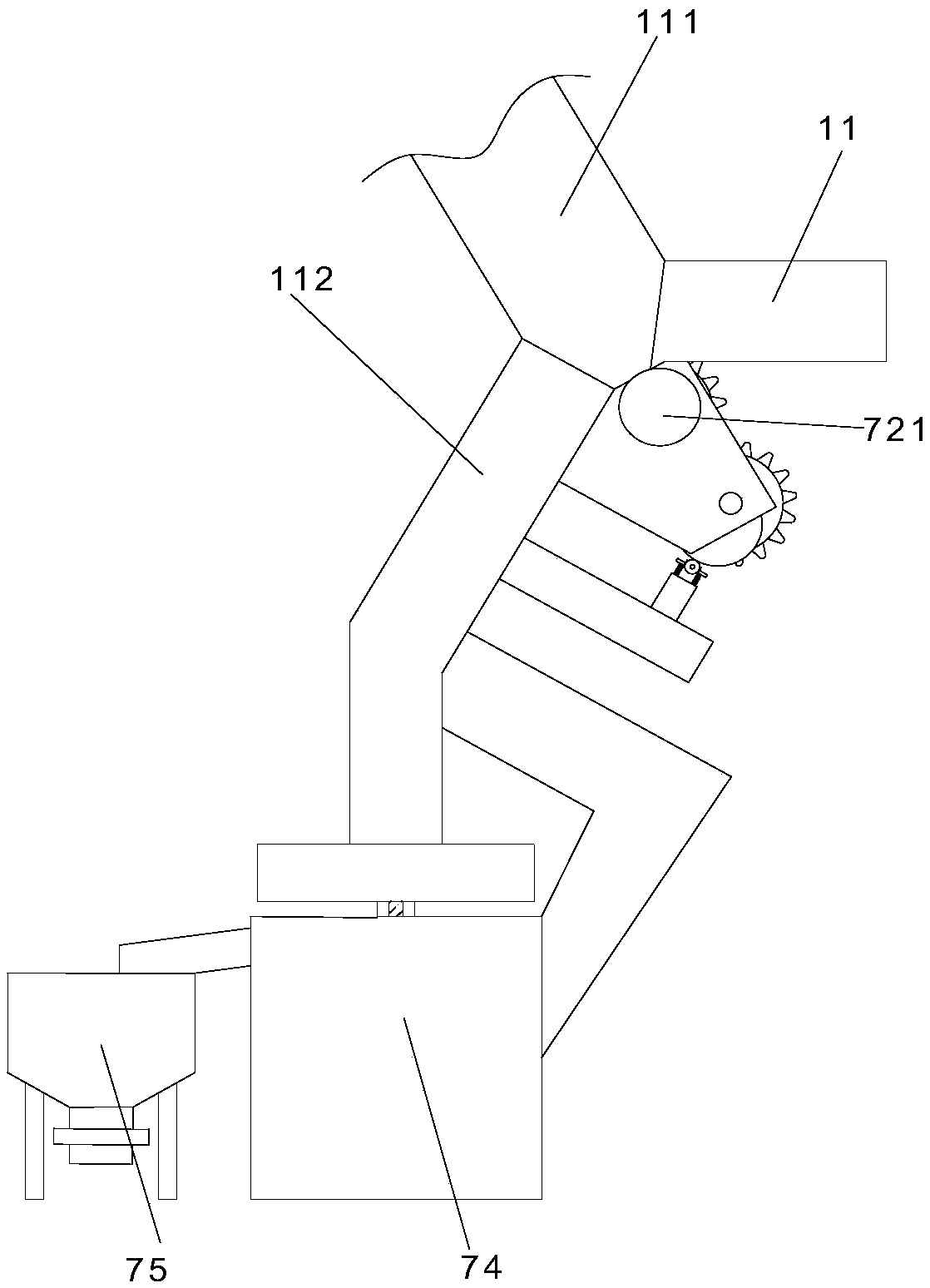

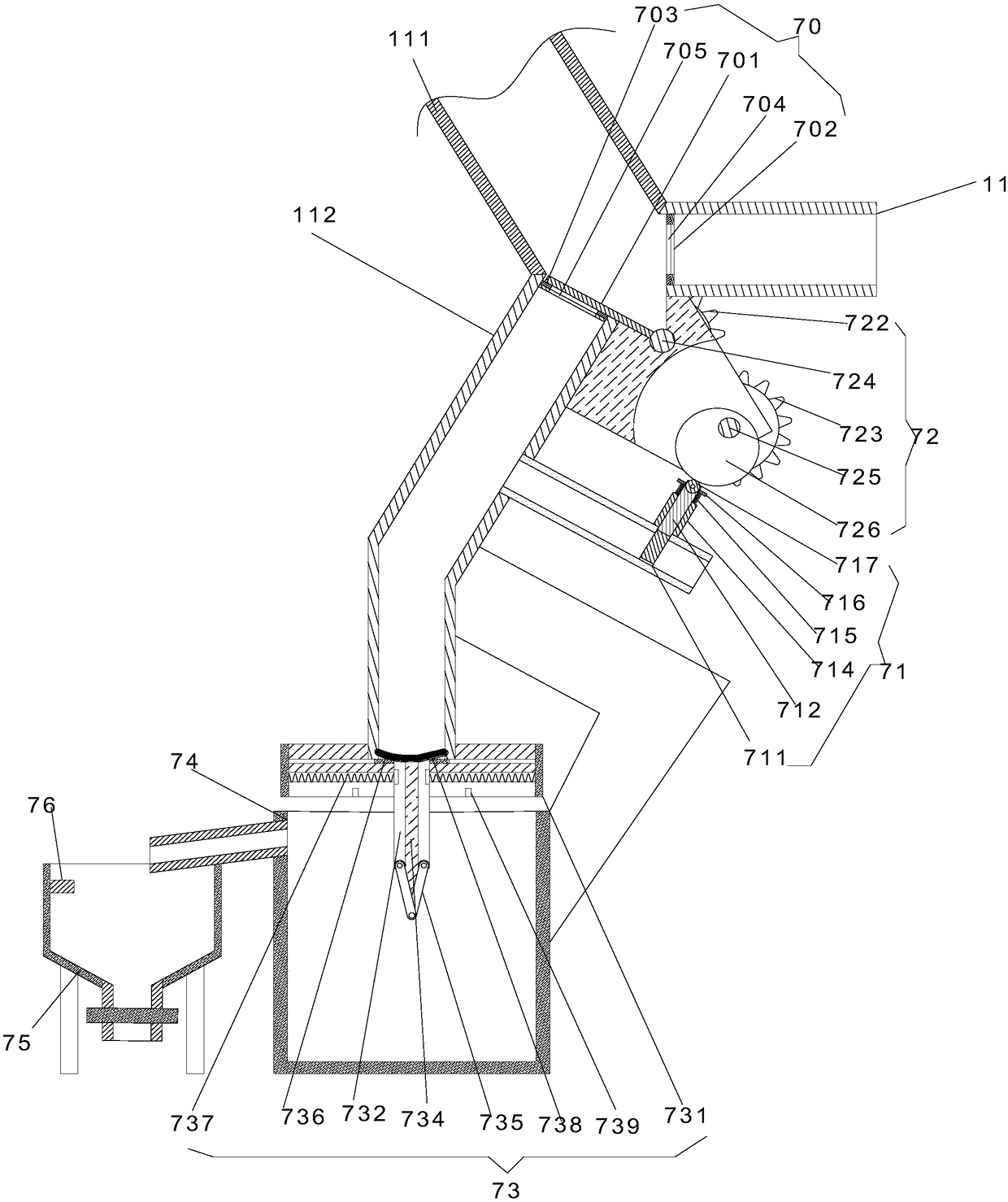

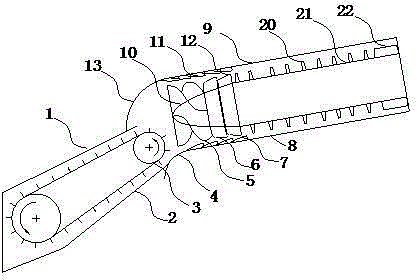

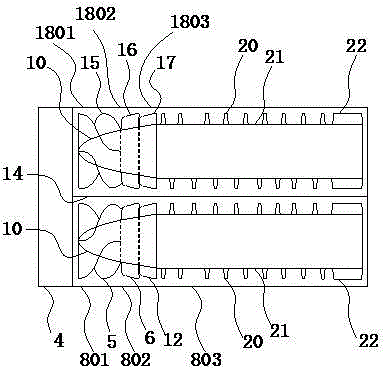

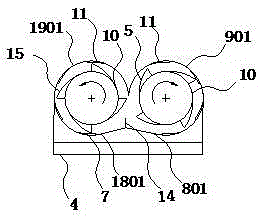

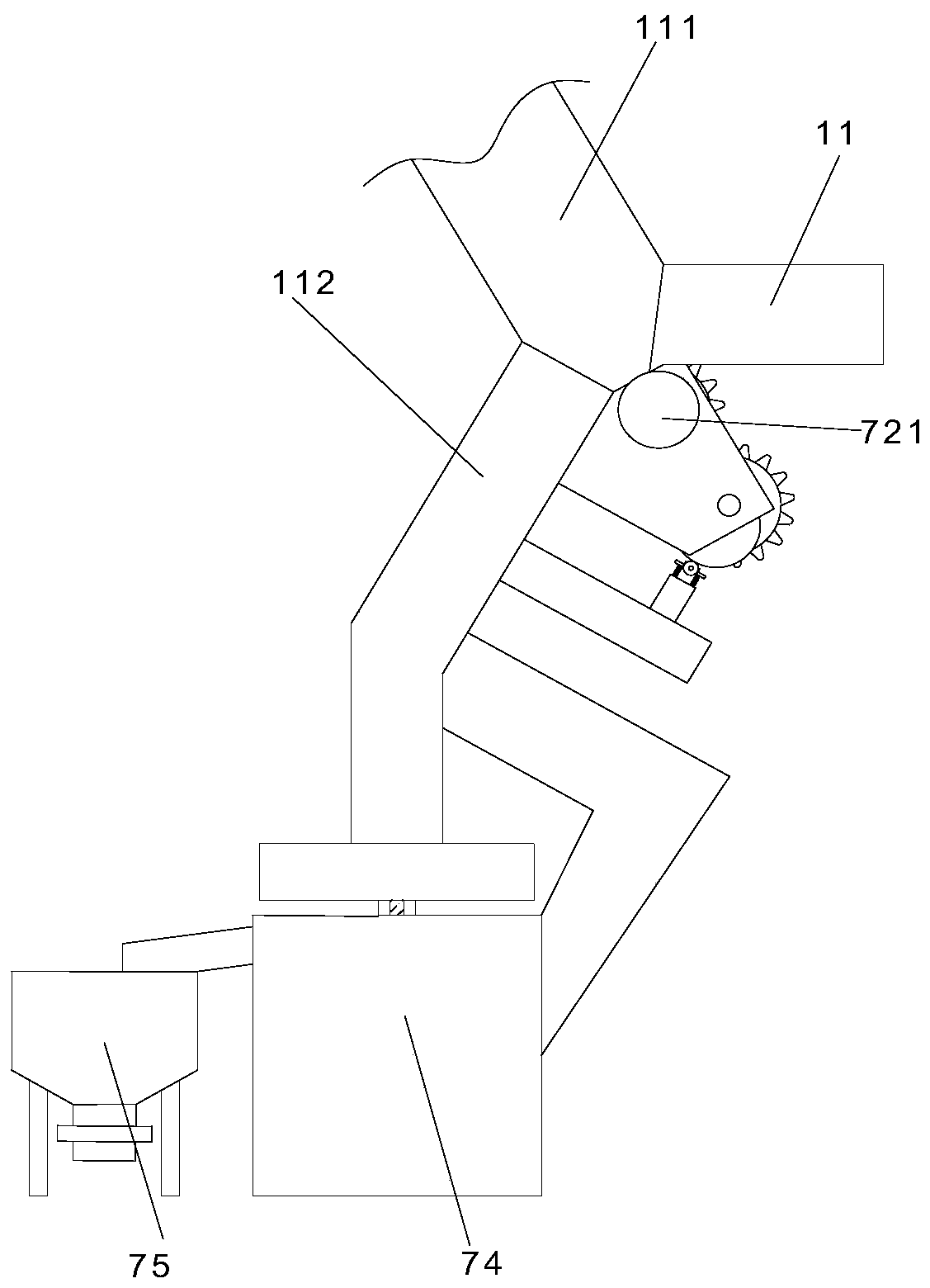

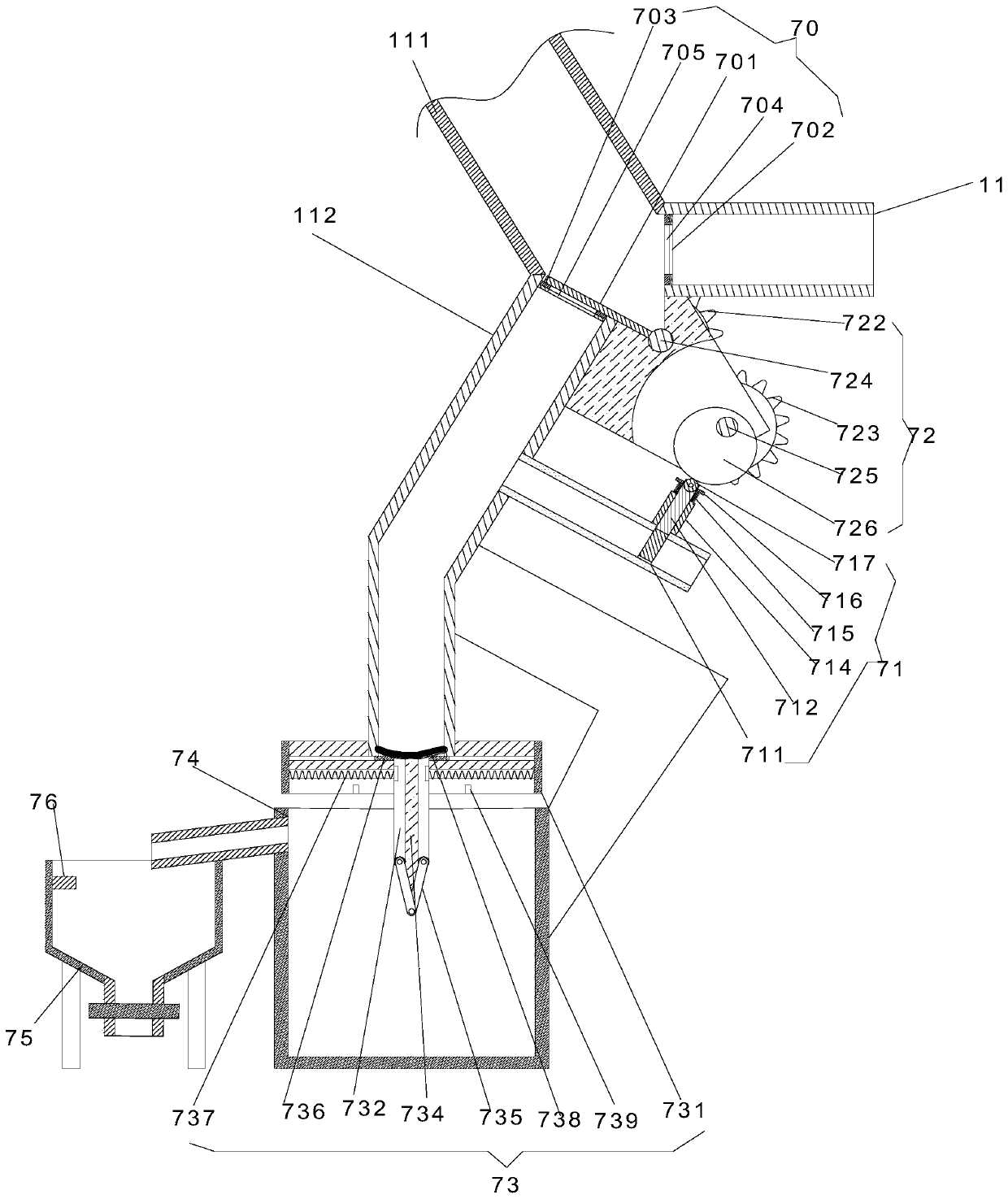

Double longitudinal axial flow rotary drum negative pressure feeding and shunting device

The invention discloses a double longitudinal axial flow rotary drum negative pressure feeding and shunting device. The device comprises a rotary drum body, a feeding head main body assembly and an auxiliary feeding accessory. When crop stalks to be threshed on a combine harvester are fed into a double longitudinal axial flow rotary drum from a conveyor trough, the stalks are grabbed by feeding helical blades, and are forcibly conveyed by negative pressure which is formed by the common effect of multistage axial flow blades which rotate at high speed, a rotary drum top cover and a rotary drum concave plate screen; the crop stalks to be threshed are shunted to the double axial flow rotary drum by the common effect of a concave plate guide plate and a shunting plate for threshing separation; the stalks subjected to threshing separation are discharged out of a machine body by a grass discharge plate on a longitudinal axial flow rotary drum body. According to the double longitudinal axial flow rotary drum negative pressure feeding and shunting device, the crop stalks such as rice, wheat and soybean which are conveyed by the conveyor trough on the combine harvester are forcibly fed and effectively shunted to the double longitudinal axial flow rotary drum for being subjected to threshing separation, and the problem that crops are easily blocked at the feeding inlet of the double longitudinal axial flow rotary drum of the combine harvester is solved.

