Patents

Literature

804 results about "Drying tube" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A drying tube or guard tube is a tube-like piece of apparatus used to house a disposable solid desiccant, wherein at one end the tube-like structure terminates in a ground glass joint for use in connecting the drying tube to a reaction vessel, for the purpose of keeping the vessel free of moisture.

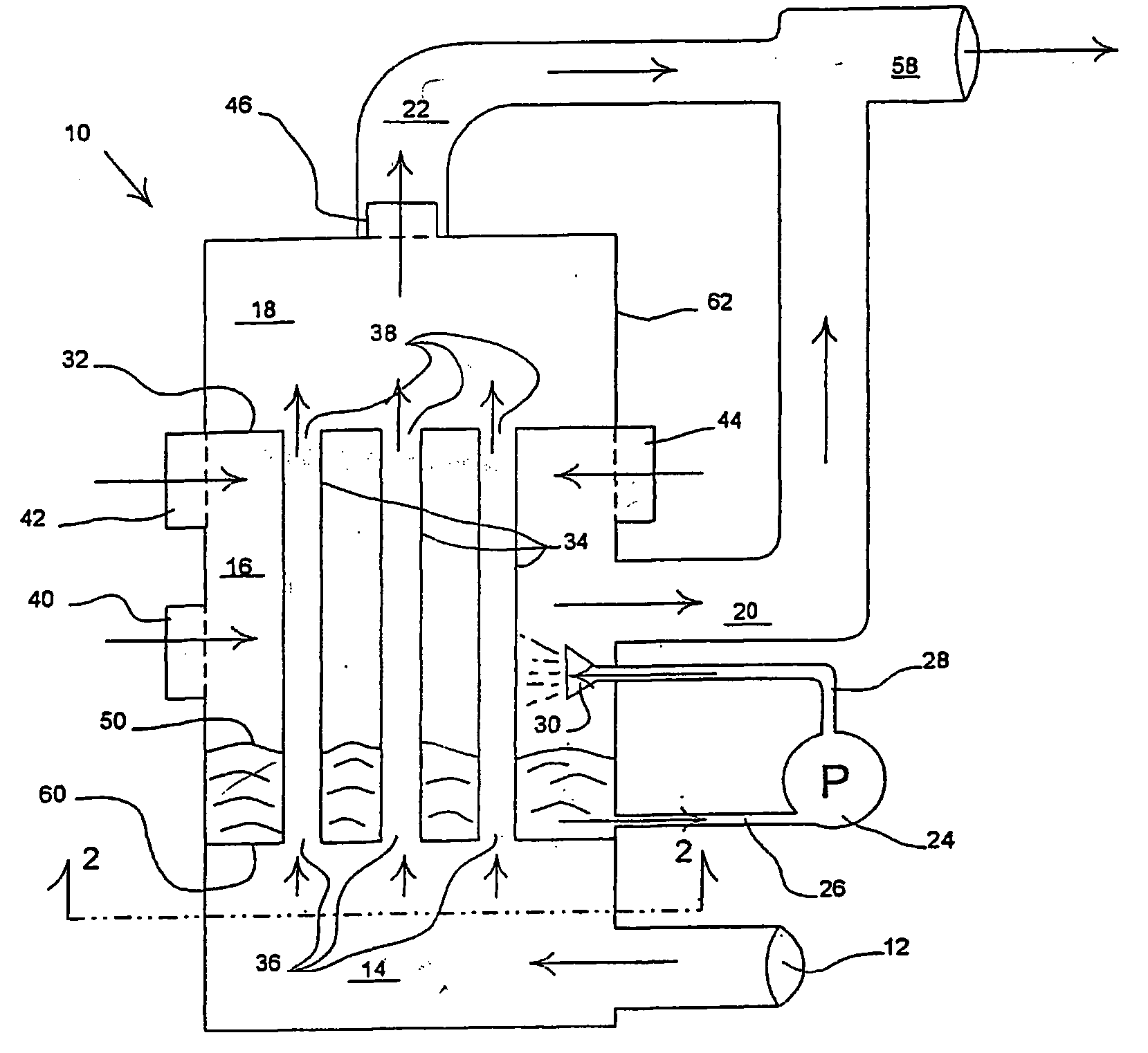

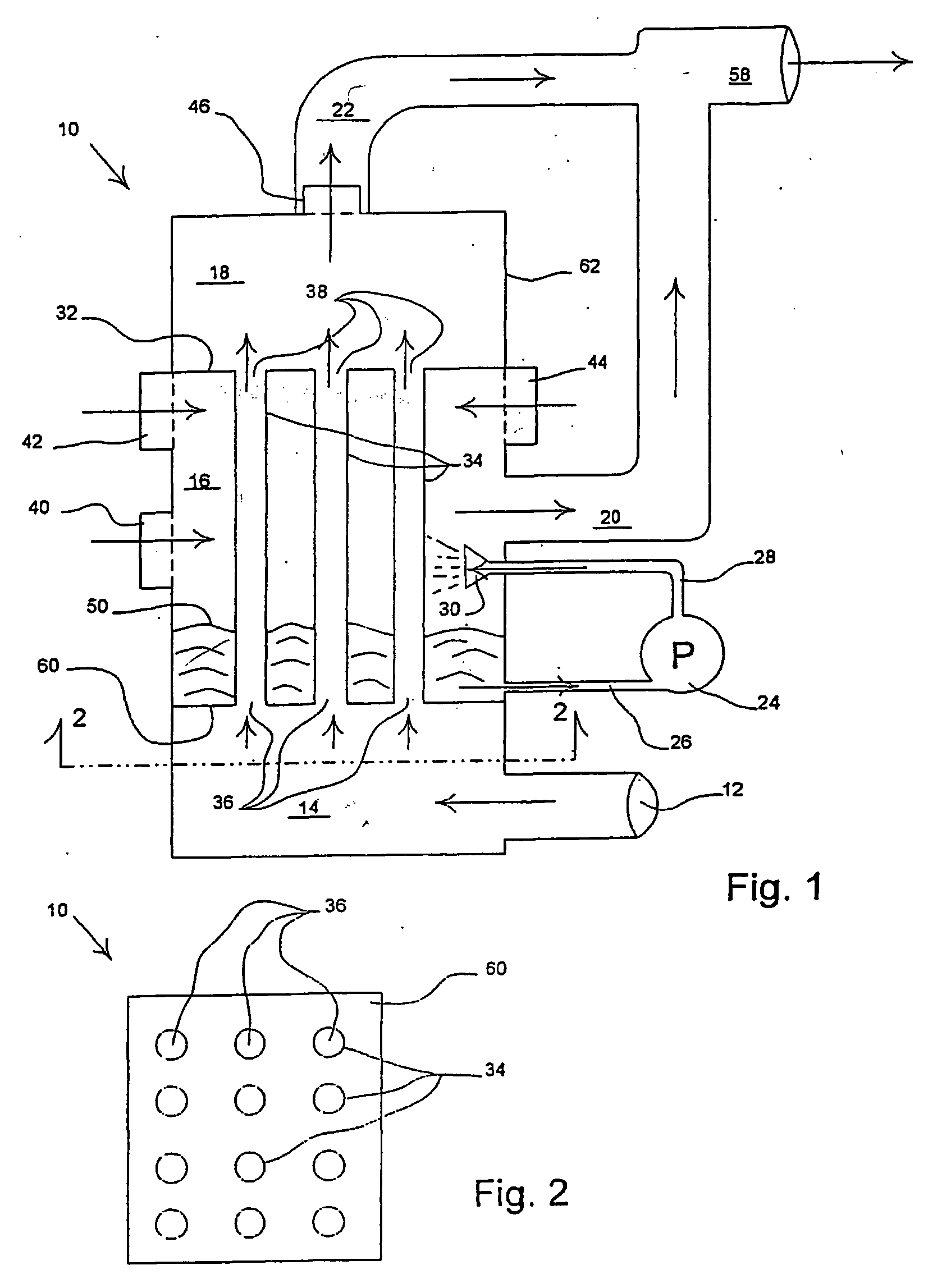

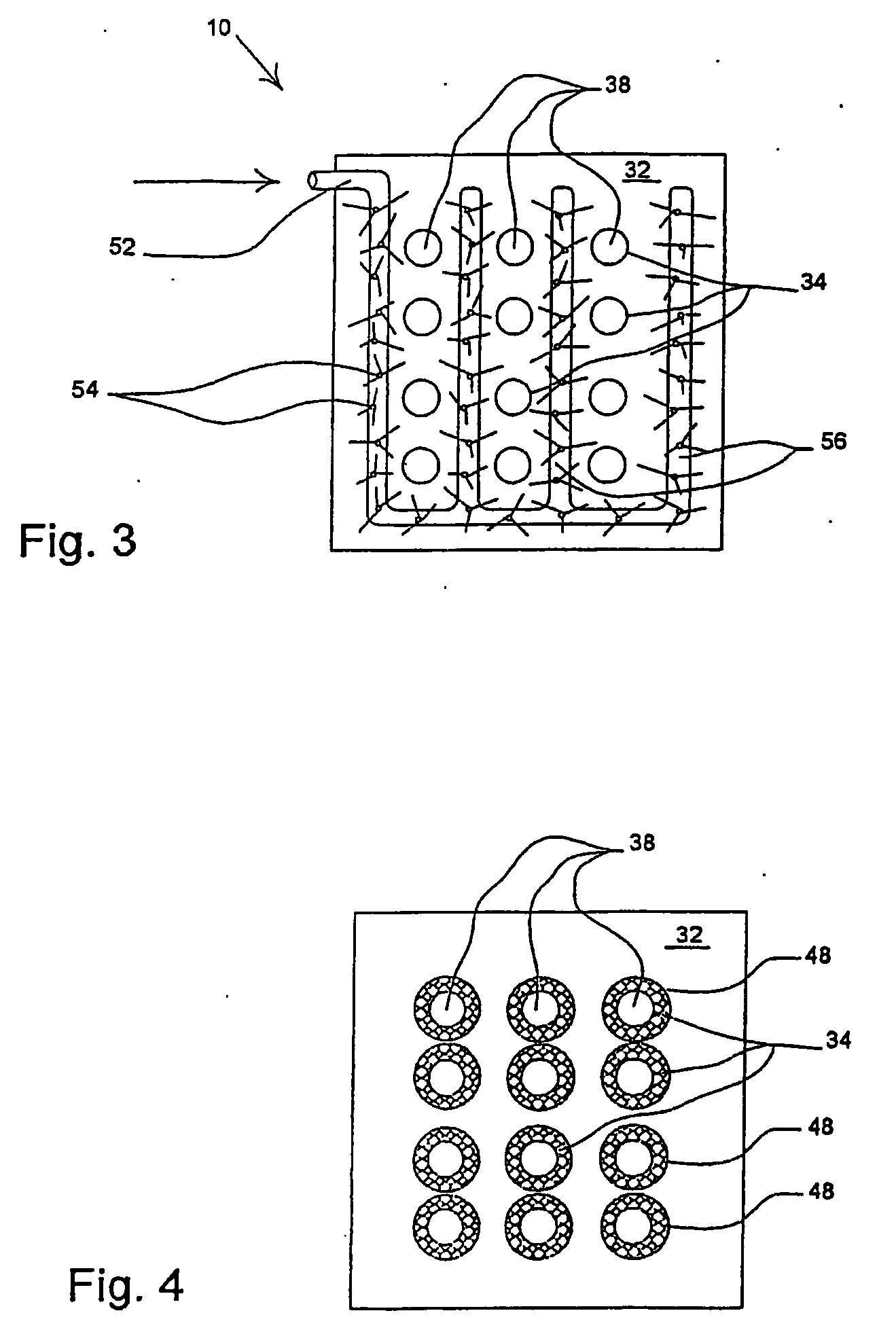

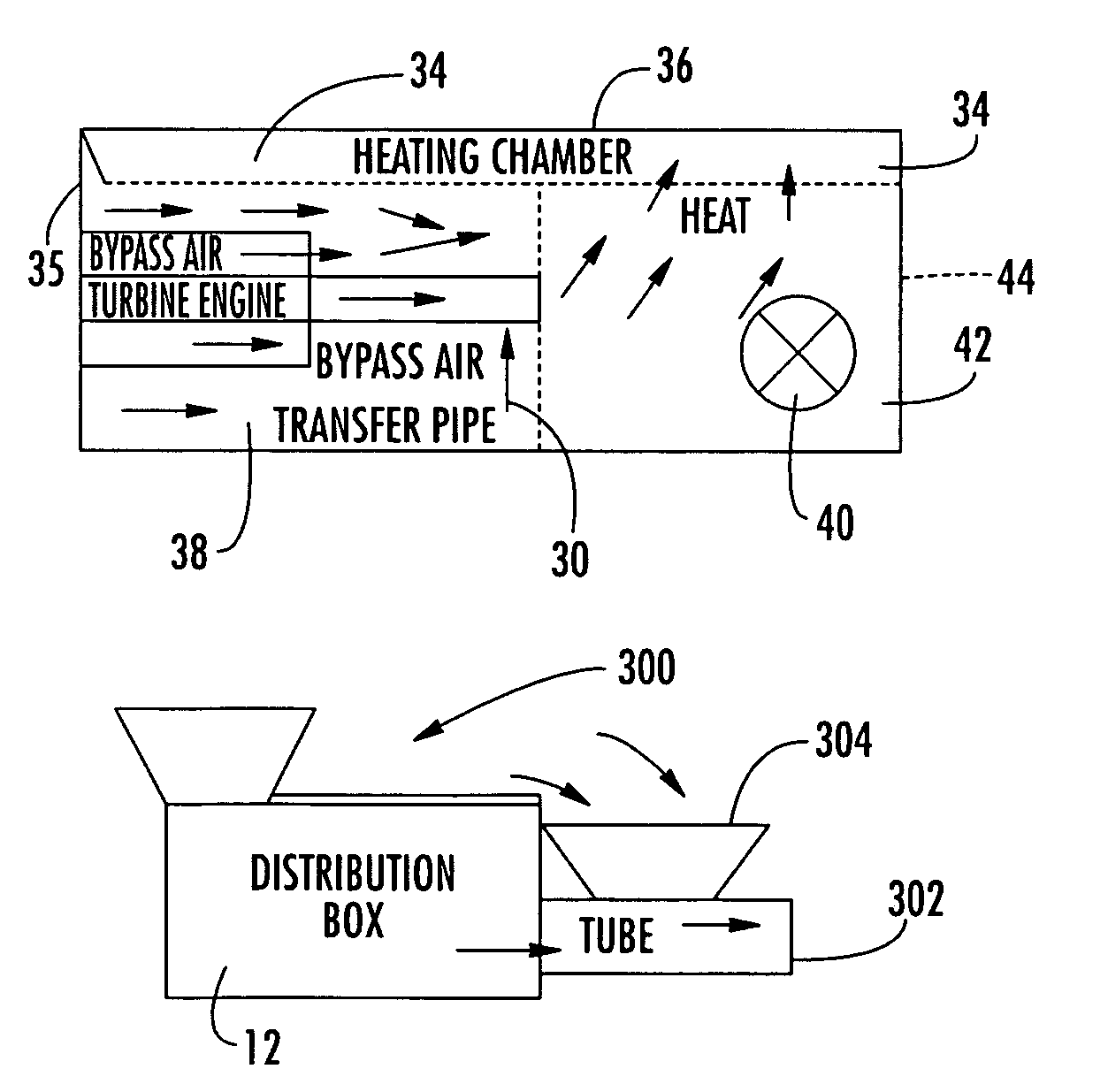

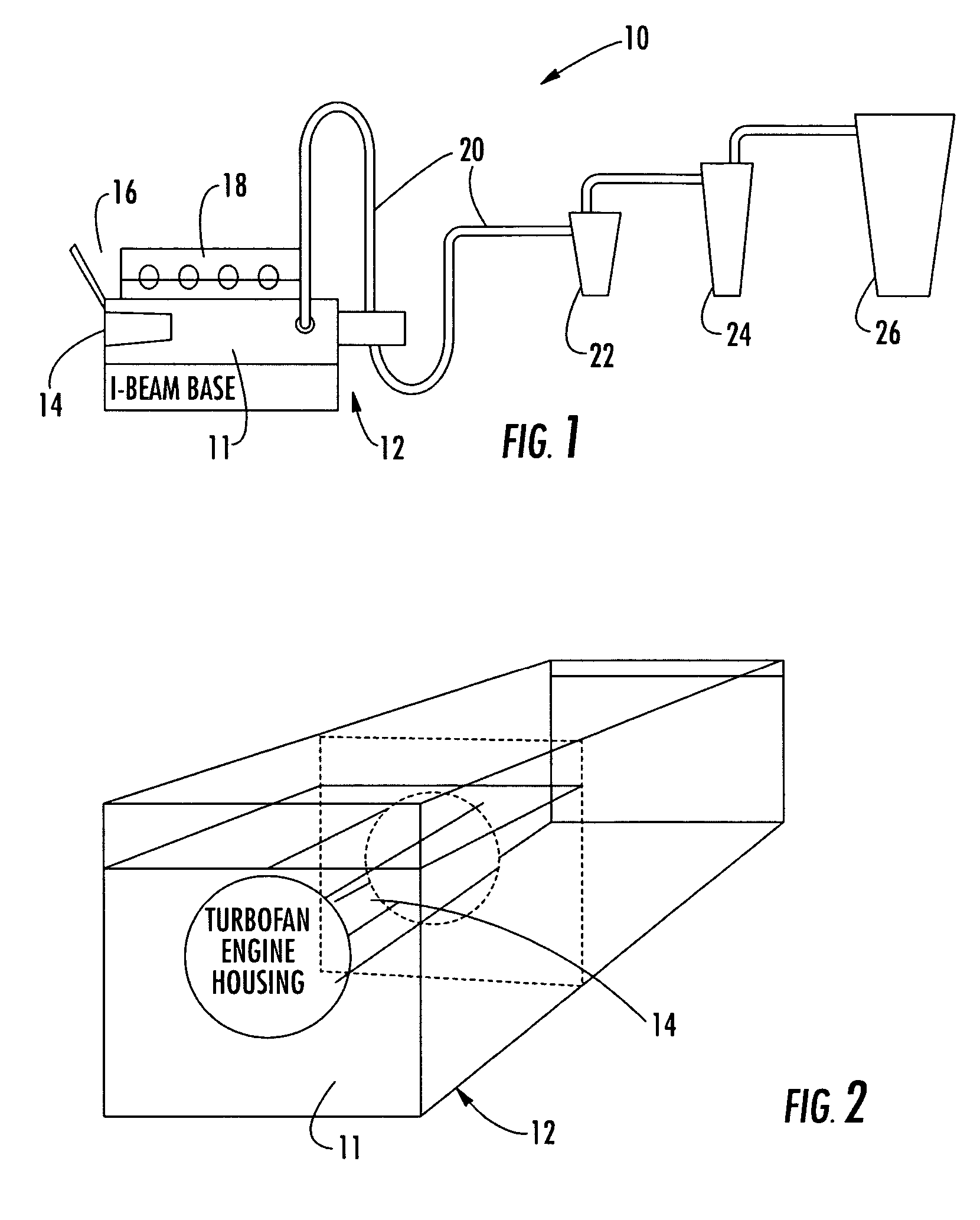

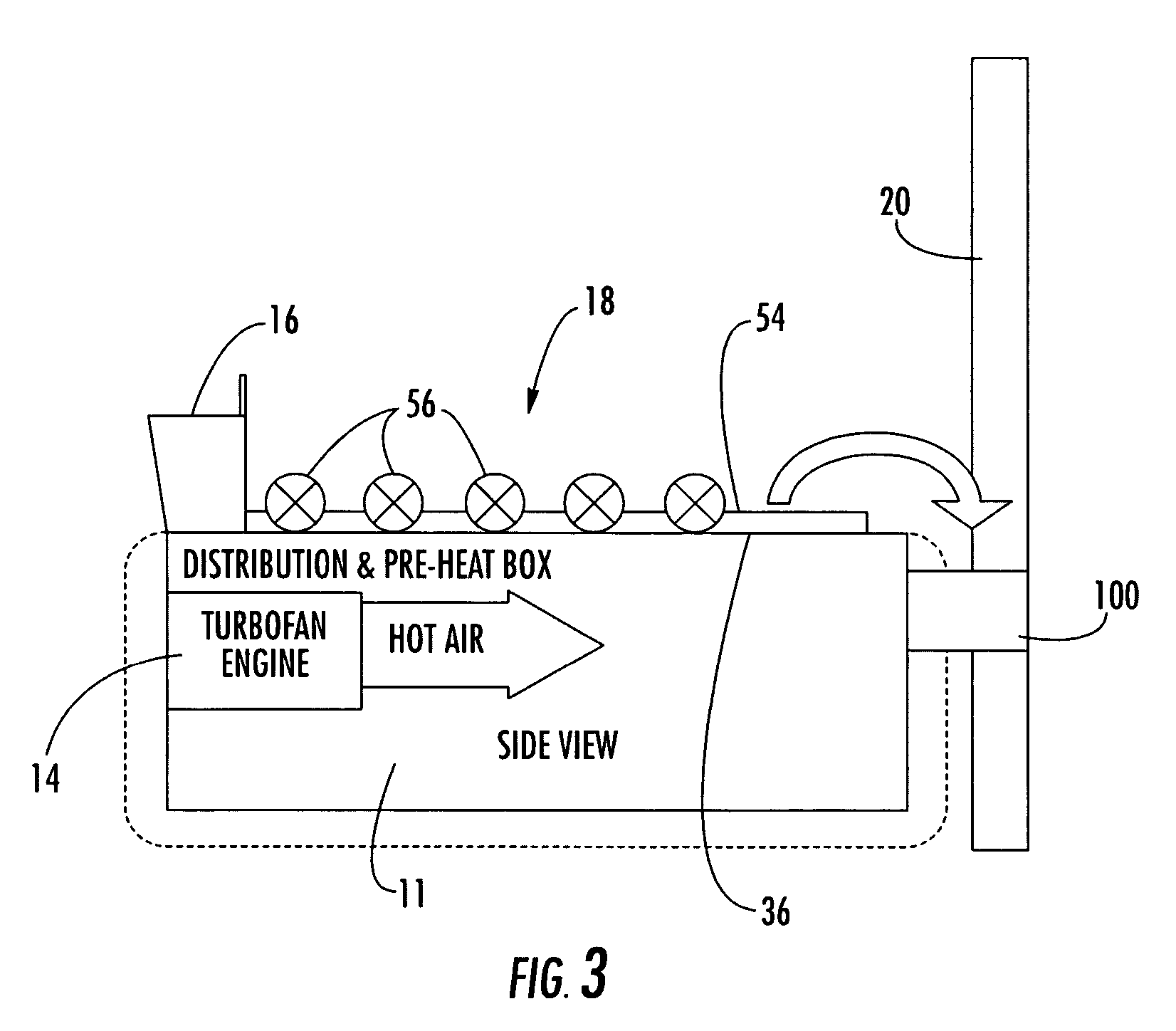

Air dryer system and method employing a jet engine

InactiveUS6944967B1Operate operating costQuality improvementDrying gas arrangementsDrying machines with non-progressive movementsJet engineTurbofan

