Through-type bar material airless blast cleaner

A shot blasting machine and bar technology, which is applied to used abrasive treatment devices, abrasive jetting machine tools, grinding/polishing equipment, etc., can solve the problems of inability to realize large-scale automatic production, high production cost, and trouble. , to achieve the effect of realizing large-scale automatic production, meeting environmental protection emission requirements, and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

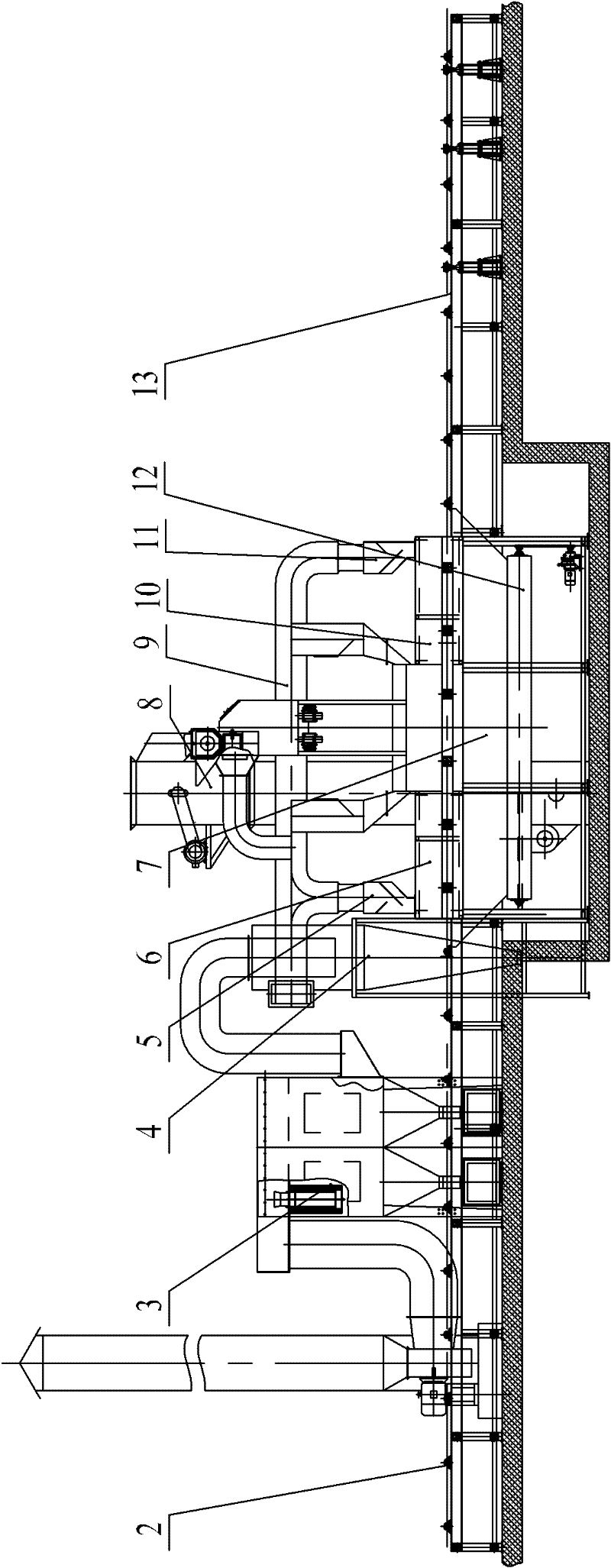

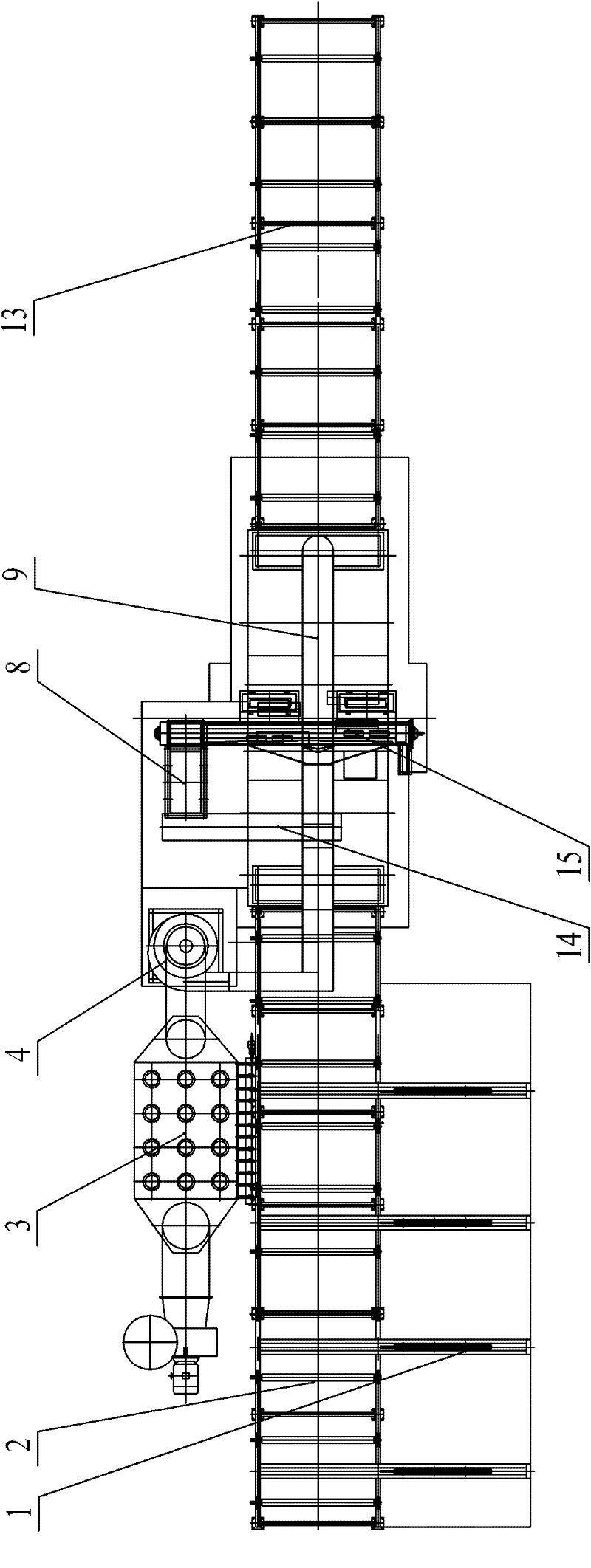

[0022] As shown in the figure: the through-type bar shot blasting machine in the embodiment is mainly composed of an automatic feeding mechanism 1, a roller conveyor system for conveying workpieces, a cleaning host for cleaning workpieces, a