Owner:JIANGSU UNIV

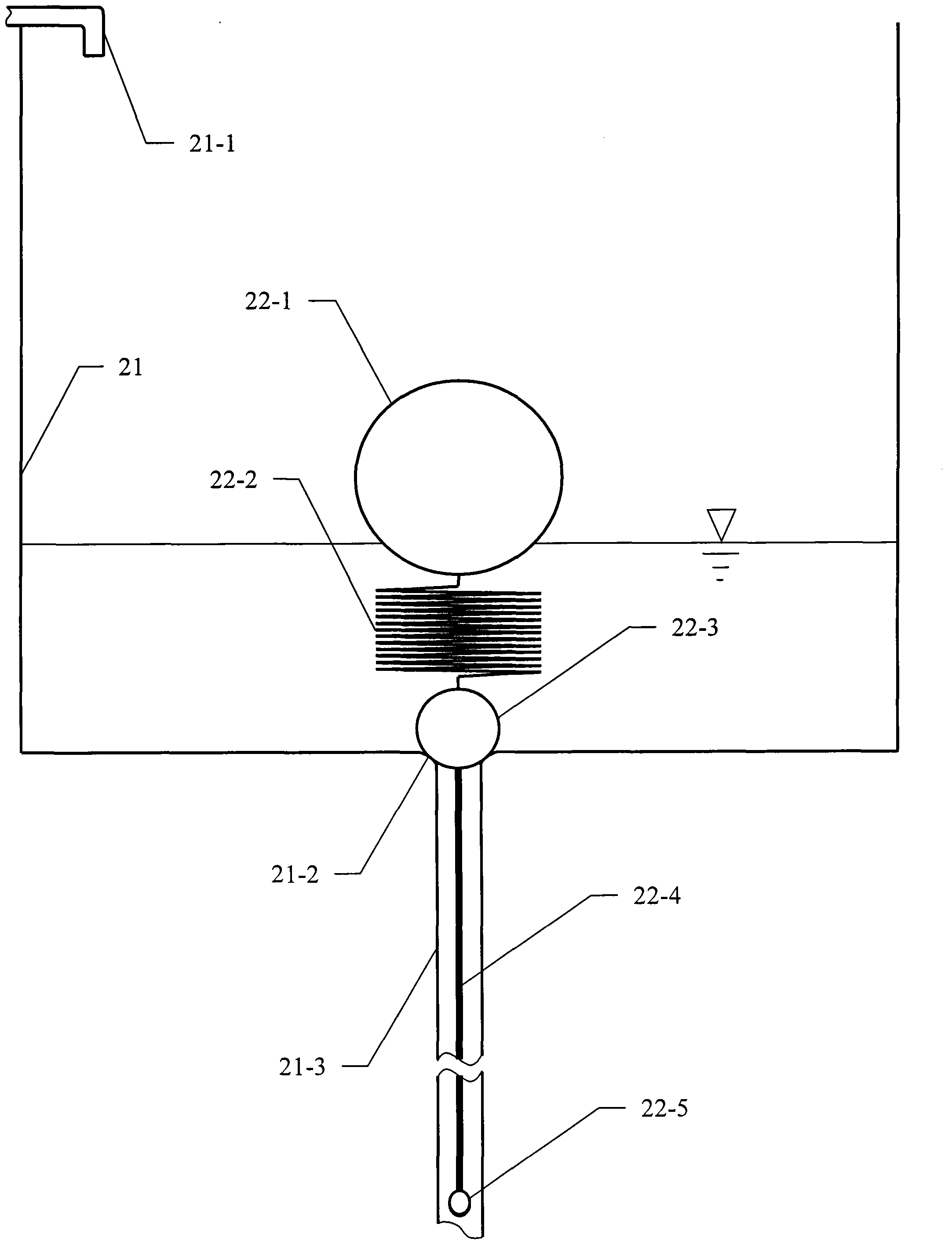

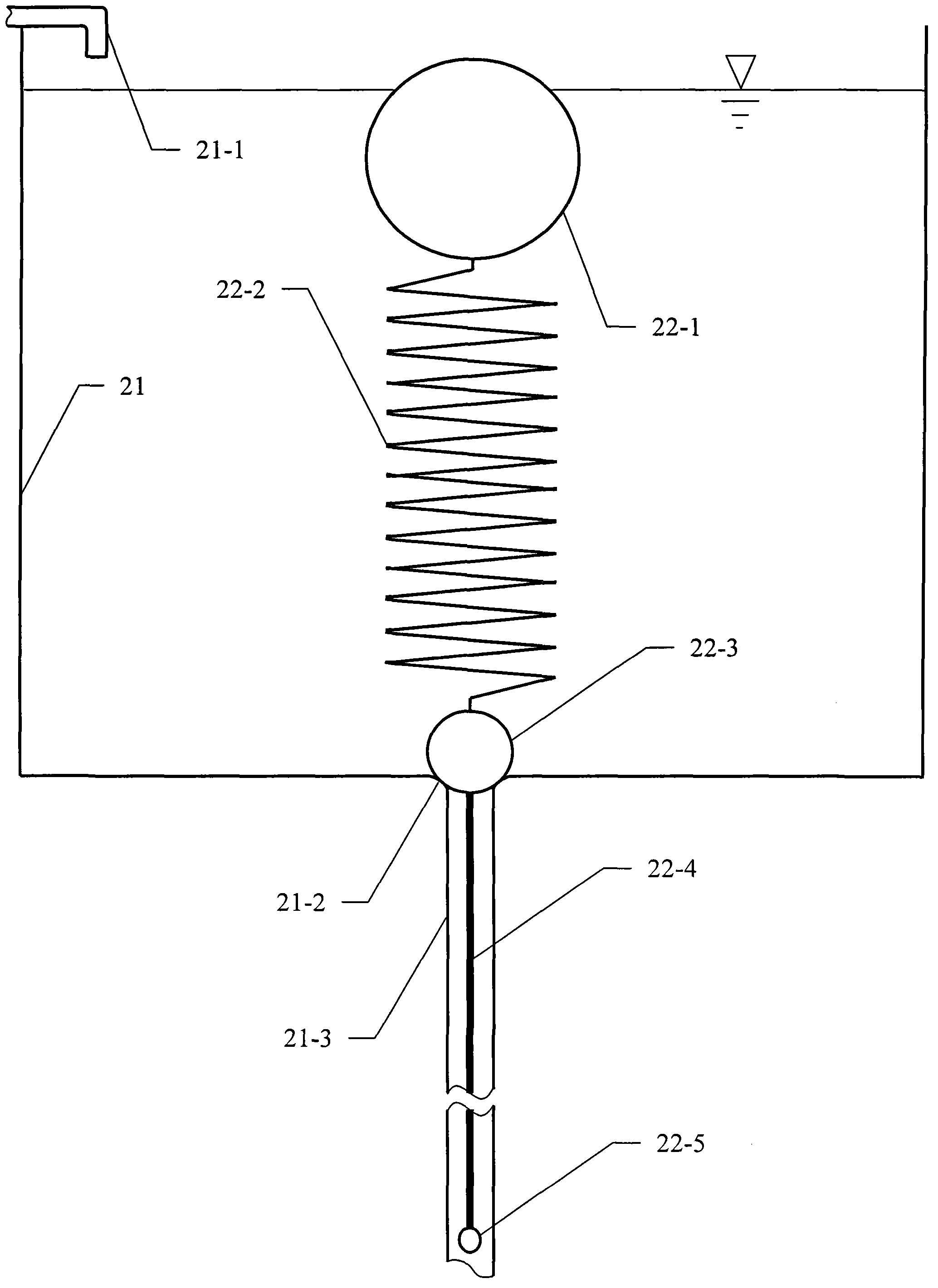

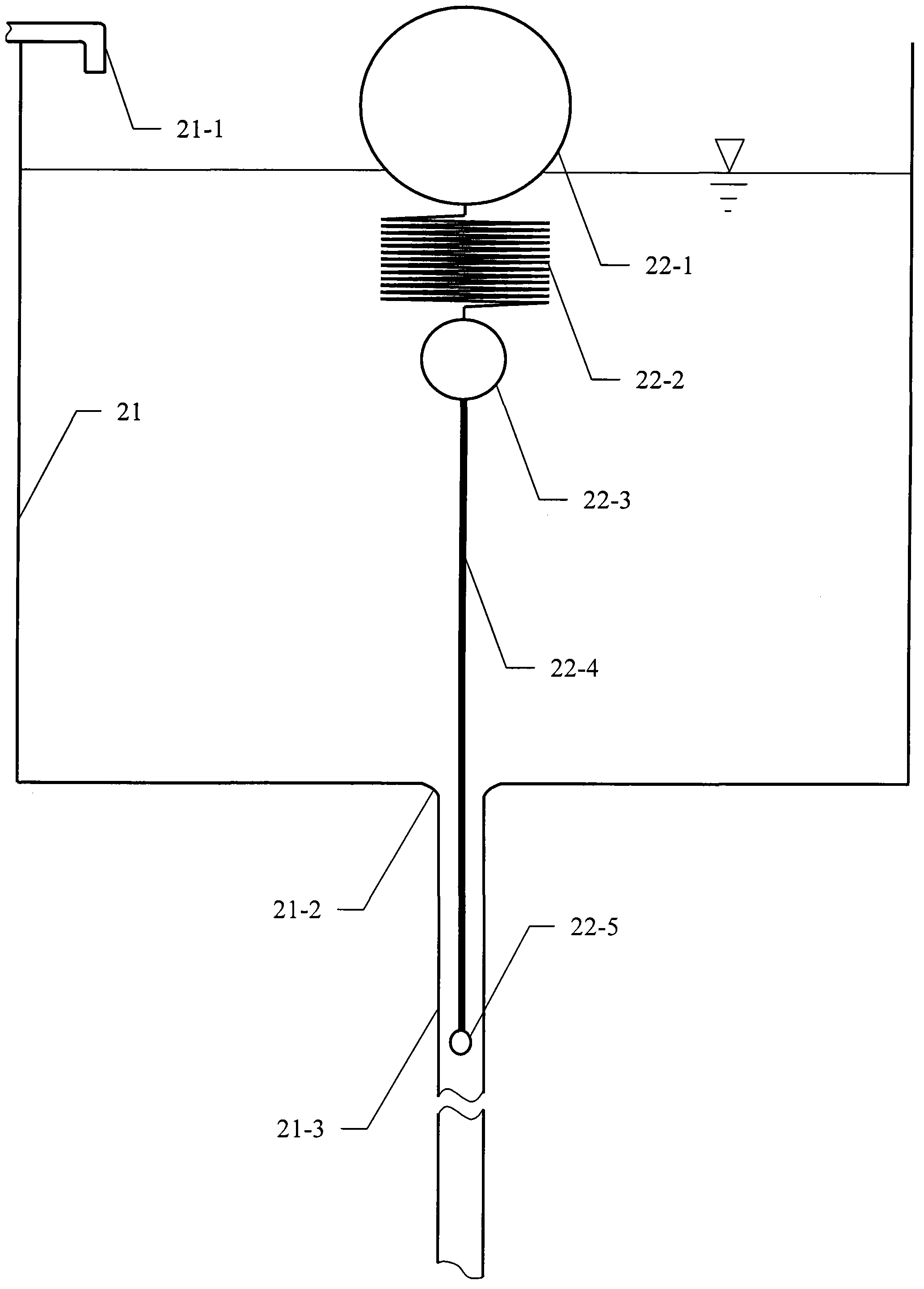

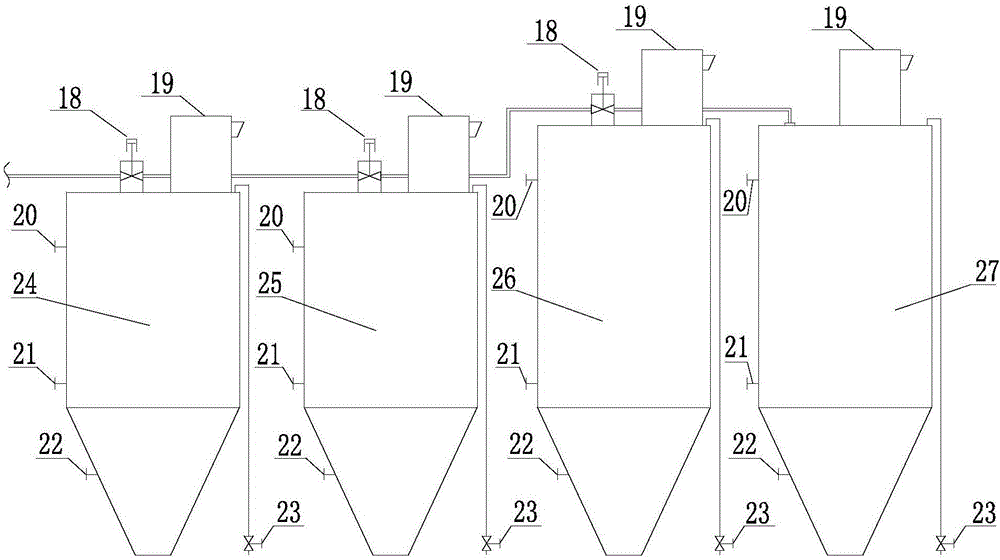

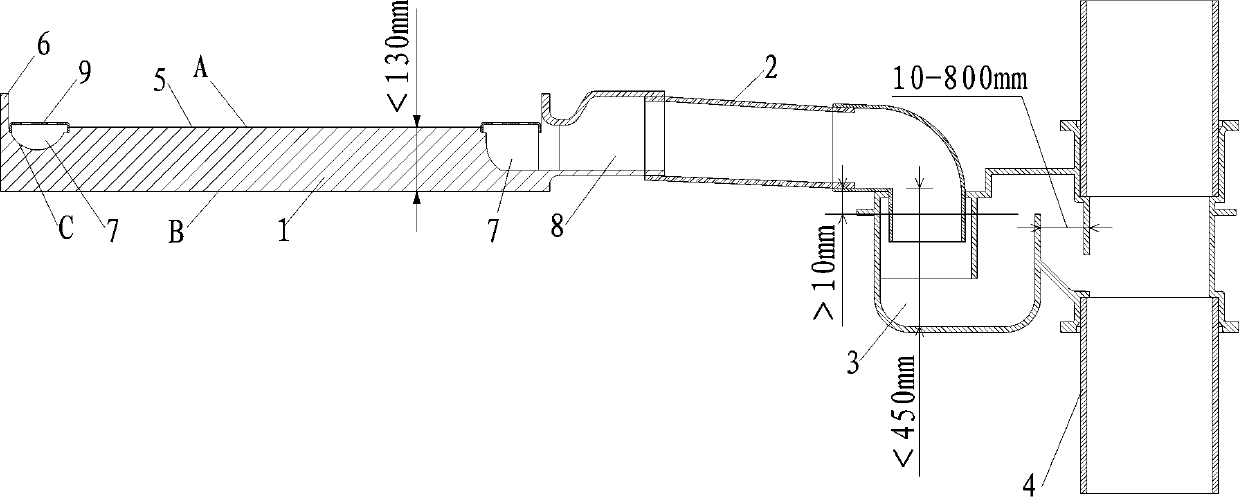

Anti-clogging gravity type underground drip irrigation system

InactiveCN103222411AGood anti-cloggingSolve the problem of easy cloggingClimate change adaptationWatering devicesWater storageDrip irrigation

The invention belongs to the technical field of agricultural water-saving irrigation and particularly relates to an anti-clogging gravity type underground drip irrigation system. The anti-clogging gravity type underground drip irrigation system comprises a water storage device, a water delivery and distribution device, an intermittent water supply device and a pressure control irrigation emitter, wherein the intermittent water supply device recurrently starts the pressure control irrigation emitter to perform irrigation; and during each round of irrigation process, an irrigation emitter water outlet of the pressure control irrigation emitter is mechanically dredged, thus effectively preventing the clogging of the irrigation emitter water outlet. The most common gravity type drip irrigation system provided by the invention adopts a special anti-clogging technical method for the gravity type drip irrigation system, and effectively solves the problem that the irrigation emitter of the most common gravity type drip irrigation system is easy to clog.

