Anti-blocking method for artificial wetland

A constructed wetland and anti-clogging technology, applied in the field of water treatment, can solve problems such as easy clogging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

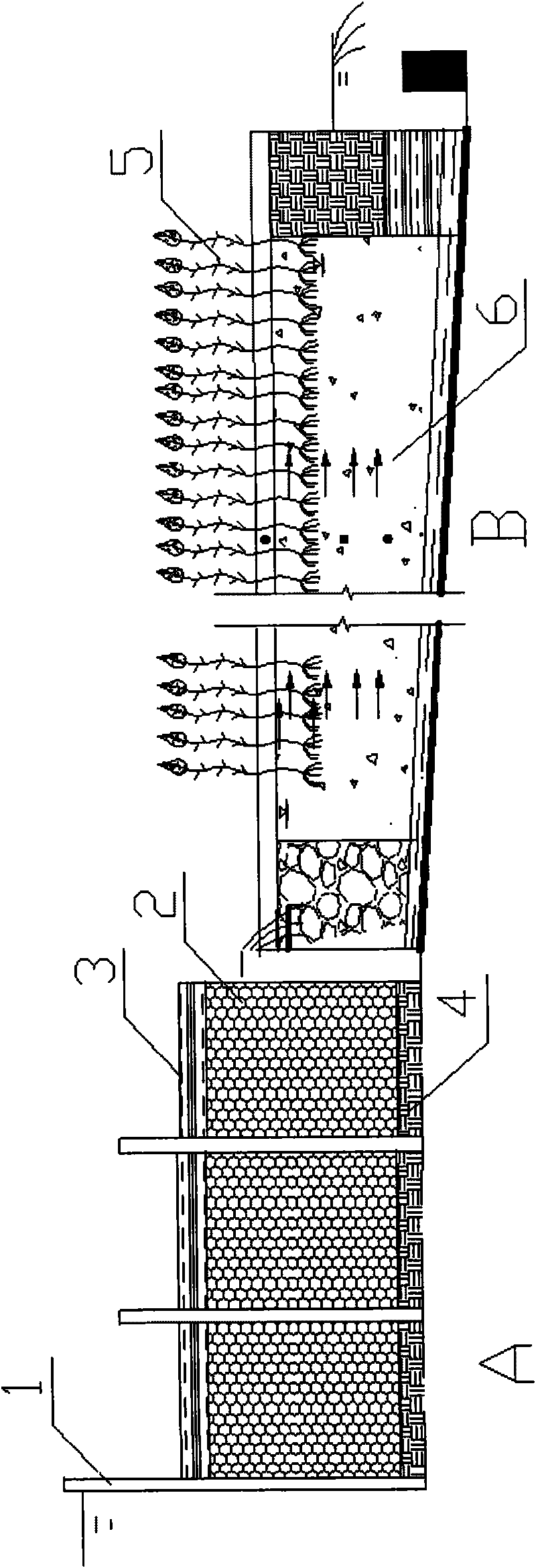

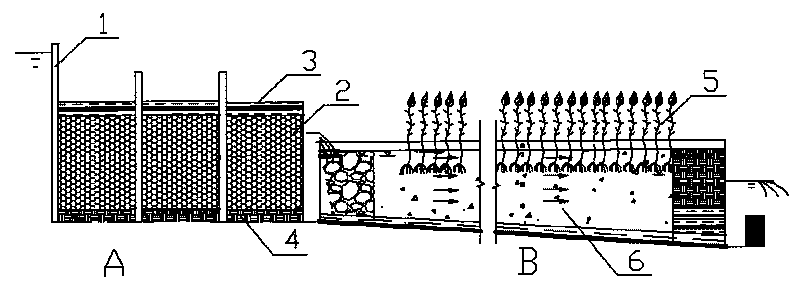

Image

Examples

Embodiment 1

[0012] The effluent of a domestic sewage plant has a COD concentration of about 50~80mg / L, ammonia nitrogen of 2.0~5.0mg / L, total phosphorus of 0.5mg / L, and total nitrogen of 10~15mg / L. After being treated by this process, it is discharged into In the source of drinking water, the height of the infiltration dam is 1.0m, the hydraulic retention time is 6 hours, the height of the wetland system is 0.6m, and the surface hydraulic load is 0.3m3 / m2.d. The effluent meets the "Surface Water Environmental Quality Standard" (GB3838-2002) Class IV water standard, effluent COD is less than about 30mg / L, ammonia nitrogen ≤1.50mg / L, total phosphorus ≤0.3mg / L and total nitrogen ≤1.5mg / L.

Embodiment 2

[0014] The effluent from an industrial sewage plant has a COD concentration of about 100mg / L, ammonia nitrogen of 10.0mg / L, total nitrogen of 15mg / L, total phosphorus of 3mg / L, and a concentration of suspended solids of 80mg / L. The height of the filter dam is 1.0m, the hydraulic retention time is 4 hours, the height of the wetland system is 0.6m, and the surface hydraulic load is 0.3m3 / m2.d. The effluent reaches the first-class B standard in GB18918-2002.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com