System and method for efficiently utilizing waste heat of flue gas of furnace to treat iron-containing resources

A flue gas waste heat and furnace body technology, applied in furnaces, hearth furnaces, furnace types, etc., can solve the problems of long pretreatment process, clogging of side wall burners, large equipment investment, etc., so as to reduce production costs and equipment. The effect of investment, shortening of pretreatment process, and high equipment operation rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

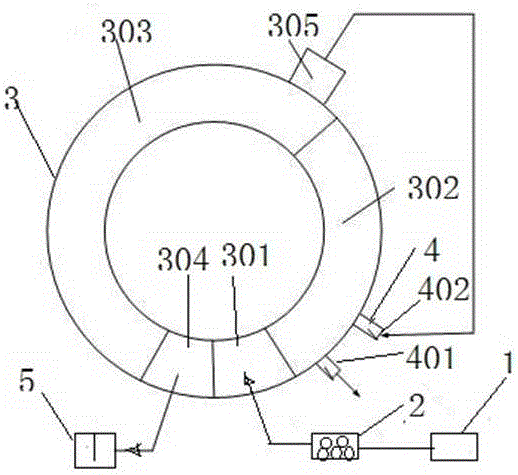

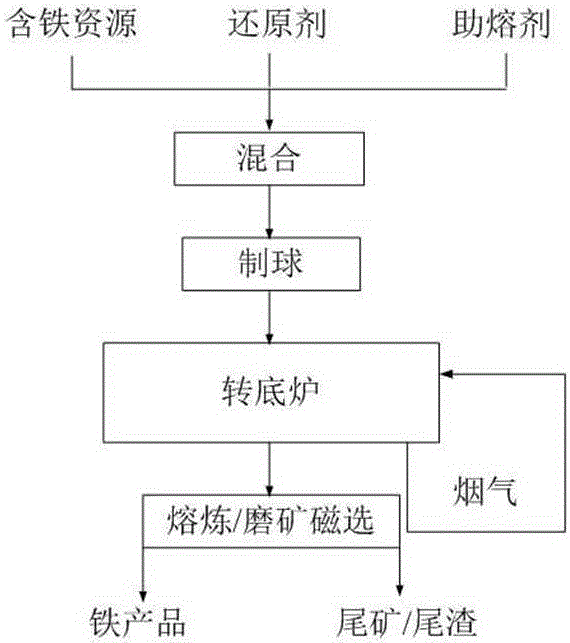

[0055] Use 20.4% TFe and laterite nickel ore containing Ni1.53% as the raw material, first crush the raw material to less than 2mm, the reducing agent is lignite with a fixed carbon content of 58%, the addition amount is 1.1 times of the theoretical addition amount, and the limestone The amount of addition is 10% of the weight of laterite nickel ore for mixing-briquetting. The moisture content of the hydrous pellets is 17%. The pressed hydrous pellets are directly placed into the rotary hearth furnace for drying-reduction treatment. The drying area of the rotary hearth furnace adopts drying The heat source of the drying pipe device comes from the high-temperature flue gas discharged from the flue of the rotary hearth furnace. The high-temperature flue gas discharged from the flue of the rotary hearth furnace is sent into the flue gas inlet of the drying pipe, and then discharged from the flue gas outlet of the drying pipe; The reduction zone is heated by burners; the included...

Embodiment 2

[0057] Use 20.4% TFe and laterite nickel ore containing Ni1.53% as raw material, first crush the raw material to less than 1mm, the reducing agent is lignite with fixed carbon content of 58%, and the addition amount is 1.2 times of the theoretical addition amount, limestone The amount of addition is 10% of the weight of laterite nickel ore for mixing-briquetting. The moisture content of the hydrous pellets is 17%. The pressed hydrous pellets are directly placed into the rotary hearth furnace for drying-reduction treatment. The drying area of the rotary hearth furnace adopts drying The heat source of the drying pipe device comes from the high-temperature flue gas discharged from the flue of the rotary hearth furnace. The high-temperature flue gas discharged from the flue of the rotary hearth furnace is sent into the flue gas inlet of the drying pipe, and then discharged from the flue gas outlet of the drying pipe; The reduction zone is heated by burners; the included angle of ...

Embodiment 3

[0059] Choose TFe content 57.10%, TiO 2 Content 12.94%, V 2 o 5 Vanadium-titanium sea sand with a content of 0.67 is used as raw material, and the reducing agent is carbon black obtained by pyrolysis of solid waste. The water content of the pellets is 14%, and the water-containing pellets are directly distributed into the rotary hearth furnace for drying-reduction treatment. The drying area of the rotary hearth furnace is heated by a drying tube device. The heat source of the drying tube device comes from the high temperature discharged from the flue of the rotary hearth furnace. Flue gas, the high-temperature flue gas discharged from the flue of the rotary hearth furnace is sent into the flue gas inlet of the drying pipe, and then discharged from the flue gas outlet of the drying pipe; the reduction area is heated by a burner; the angle of the ring in the drying area is 50°, The included angle of the circular ring is 260°; the minimum temperature in the drying zone is 90...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com