Owner:FARMLAND IRRIGATION RES INST CHINESE ACAD OF AGRI SCI

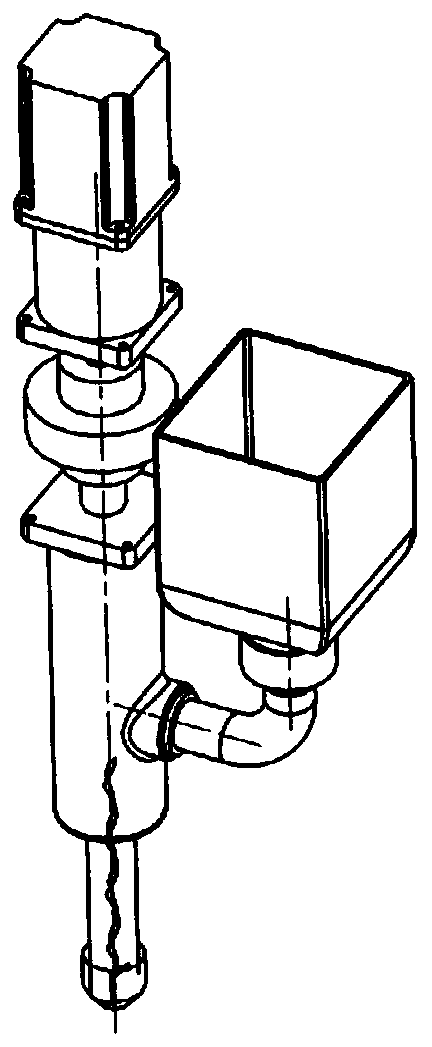

Vibrating straw pulverizer facilitating blanking

The invention discloses a vibrating straw pulverizer facilitating blanking, comprising a pulverizing bin, a feeding port, a left pulverizing shaft, a right pulverizing shaft, a pulverizing blade and adischarging opening, wherein a blanking bin is installed on the upper surface of the pulverizing bin, the left side wall of the blanking bin is fixedly connected with a cutting motor, the shaft end of a blanking motor is fixedly connected with a crankshaft, a connecting rod is connected to a journal of the crankshaft, and a movable block is arranged inside the blanking motor. The lower end of theconnecting rod is hinged to the upper surface of the movable block, and the lower surface of the movable block is distributed with a plurality of blanking cutting blade s, and a grid plate is arranged below the cutting blades. Straws are initially cut by the blanking cutting blades, and the cutting blades apply downward force on the straws to allow the straws to be dropped into the pulverizing bin after passing through the grid plate to prevent the straws from accumulating inside the blanking bin, which facilitates the straw blanking. A left pulverizing shaft and a right pulverizing shaft arearranged, the straws are crushed by the pulverizing blade, so that the straws are pulverized smash more fully and the pulverization efficiency is improved.

Owner:临泉县隆源农业有限公司

Wetting and drying alternation type sewage purification method

InactiveCN104671421AEasy to handleNot prone to corruptionTreatment with aerobic and anaerobic processesSustainable biological treatmentSiphonPurification methods

The invention discloses a wetting and drying alternation type sewage purification method. Sewage flows into a wetland filler layer of a wetting and drying alternation type sewage purification device until the sewage submerges wetland filler, the wetland filler is submerged in the sewage to be in an anaerobic state, and gaps of the wetland filler are filled with air to be in an oxygen-containing state when the sewage is pumped out of the wetland filler layer, so that the wetland filler and sewage are in a wetting and drying alternation circulation state. A natural siphon or water pump including but not limited to a siphon pipeline pumps out sewage intermittently, so that the wetting and drying alternation function of an upper wetland filler layer is realized. Wetting and drying alternation circulation of the wetland filler in the sewage is realized, and the gaps of the wetland filler are in an oxygen-enriched state due to the fact that oxygen is accommodated in the gaps of the wetland filler and root systems of a wetland plate are contacted with air, so that the treatment effect of sewage is improved. Devices are used simultaneously in a parallel-connection or series-connection manner, and the continuous stable effect of water quality of the treated domestic sewage is remarkable.

Owner:吴永贵 +2

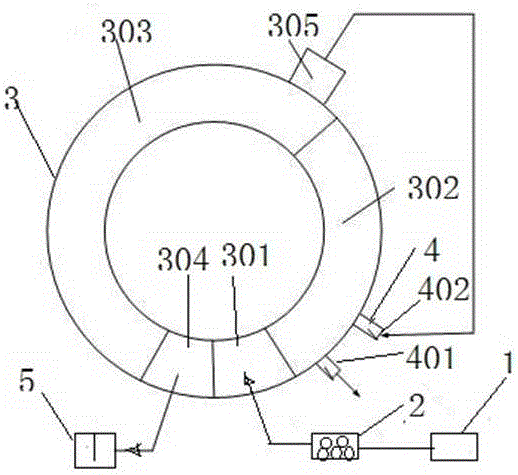

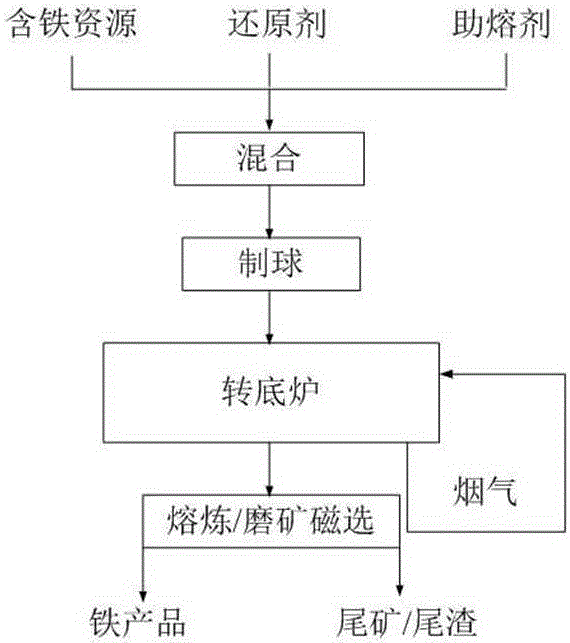

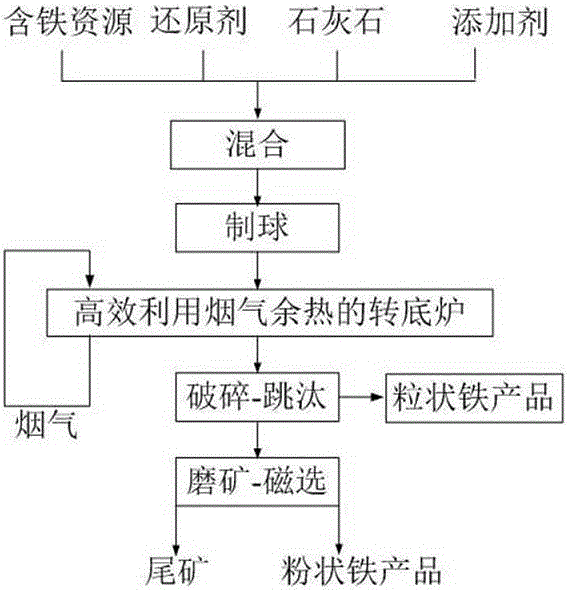

System and method for efficiently utilizing waste heat of flue gas of furnace to treat iron-containing resources

InactiveCN106244758ASolve the problem of easy cloggingAvoid easy cloggingHearth type furnacesFlue gasProcess engineering

The invention relates to the field of chemical metallurgy, in particular to a system and method for processing iron-containing resources. Aiming at the deficiencies of the prior art, the present invention proposes a system and method for efficiently utilizing waste heat of furnace flue gas to treat iron-containing resources. The system and method improve the heating mode of the rotary hearth furnace, on the one hand, make the flue gas of the rotary hearth furnace The waste heat can be reused inside the rotary hearth furnace, which improves the utilization efficiency of the waste heat of the flue gas in the rotary hearth furnace. The technological process reduces equipment investment, and the invention has the advantages of high flue gas waste heat utilization rate, short treatment process, low equipment investment, high equipment operation rate, low energy consumption, and wide application range.

Owner:JIANGSU PROVINCE METALLURGICAL DESIGN INST

Wet dust collector with high-frequency vibration filter screen

PendingCN108452628ASolve the problem of easy cloggingImprove contact efficiencyCombination devicesSeparation devicesAir filtrationFiber bundle

The invention discloses a wet dust collector with a high-frequency vibration filter screen and belongs to the field of air filtration. The wet dust collector with the high-frequency vibration filter screen mainly comprises a dust collector housing, a spray component, an excitation device, a filter component, a dewatering component, an axial flow fan and the like. The spray component, the filter component, the dewatering component and the axial flow fan are sequentially mounted in the dust collector housing in the direction from the inlet to the outlet. A filtering filter element of the filtercomponent is obtained by laminating fiber bundles with nano-fiber whiskers after being subjected to hydrophobic treatment. In the process of filtration, a high-frequency vibration source excites the filter component, so that the fiber whiskers vibrate at high frequency in an equilibrium position to enhance the contact probability among the whiskers, dust and water mist, so as to improve the capture efficiency of fine dust. Furthermore, the vibration of the fiber bundles and the fiber whiskers effectively prevents the stagnation of dust-containing water droplets inside the filter component to accelerate the flow of the dust-containing water droplets so as to solve the blocking problem of the filter component. The dust collector has the advantages of high dust removal efficiency, difficultyin blocking of wire meshes and low pressure loss.

Owner:BEIJING UNIV OF CHEM TECH

Pneumatic calcium hydroxide conveying system

InactiveCN106006035ARealize automatic circulation conveyingSolve the problem of easy cloggingBulk conveyorsCalcium hydroxideAutomatic control

The invention discloses apneumatic calcium hydroxide conveying system. The pneumatic calcium hydroxide conveying system comprises a feeding device, an air source device, an air conveying pipe, a feed bin and a full-automatic control room, wherein the feeding device comprises a discharging pipe and a bin pump which are arranged below a calcium hydroxide producing system; a feeding valve is arranged on the bin pump; an intake pipe and a vent pipe are connected to the bottom of the bin pump; the air source device comprises an air storage tank connected with the intake pipe and a pneumatic conveying air supply system connected to the air storage tank; the air conveying pipe is connected with the vent pipe through a discharging valve; the feed bin comprises a plurality of terminal bins connected to the air conveying pipe; and automatic dust collecting systems and returning valves are arranged on the terminal bins. The pneumatic calcium hydroxide conveying system can automatically and circularly convey a material to the terminal bins at intervals or in a skipping way, is safe and reliable and economical and practical, and effectively solves the problem that the pipes are easily blocked.

