Sleeve type fuel assembly and supercritical water cooled reactor

A fuel assembly and sleeve-type technology, applied in the field of nuclear reactors, can solve the problems of complicated fuel assemblies and core structures, and achieve the effects of reducing the ineffective flow area, simplifying the core structure, and enhancing the heat transfer capability of the coolant.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

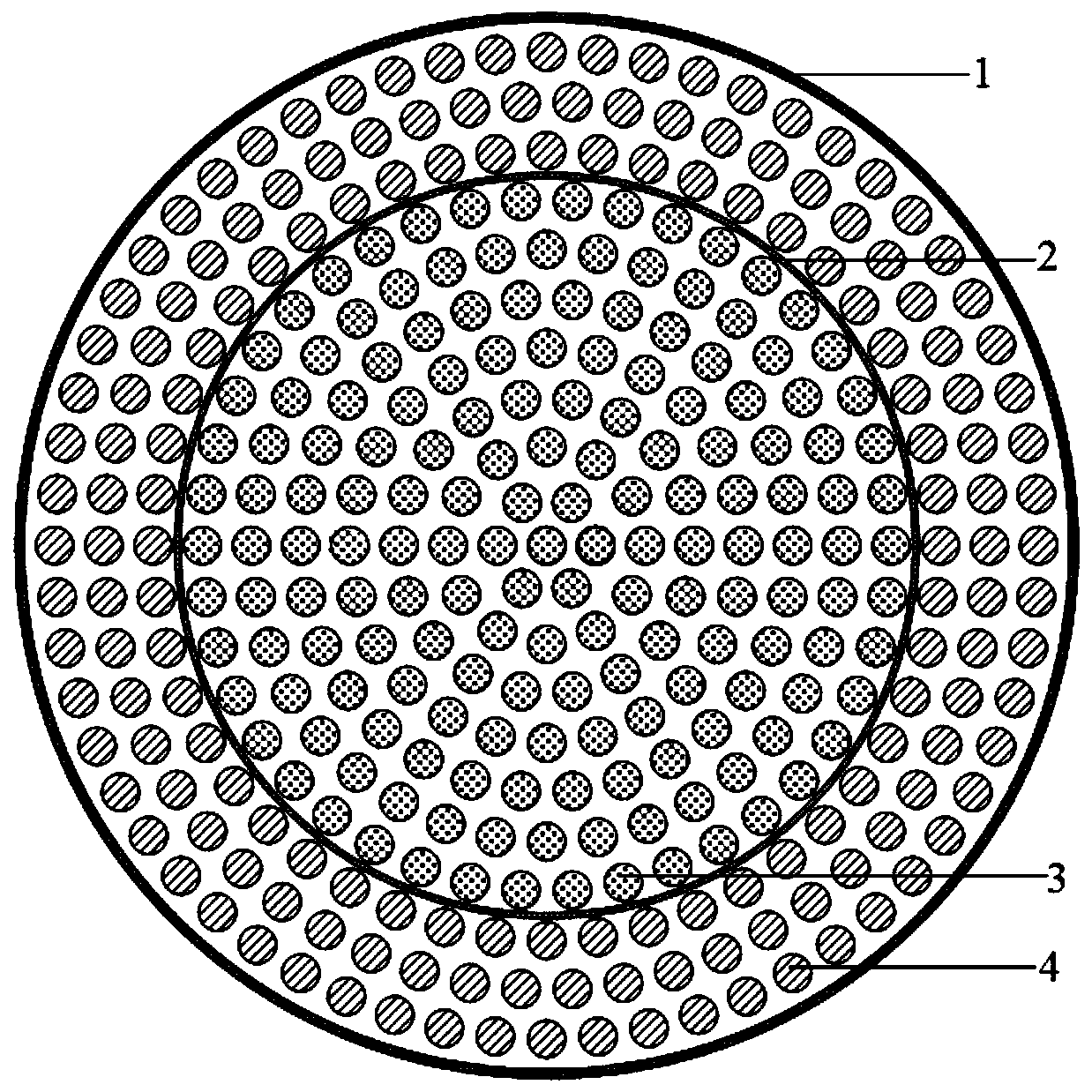

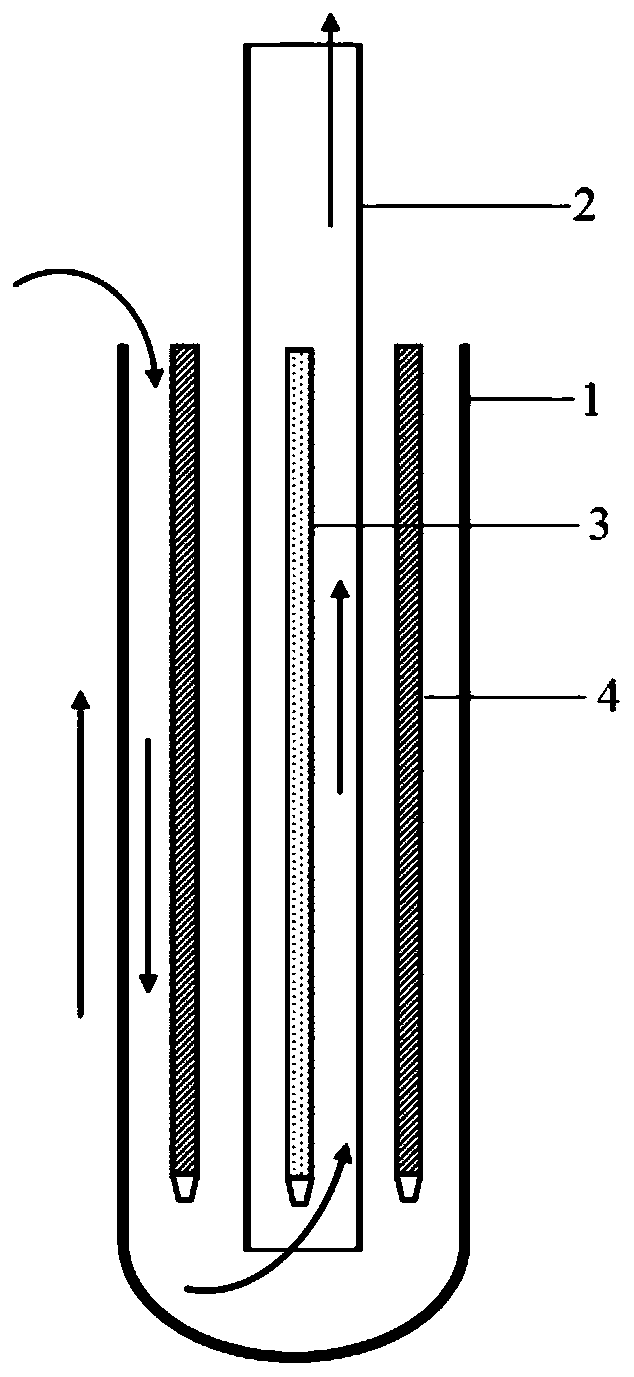

[0032] Such as figure 1 , figure 2 As shown, a sleeve-type fuel assembly, the fuel assembly 5 along the radial direction from the inside to the outside is an inner tube 2 and an outer tube 1. The radius of the inner tube 2 is 90.5 mm, and the wall thickness is 1.0 mm. , the radius of the outer tube 1 is 128 mm, and the wall thickness is 2.0 mm. The area surrounded by the inner tube 2 is an inner area, and the inner area fuel rods 3 are arranged in the inner area. The area in between is the outer area, and the outer area is arranged with the outer area fuel rods 4, the outer diameter of the inner area fuel rods 3 and the outer area fuel rods 4 is Φ9.5mm, the thickness of the cladding is 0.57mm, and the fuel core is UO 2 Ceramic fuel, the diameter of the core is 8.19mm, and the cladding material is stainless steel. The upper part of the outer tube 1 is an open structure, which is the inlet of the coolant, and the lower part is a closed structure, which is used to isolate the ...