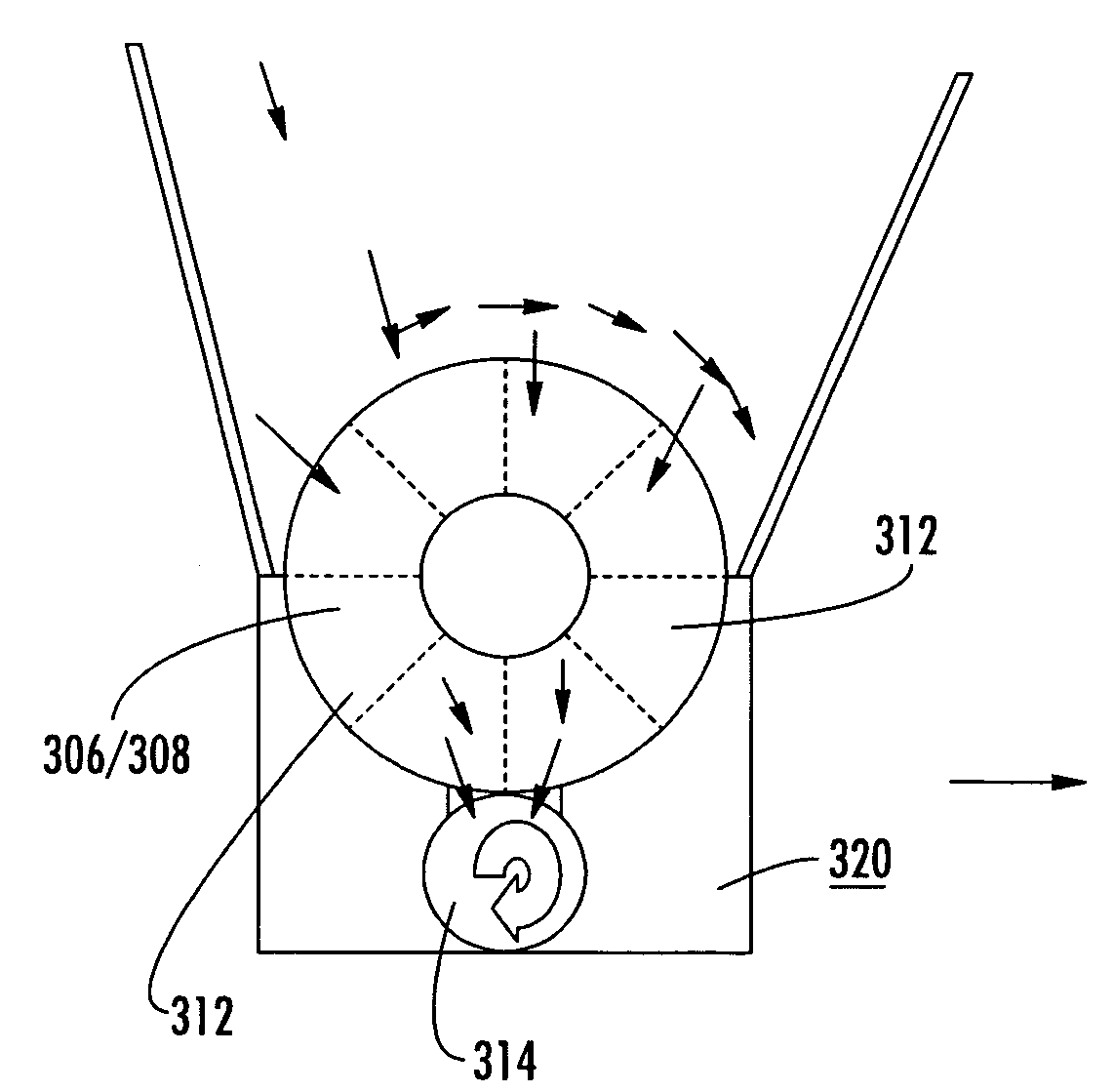

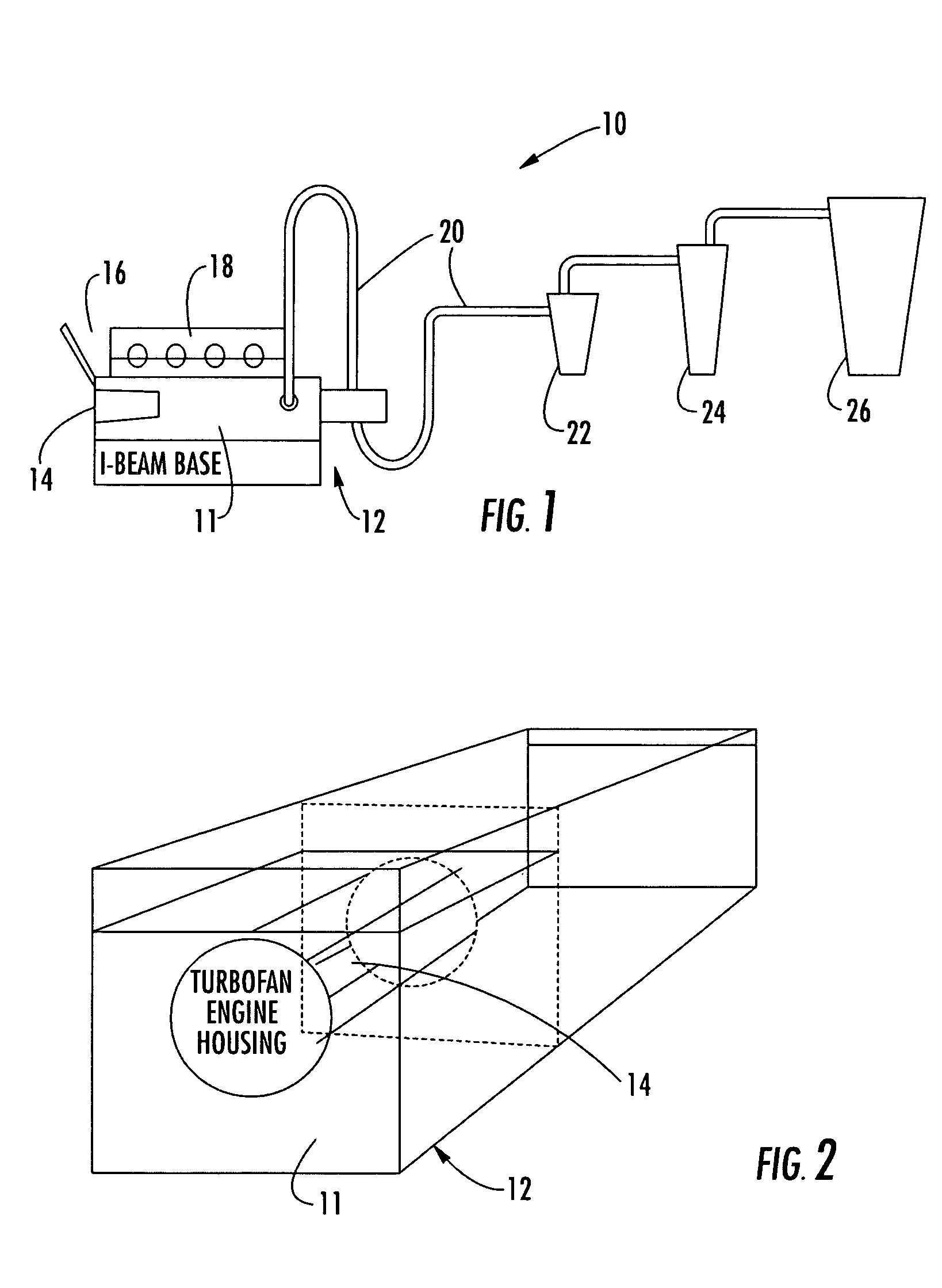

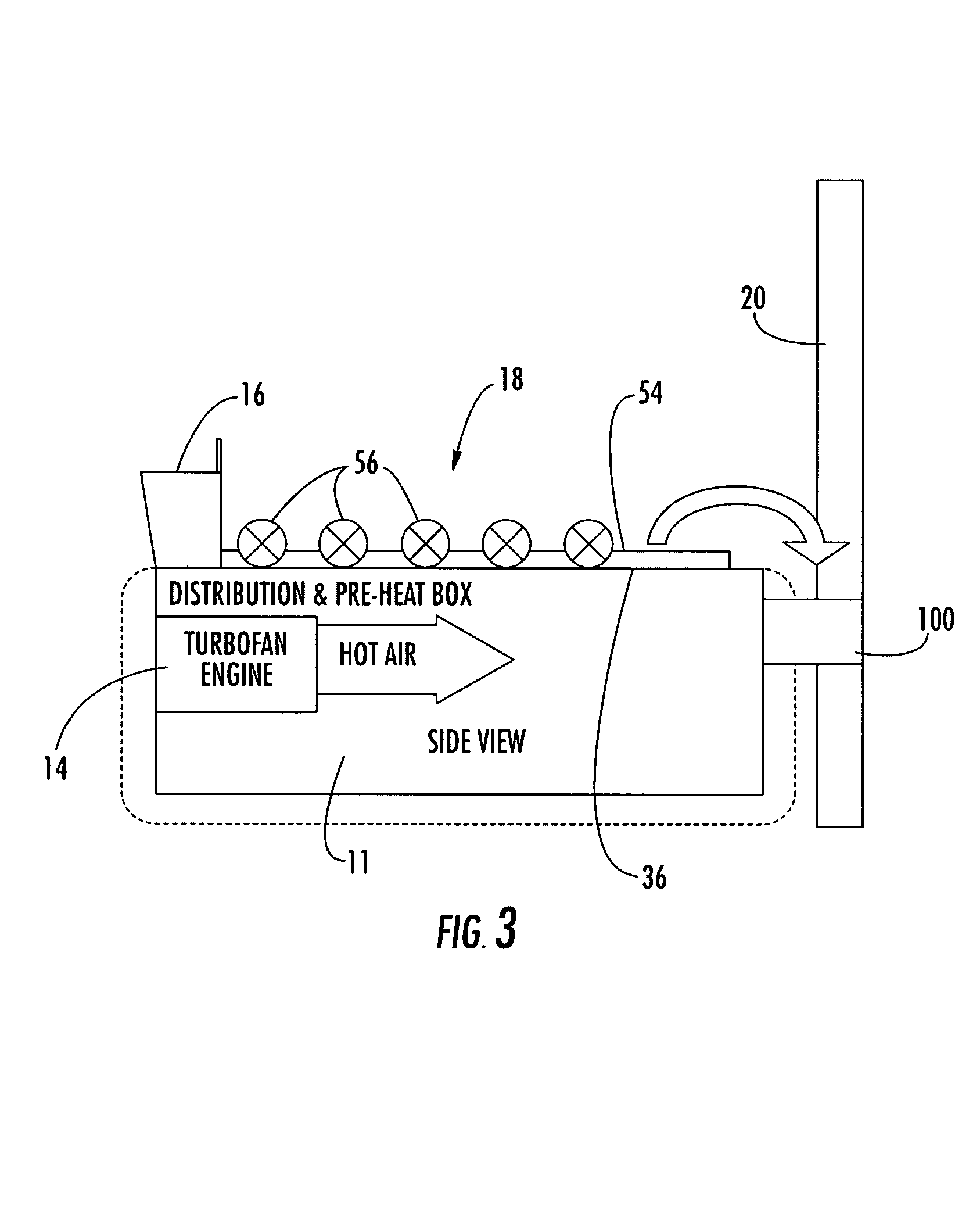

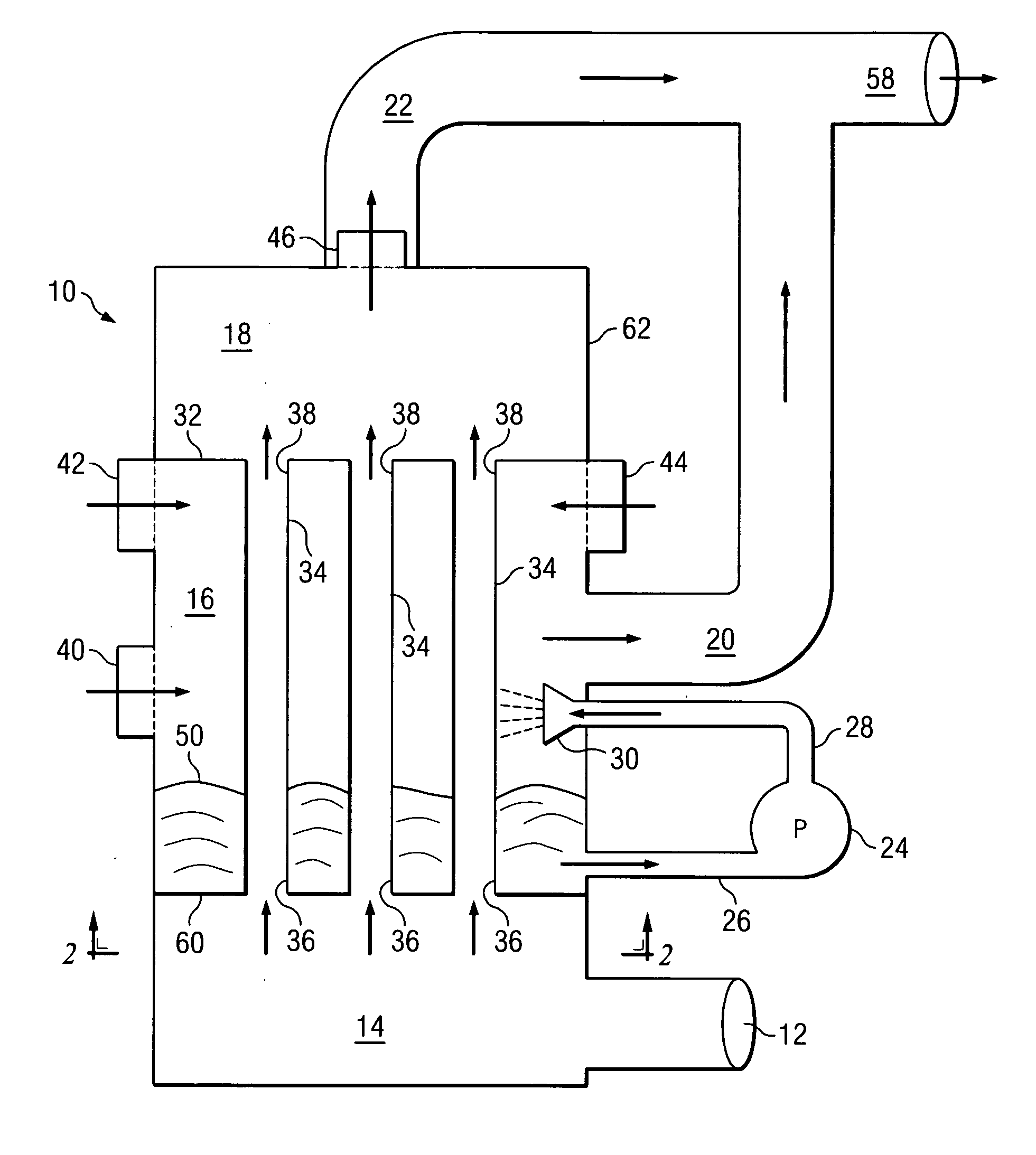

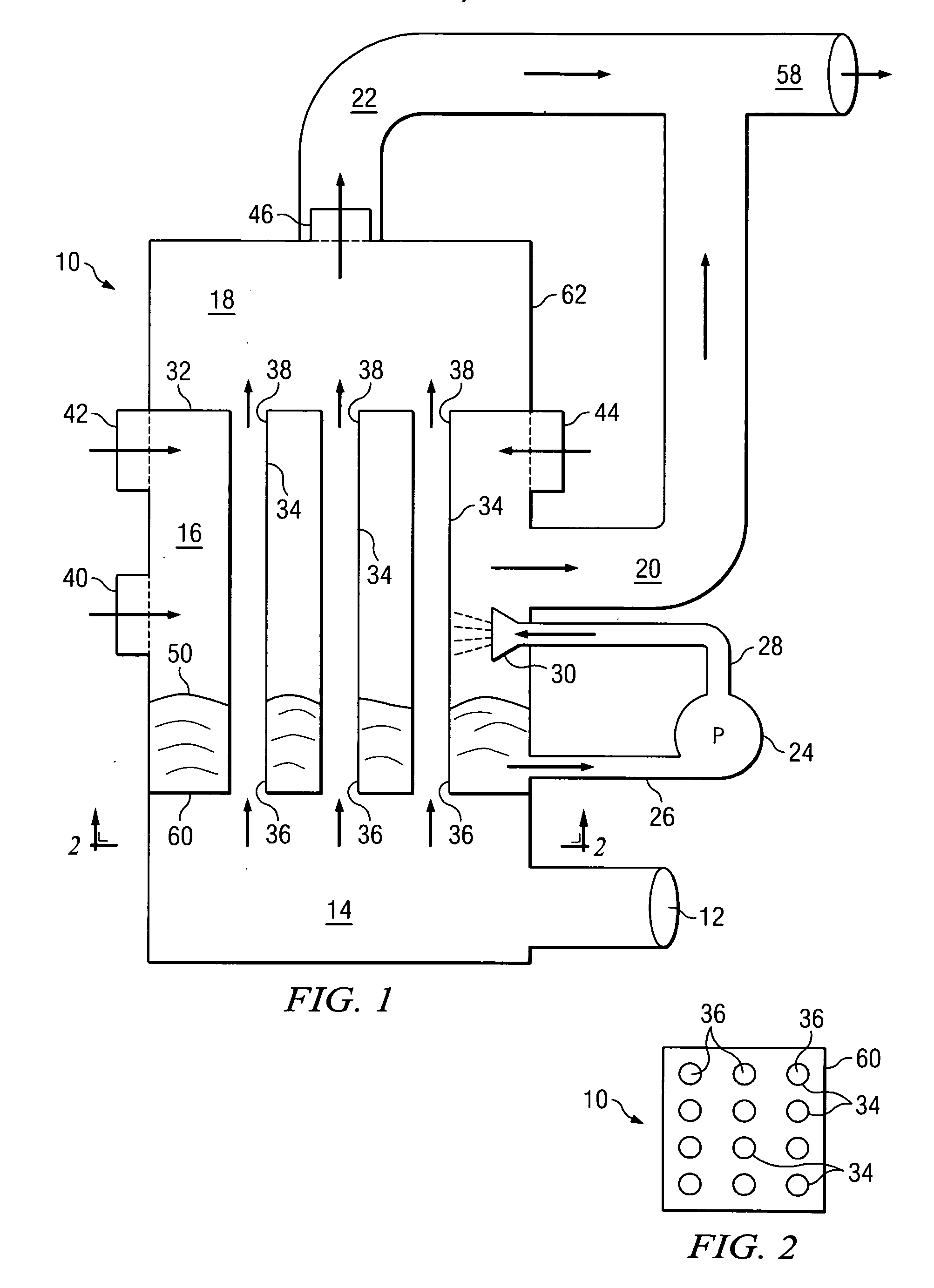

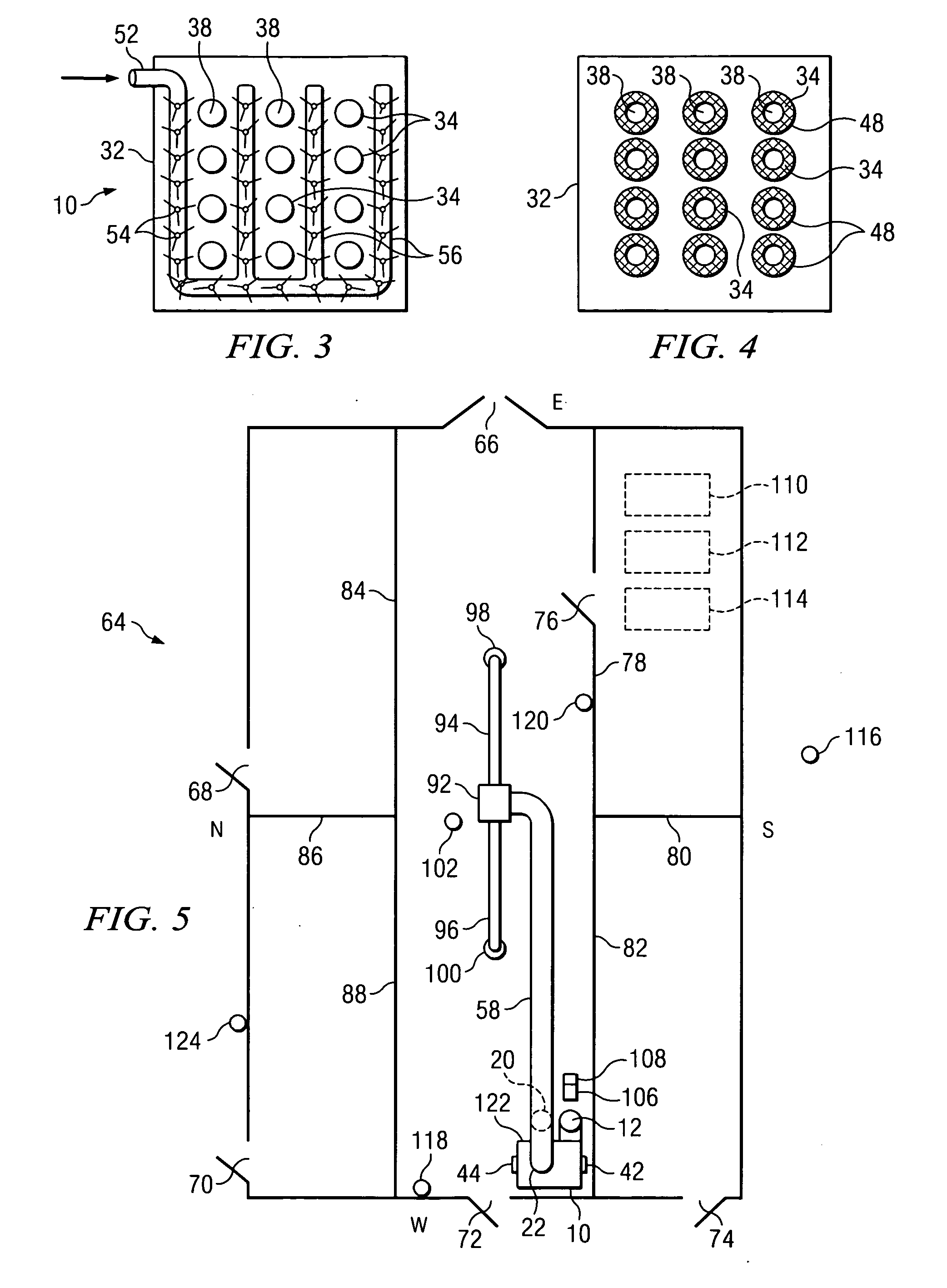

An air dryer and process employs a jet engine for producing high quality dried products. A turbofan jet engine in an air-drying system uses both thermal and non-thermal air-drying. The turbofan jet engine is housed within an air distribution chamber for directing exhaust air and bypass air from the jet engine into a product drying tube, where it is dried through a combination of thermal drying from heat content in an engine exhaust, and by the kinetic energy of air flowing past the product traveling through the drying tube, that may include a physical impediment for retarding retard the speed of the product solids flowing in the air stream through the tube.

Owner:STAPLES WESLEY A

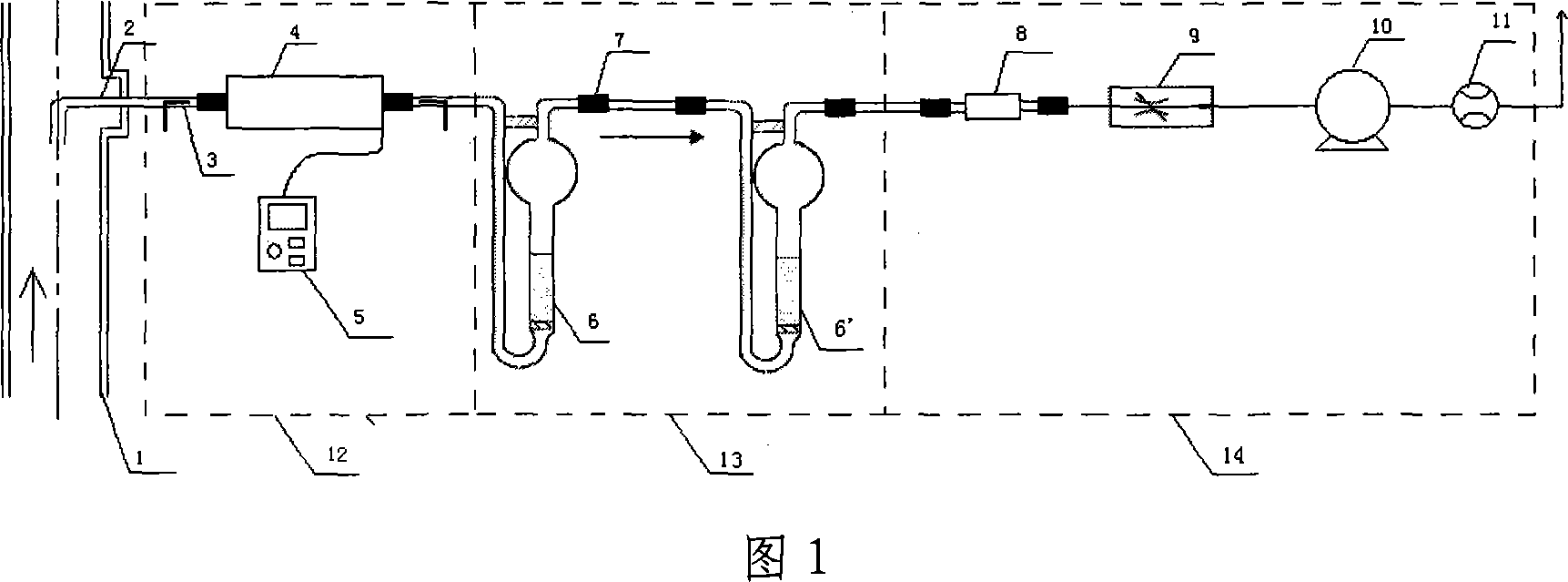

Method and device for measuring radon exhalation rate on medium surface

ActiveCN101644700AEliminate emanation interferenceEliminate leaksX/gamma/cosmic radiation measurmentMaterial analysisMeasurement deviceAir pump

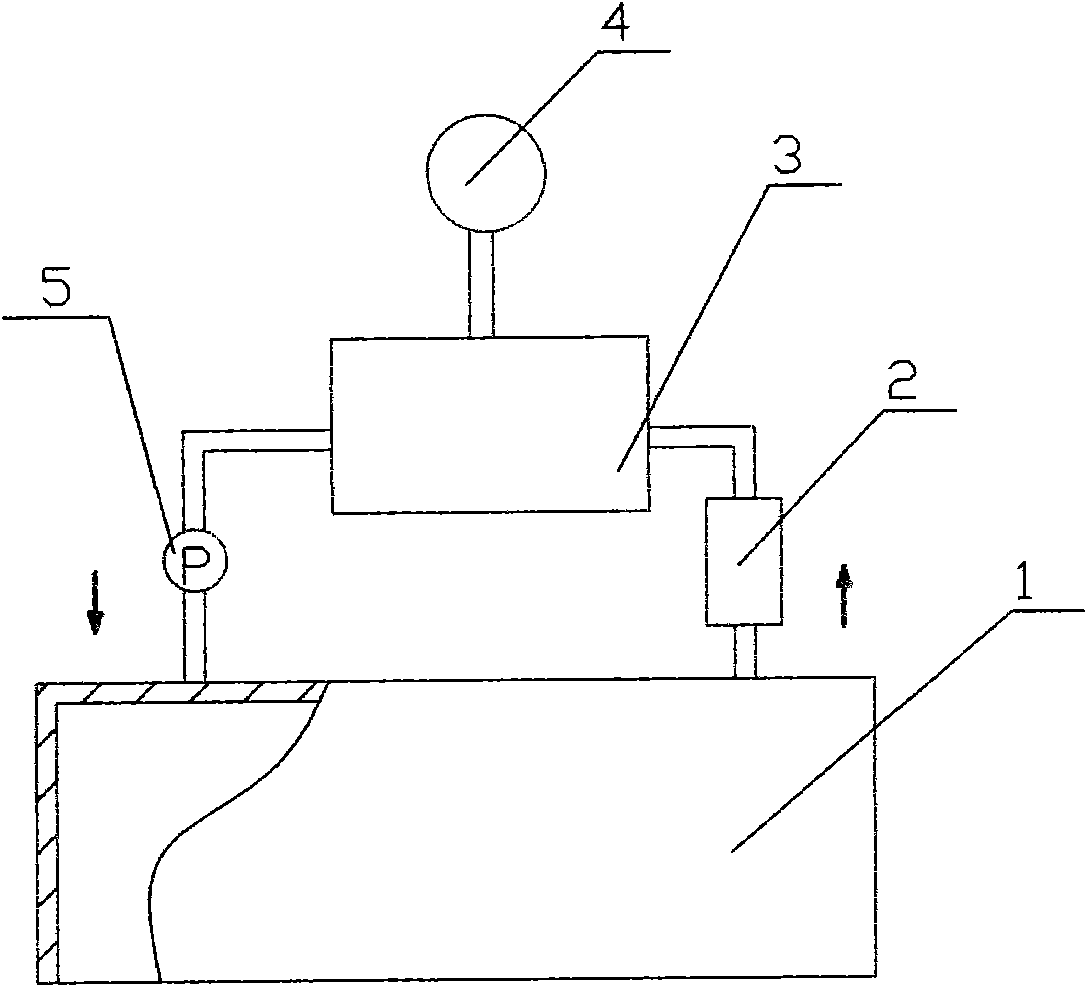

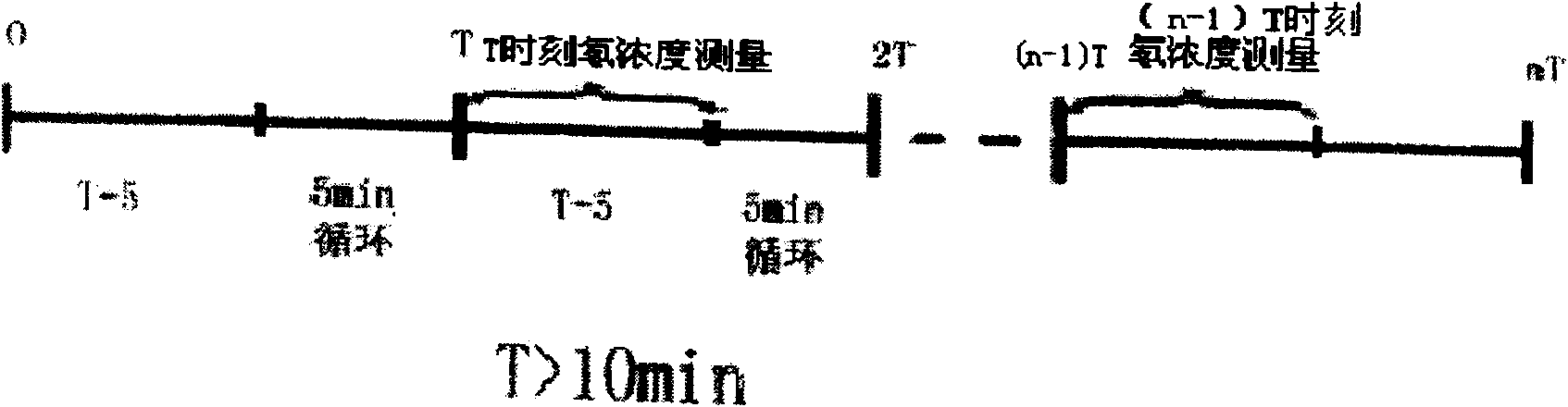

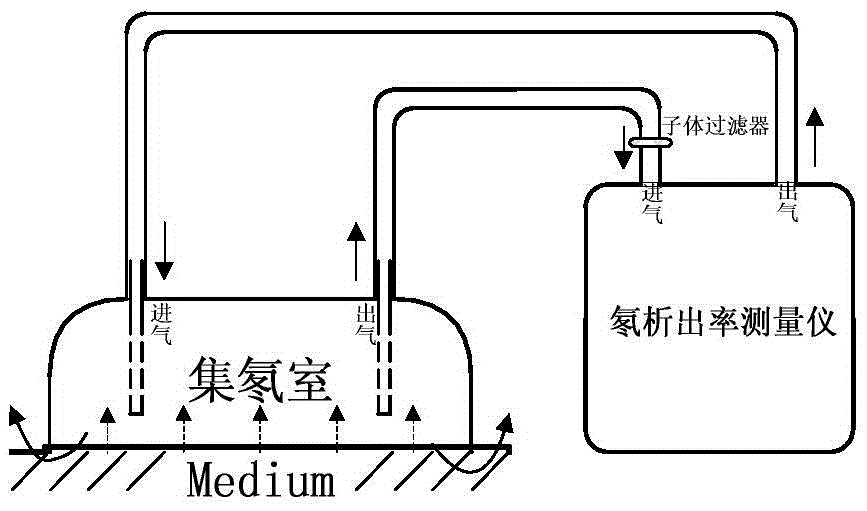

The invention discloses a method and a device for measuring a radon exhalation rate on a medium surface. The measuring method comprises a measuring process and a calculating process. The measuring method comprises the following steps: during measurement, inversely covering a radon accumulation chamber on the surface of a medium to be measured; connecting a sealed measuring chamber with the radon accumulation chamber to form a loop; after collecting a certain time period of 5 minutes, turning on an air pump to mix the radon in the radon accumulation chamber and the measuring chamber at a smallflow rate less than 3L / min for 5 minutes, wherein at this time, the radon concentration in the measuring chamber is the radon concentration in the radon accumulation chamber at the time T; repeatedlymeasuring the radon concentration in the radon accumulation chamber to obtain a group of data of radon concentration in the radon accumulation chamber at equal time intervals by taking T which is