Owner:崔洪良

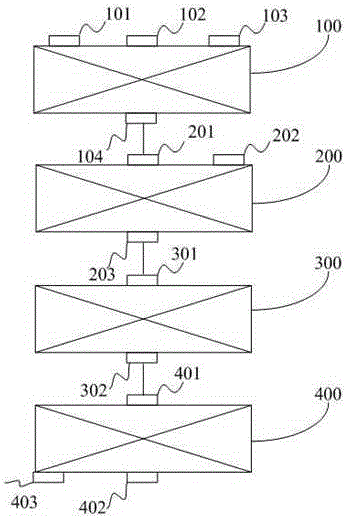

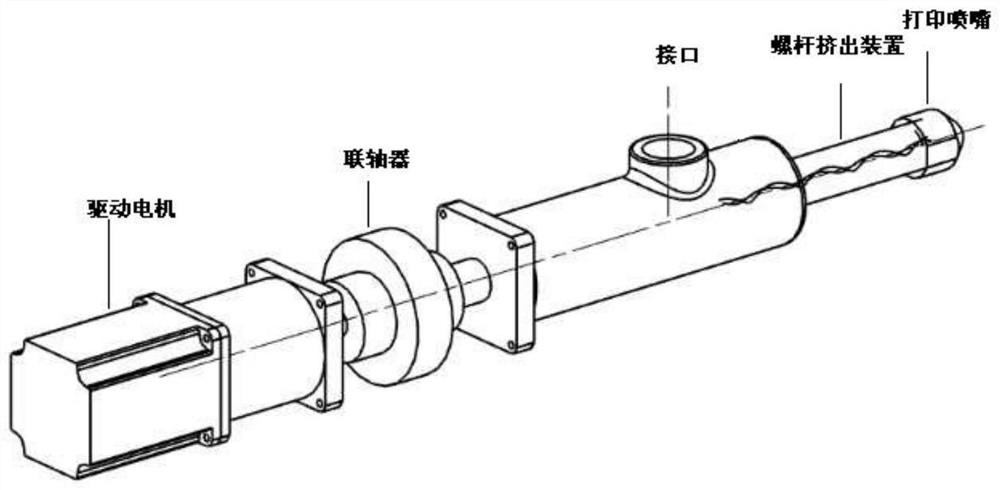

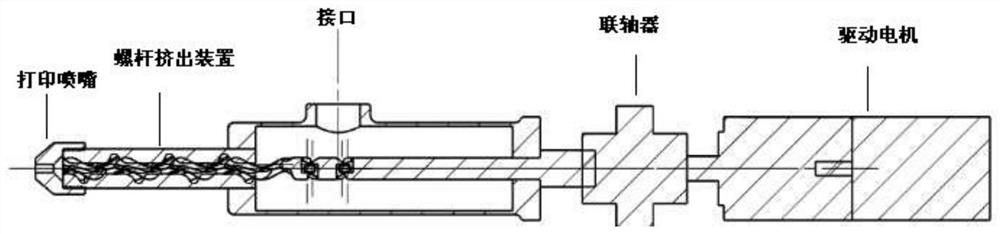

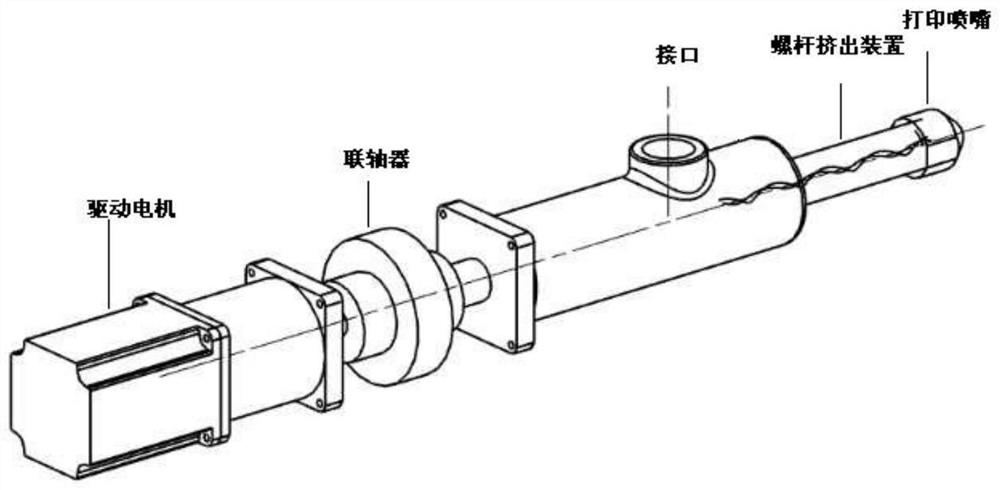

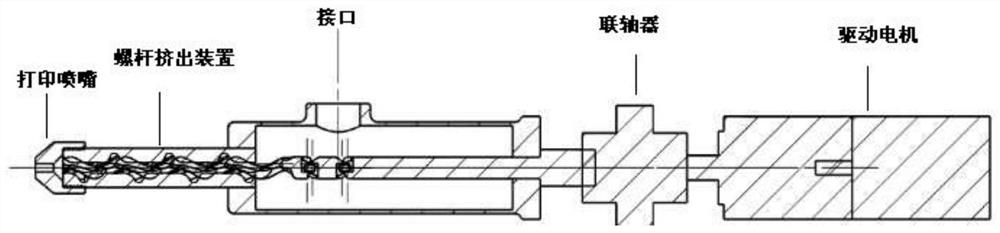

Lunar soil concrete and preparation method thereof

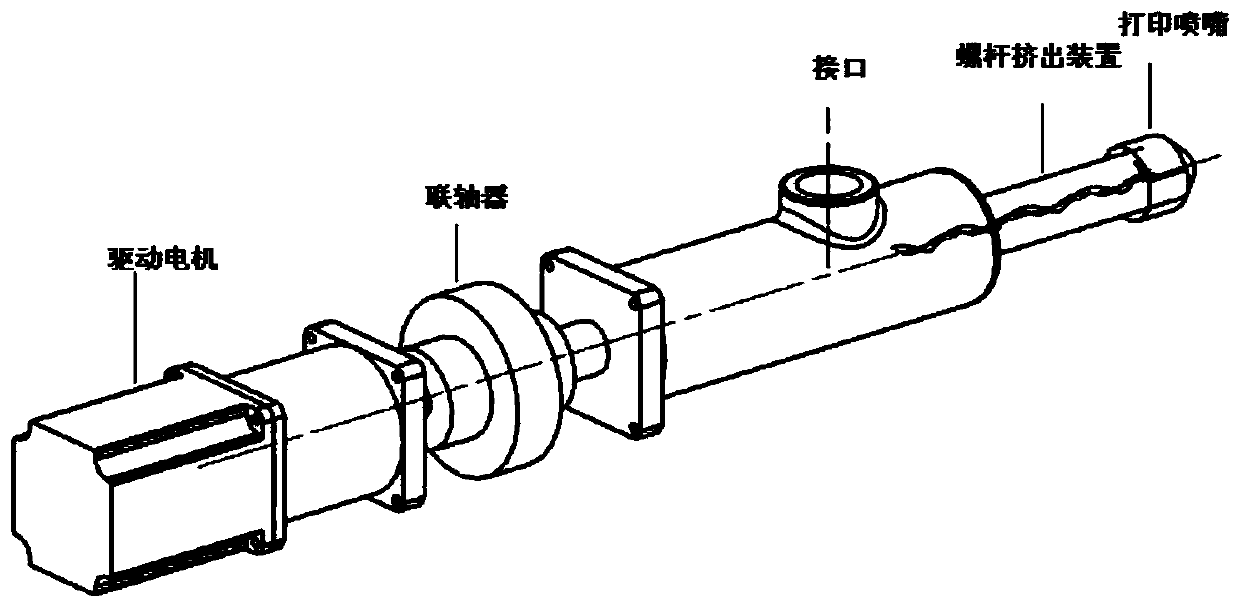

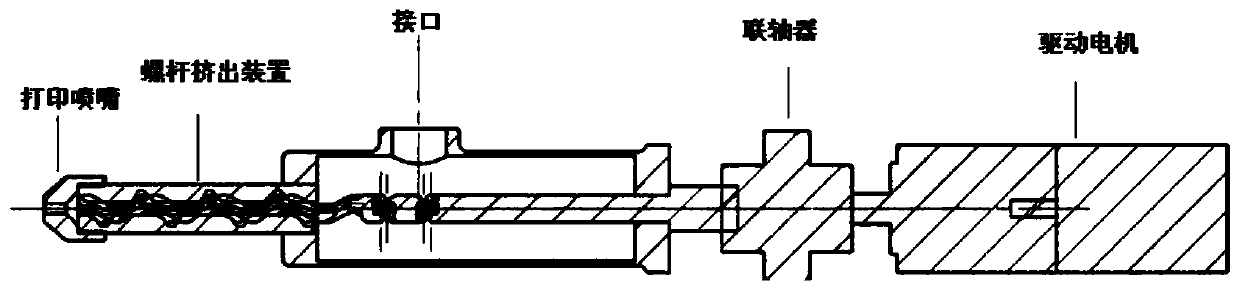

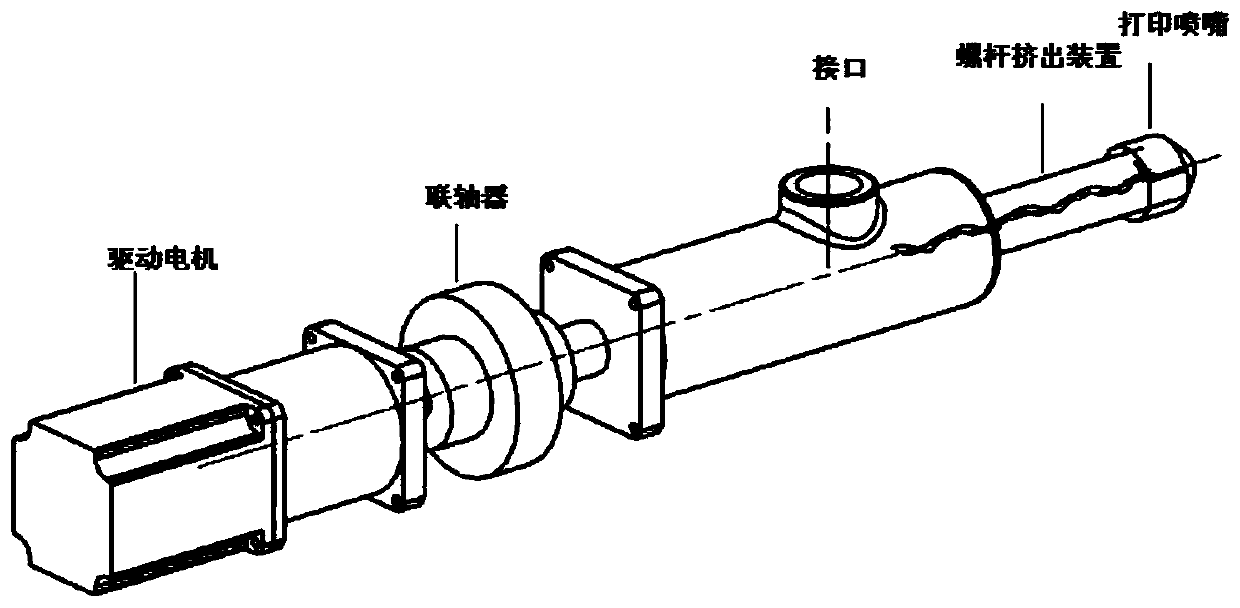

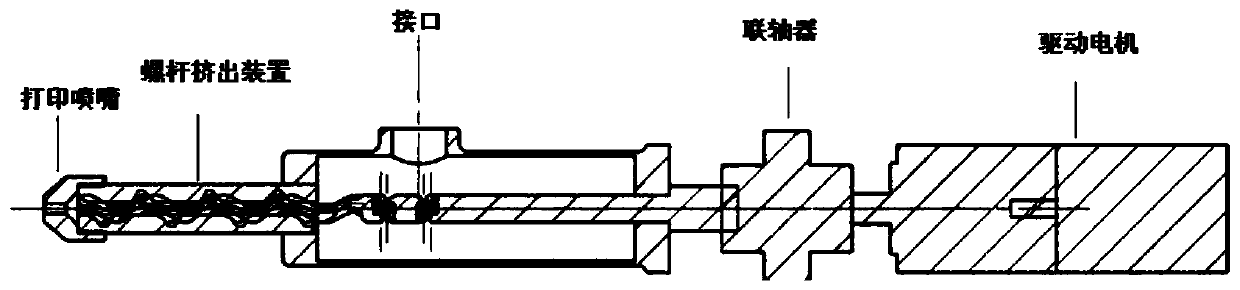

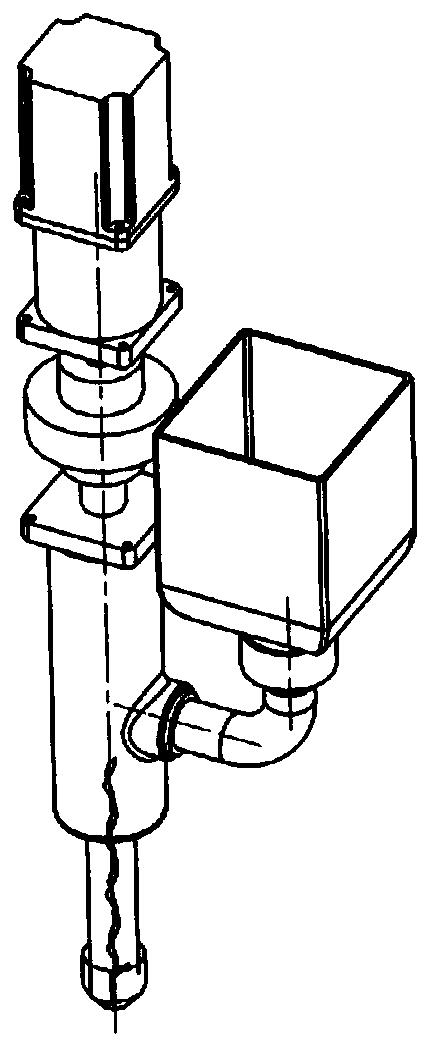

ActiveCN110256039ARealize instant refillAvoid cloggingAdditive manufacturing apparatusAviationCoupling

The invention relates to a lunar soil "concrete" and a preparation method thereof, and the lunar soil "concrete" is mainly used for aerospace, aviation, architectural paint and other technical fields. Lunar soil "concrete" hybrid 3D printing technology is an important key technology for follow-up lunar surface base construction of the moon in the future. A lunar soil simulant hybrid 3D printing device can realize continuous and controllable extrusion molding of lunar soil "concrete" by designing a lunar soil simulant hybrid 3D printing head. The hybrid 3D printing head is a key component of the lunar soil hybrid printing device, and can be employed to realize the continuous and controllable extrusion of lunar soil "concrete". The hybrid 3D printing head is a functional component integrating a drive motor, a coupling, a screw pump, an interface, a screw extrusion apparatus, a printing nozzle and other parts, and can realize the continuous and controllable extrusion molding of lunar soil "concrete" material.

Owner:BEIJING SATELLITE MFG FACTORY

Indoor decoration dust isolation equipment

PendingCN111701974AAvoid cloggingSolve the problem of easy cloggingDispersed particle filtrationTransportation and packagingDust particlesStructural engineering

The invention relates to indoor decoration dust isolation equipment. The indoor decoration dust isolation equipment comprises an isolation box, a suction fan, a filter screen, an exhaust port, a filter plate, a rotating shaft, a brush mechanism and a discharging hopper, wherein a collection space is formed in the isolation box, and an opening is formed in the top of the isolation box; the suctionfan is arranged at the opening; the filter screen is arranged in the isolation box, the filter screen is in an inverted cone shape, the bottom of the filter screen is fixedly connected with the innerwall of the isolation box, and the filter screen faces the opening; the exhaust port is formed in the side part of the isolation box and is correspondingly arranged below the filter screen; the filterplate is arranged at the exhaust port; the rotating shaft is rotatably installed at the top of the isolation box; the brush mechanism is connected to the bottom of the rotating shaft and arranged onthe surface of the filter screen, and the rotating shaft is rotated to drive the brush mechanism to rotate so that the surface of the filter screen can be cleaned; and the discharging hopper is arranged on the side part of the isolation box and is arranged corresponding to the bottom of the filter screen. Dust particles accumulated on the surface of the filter screen are cleaned up through the brush mechanism, so that the filter screen is prevented from being blocked, and the indoor dust particles are continuously cleaned up and isolated.

Owner:中建八局装饰工程有限公司

Cleaning device of mortar spray coater

InactiveCN107130780ASolve cleaningSolve the problem of easy cloggingBuilding constructionsElectrical controlEngineering

The invention discloses a cleaning device for a mortar spraying machine, which comprises a frame, a pushing device is arranged at the rear of the frame; a locking wheel and a rolling wheel are arranged at the bottom of the frame, and a motor is arranged at the rear of the frame; There is a reducer and an electric control box in the middle of the frame, a hopper is installed in the front of the frame, and the hopper is installed above the rolling wheel; the outlet on one side of the hopper is connected to one end of the pipeline, and a baffle is installed inside the pipeline; There is a water inlet, and a screw pump is arranged on one side of the pipeline. The cleaning device of this mortar spraying machine, through the set pipeline, baffle plate, handle and water inlet, after the mortar spraying machine completes the spraying work, turn off the mixer power switch and the forward and reverse switch on the electric control box, and close the baffle inside the pipeline. Plate, connect the water pipe to the water inlet, turn on the faucet to discharge water, so the structure of part A-A is cleaned, and the problems of difficult cleaning and easy blockage in the prior art are solved.

Owner:海宁市引领知识产权咨询服务有限公司

Plastic extruder facilitating filtering of impurities

The invention provides a plastic extruder facilitating filtering of impurities. The plastic extruder comprises a machine head gland, a fine filter screen, an end plate, a material conveying plate, a filter screen, a vibration motor, a filter cartridge, an injection chamber and a spring, wherein the machine head gland is arranged on the annular left side of a machine barrel, the fine filter screenis arranged on the rear side of the inner part of the machine head gland, and the material conveying plate is arranged on the left end face of the fine filter screen; the filter screen is arranged onthe annular side face of the filter cartridge in a sleeving mode, the filter cartridge is arranged on the left end face of the end plate, the injection chamber is formed inside the filter cartridge, and the spring is arranged on the annular side face of the filter cartridge; and the end plate is arranged on the left side of the material conveying plate, and the filter cartridge is arranged on theleft end face of the end plate. The design solves the problems that an original plastic extruder is poor in filtering effect and prone to being blocked, and the plastic extruder facilitating filteringof the impurities is reasonable in structure, good in filtering effect and convenient to clean and maintain.