Embodiment 2

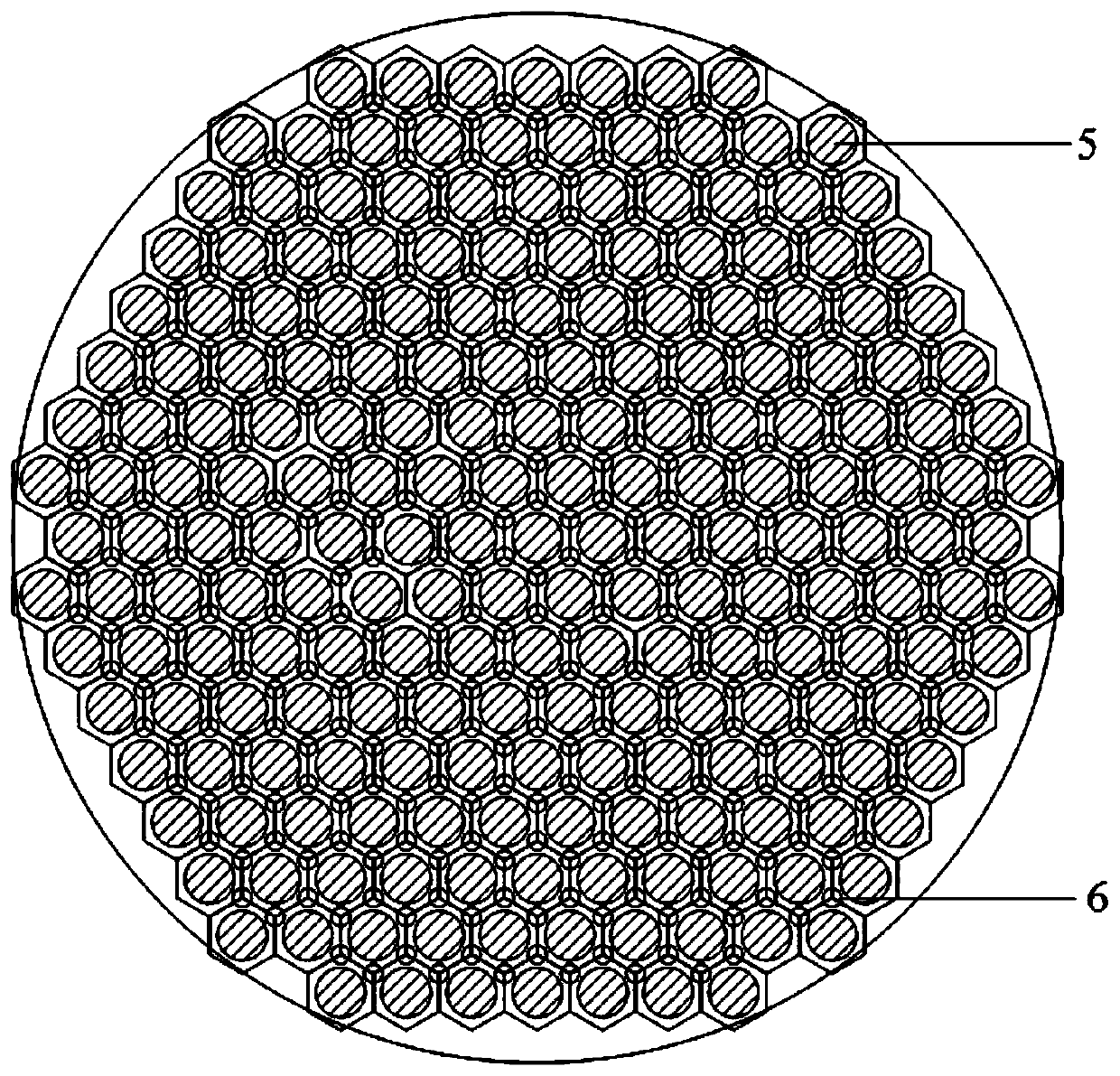

[0034] Such as image 3 , Figure 4 As shown, a supercritical water-cooled reactor comprising the casing type fuel assembly described in Embodiment 1, the supercritical water-cooled reactor is composed of 211 boxes of fuel assemblies 5 and 372 guide pipes 6, and the fuel assemblies 5 are formed according to the shape of an equilateral triangle The grid is arranged, and the guide tube 6 is arranged at the center of the equilateral triangle area formed by three adjacent fuel assemblies 5. The center-to-center distance between any two adjacent fuel assemblies 5 is 270mm, the outer diameter of the guide tube 6 is 40mm, and the wall thickness 1.0mm. The diameter of the circumscribed circle of the core is 4364mm, and the height of the active zone is 4200mm. The thermal power of the core is 3600MWth, and the volume average power density is 64.4MW / m 3 , the average linear power density is 10.6kW / m.

[0035] In this embodiment, after the coolant enters from the cold end of the pres...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com