greater than or equal to 10 minutes as a period; and solving the radon exhalation on the surface of the medium to be measured according to a theoretical formula. The measuring device consists of the radon accumulation chamber, the air pump, the measuring chamber, a secondary instrument and a drying pipe, wherein one end of the air pump is connected with the radon accumulation chamber, while the otherend is connected with the measuring chamber through a pipe; one end of the drying pipe is connected with the radon accumulation radon through a pipe, while the other end is connected with the measuring chamber through a pipe; and the secondary instrument is connected with the measuring chamber.

Owner:NANHUA UNIV

Spraying and dripping irrigating system for fruit trees

InactiveCN104663103AReasonable designSimple structureClimate change adaptationWatering devicesWater savingFruit tree

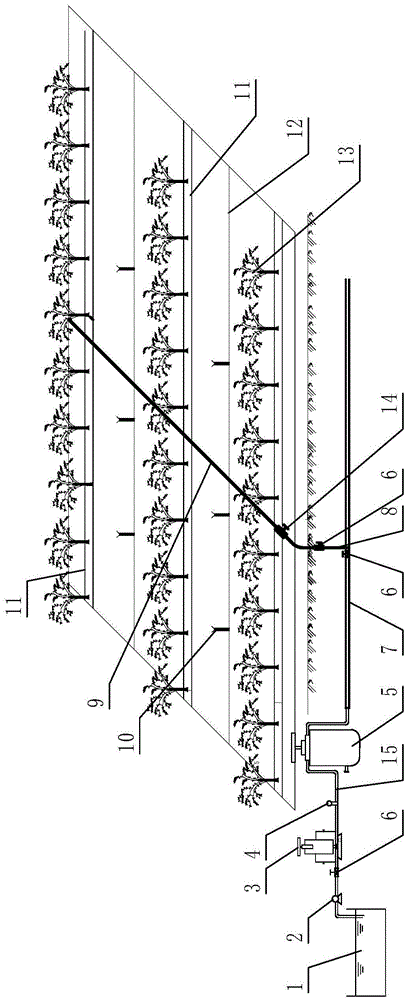

The invention relates to the farmland water conservancy field, in particular to a spraying and dripping irrigating system for fruit trees. The spraying and dripping irrigating system mainly comprises a water source, a front hub, a trunk tube, a dry tube, a spraying and dripping irrigating branch tube, a spray head and a dripping head, wherein the front hub mainly comprises a water pump, a fertilizer applying tank, a filter, a control valve and a pressure meter; the trunk tube is communicated with the dry tube; a water outlet pile is further arranged on the dry tube; water in the dry tube is filtered and then conveyed to the ground branch tube through the water outlet pile; the control valve is arranged at the connecting part between the water outlet pile and the ground branch tube; a three-phase valve is arranged on the upstream of the branch tube. The spraying and dripping irrigating system is reasonable in design, simple in structure, beneficial to irrigation and fertilization, capable of regulating the field microclimate, suitable for irrigating in a frozen period, and not prone to salt accumulation. Compared with the prior art, the spraying and dripping irrigating system is simple and convenient to operate, is economical and practical, is more suitable for practical production needs and is capable of further improving the water-saving efficiency of dripping irrigation.

