High-purity hydrogen selenide production equipment and high-purity hydrogen selenide production process based on it

A production equipment and technology of hydrogen selenide, applied in the direction of binary selenium/tellurium compounds, chemical instruments and methods, chemical/physical processes, etc., can solve problems such as inability to remove heavy components, insufficient purity of hydrogen selenide, etc., and achieve energy consumption And the effects of low cost, easy access, and low equipment material requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to make the technical means, creative features, goals and functions achieved by the present invention clearer and easier to understand, the present invention will be further elaborated below in conjunction with the accompanying drawings and specific embodiments:

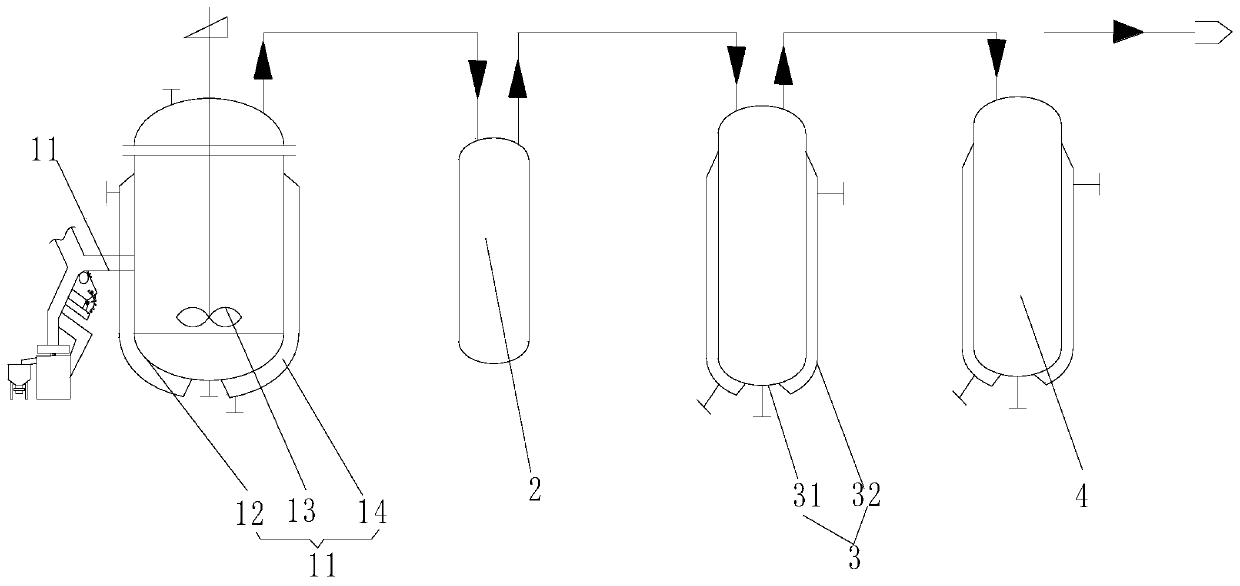

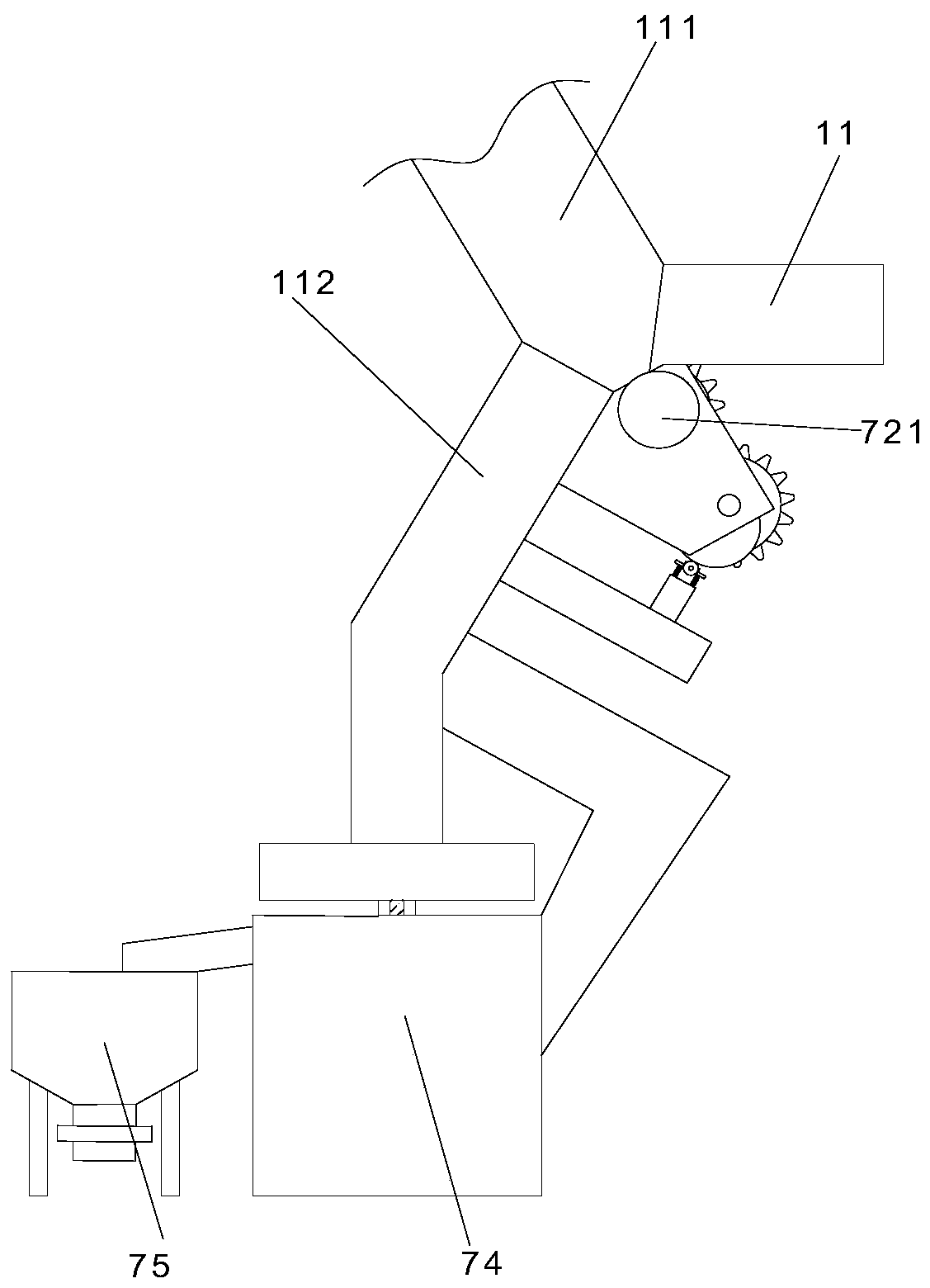

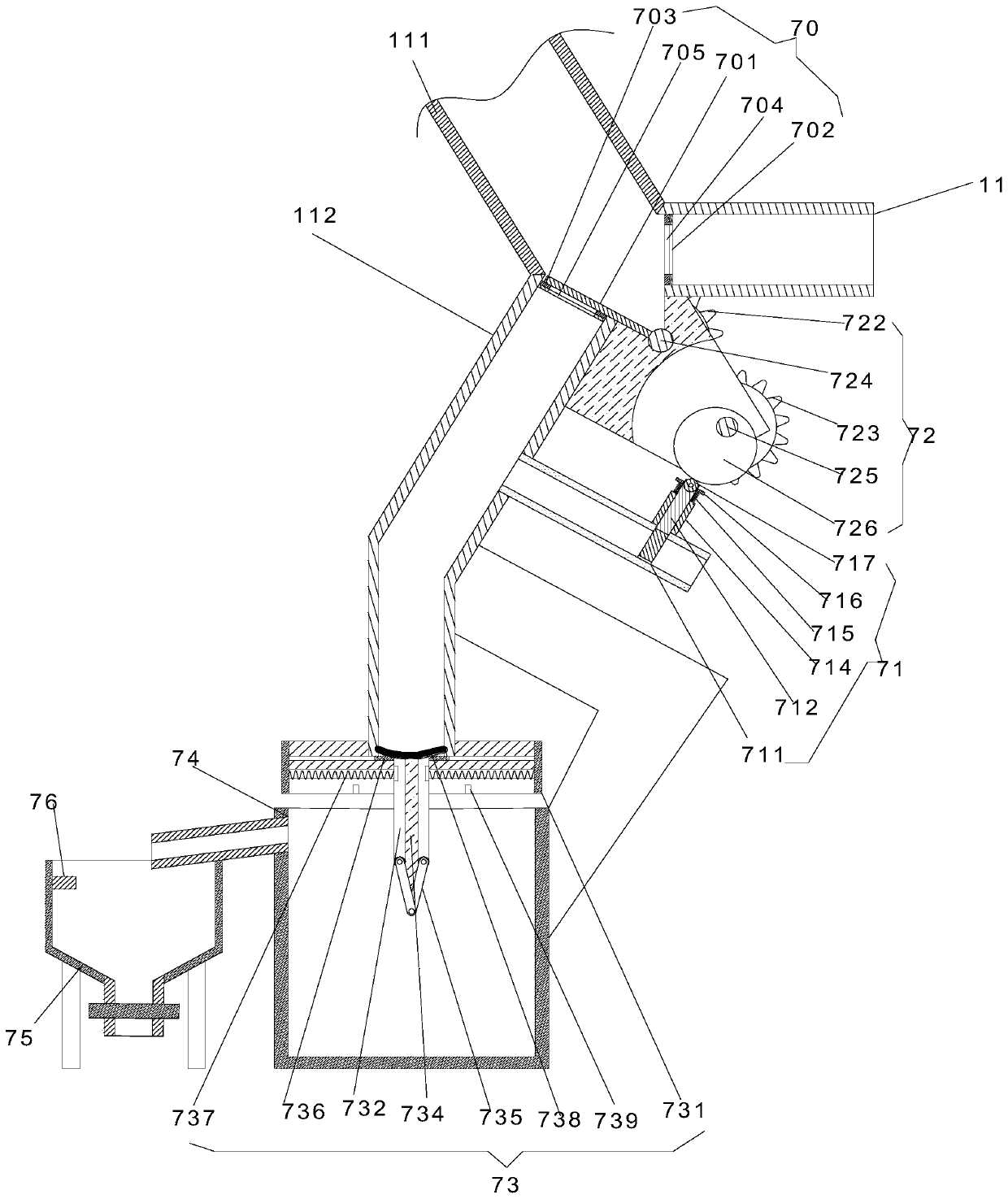

[0025] Such as figure 1 , figure 2 ,as well as image 3 Shown, the present invention proposes a kind of high-purity hydrogen selenide production equipment, comprising:

[0026] Reactor 1, which is provided with an inlet for adding selenium particles, catalysts and solvents, the reactor 1 is connected with an inlet pipe 11 for being connected to a hydrogen source, and the reactor 1 includes: a kettle body 12, an agitator 13 and a heater 14 , the heater 14 is connected with the kettle body 12 to heat the material in the reactor 1, the agitator 13 is installed on the kettle body 12, and the stirring blade of the agitator 13 extends into the agitator 13;

[0027] Drier 2, its input end communicates wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com