Owner:SUZHOU DOUBLE GOLD IND

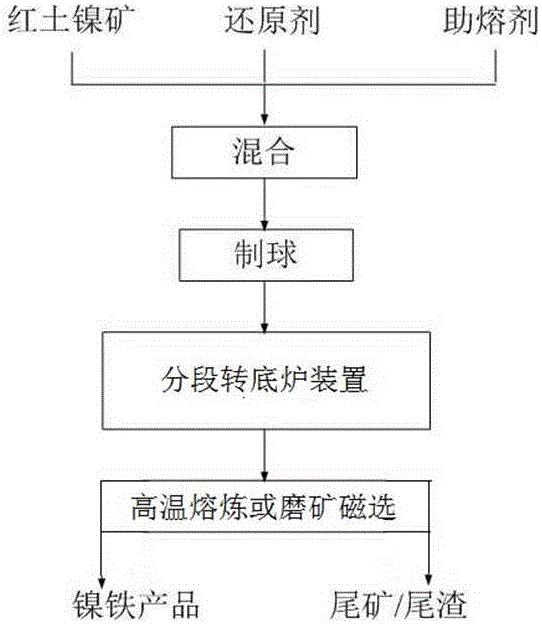

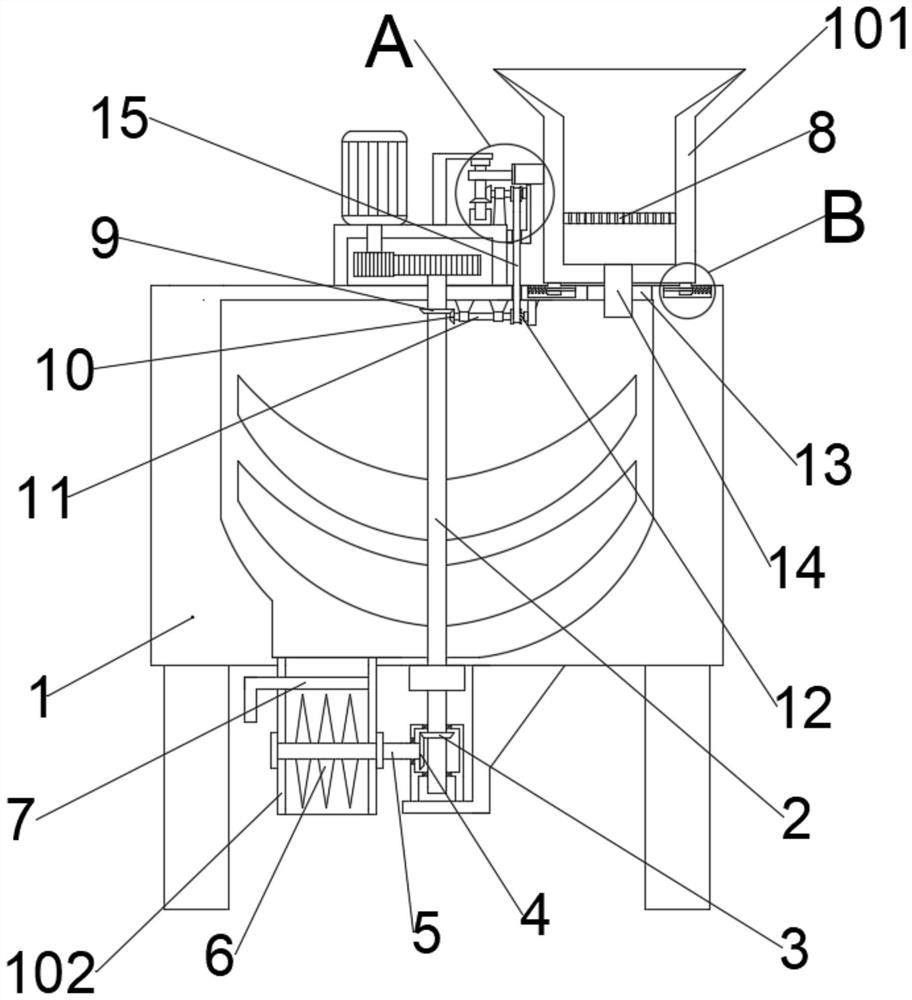

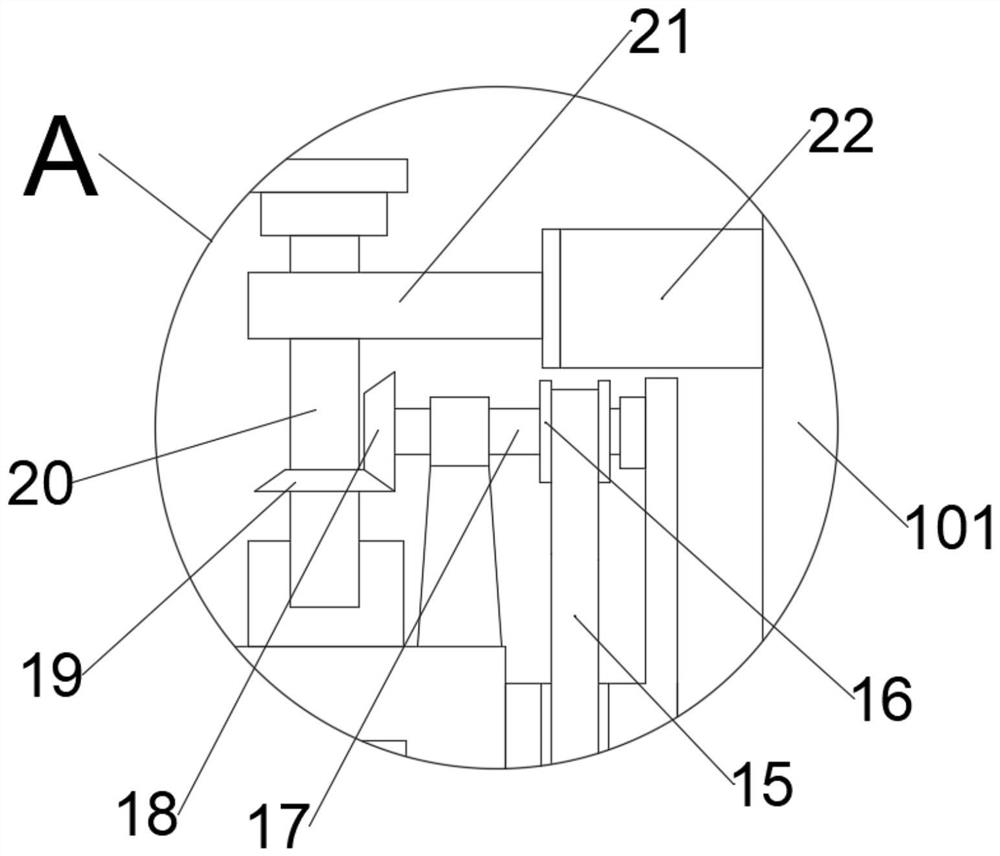

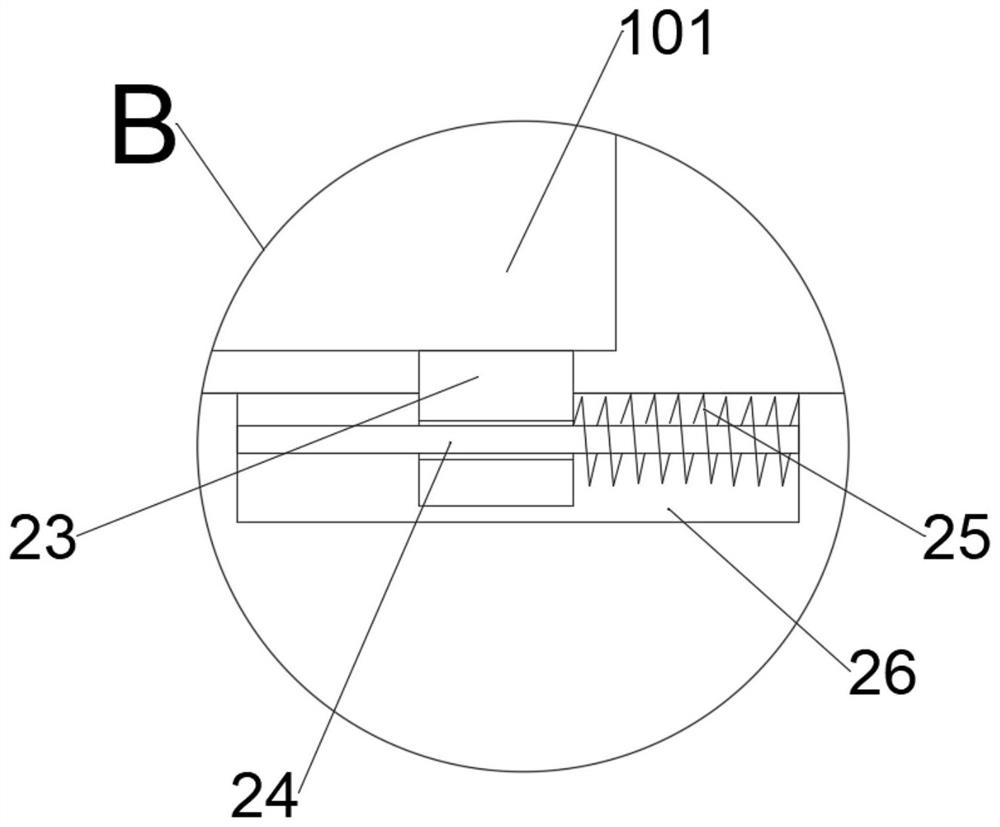

Reduction reaction system and method of nickel laterite ore water-contained pellet

The invention relates to the field of chemical engineering metallurgy, in particular to a system and a method using a nickel laterite ore reduction reaction. Aiming at the defects in the prior art, the invention proposes a reduction reaction system and a method of a nickel laterite ore water-contained pellet. The system and the method improve a heating mode of a segmented rotary hearth furnace device to remove a pellet drying process before the segmented rotary hearth furnace device under the precondition of not influencing product indexes so as to shorten the process flow and to reduce the equipment investment, and have such advantages as short treatment flow, low equipment investment, high equipment operation rate, low energy consumption and wide application range.

Owner:JIANGSU PROVINCE METALLURGICAL DESIGN INST

Chemical industry raw material efficient stirring treatment equipment

InactiveCN112263930AEnsure smooth circulationSolve the problem of easy cloggingRotary stirring mixersTransportation and packagingChemical industryControl engineering

The invention discloses chemical industry raw material efficient stirring treatment equipment, which comprises a treatment tank, wherein a stirring shaft is arranged on the central axis of the tank cavity of the treatment tank through a bearing in a vertical rotating state, a layer of impurity filter screen is horizontally fixed in the barrel cavity of a feeding barrel, each lifting sliding blockis arranged on a supporting sliding rod in a sliding fit and penetrating mode, the rod body of each supporting sliding rod is further correspondingly sleeved with an extrusion reset spring, a force application cam is located on the horizontal plane, the force application cam and a stress push block are arranged in a mutual extrusion fit mode, a driving belt wheel and a driven belt wheel are in transmission connection through an anti-skid belt, a third driven bevel gear is coaxially and fixedly installed at the left end of an auxiliary dredging shaft, the auxiliary dredging shaft horizontally extends leftwards into a discharging channel in a matched mode, and a plurality of dredging blades are arranged on the circumferential shaft wall of the auxiliary dredging shaft. According to the invention, the screening efficiency is improved while the stirring work is normally carried out, the high efficiency of the screening operation is ensured, and the circulation smoothness of the discharge channel is ensured.

Owner:陆雯艳

Lunar regolith concrete suitable for being extruded and preparation method thereof

ActiveCN110405903ARealize instant refillAvoid cloggingAdditive manufacturing apparatusCeramic shaping apparatusAviationDrive motor

The invention relates to lunar regolith concrete suitable for being extruded and a preparation method thereof, and the lunar regolith concrete suitable for being extruded and the preparation method thereof are mainly used in the technical fields of aerospace, aviation, building coatings and the like. A lunar regolith 'concrete' hybrid 3D printing technology is an important key technology in the future lunar follow-up lunar surface base construction. A lunar regolith simulant hybrid 3D printing device can realize continuous and controllable lunar regolith 'concrete' extrusion molding by designing a lunar regolith simulant hybrid 3D printing head. The hybrid 3D printing head is the key component of the lunar regolith hybrid printing device and is used for realizing continuous and controllable extrusion of lunar regolith 'concrete'. The device is a functional assembly integrating parts such as a driving motor, a coupler, a screw pump, a connector, a screw extrusion device and a printing nozzle into a whole, so that the continuous and controllable extrusion molding of the lunar regolith 'concrete' material is realized.

Owner:BEIJING SATELLITE MFG FACTORY

Integrated bathroom water discharging system

PendingCN110578364AIncrease profitSolve the problem of easy cloggingSewerage structuresDomestic plumbingWater dischargeEngineering

An integrated bathroom water discharging system is composed of a waterproof base plate, a water discharging transverse branch pipe, an integrated water seal and a water discharging vertical pipe. Thewaterproof base plate is composed of waterproof grounds and a waterproof stop strip, and an integrated structure is formed by the waterproof stop strip and the waterproof grounds. At least one waterproof ground close to the waterproof stop strip is provided with a ground water outlet, a water discharging outlet of the ground water outlet is connected with the water discharging transverse branch pipe, the water discharging transverse branch pipe is connected with the integrated water seal, and the integrated water seal communicates with the water discharging vertical pipe. The integrated bathroom water discharging system can solve the problems that a water discharging transverse branch pipe of a current integrated bathroom water discharging system needs to be arranged below a waterproof base plate, a water discharging branch pipe needs to vertically penetrate through the waterproof base plate, consequently, the usage clear height in a bathroom is reduced, and seepage hidden danger and difficult overhauling exist; by usage of the integrated water seal, the problem that water seals are independently arranged at various water discharging points of the bathroom water discharging system,and dryness is likely to be caused is solved, the bathroom plane and height space utilization rate can be increased, and the water discharging sanitation performance of the bathroom is improved.

Owner:林国强

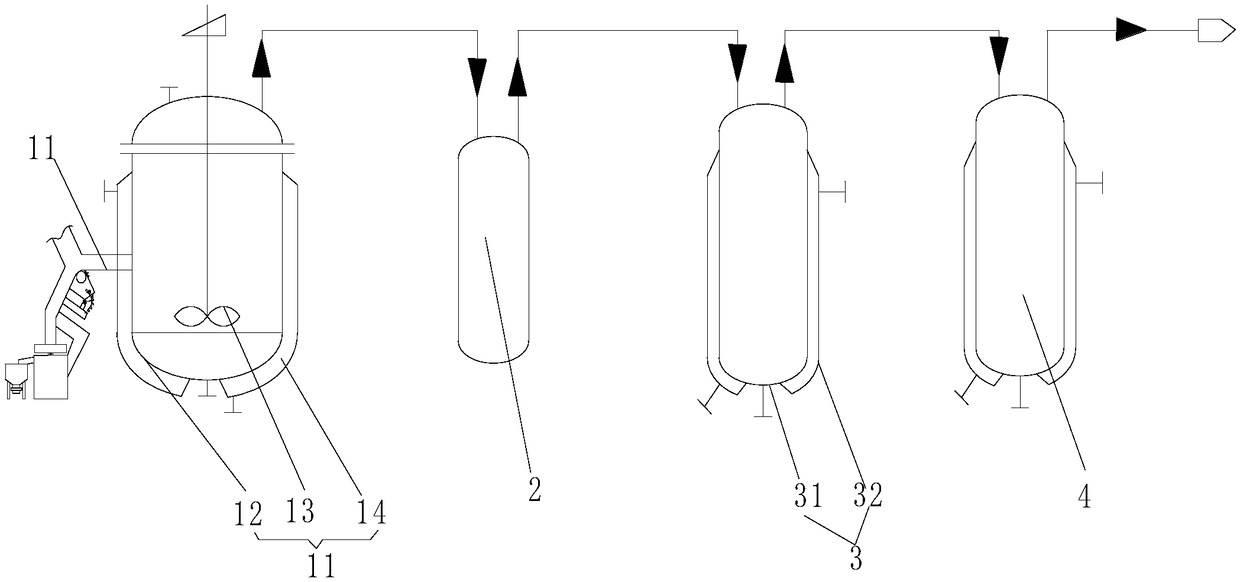

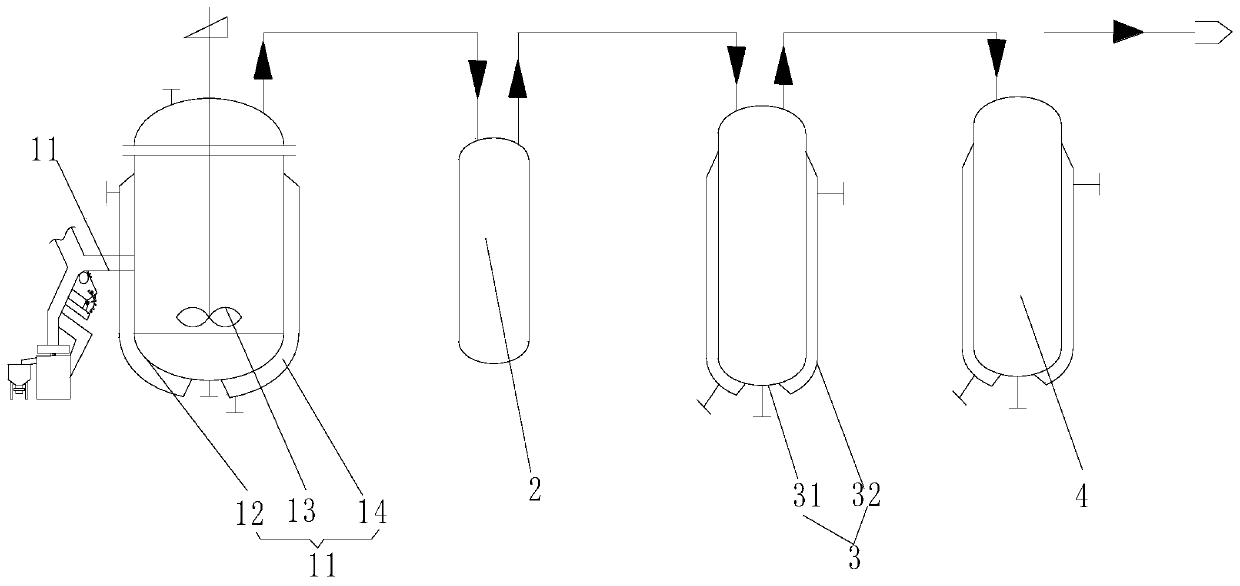

High-purity hydrogen selenide production equipment and high-purity hydrogen selenide production process based thereon

ActiveCN108726492AHigh puritySolve the problem of easy cloggingChemical/physical processesBinary selenium/tellurium compoundsHydrogenMetal impurities

The invention provides high-purity hydrogen selenide production equipment and a high-purity hydrogen selenide production process based thereon. The high-purity hydrogen selenide production equipment comprises a reaction kettle, a dryer and a heavy-component filter, wherein the reaction kettle is provided with an inlet for feeding selenium particles, a catalyst and a solvent, is communicated with agas feeding pipe for communication to a hydrogen source and comprises a kettle body, a stirrer and a heater; the input end of the dryer is communicated with the top part of the reaction kettle; the input end of the heavy-component filter is communicated with the output end of the dryer, the heavy-component filter comprises a first tank body and a first refrigerator, and the first refrigerator isarranged on the first tank body. The high-purity hydrogen selenide production equipment and the high-purity hydrogen selenide production process provided by the invention have the beneficial effect that the problem of insufficient purity of the hydrogen selenide synthesized by reaction of high-purity hydrogen and the selenium particles due to failure in removing heavy components (such as aromaticsolvents and metal impurities) and light components (such as nitrogen, hydrogen, methane and carbon dioxide) in the prior art is solved.

Owner:TAIHE GAS JINGZHOU

System and method for utilizing flue gas residual heat of furnace body and efficiently recycling iron-containing resources

InactiveCN106222354ASolve the problem of easy cloggingAvoid easy cloggingRotary drum furnacesFlue gasHearth

The invention belongs to the field of metallurgy, particularly relates to a rotary hearth furnace which efficiently utilizes residual heat of flue gas, and a system and a method capable of smelting iron-containing resources at a high temperature through utilizing the rotary hearth furnace, and provides a system and a method for utilizing flue gas residual heat of a furnace body and efficiently recycling iron-containing resources aimed at defects of the prior art. According to the system and the method, through improving the heating mode of the rotary hearth furnace, on one hand, residual heat of flue gas of the rotary hearth furnace is reutilized inside the rotary hearth furnace, and the utilization efficiency of residual heat of flue gas of the rotary hearth furnace is increased; on the other hand, a pellet drying technology before the rotary hearth furnace is eliminated under the precondition that product indexes are not affected, the technological process is shortened, and the equipment investment is reduced; and the system and the method have the characteristics that the utilization rate of residual heat of flue gas is high, the treatment process is short, the equipment investment is low, the equipment operation rate is high, the energy consumption is low, and the application range of raw materials is wide, and various different iron-containing resources can be treated.