Owner:SHIHEZI UNIVERSITY

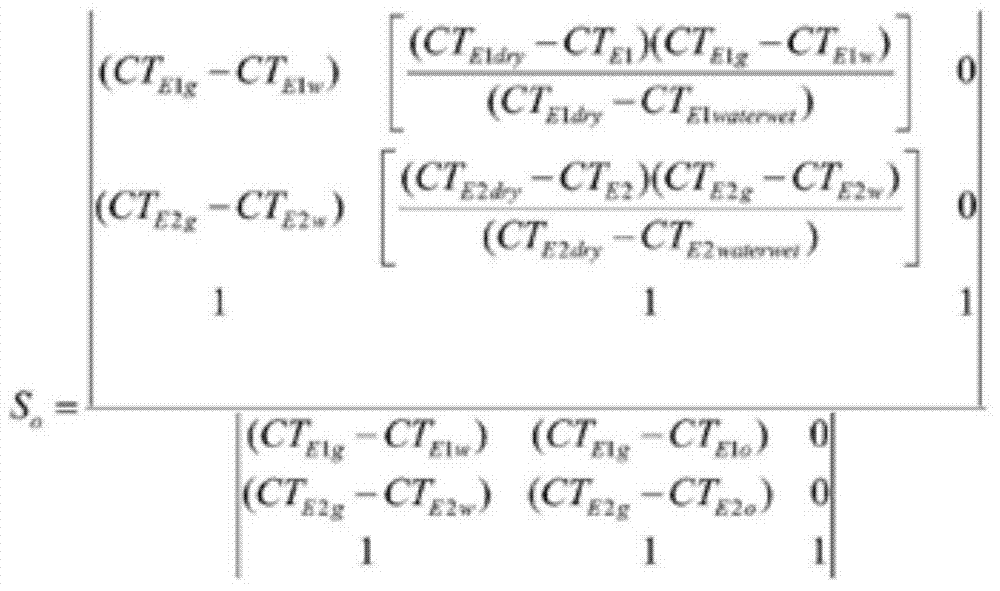

Device and method for measuring three-phase permeability of supercritical CO2 emulsion by steady-state flow method

InactiveCN104777086AReasonably closeReduce limitationsPermeability/surface area analysisFluid saturationEmulsion

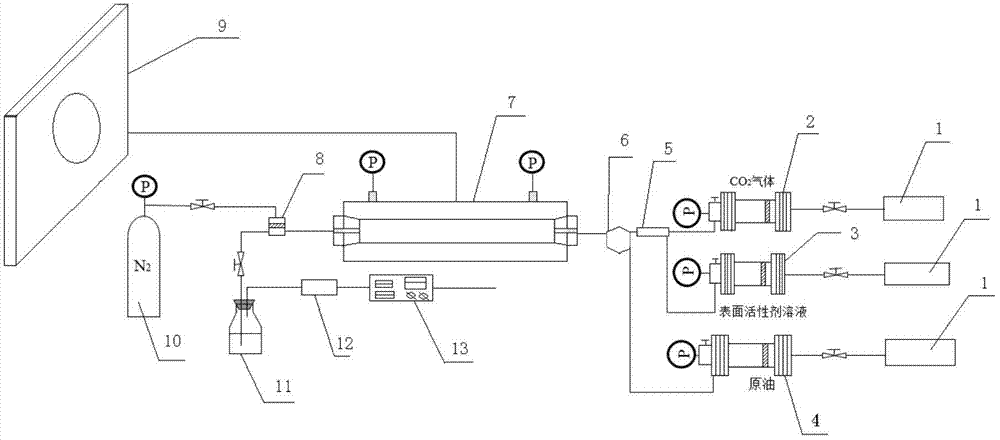

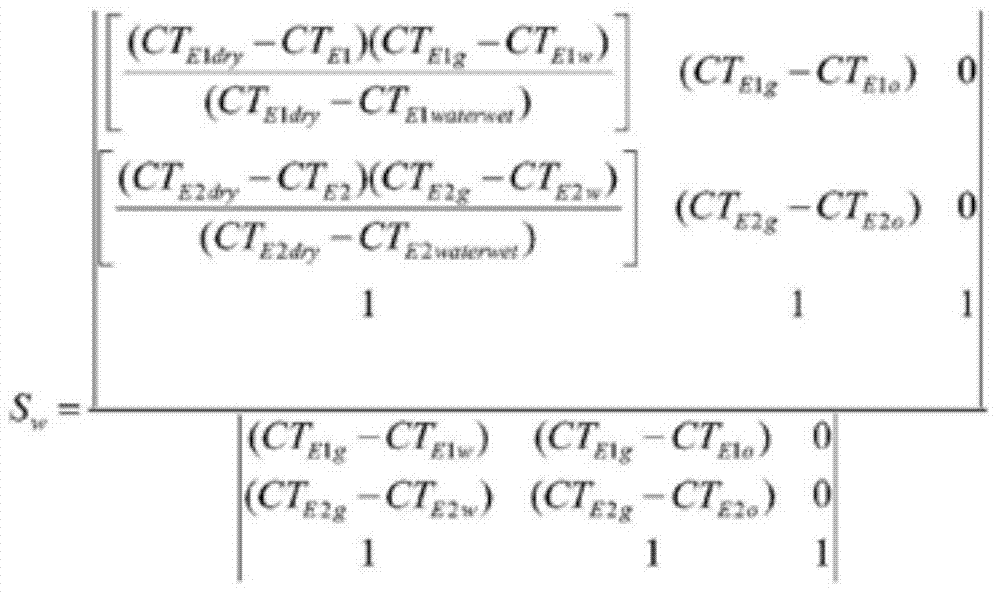

The invention relates to a device for measuring the three-phase permeability of supercritical CO2 emulsion by a steady-state flow method. The device comprises a one-dimensional rock core model and a computed tomography (CT) scanner, wherein an inlet end of the one-dimensional rock core model is connected an emulsion generator and a crude oil injection device which are connected with each other in parallel; an inlet end of the emulsion generator is connected with a CO2 gas injection device and a surface active agent injection device which are connected with each other in parallel; an outlet end of the one-dimensional rock core model is connected with a gas source bottle and a liquid-containing narrow-mouth bottle which are connected with each other in parallel; a gas outlet pipe of the liquid-containing narrow-mouth bottle is sequentially connected with a drying pipe and a flow meter. According to the method for measuring the three-phase permeability of the supercritical CO2 emulsion, the three-phase fluid saturation of the supercritical CO2 emulsion is accurately obtained by a CT double-energy synchronous scanning method, and the relevant data measured by the experiment is substituted into a Darcy-Weisbach formula, so that the three-phase relative permeability of the supercritical CO2 emulsion under the different degrees of saturation can be obtained; the method is also used for measuring CO2 foam flooding two-phase permeability. The device and the method are small in limitation, are capable of reasonably approaching the experimental real value, and are simple in operation and accurate in measurement.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

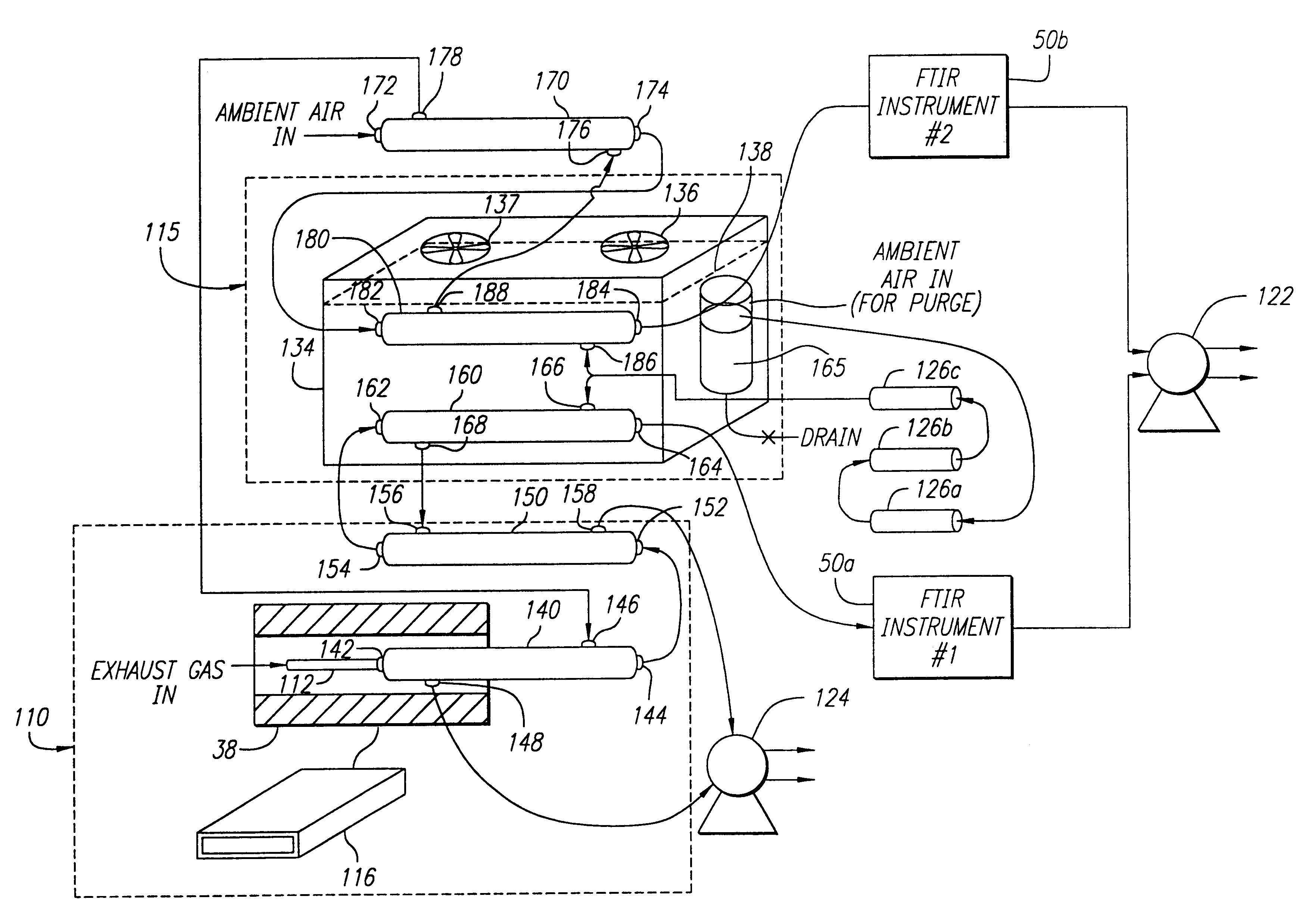

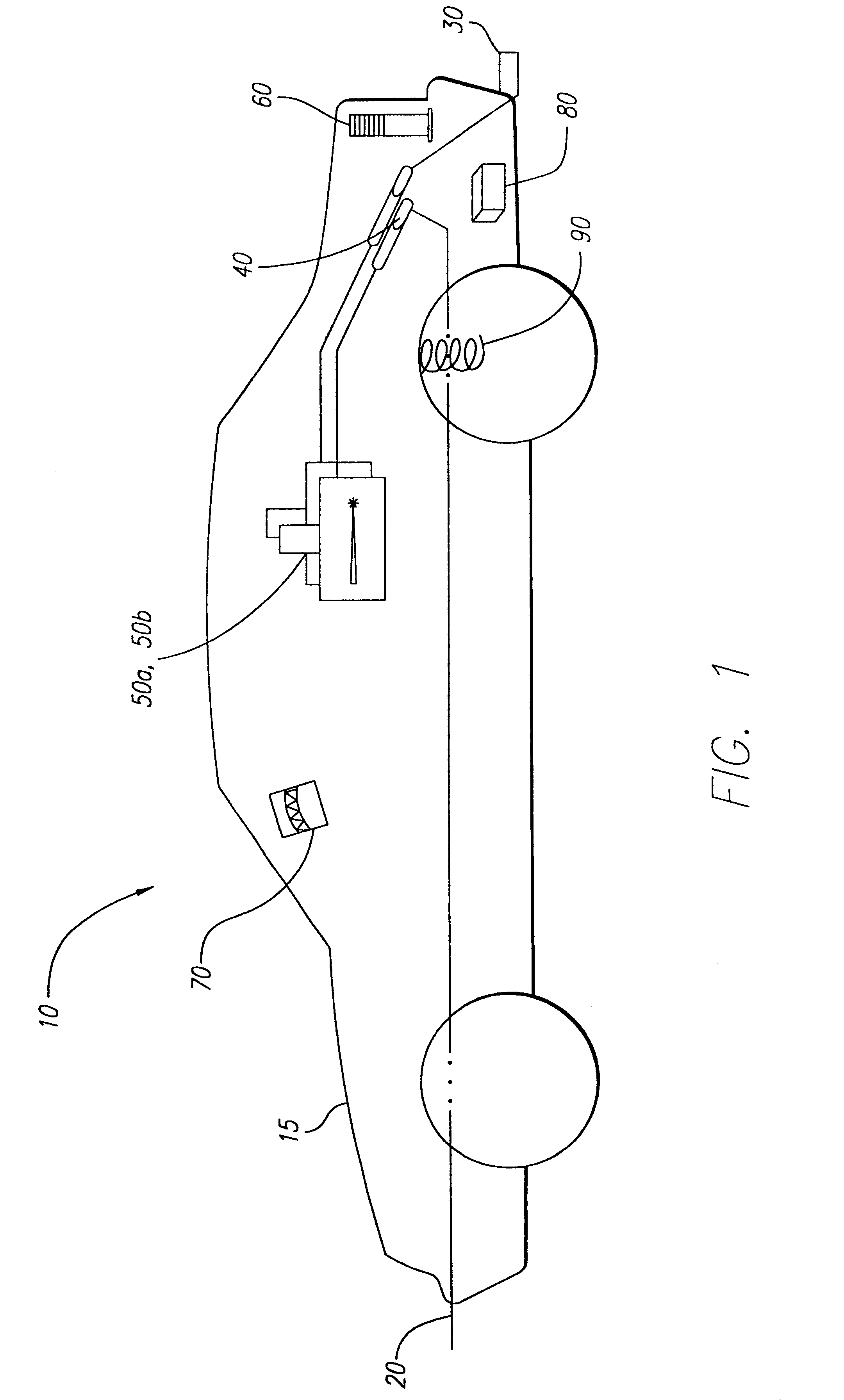

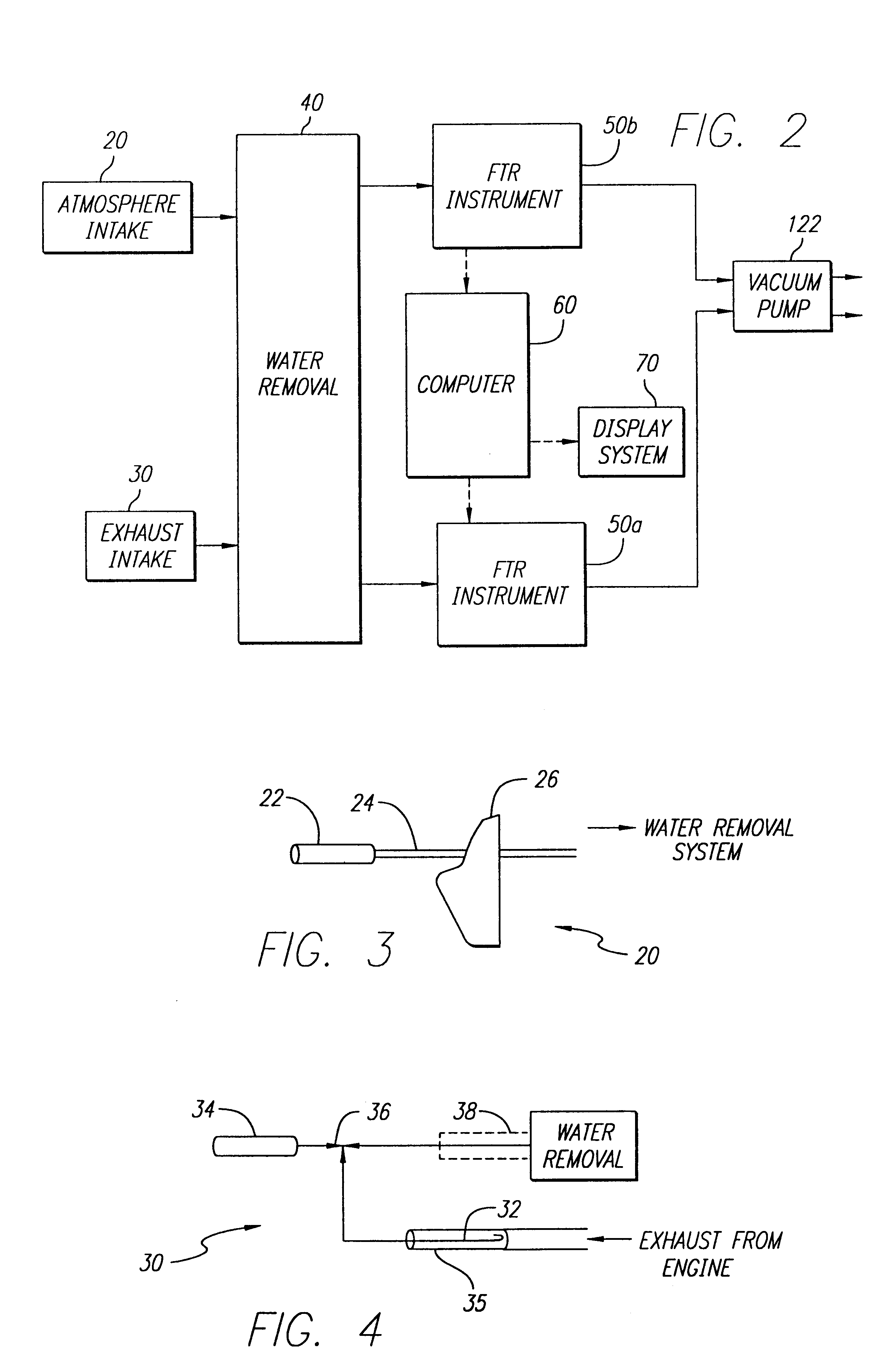

System for vehicle emission sampling and measurement

InactiveUS6516656B1Improve drying efficiencyImprove efficiencyInternal-combustion engine testingChemical compositionEngineering

An improved emission sampling and measurement system is provided for continuously sampling and analyzing the chemical content of a vehicle emissions and the ambient air for data evaluation and comparison. The emission sampling and measurement system comprises a vehicle having an emissions source, devices for intaking vehicle emissions and ambient air, and analysis devices for determining the chemical content of the emissions and ambient air. The gas streams may be dried in a series of selectively permeable drying tubes prior to measurement in the analysis devices, in order to effectuate a more precise sample of the constituent elements of the gases. Following analysis, the data collected is processed, stored, and compared, and the results displayed on a screen in the vehicle driver's compartment in a real-time manner. In this fashion, real-time comparative data analysis is presented in a format not presently available.