projectile circulation system, a dust removal system, It is composed of automatic feeding mechanism and supporting electric control system.

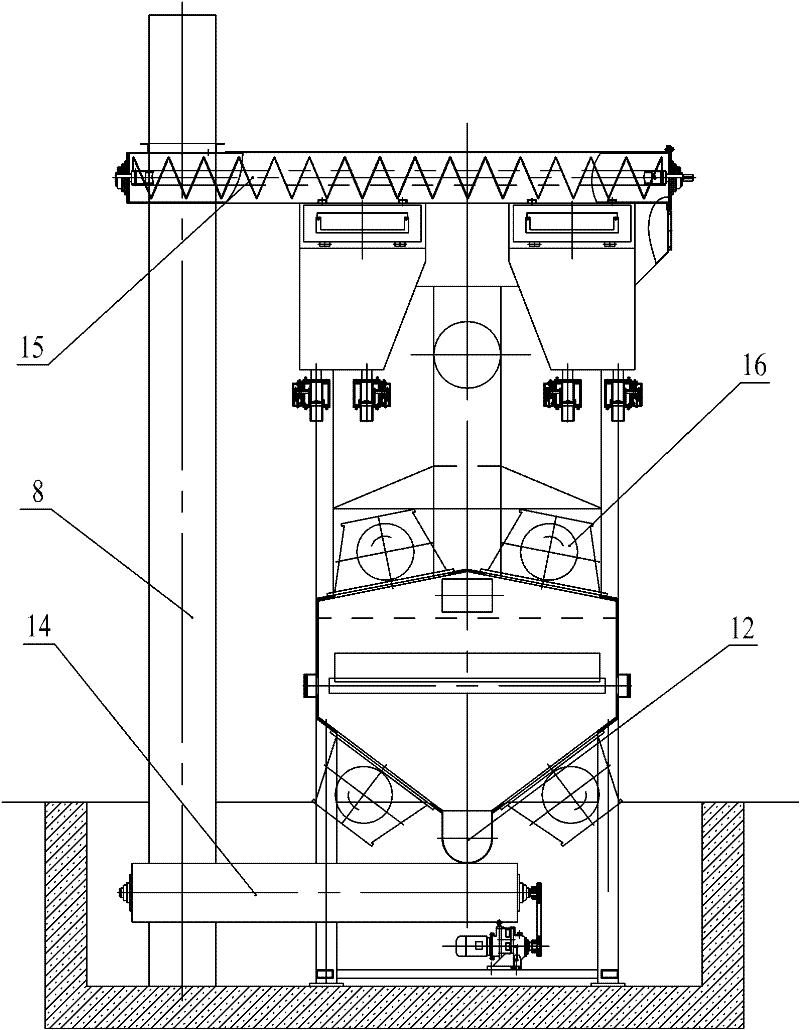

[0023] Such as Figure 1~Figure 3 As shown, the cleaning host includes a feed isolation chamber 6, a cleaning chamber 7, a discharge isolation chamber 10 and a blasting device 16, and at least four blasting devices 16 are arranged at the upper and lower positions of the cleaning chamber 7, and the cleaning The chamber 7 is provided with a projectile circulation system, and the steel shot thrown by the shot blaster 16 remains in the cleaning chamber 7 and enters the projectile circulation system; the feeding isolation chamber 6 and the discharging isolation chamber 10 are respectively arranged before ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com