Owner:JIANGSU PROVINCE METALLURGICAL DESIGN INST

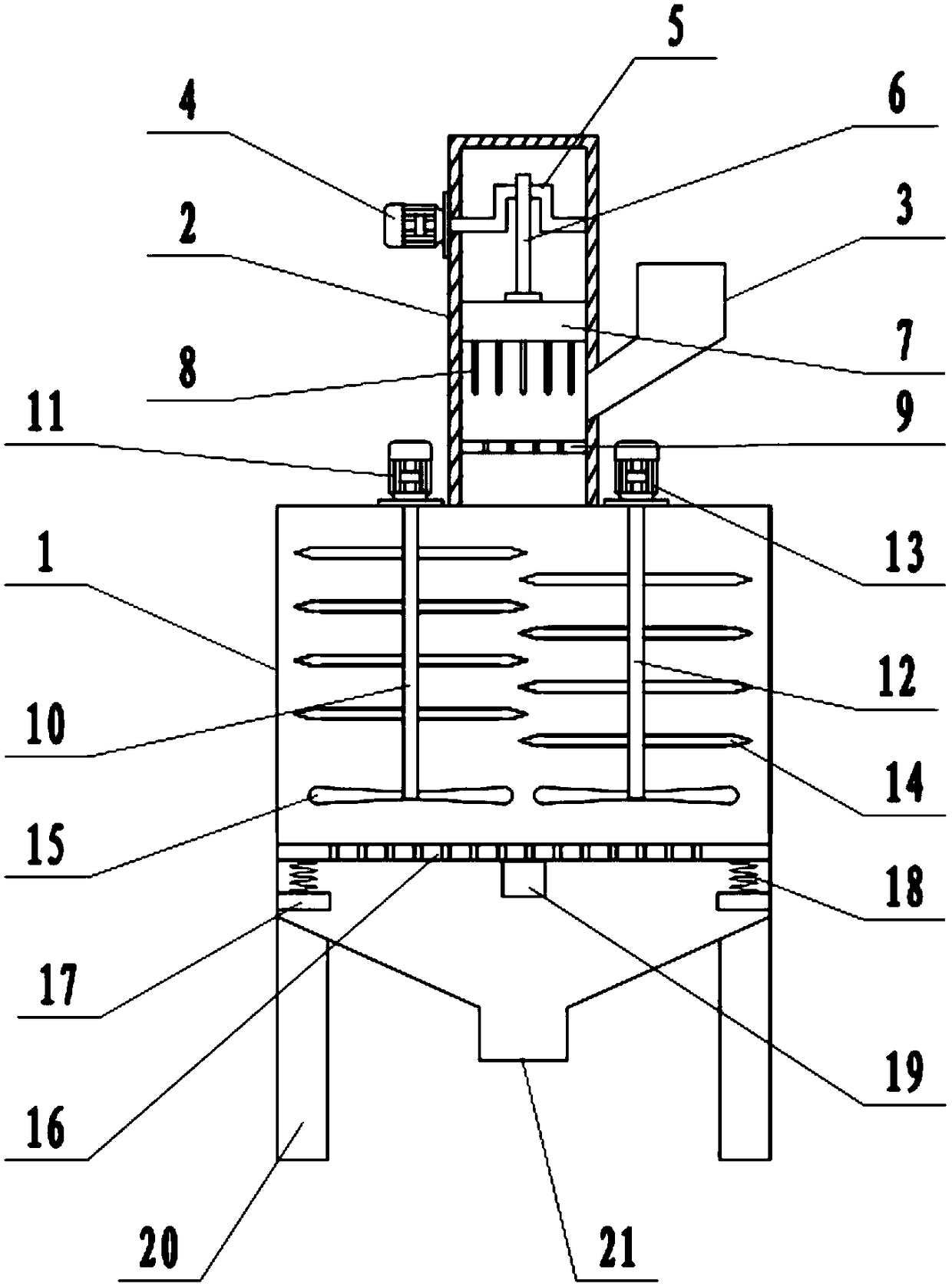

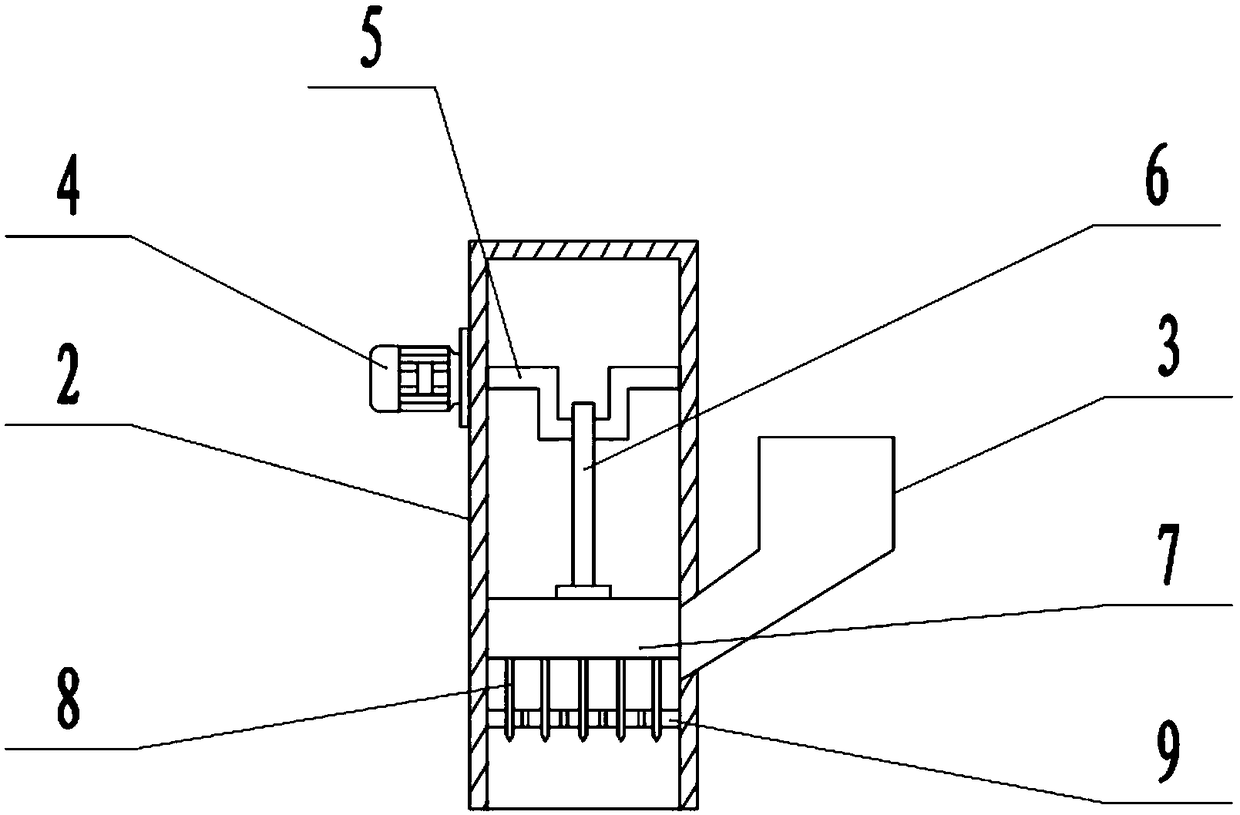

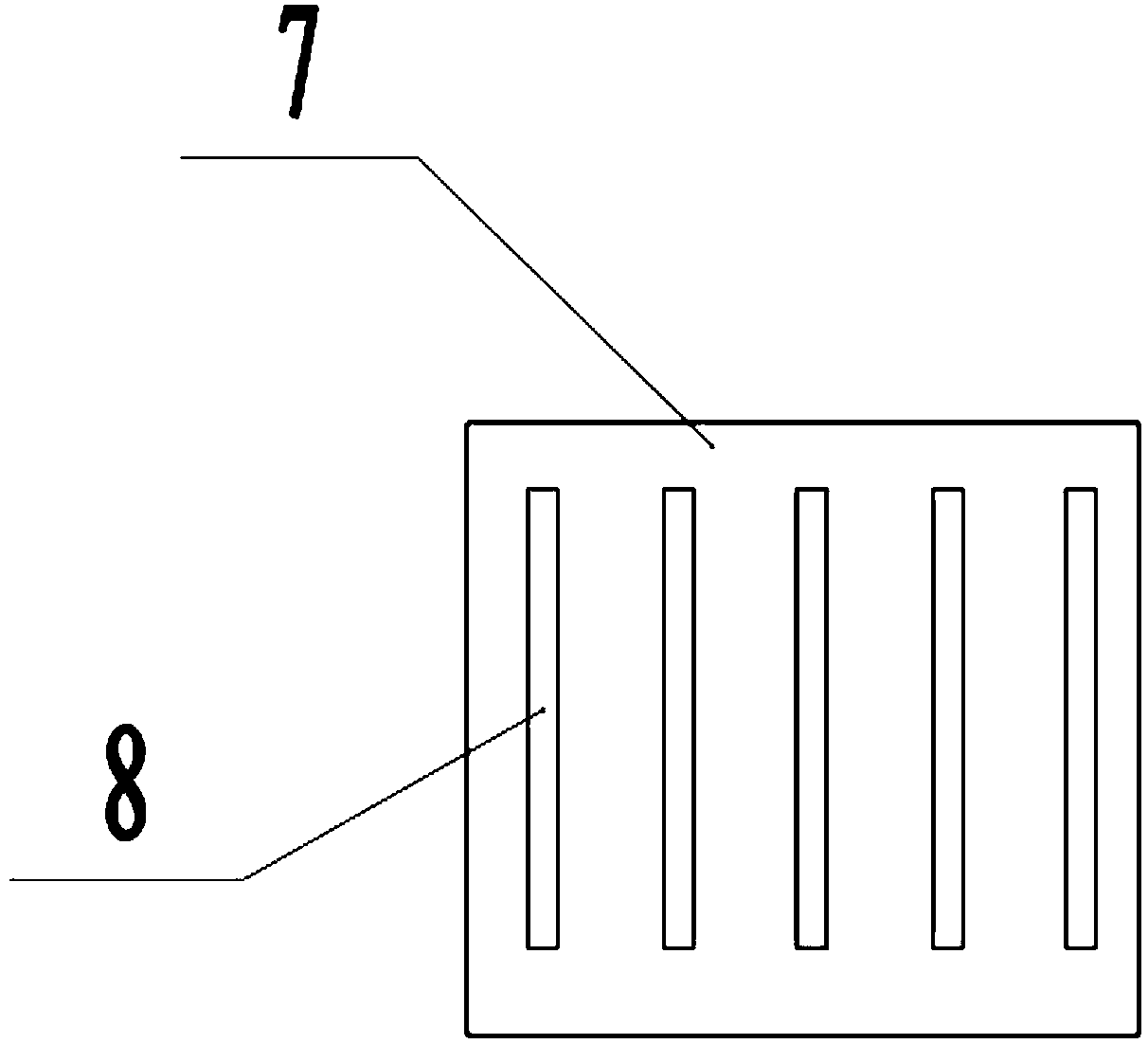

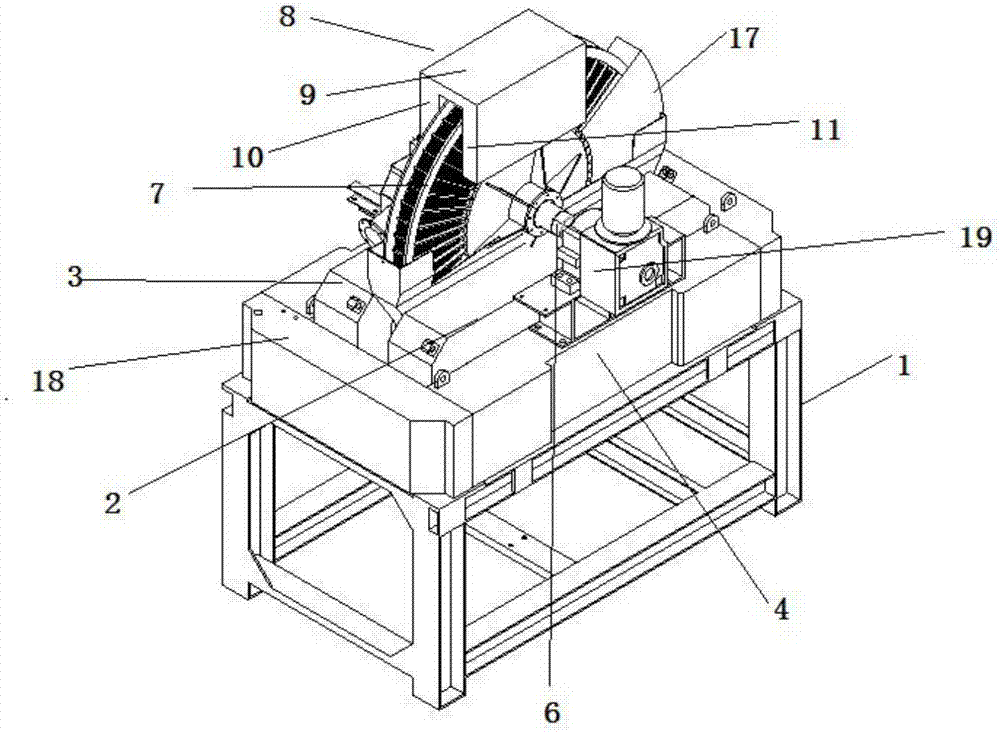

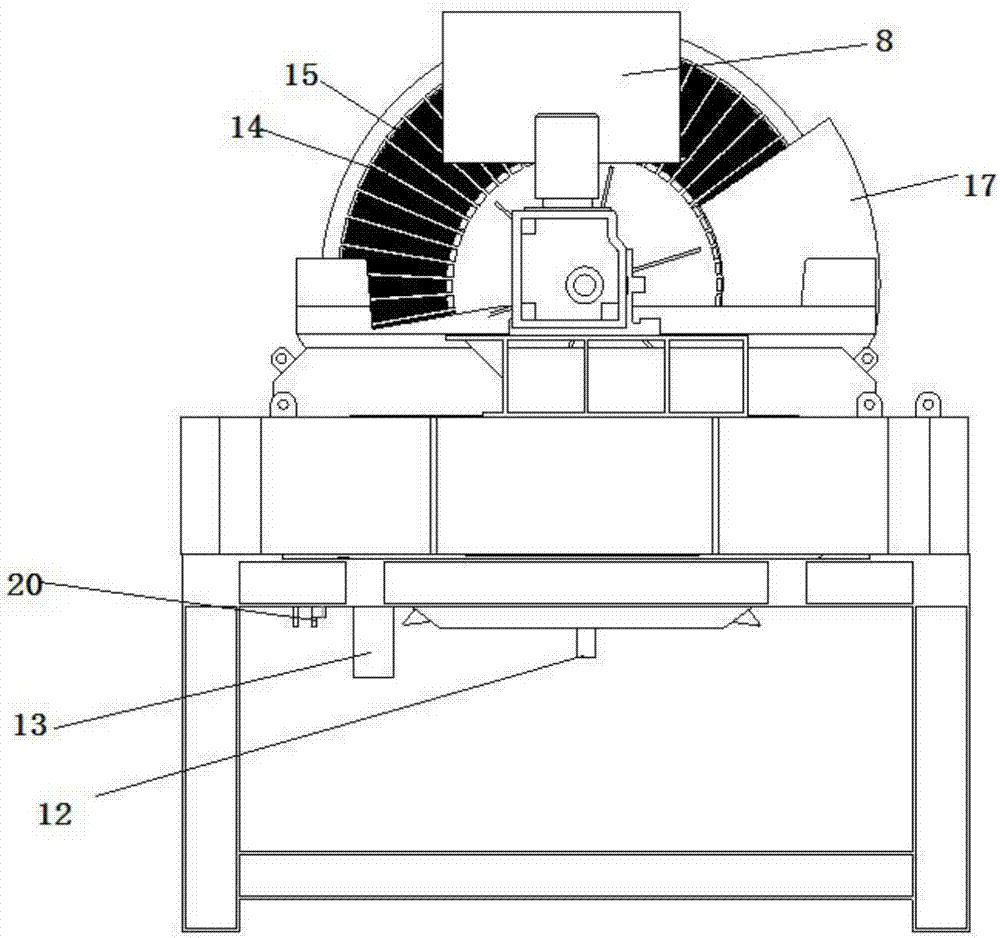

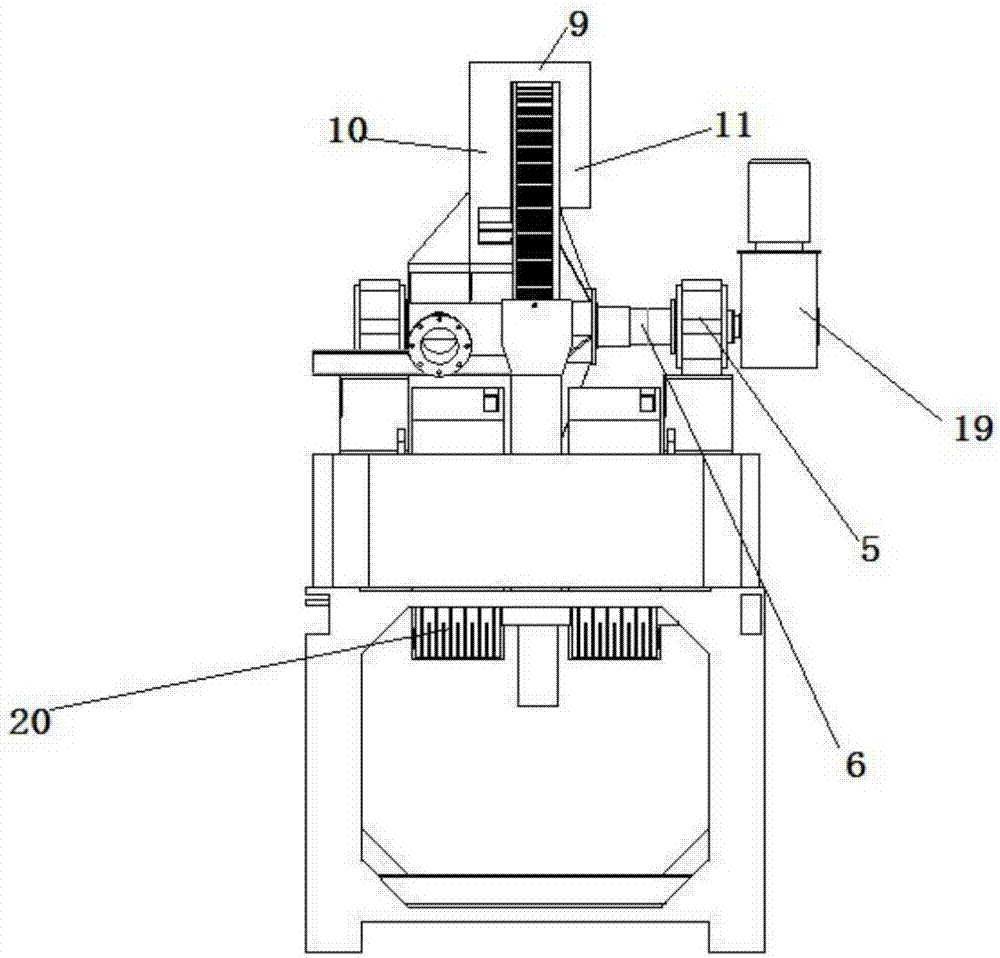

High-gradient iron remover

ActiveCN107282291ASolve the problem of easy cloggingSolve the shortcoming of short pulping timeHigh gradient magnetic separatorsMagnetic mediaIron removal

The invention discloses a high-gradient iron remover. The high-gradient iron remover comprises a support. A first magnetic pole and a second magnetic pole are arranged on the support in parallel. The outer sides of the first magnetic pole and the second magnetic pole are provided with bases. A rotary shaft is erected on the bases. The rotary shaft is sleeved with a rotary ring located between the first magnetic pole and the second magnetic pole. A mineral discharge device is mounted above the rotary ring. The support is provided with a feed port. A discharge port is formed above the first magnetic pole and the second magnetic pole. The feed port and the discharge port are collinear with the center lines of the rotary ring correspondingly. A magnetic medium arranged along the center lines of the rotary ring is nested in the rotary ring. The feed port is located below the rotary ring and communicates with the magnetic medium on the rotary ring. By adopting the high-gradient iron remover provided by the invention, the iron removing efficiency of nonmetallic minerals is high, iron removal is thorough, and the processing method is simple.