Owner:HONDA MOTOR CO LTD

Continuous sludge treatment device

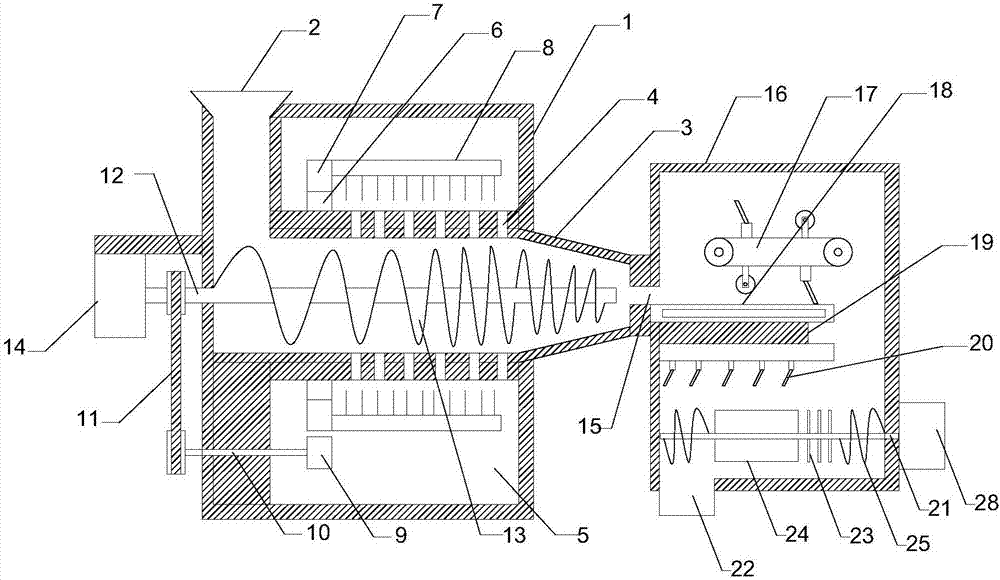

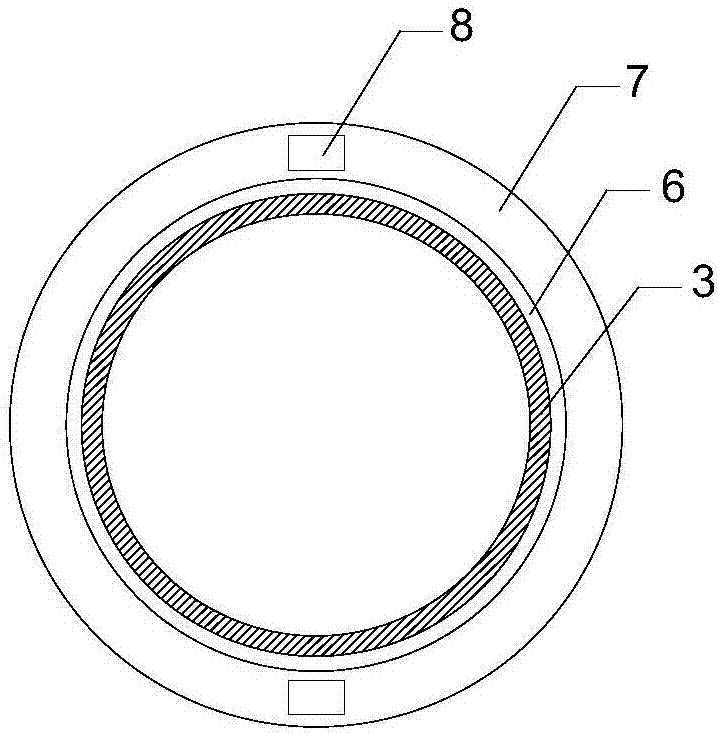

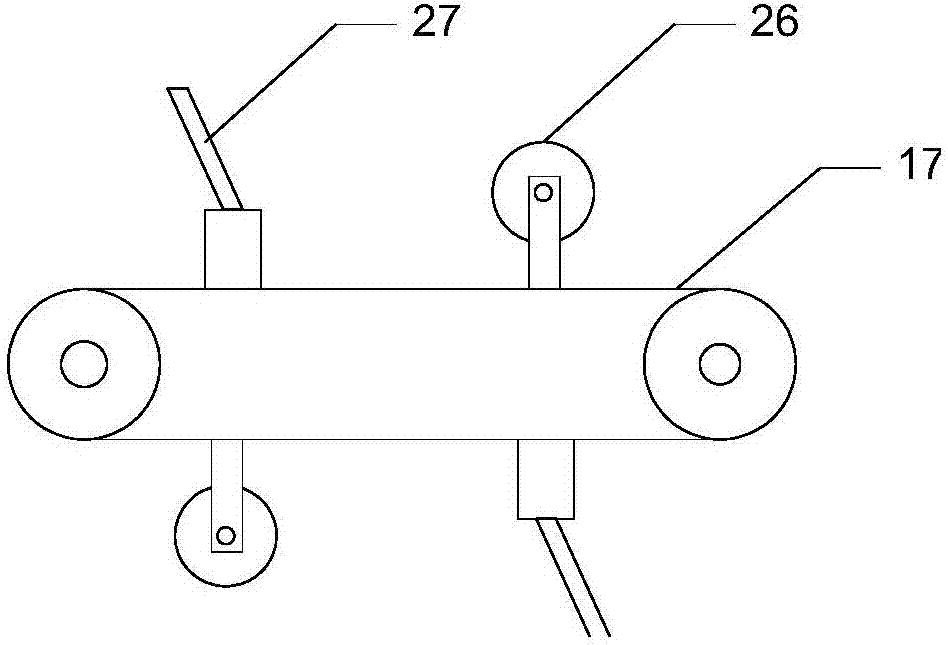

InactiveCN107176780AAvoid cloggingEfficient heatingSludge treatment by de-watering/drying/thickeningSludgePulp and paper industry

The invention discloses a continuous sludge treatment device. The continuous sludge treatment device comprises a feeding hopper, a first driving motor and a second driving motor, wherein the feeding hopper is communicated with a dewatering box, a screen drum is arranged in the dewatering box and sleeved with a rack ring, and the rack ring is rotationally connected with the screen drum through a bearing; strip-shaped brushes which are symmetrically arranged are fixedly connected with the right side wall of the rack ring; a drying box is communicated with the right side of the screen drum through a sludge pipe. With the arrangement of a screw extrusion dewatering device provided with the rotating brushes, sieve meshes are prevented from being blocked, continuous dewatering work is guaranteed, and the continuous sludge treatment device has higher dewatering efficiency; the continuous sludge treatment device is equipped with a drying device consisting of a heating plate, flat spreading rollers and scrapers, therefore, sludge is efficiently and uniformly heated, and drying efficiency is improved; an auxiliary drying device consisting of hot air spray nozzles, smashing blades and a turning plate is arranged, so that the sludge is thoroughly dried, and the drying effect is guaranteed.

Owner:李群珍

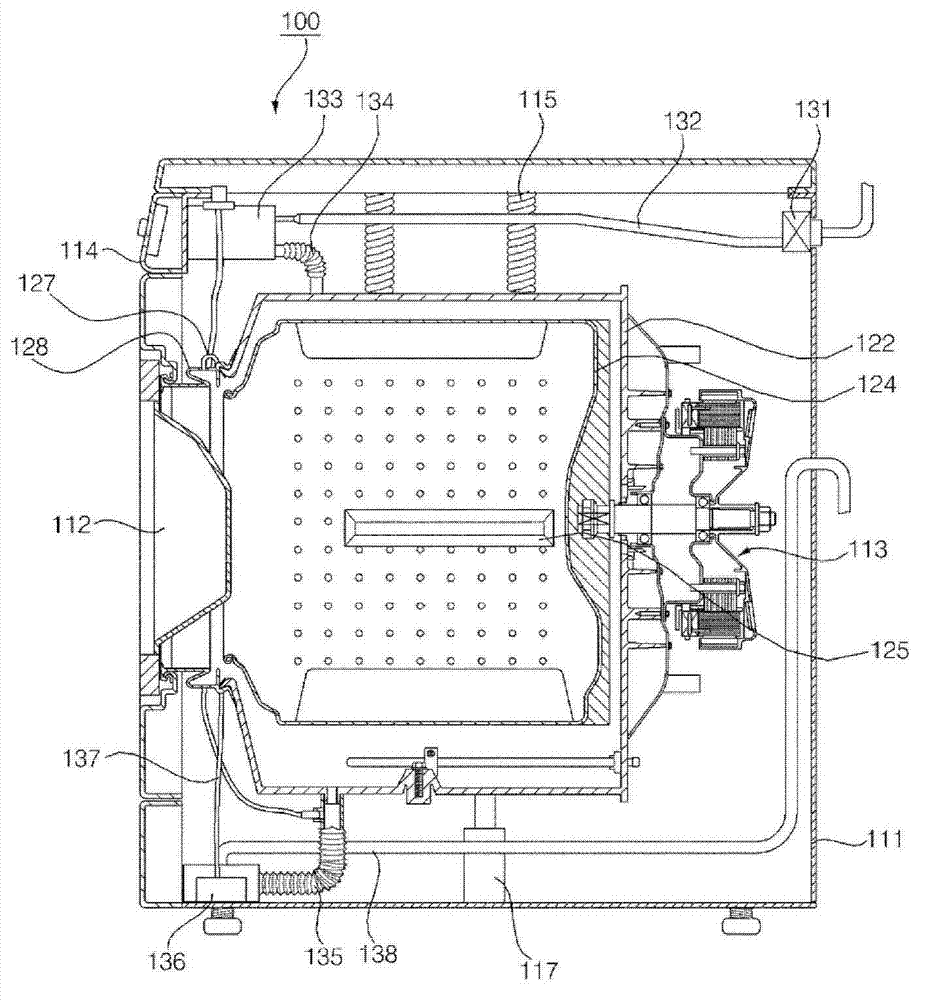

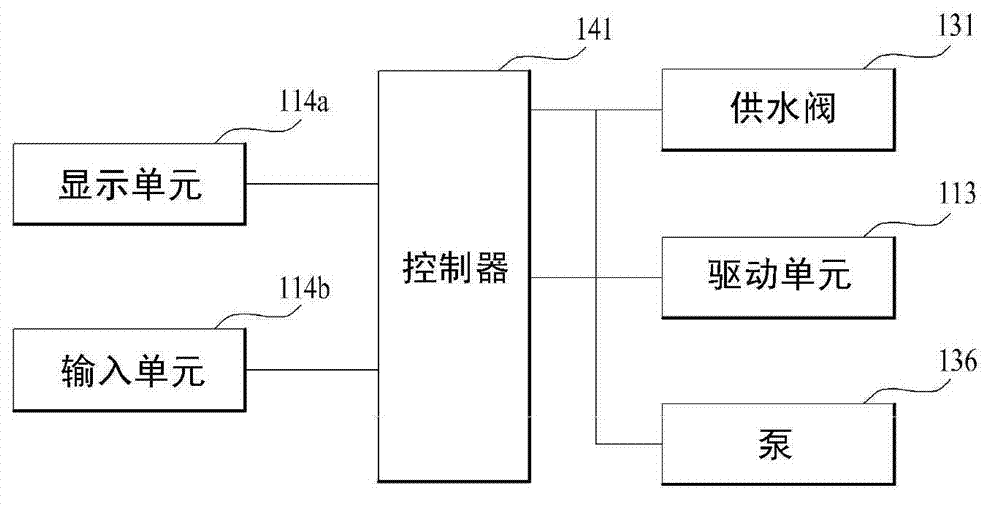

Laundry machine and controlling method thereof

A control method of a clothes treatment apparatus is disclosed, the clothes treatment apparatus having a drying duct (1210), a first blower fan (1230) located in the drying duct (1210) to enable circulation of interior air of the drying duct (1210) and a filter (1250) located in the drying duct (1210), wherein the method includes the steps of sensing clogging of the filter (1250),and switching a flow of air passing through the filter (1250) from a first direction to an opposite second direction if clogging of the filter is sensed. Moreover, the control method may include a washing cycle (200) for washing clothes, and a drying cycle (300) for drying the clothes. The implementation time of the washing cycle (200) is less than the implementation time of the drying cycle (300).

Owner:LG ELECTRONICS INC

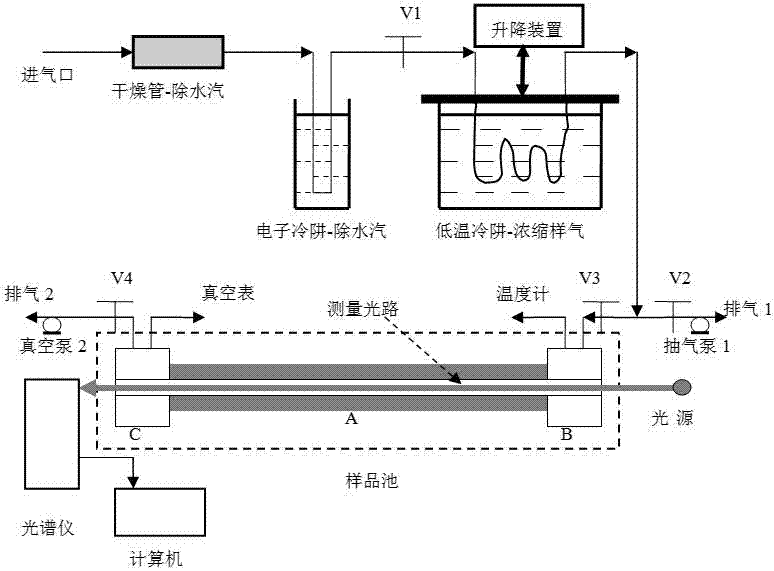

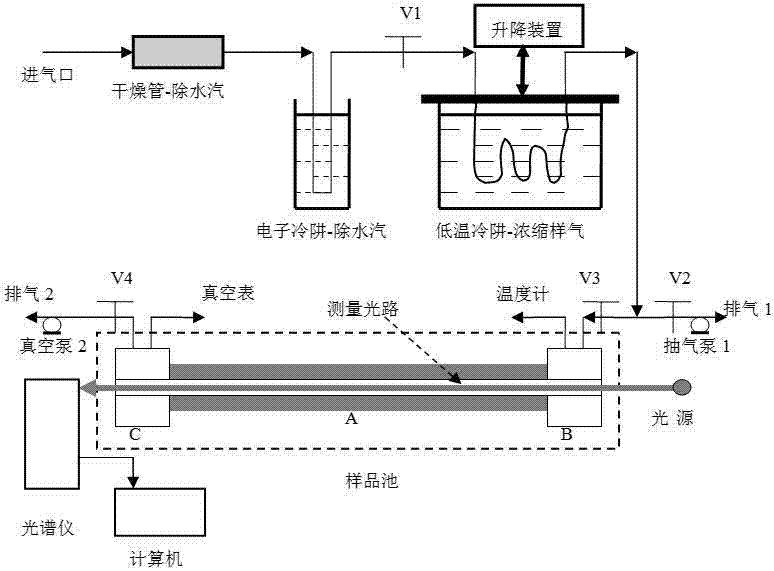

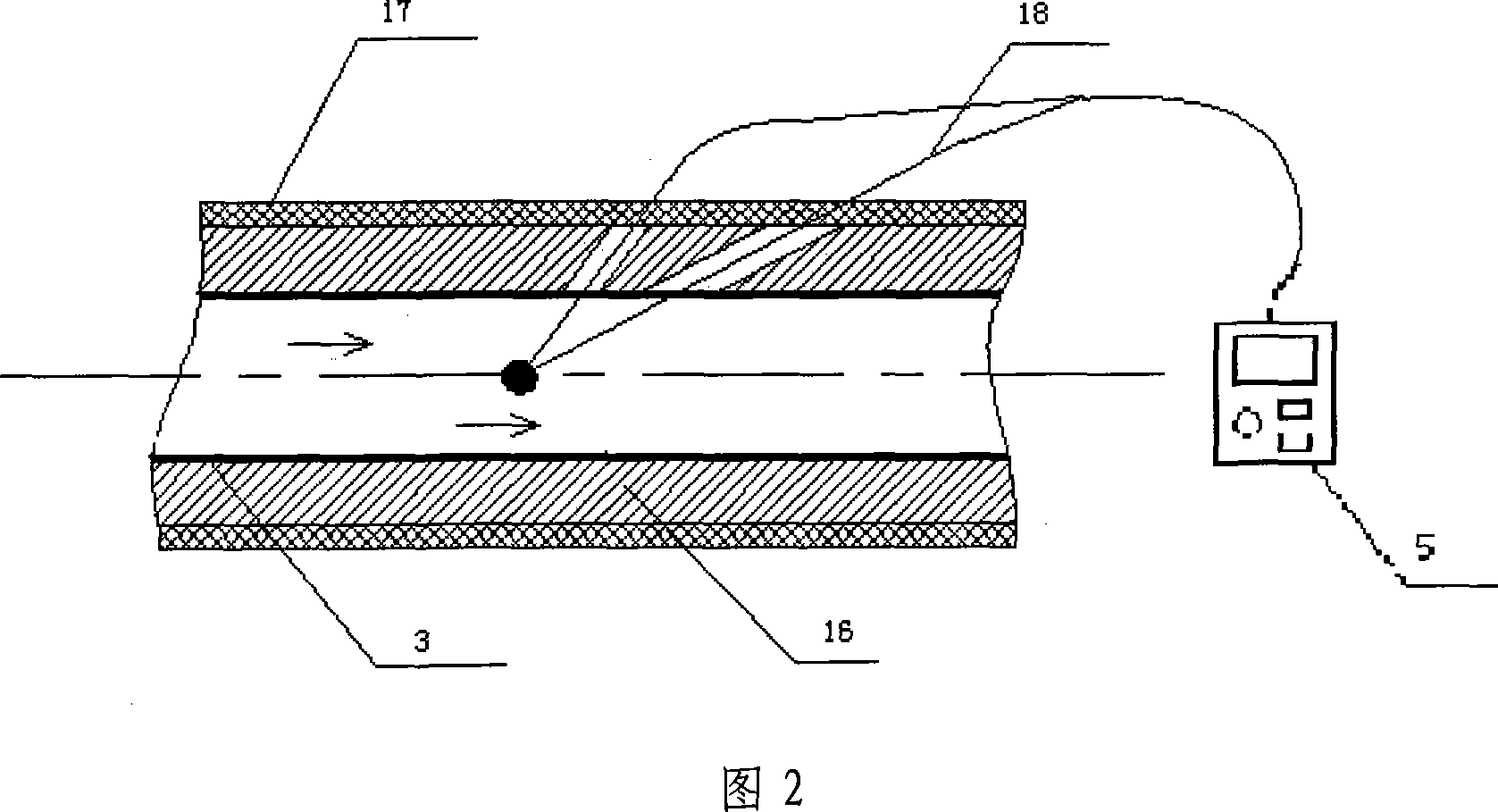

Online automatic measuring system for environment air quality based on low-temperature condensing method sampling

InactiveCN102410986AHigh cost performanceEliminate measurement effectsWithdrawing sample devicesPreparing sample for investigationComputer analysisSulfur dioxide

The invention belongs to the measurement technical field of atmosphere environment quality, which specifically relates to an online automatic measuring system for environment air quality based on low-temperature condensing method sampling. The system is composed of a low-temperature condensing sampling system and an analyzing system; the low-temperature condensing sampling system comprises a drying pipe, an electronic cold trap and a low-temperature low trap that are connected in turn; the drying pipe is connected with an air inlet pipeline for removing vapor and condensing the environment air sample at low temperature; the analyzing system comprises a light source, a sampling battery, an optical spectrum instrument and a computer; the analyzing system splits and detects the air condensed by the sampling system through the optical spectrum instrument by the ultraviolet function from the light source and then analyzes the air by the computer. The system is high in integrated degree and measuring efficiency, which is suitable for continuous, real-time and online measurement of various pollutants of atmosphere environment (including sulfur dioxide, nitrogen dioxide, ozone, ammonia, formaldehyde and part of benzene series) in environment air.

