Pneumatic calcium hydroxide conveying system

A pneumatic conveying system, calcium hydroxide technology, applied in conveyors, conveying bulk materials, transportation and packaging, etc., can solve problems such as easy blockage of pipelines, and achieve the effect of high degree of automation and quality assurance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

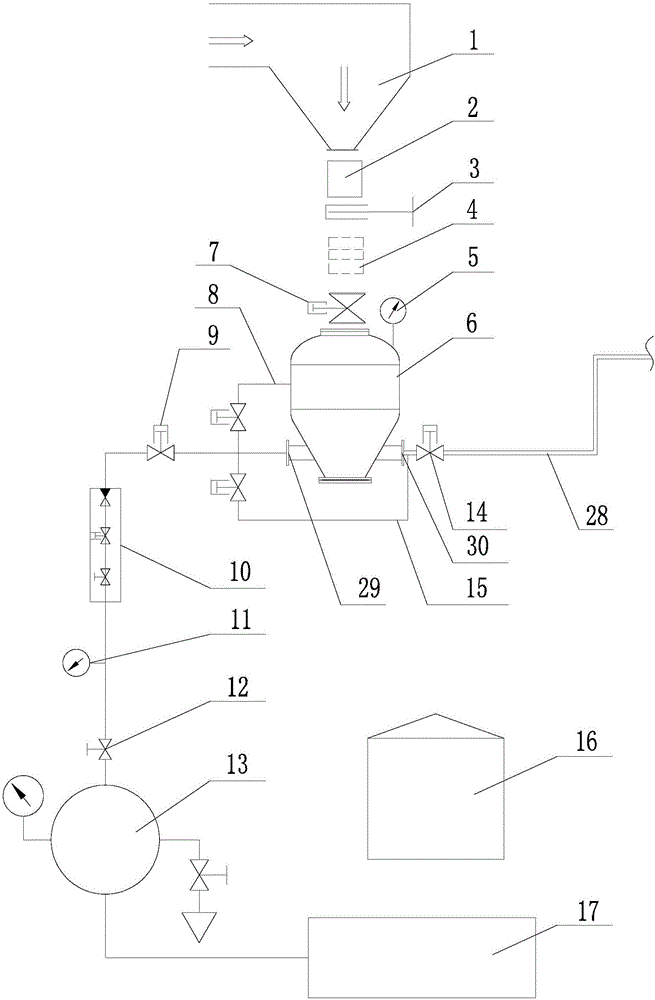

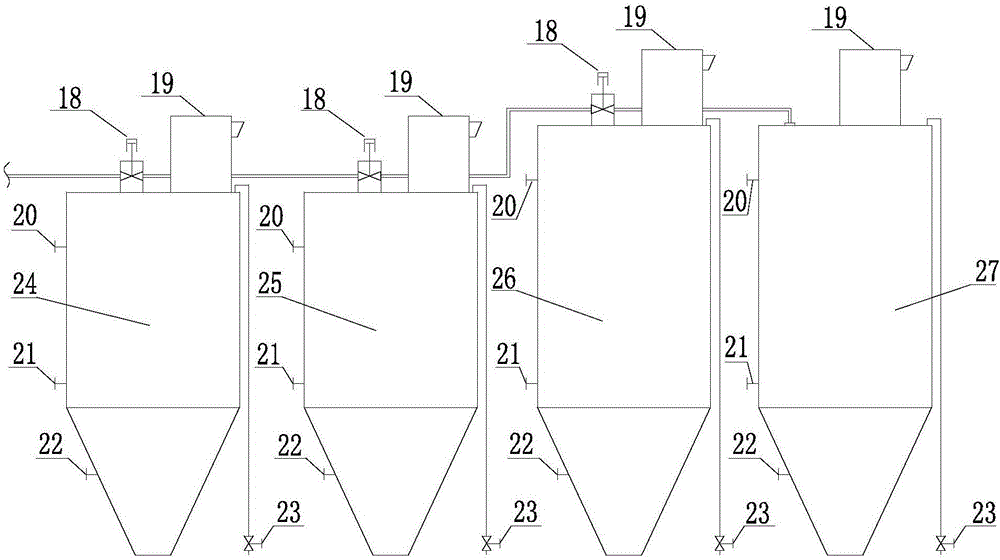

[0022] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0023] refer to figure 1 , figure 2 As shown, the present invention discloses a calcium hydroxide pneumatic conveying system, comprising a feeding device, a gas source device, an air pipe 28, a feed bin and a fully automatic control room 16, and the described feeding device includes a calcium hydroxide The feed pipe 2 and the warehouse pump 6 below the production system 1 are also connected with the maintenance system 3 and the expansion system 4 between the feed pipe 2 and the feed valve 7, wherein the feed valve 7 is arranged on the warehouse pump 6 , the warehouse pump 6 is provided with an automatic safety control system 5, the bottom of the warehouse pump 6 is respectively connected with an intake pipe and an exhaust pipe, a number of sensors for measuring air pressure are arranged in the warehouse pump, and at least one set of gas pressure is installe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com