Owner:北京昆仑海岸科技股份有限公司

Simulated Mars soil concrete suitable for extrusion and preparation method thereof

PendingCN111925182AEasy to controlAvoid cloggingAdditive manufacturing apparatusHydroxypropylmethyl celluloseChemistry

The invention relates to a simulated Mars soil concrete suitable for extrusion and a preparation method thereof. The simulated Mars soil concrete comprises simulated Mars soil, calcium silicate, hydroxypropyl methyl cellulose and water. Calculated by taking the mass of the simulated Mars soil as 100 parts, the concrete is prepared from the following components in parts by mass: 45 to 46 parts of calcium silicate, 57 to 59 parts of water and 0.4 to 0.5 part of hydroxypropyl methyl cellulose. The concrete is added into a screw extrusion device through a feeding port in the screw extrusion device, then a driving motor is started, and the concrete is extruded and moulded.

Owner:BEIJING SATELLITE MFG FACTORY

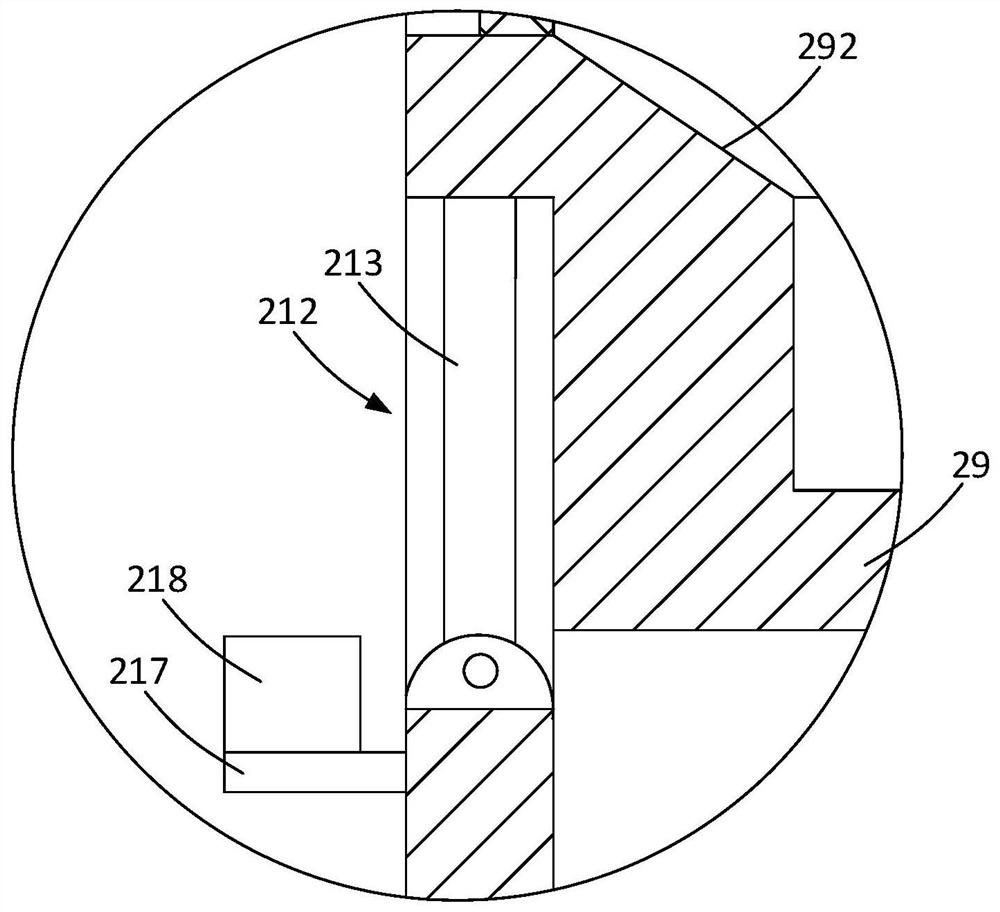

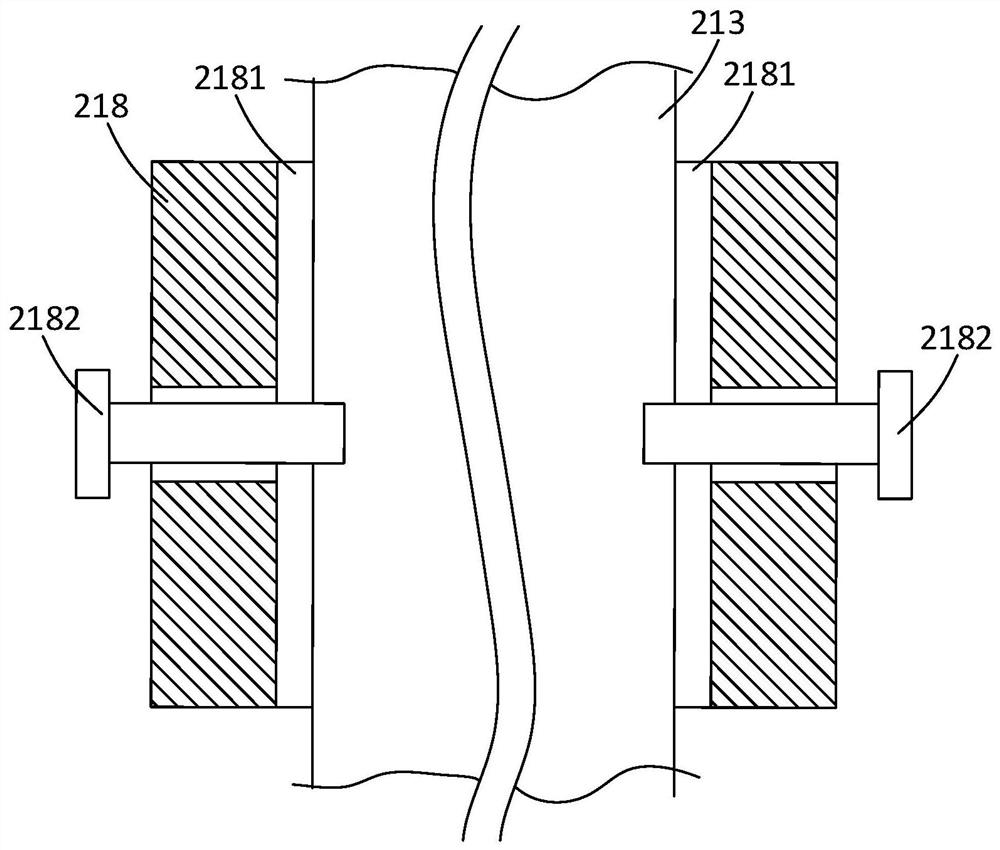

A dual-longitudinal axial-flow drum negative pressure feeding and splitting device

ActiveCN103947391BEnhance negative pressure inhalation effectImprove crawling efficiencyThreshersHelical bladeEngineering

The invention discloses a double longitudinal axial flow rotary drum negative pressure feeding and shunting device. The device comprises a rotary drum body, a feeding head main body assembly and an auxiliary feeding accessory. When crop stalks to be threshed on a combine harvester are fed into a double longitudinal axial flow rotary drum from a conveyor trough, the stalks are grabbed by feeding helical blades, and are forcibly conveyed by negative pressure which is formed by the common effect of multistage axial flow blades which rotate at high speed, a rotary drum top cover and a rotary drum concave plate screen; the crop stalks to be threshed are shunted to the double axial flow rotary drum by the common effect of a concave plate guide plate and a shunting plate for threshing separation; the stalks subjected to threshing separation are discharged out of a machine body by a grass discharge plate on a longitudinal axial flow rotary drum body. According to the double longitudinal axial flow rotary drum negative pressure feeding and shunting device, the crop stalks such as rice, wheat and soybean which are conveyed by the conveyor trough on the combine harvester are forcibly fed and effectively shunted to the double longitudinal axial flow rotary drum for being subjected to threshing separation, and the problem that crops are easily blocked at the feeding inlet of the double longitudinal axial flow rotary drum of the combine harvester is solved.