Owner:FUDAN UNIV

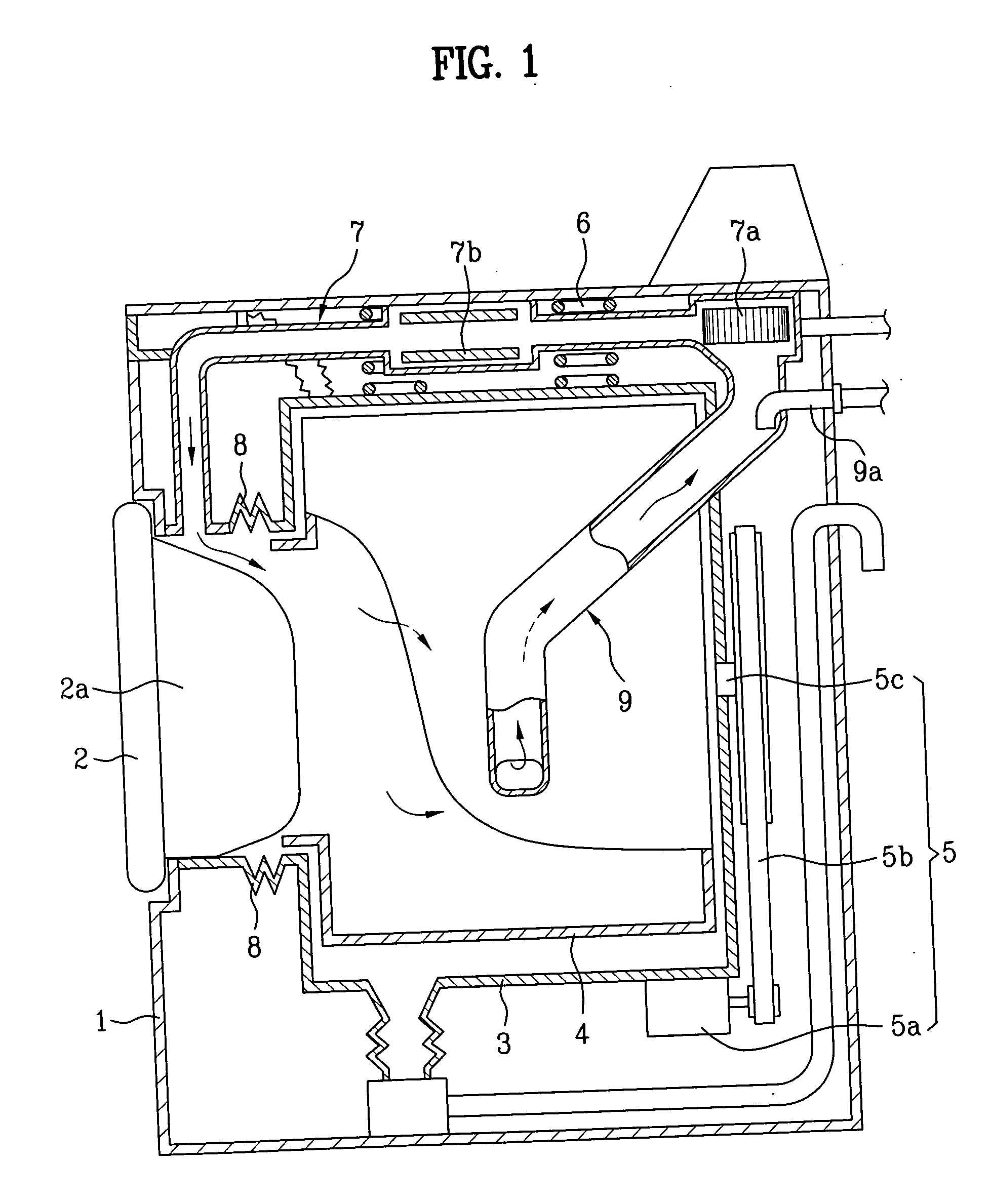

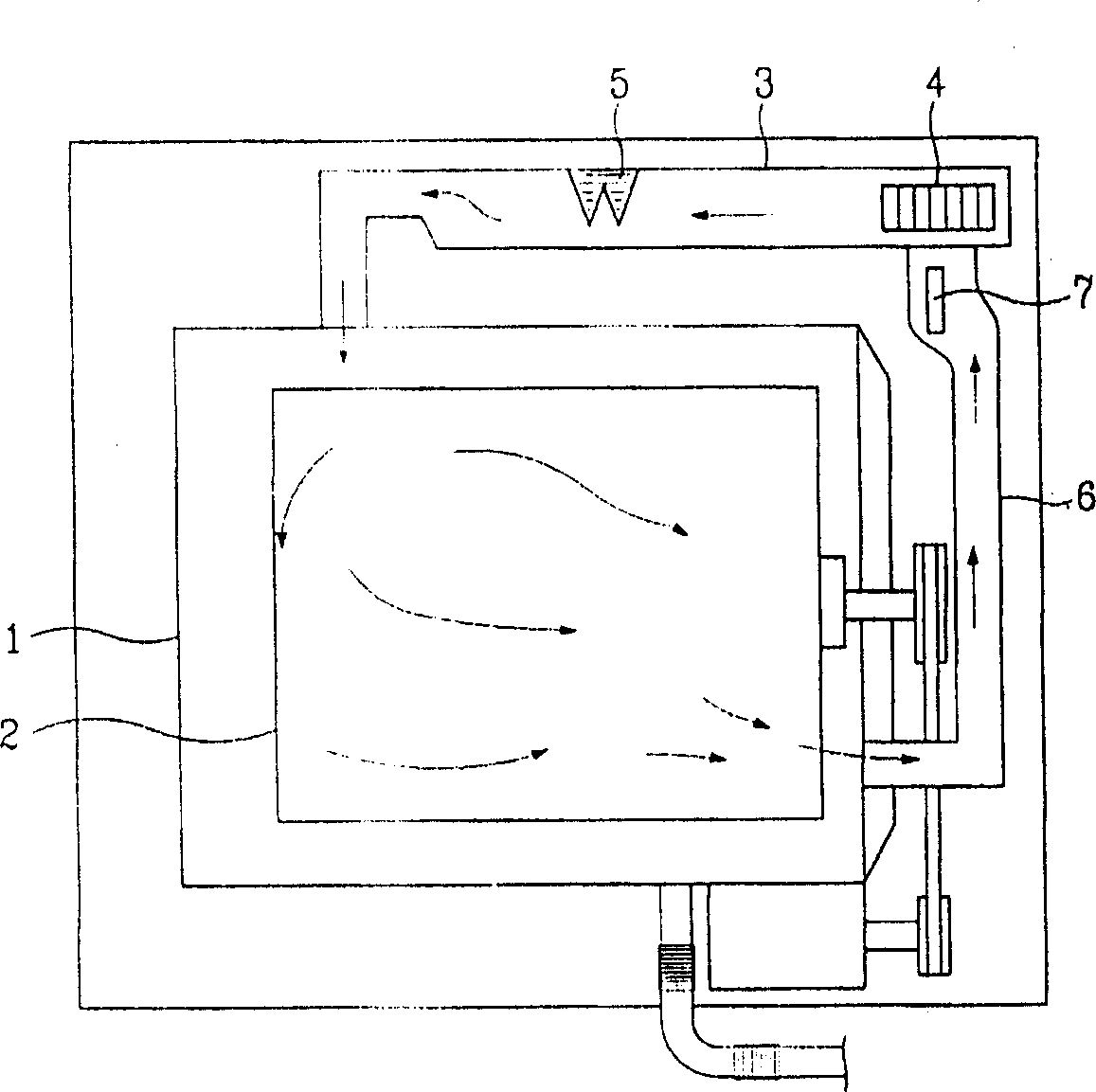

Drying unit for washing machines

InactiveUS20050223583A1Reduce consumptionLiquid/gas/vapor open-width material treatmentDrying gas arrangementsCold airPulp and paper industry

Disclosed herein is a drying unit for washing machines that is capable of fully drying the wet laundry using hot wind. A condensing duct and a drying duct are connected to a tub to circulate air in the tub. Between the drying duct and the condensing duct is disposed a drying fan. To the condensing duct is attached air cooling device for condensing air in the condensing duct by means of cool air. In the drying duct is mounted a drying heater for heating air in the drying duct to change the air into hot wind. During the drying operation of the washing machine, the air passing through the condensing duct is condensed by air, which is an unlimited resource. Consequently, consumption of energy and resources is minimized during the drying operation of the washing machine.

Owner:LG ELECTRONICS INC

Cooling assembly

InactiveUS20050076665A1Easy to transportEfficient and reliable and economical and simple and effectiveFree-cooling systemsStationary conduit assembliesEvaporative coolerShell and tube heat exchanger

A process and the required apparatus for air conditioning the interior of a structure is shown which can be run entirely off a DC power source, such as a storage battery. A shell and tube heat exchanger is combined with a mechanical refrigeration system to provide a wet shell side and a dry tube side of the apparatus. In the operation of the air conditioner, a mass of distributed water is established on the wet shell side, and a flow of ambient air is passed through the wet shell side to form a resulting stream of moist air. A flow of ambient air is passed through the dry tube side and a resulting stream of dry cooled air is recovered. The streams of most and cooled air can either be combined or routed separately depending primarily upon the humidity of the surrounding environment to be cooled. The air conditioning unit is not hermetically sealed and the water consumption rate is generally less than that required for a conventional evaporative cooler.

Owner:GPM INC

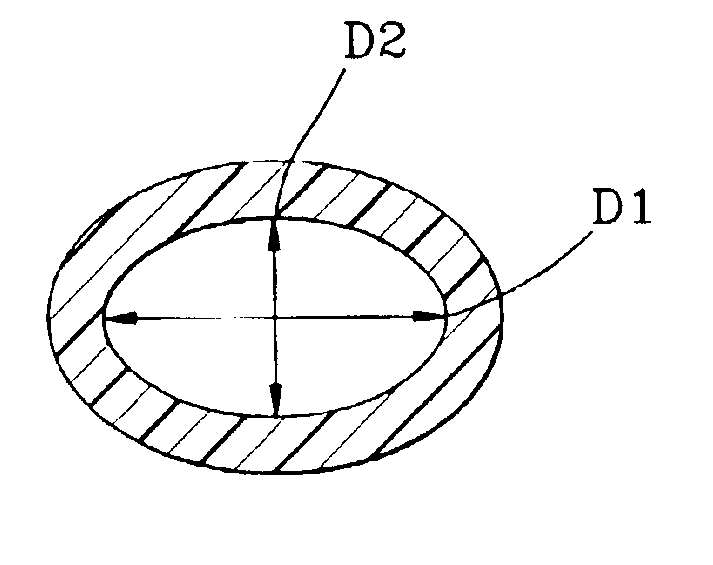

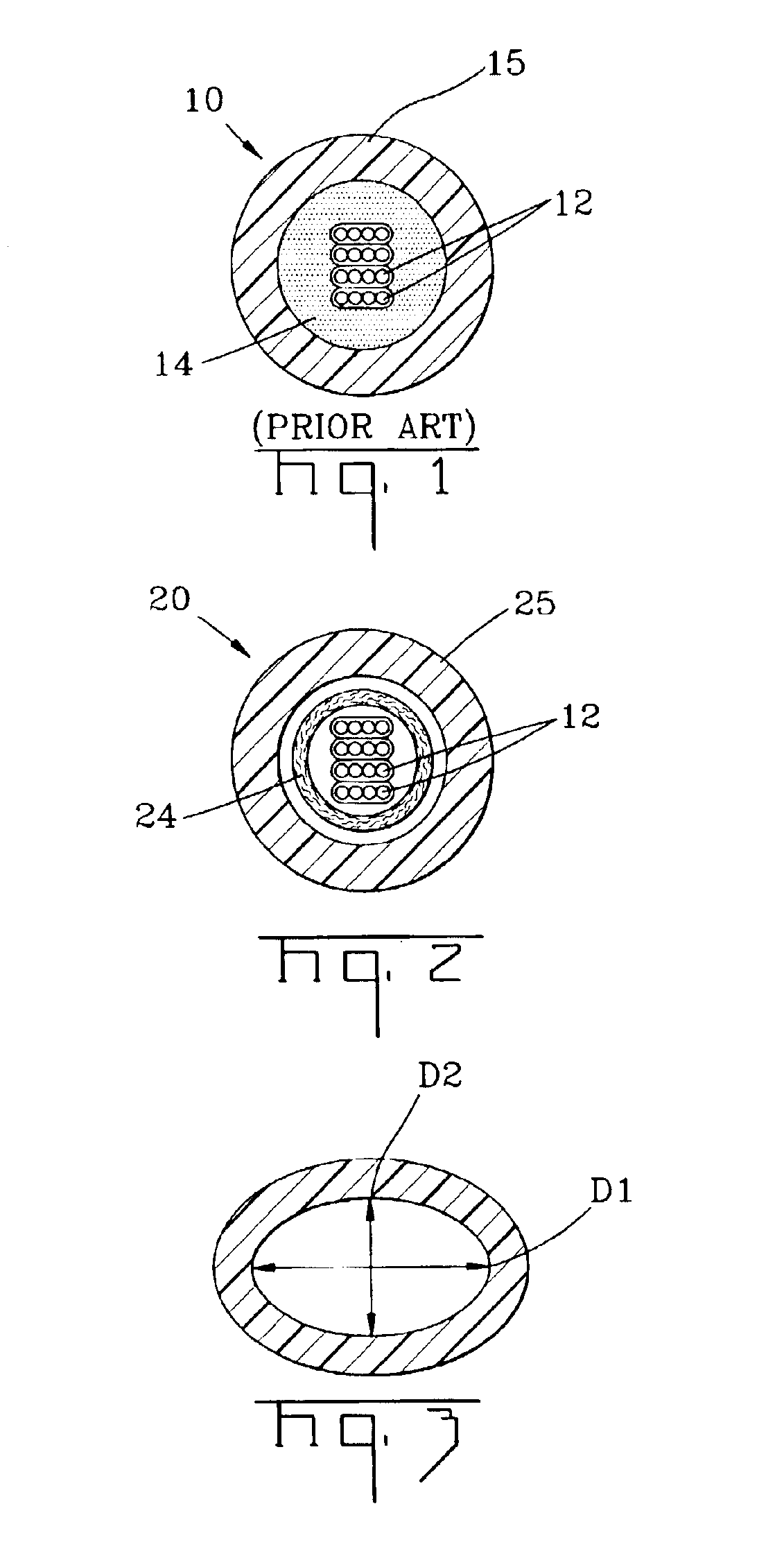

Dry tube fiber optic assemblies, cables, and manufacturing methods therefor

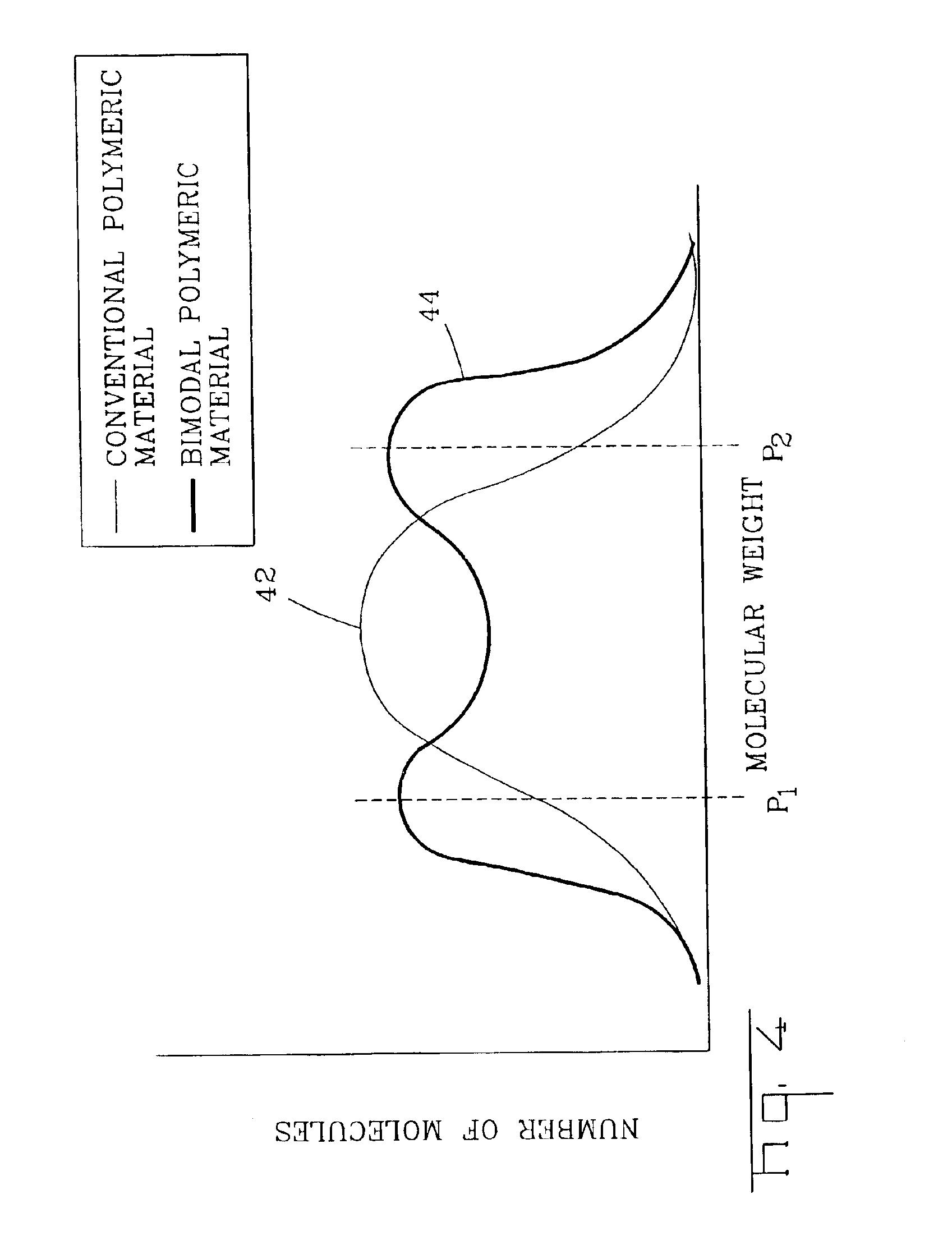

A fiber optic dry tube assembly and a method of manufacturing the same includes at least one optical waveguide and a tube. The tube houses at least a portion of the at least one optical fiber and is formed from a bimodal polymeric material. The tube has an average ovality of about 10 percent or less. In other embodiments, the bimodal polymeric material that forms the tube has a melt index of about 1.0 g / 10 minutes or less, a melt strength in the range of about 8 cN to about 35 cN at 190° C,. and / or a polydisperity of about 7 or greater. Additionally, the dry tube assemblies of the present invention can form a portion of a cable.