Owner:JIANGSU UNIV

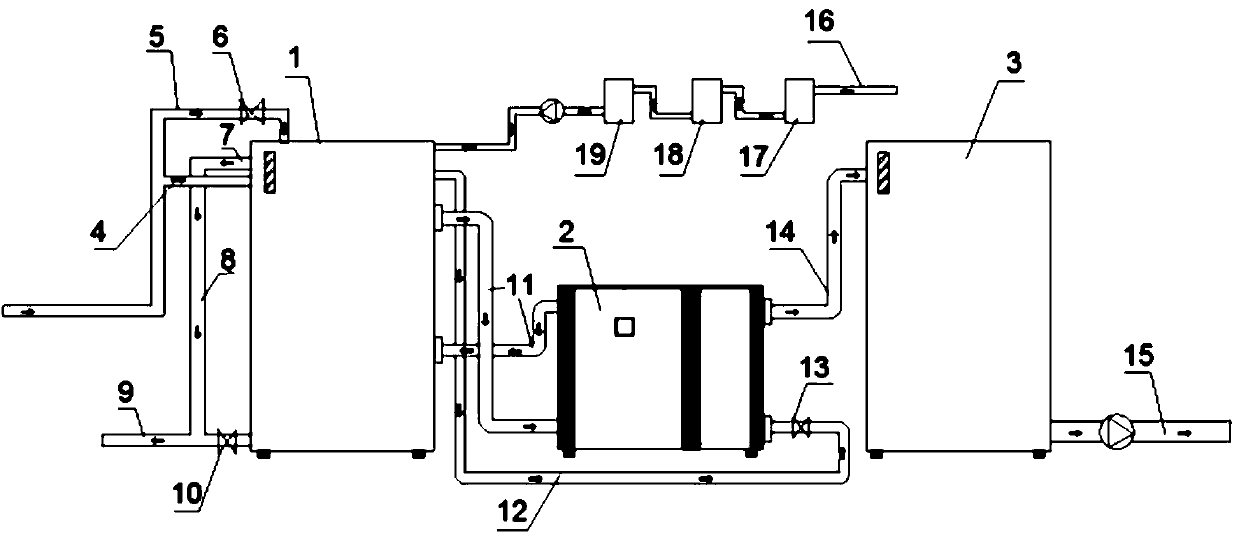

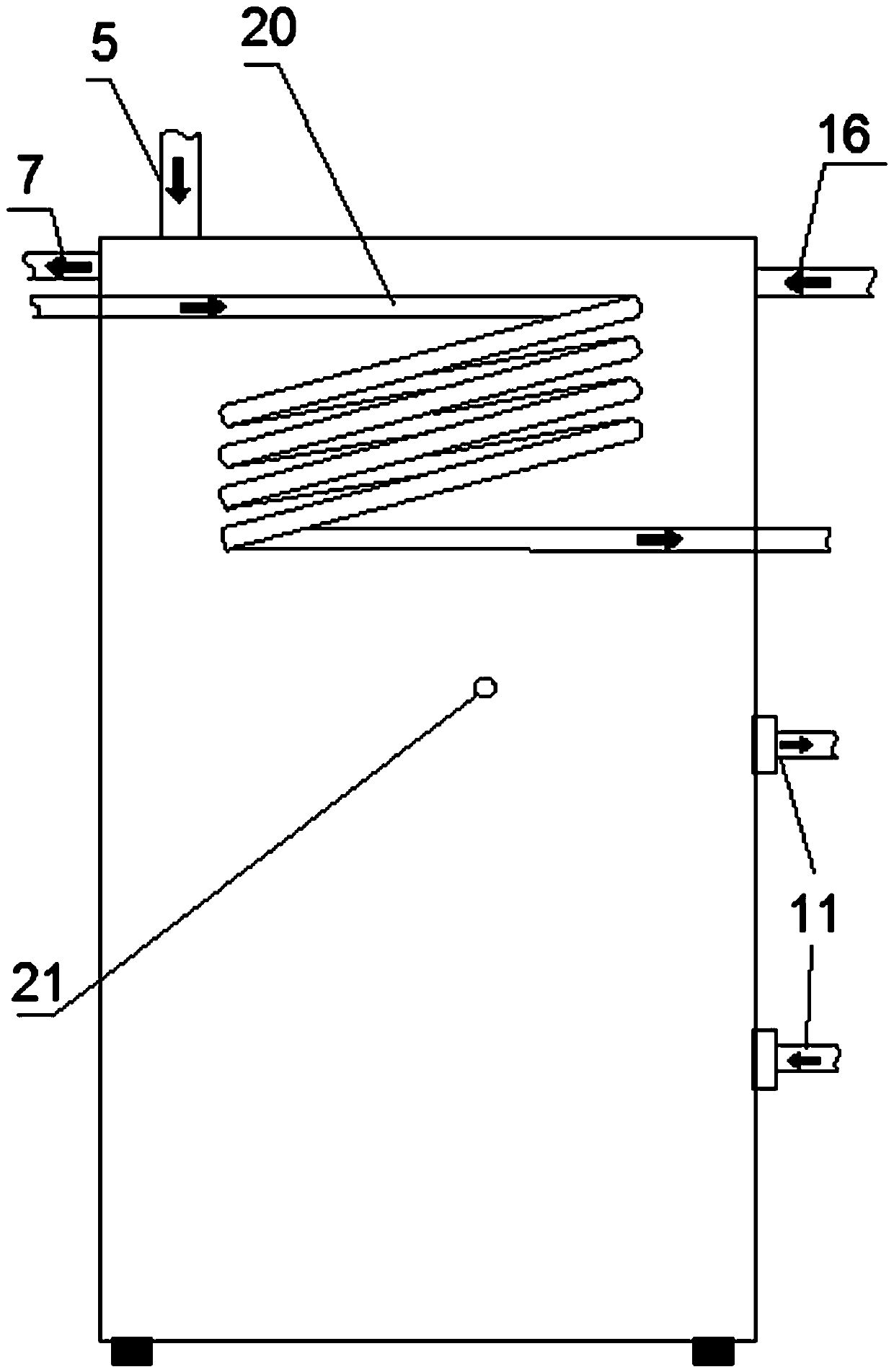

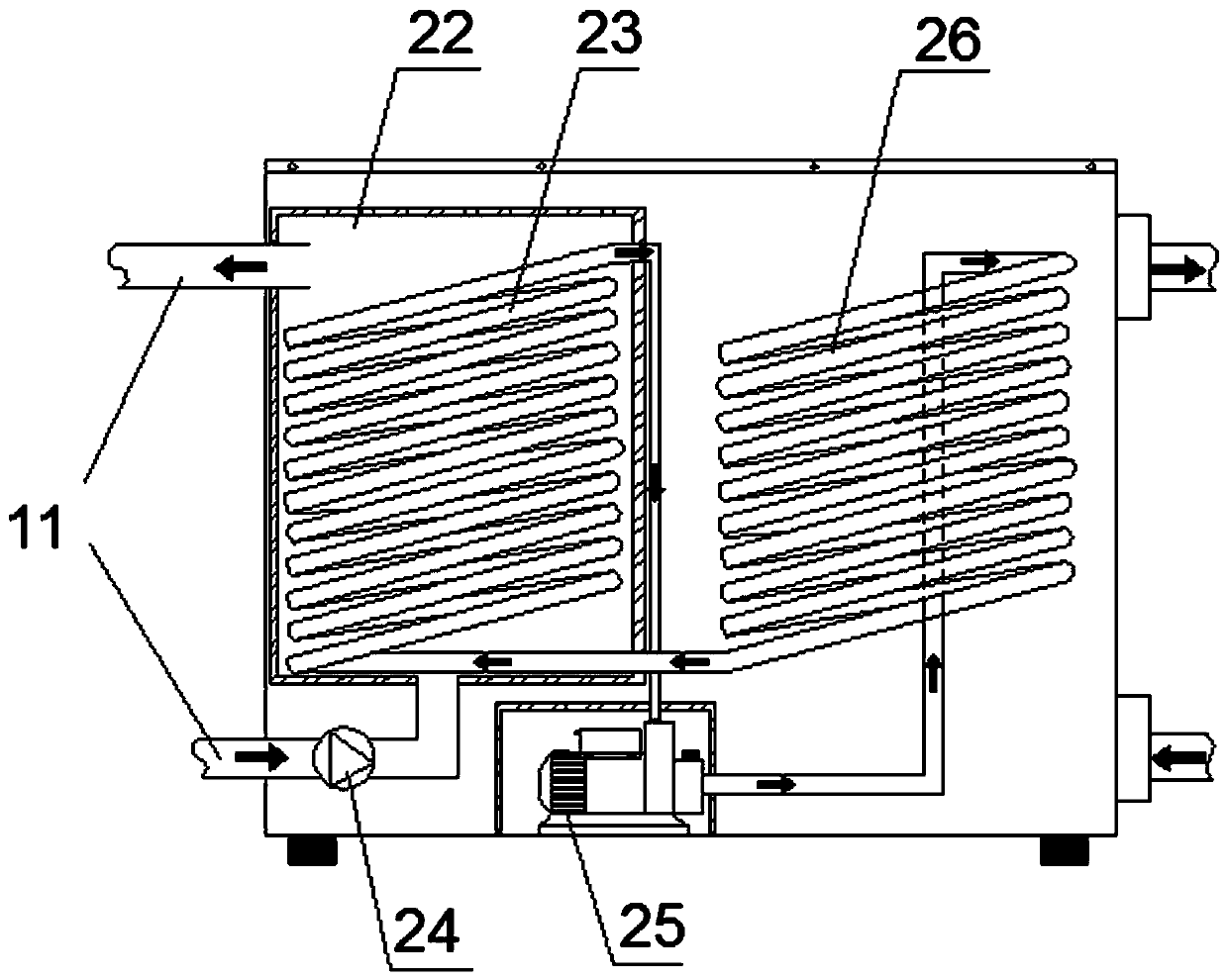

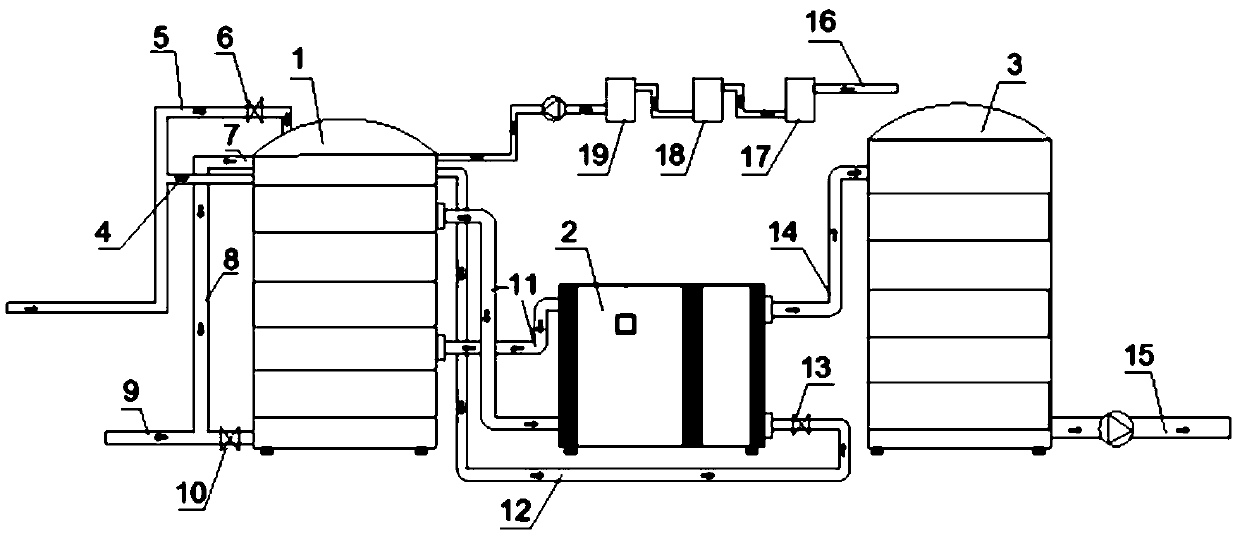

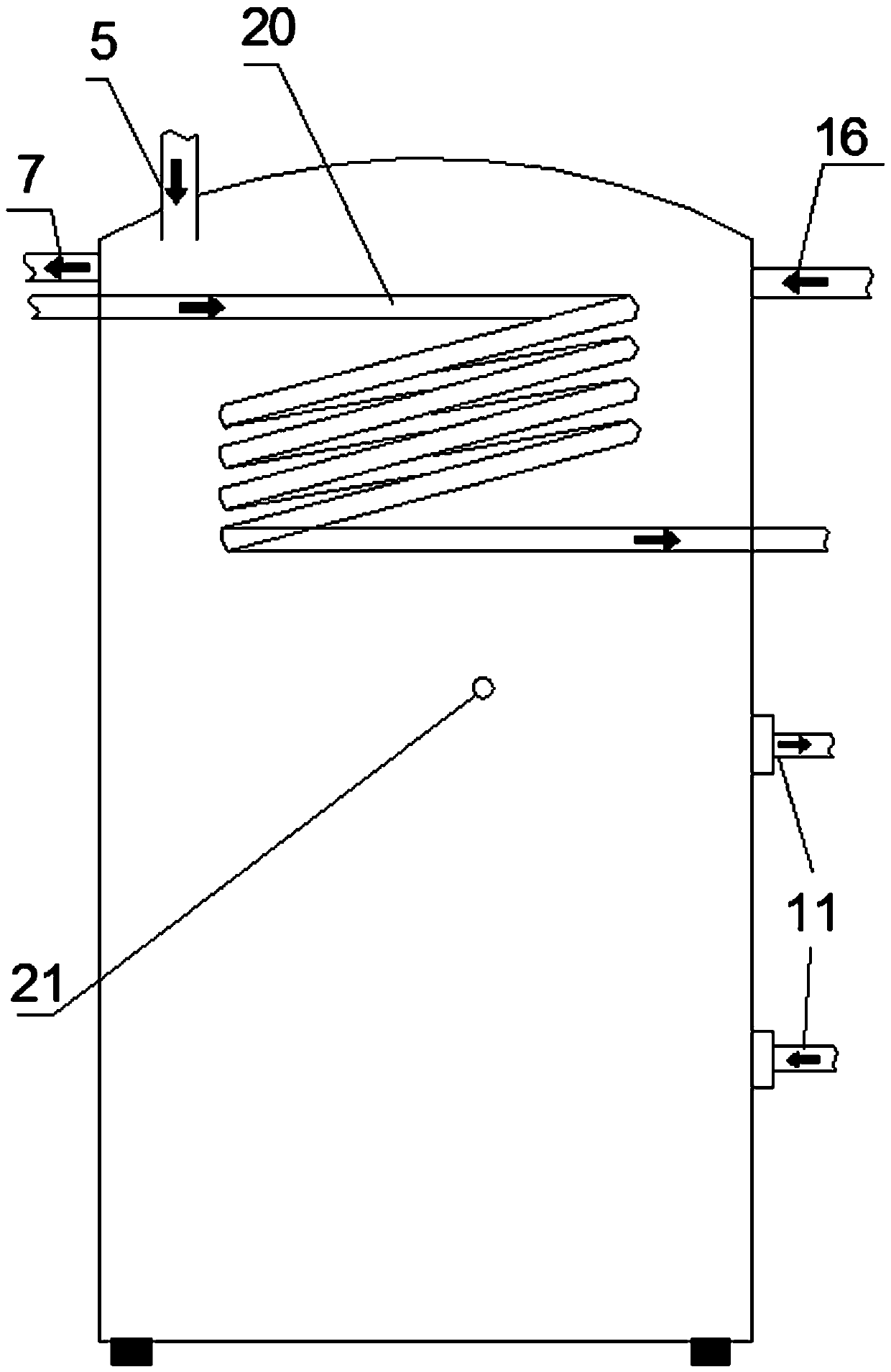

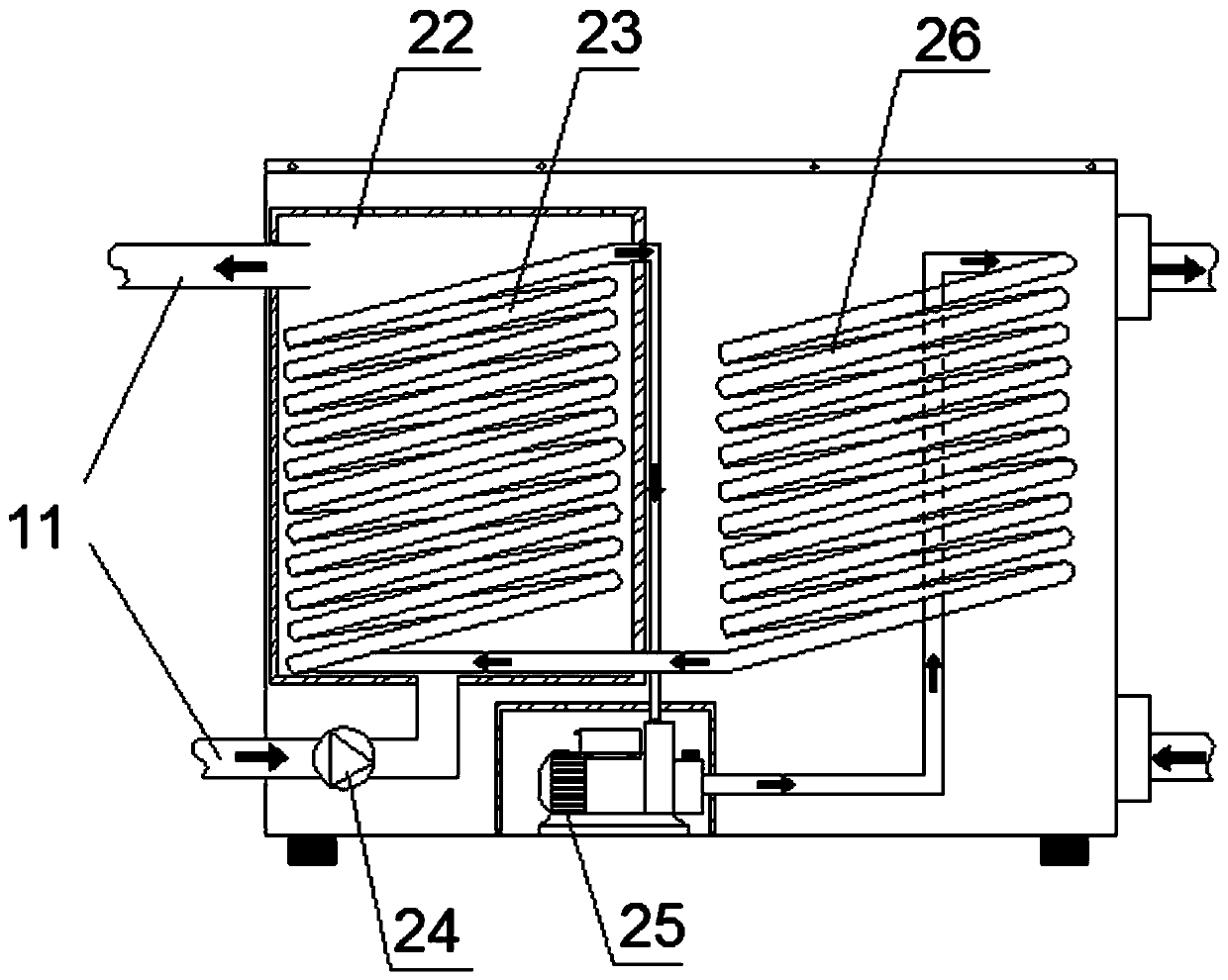

Integral confined water source hot water supply system

InactiveCN107906587AImprove heat utilizationReduce heat lossLighting and heating apparatusEnergy efficient heating/coolingWater recoveryWater pipe

An integral confined water source hot water supply system comprises a waste hot water tank, a main machine, a hot water storage tank, a tap water inlet pipe, a manual water supply pipe, a manual watersupply valve, an overflow port, an overflow water pipe, a blowdown pipe, a blowdown valve, a wastewater source circulation pipe, a preheated water inlet pipe, a water supply electromagnetic valve, ahot water conveying pipe, a hot water supply pipe, a waste hot water recovery pipe, a desander, a grease trap and a filter. The waste hot water tank is provided with the overflow port. Through the system, low heat in recovered waste hot water is transferred into tap water, and the problems that traditional hot water supply systems are low in heat recovery rate, and heat energy is wasted are solved.

Owner:WUXUAN YUTE ENERGY TECH

Coating preparation liquid stirring device

InactiveCN107570058AStructural solutionSolve the problem of easy cloggingRotary stirring mixersMixer accessoriesAgricultural engineeringHinge angle

The invention discloses a coating preparation liquid stirring device which comprises a tank body, wherein the left side of the upper surface of the tank body is moveably connected with a left cover plate of a stirring machine through a first hinge; one side of the left cover plate of the stirring machine is moveably connected with a right cover plate of the stirring machine through a second hinge;the other bottom side surface, far away from the left cover plate of the stirring machine, of the right cover plate is moveably connected onto the tank body; a feeding hole is formed in the right cover plate of the stirring machine; an electromotor bracket is fixedly connected with the upper surface of the left cover plate of the stirring machine; and a first output shaft of a first electromotoris fixedly connected with a first rotating shaft through a first coupling. According to the coating preparation liquid stirring device, due to structural design of a baffle plug, stirring blades, a discharge hole and a receiving hole, and under the action of a second rotating shaft, a support rack, a second output shaft, a second electromotor and a second coupling, materials are prevented from blocking the discharge hole, the structure is reasonable, the working efficiency is improved, and the burden of operators is alleviated.

Owner:王丽

Waste gas recycling buffer system of vulcanizing tank

InactiveCN104226085ASimple structureReasonable designUsing liquid separation agentExhaust valveWaste management

The invention provides a waste gas recycling buffer system of a vulcanizing tank. The waste gas recycling buffer system comprises a waste gas recycling tank, a gas inlet pipe and a gas outlet pipe are arranged on the waste gas recycling tank, and a defined amount of absorbing liquid is arranged in the waste gas recycling tank. The waste gas recycling buffer system is characterized in that the waste gas recycling tank is connected with a sundry box by virtue of a pipeline, a buffer pipe is arranged on the sundry box and is communicated with the outside, and the gas outlet pipe is communicated with the sundry box. An exhaust valve is arranged between the gas outlet pipe and the waste gas recycling tank, and a safety overflow valve is arranged between the sundry box and the waste gas recycling tank. The waste gas recycling buffer system has the advantages and the positive effects of being simple in structure and reasonable in design, being capable of overcoming the difficulty that an existing waste gas recycling tank is likely to block, being capable of collecting waste generated in a waste gas recycling process and being simple and convenient.

Owner:天津天元亨橡胶制品厂

High-purity hydrogen selenide production equipment and high-purity hydrogen selenide production process based on it

ActiveCN108726492BHigh puritySolve the problem of easy cloggingChemical/physical processesBinary selenium/tellurium compoundsPtru catalystPhysical chemistry

The invention provides high-purity hydrogen selenide production equipment and a high-purity hydrogen selenide production process based thereon. The high-purity hydrogen selenide production equipment comprises a reaction kettle, a dryer and a heavy-component filter, wherein the reaction kettle is provided with an inlet for feeding selenium particles, a catalyst and a solvent, is communicated with agas feeding pipe for communication to a hydrogen source and comprises a kettle body, a stirrer and a heater; the input end of the dryer is communicated with the top part of the reaction kettle; the input end of the heavy-component filter is communicated with the output end of the dryer, the heavy-component filter comprises a first tank body and a first refrigerator, and the first refrigerator isarranged on the first tank body. The high-purity hydrogen selenide production equipment and the high-purity hydrogen selenide production process provided by the invention have the beneficial effect that the problem of insufficient purity of the hydrogen selenide synthesized by reaction of high-purity hydrogen and the selenium particles due to failure in removing heavy components (such as aromaticsolvents and metal impurities) and light components (such as nitrogen, hydrogen, methane and carbon dioxide) in the prior art is solved.

Owner:TAIHE GAS JINGZHOU

A new type of flotation column

The invention relates to a novel flotation column. A main body of the novel flotation column is a column body; two-section type pore plate rolling padding is arranged in the column body; a middling circulating device is arranged on the lower portion of the column body and comprises an inverted-cone-shaped barrel, a circulating pump and an air bubble generator which are sequentially connected to one another through a pipe; the inverted-cone-shaped barrel is arranged in the column body; an opening of the inverted-cone-shaped barrel is upward; the circulating pump and the air bubble generator are arranged on the outside of the column body; the inverted-cone-shaped barrel is connected with the circulating pump through a liquid inlet pipe; and the air bubble generator is connected with the inside of the column body through a liquid outlet pipe. The novel flotation column is simple in structure and cannot be blocked easily; rising air bubbles are in contact with descending ore pulp sufficiently; and the flow state of the ore pulp is stable.

Owner:WUHAN INSTITUTE OF TECHNOLOGY

A kind of lunar soil concrete and preparation method thereof

ActiveCN110256039BRealize instant refillAvoid cloggingAdditive manufacturing apparatusCeramic shaping apparatusAviationSoil science

The invention relates to a lunar soil "concrete" and a preparation method thereof, which are mainly used in technical fields such as aerospace, aviation, and architectural coatings. The lunar soil "concrete" hybrid 3D printing technology is an important key technology for the construction of the future lunar base. The lunar soil simulant hybrid 3D printing device can realize continuous and controllable printing by designing the lunar soil simulant hybrid 3D printing head. Extrusion of lunar soil "concrete". The hybrid 3D printing head is a key component of the lunar soil hybrid printing device, which is used to realize the continuous and controllable extrusion of lunar soil "concrete". It is a functional component that integrates drive motors, couplings, screw pumps, interfaces, screw extrusion devices, printing nozzles and other components to realize the continuous and controllable extrusion of lunar soil "concrete" materials.

Owner:BEIJING SATELLITE MFG FACTORY

Integrated unpressurized water source hot-water supply system

InactiveCN107892401AGuaranteed qualityReduce lossesFatty/oily/floating substances removal devicesTreatment involving filtrationWater sourceSolenoid valve

The invention discloses an integrated unpressurized water source hot-water supply system. The system includes a waste-hot-water tank, a main machine, a hot-water storage tank, a tap water inlet pipe,a manual water supplement pipe, a manual water supplement valve, an overflow opening, an overflow water pipe, a sewage discharging pipe, a sewage discharging valve, a wastewater source circulation pipe, a preheated-water inlet pipe, a water supplement solenoid valve, a hot-water conveying pipe, a hot-water supply pipe, a waste-hot-water recovery pipe, a sand remover, an oil separator and a filter;and the overflow opening is arranged in the waste-hot-water tank. The system provided by the invention can recover low heat quantity of waste hot water and transfer the low heat quantity to tap waterto solve the problems of a low heat recovery rate, waste of heat energy and the like in a traditional hot-water supply system.

Owner:WUXUAN YUTE ENERGY TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com