Owner:CORNING OPTICAL COMM LLC

System and method for measuring evolution rate of radon

InactiveCN105425267AReliable measurementGood measurement needsRadiation intensity measurementSoil scienceDielectric surface

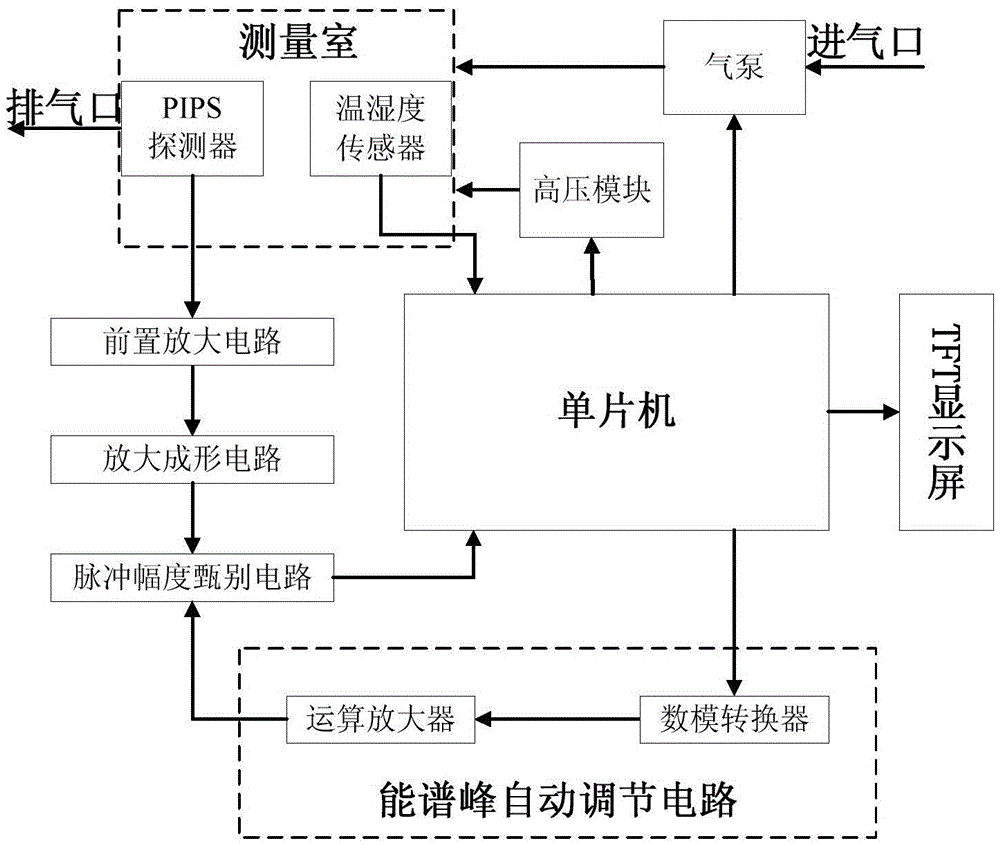

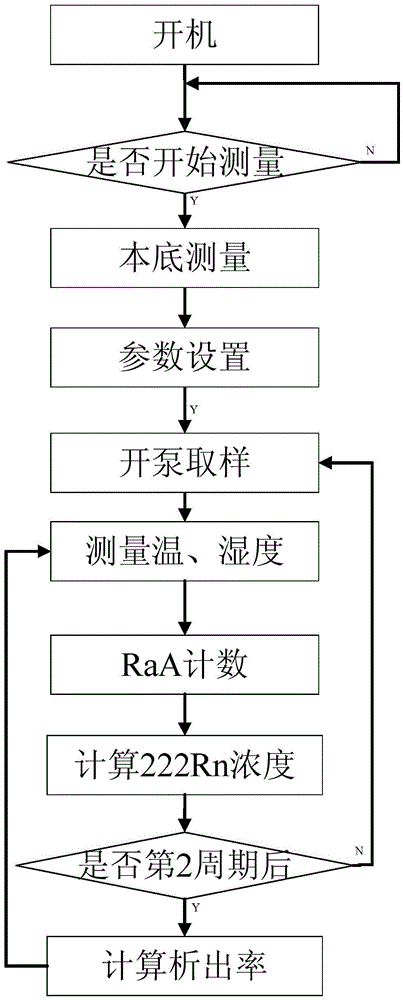

The invention discloses a system and method for measuring the evolution rate of radon. The system does not need a drying tube to dry sample gas, thereby reducing the impact on the evolution rate of radon of the internal dielectric surface of a radon collection cover from a drying agent. In a natural environment, a measurement instrument can accurately measure the instantaneous concentration of radon, and does not need to correct the measured concentration of radon for calculation. The measurement instrument can automatically solve the evolution rate of radon through the measured concentration of radon, and can obtain the value of the evolution rate of radon with no need of a PC for linear fitting processing. An experiment indicates that the measurement error of the radon evolution rate measurement instrument is within the range 5% on a radon evolution rate standard device. After measurement, the evolution rate of radon is directly obtained, thereby meeting the demands of on-site measurement of the evolution rate of radon. The system and method are easy to implement, and are high in measurement efficiency.

Owner:NANHUA UNIV

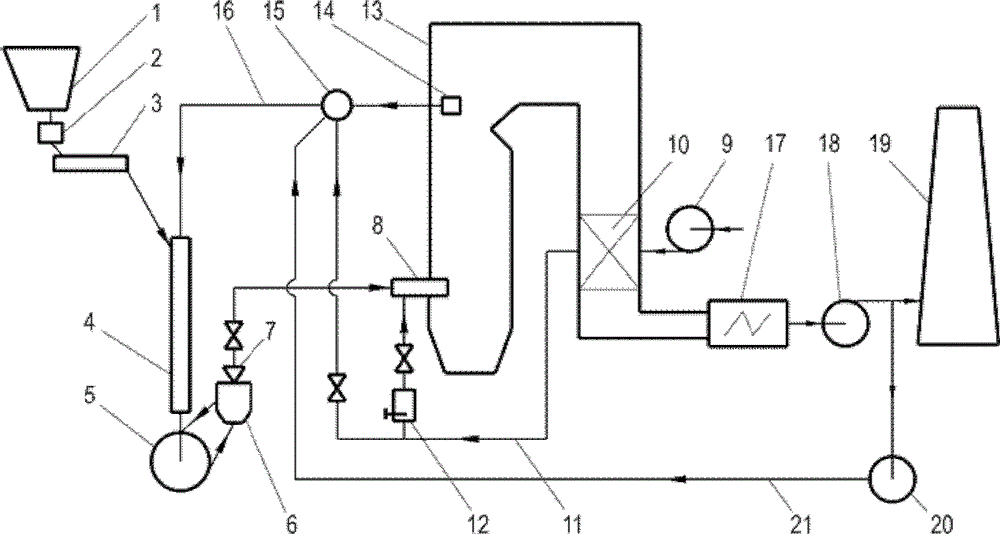

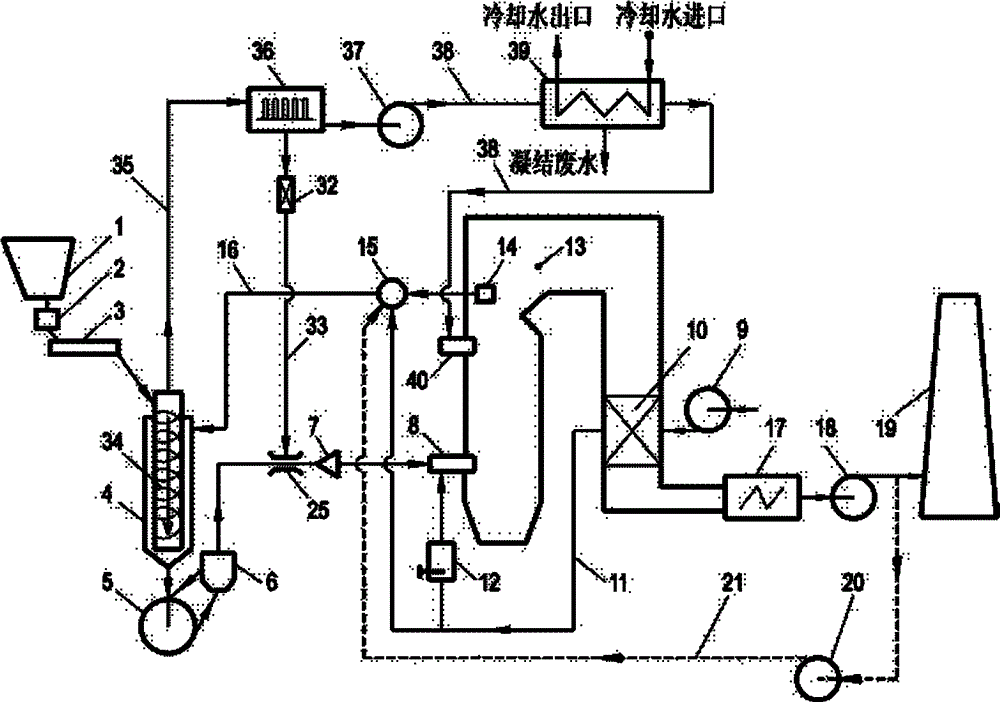

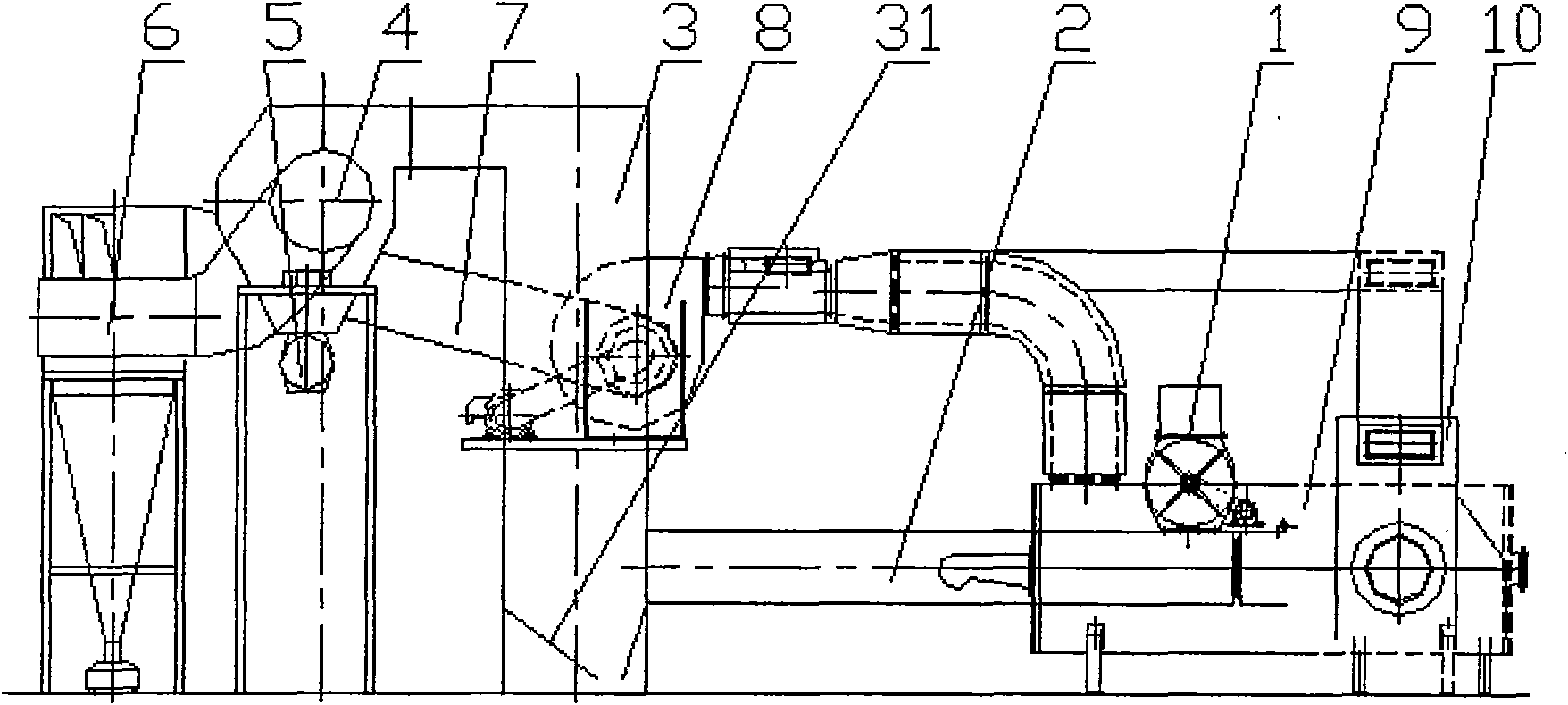

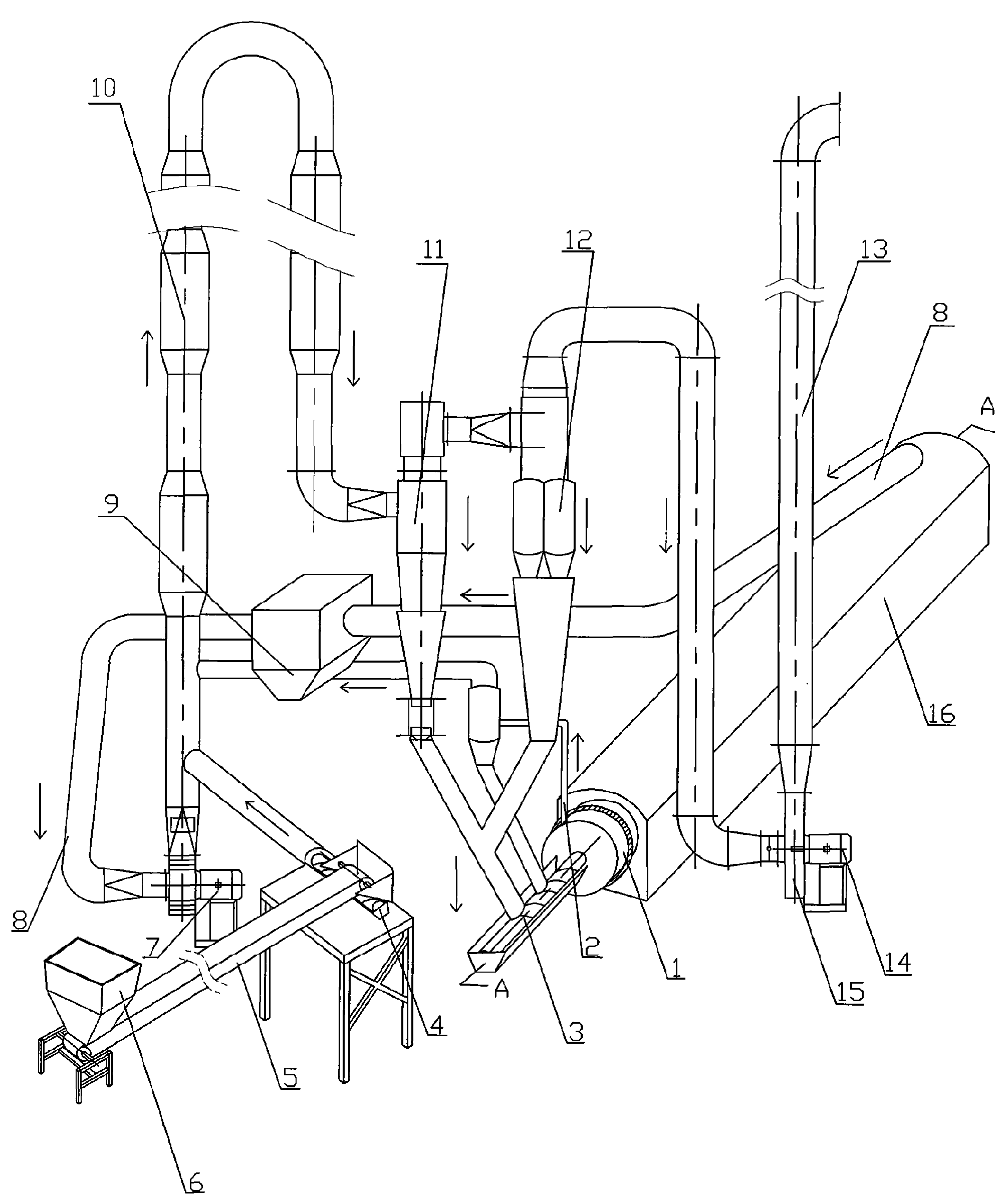

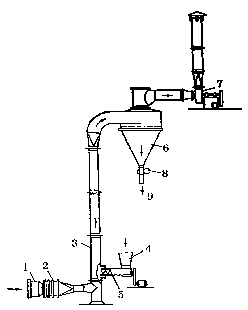

Fan mill front counter flow type furnace-smoke drying dewatering direct blowing pulverization system

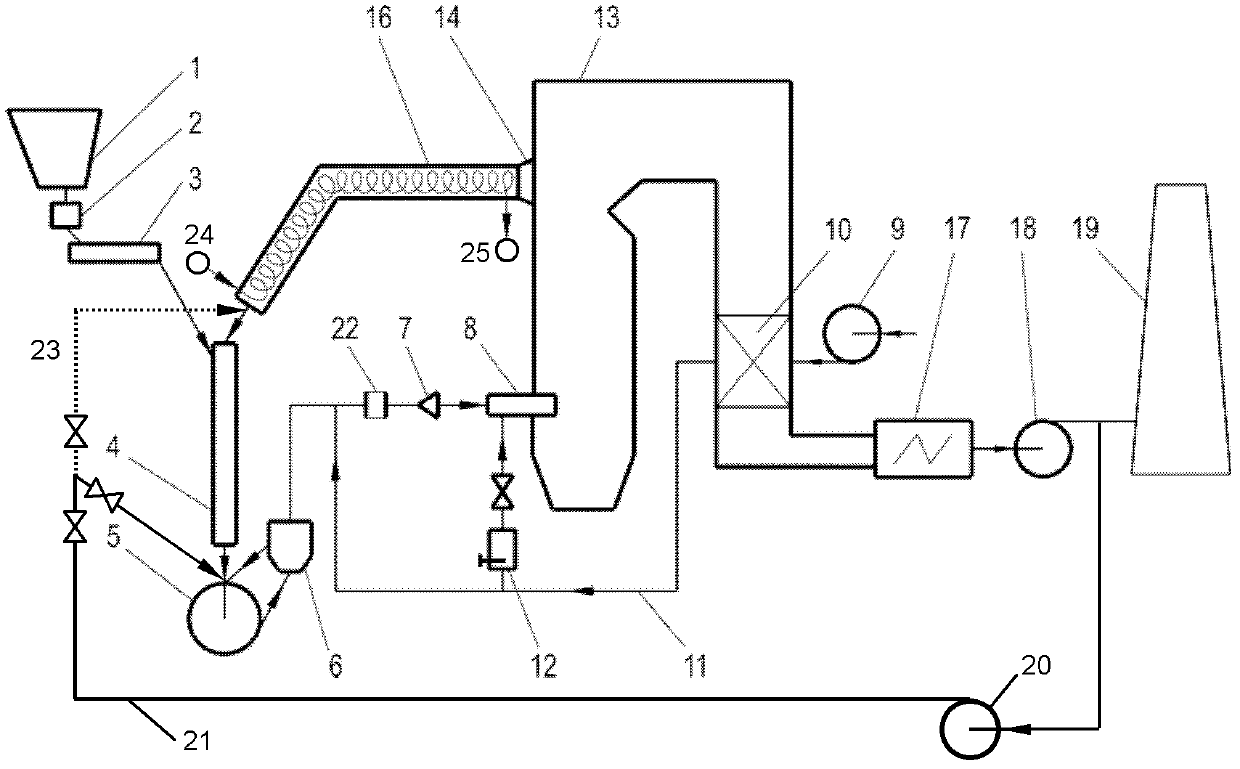

ActiveCN102798132AImprove combustion qualityReduce volumeSolid fuelsLump/pulverulent fuel feeder/distributionBrown coalCounter flow

The invention discloses a fan mill front counter flow type furnace-smoke drying dewatering direct blowing pulverization system. A pulverized coal mixer is arranged between a coarse powder separator and a pulverized coal distributor. The upper part of the lower drying pipe is provided with a coal gas outlet which is communicated with a coal gas filter. A coal outlet of the coal gas filter is also communicated with the pulverized coal mixer, a gas outlet of the coal gas separator is communicated with a coal gas fan, the coal gas fan is also communicated with a coal gas cooler, the coal gas cooler is provided with a condensation water outlet and a coal gas outlet, and the coal gas outlet is communicated with a coal gas burner of a boiler. The fan mill front counter flow type furnace-smoke drying dewatering direct blowing pulverization system has advantages of improving the burn-up quality of brown coal so as to enhance the thermal efficiency of the coal, recovering a large quantity of water vapor, obviously reducing the size and the manufacturing cost of the boiler, realizing zero pollution discharge and the like.

Owner:NORTHEAST ELECTRIC POWER DESIGN INST CO LTD OF CHINA POWER ENG CONSULTING GRP +1

Method for preparing epoxy chloropropane by using glycerol method

This invention discloses a glycerol method for preparing epoxy chloropropane. The method comprises: (1) introducing dried HCl gas through 95% glycerol at 90-110 deg.C in the presence of absolute acetic acid, and reacting for 1-3 h; (2) adding the obtained dichloropropanol into a round bottom flask loaded with solid super-strong alkali catalyst, equipping condensing and drying tubes, stirring, heating to 70-90 deg.C, reacting for 3-5 h, filtering, and separating the catalyst to obtain chloropropane.

Owner:INST OF CHEM IND OF FOREST PROD CHINESE ACAD OF FORESTRY +1

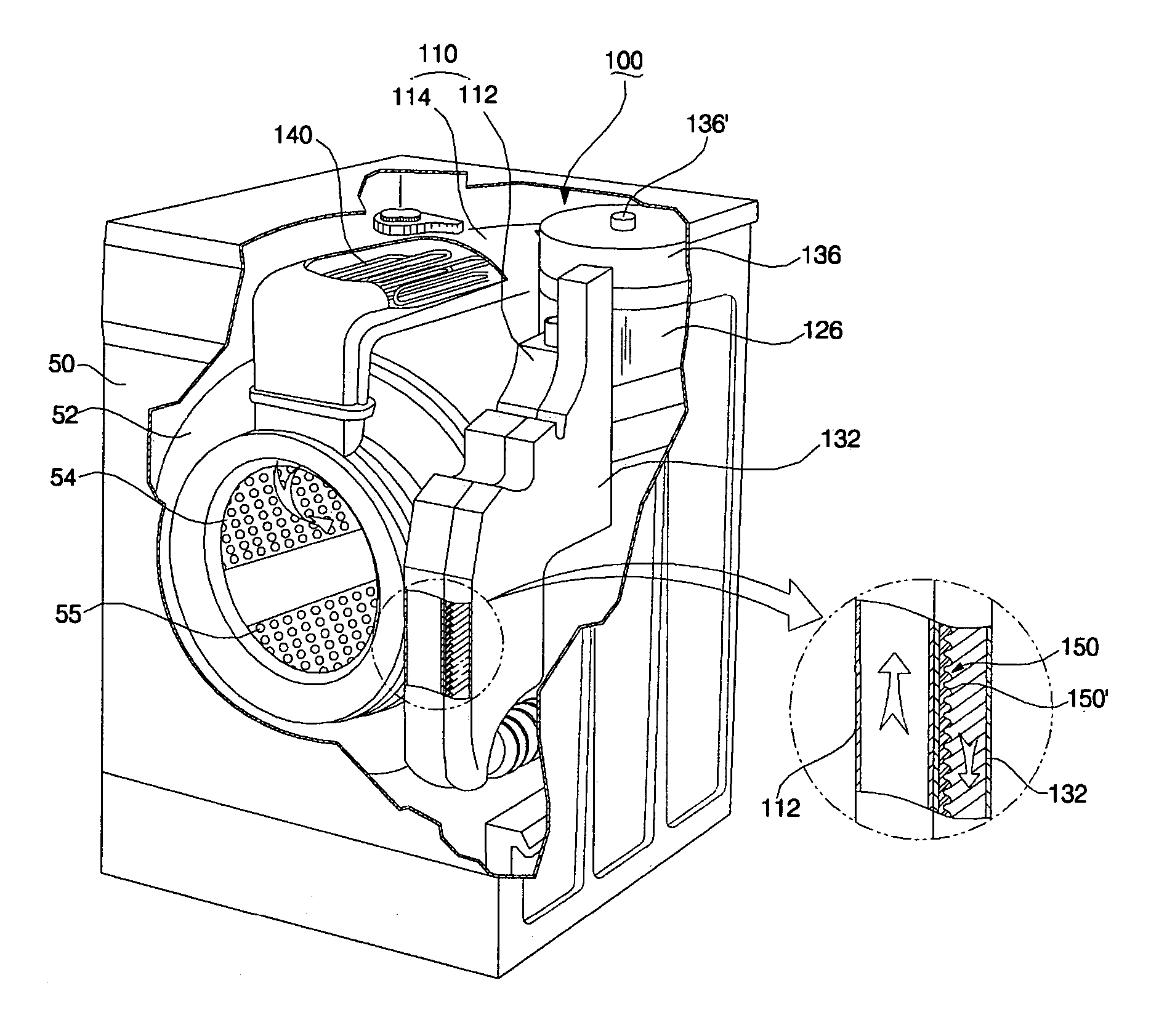

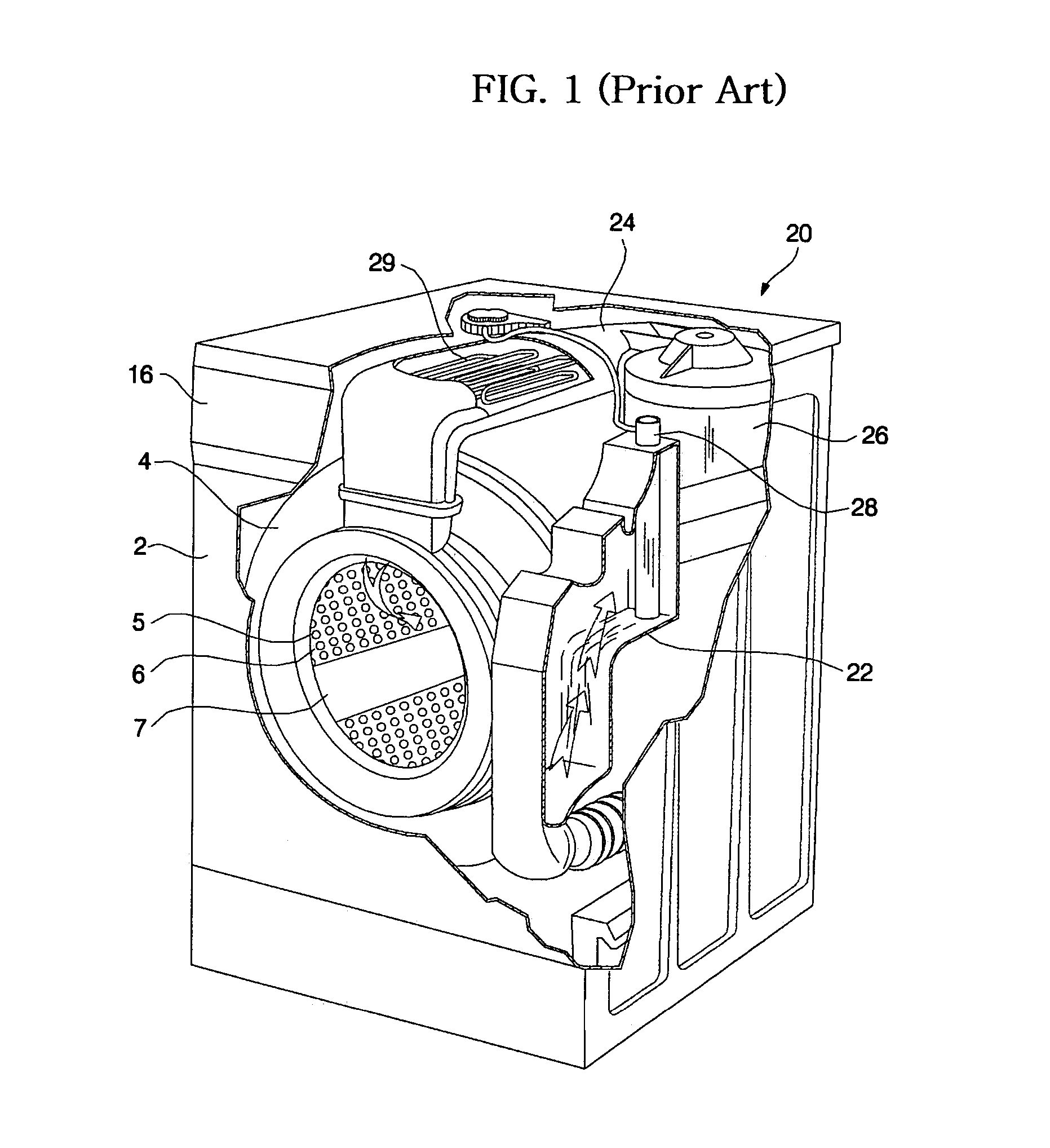

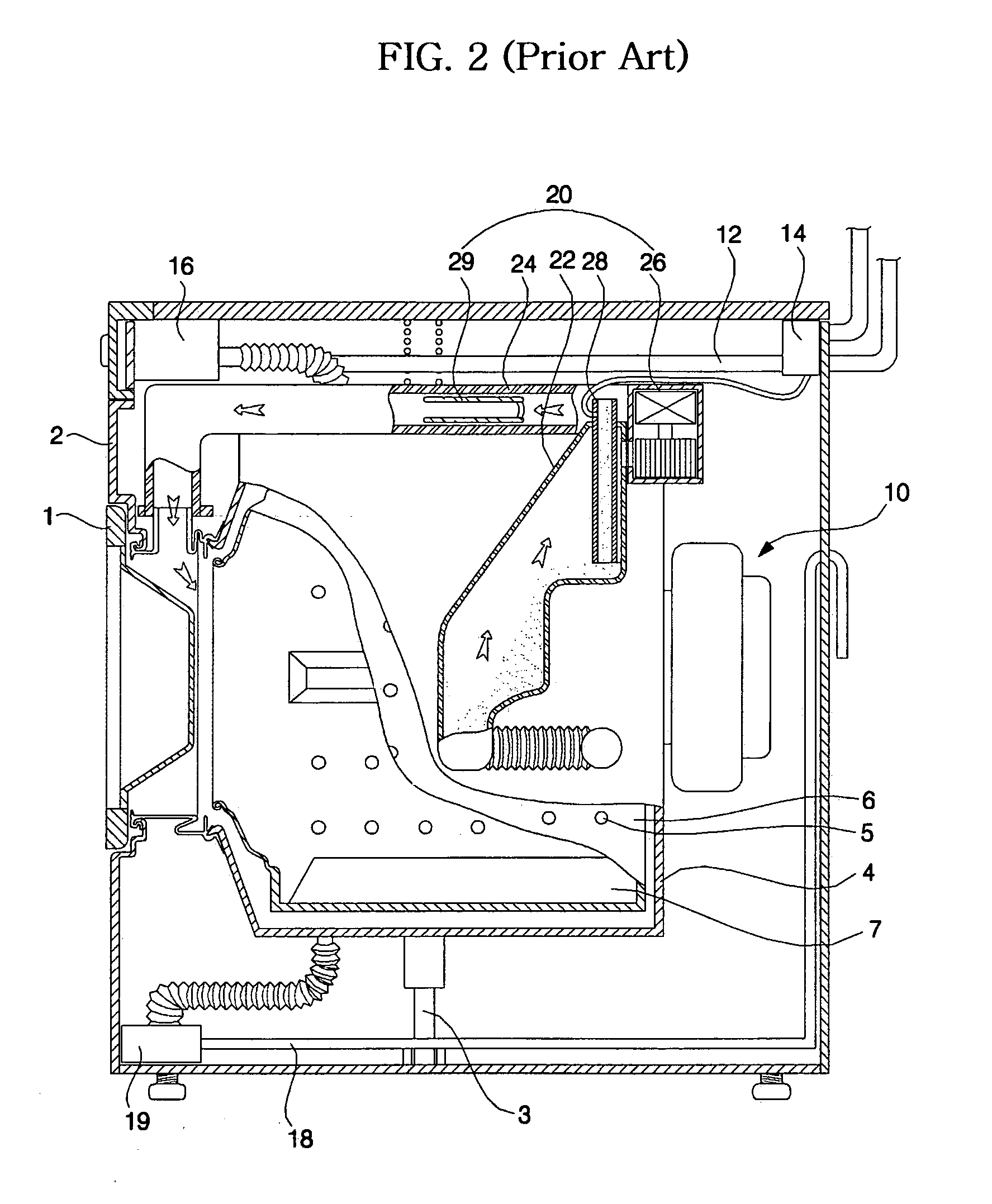

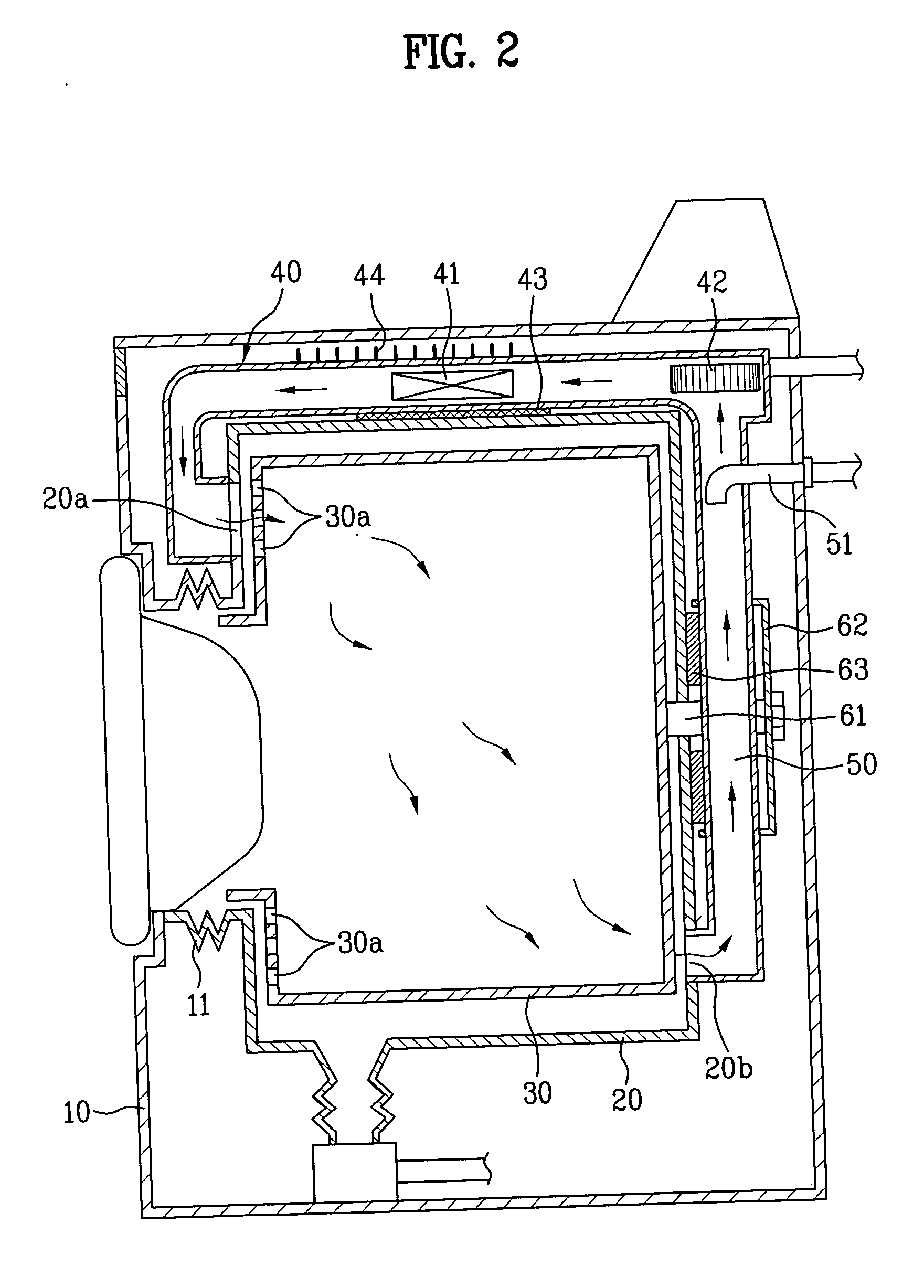

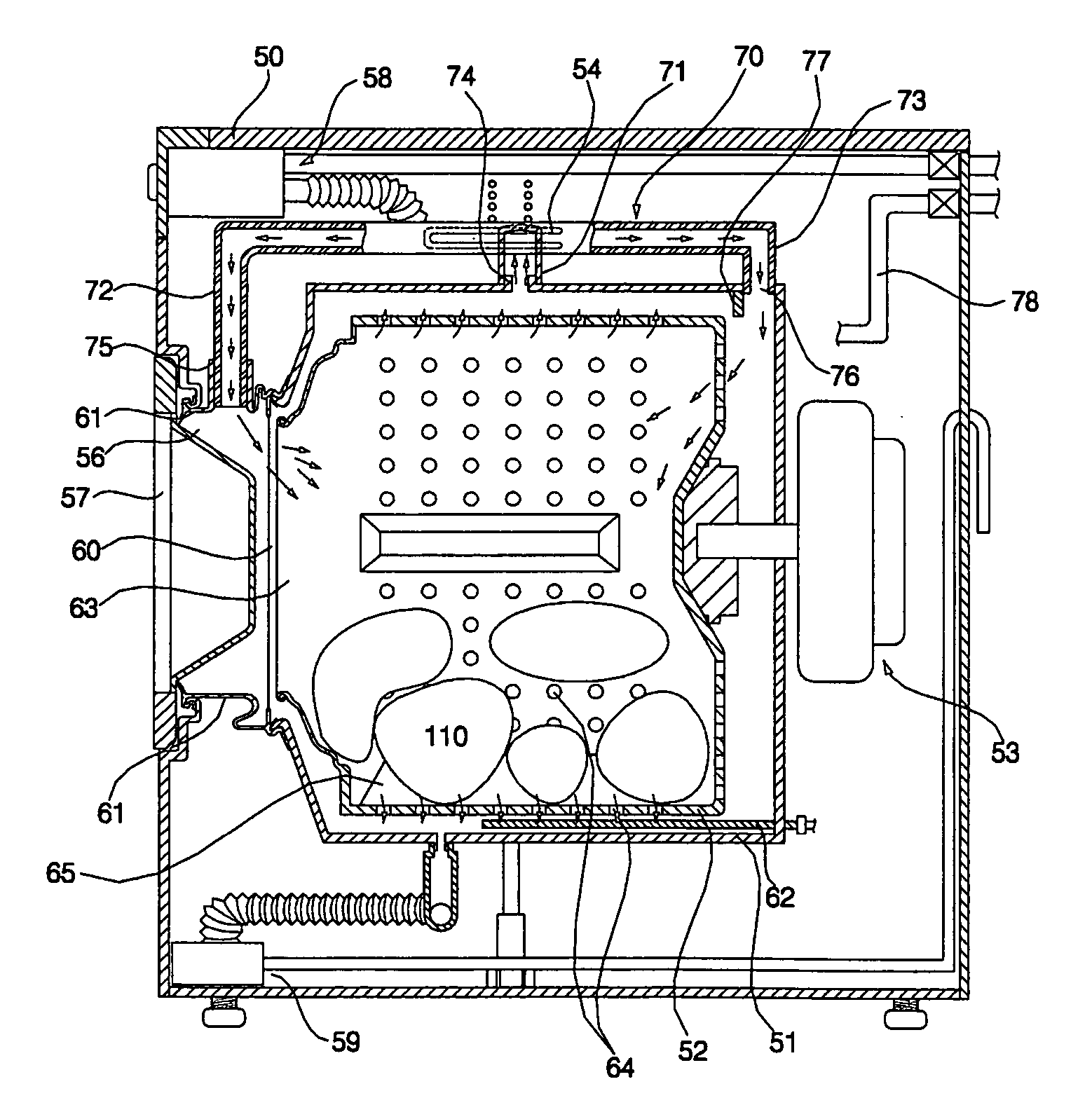

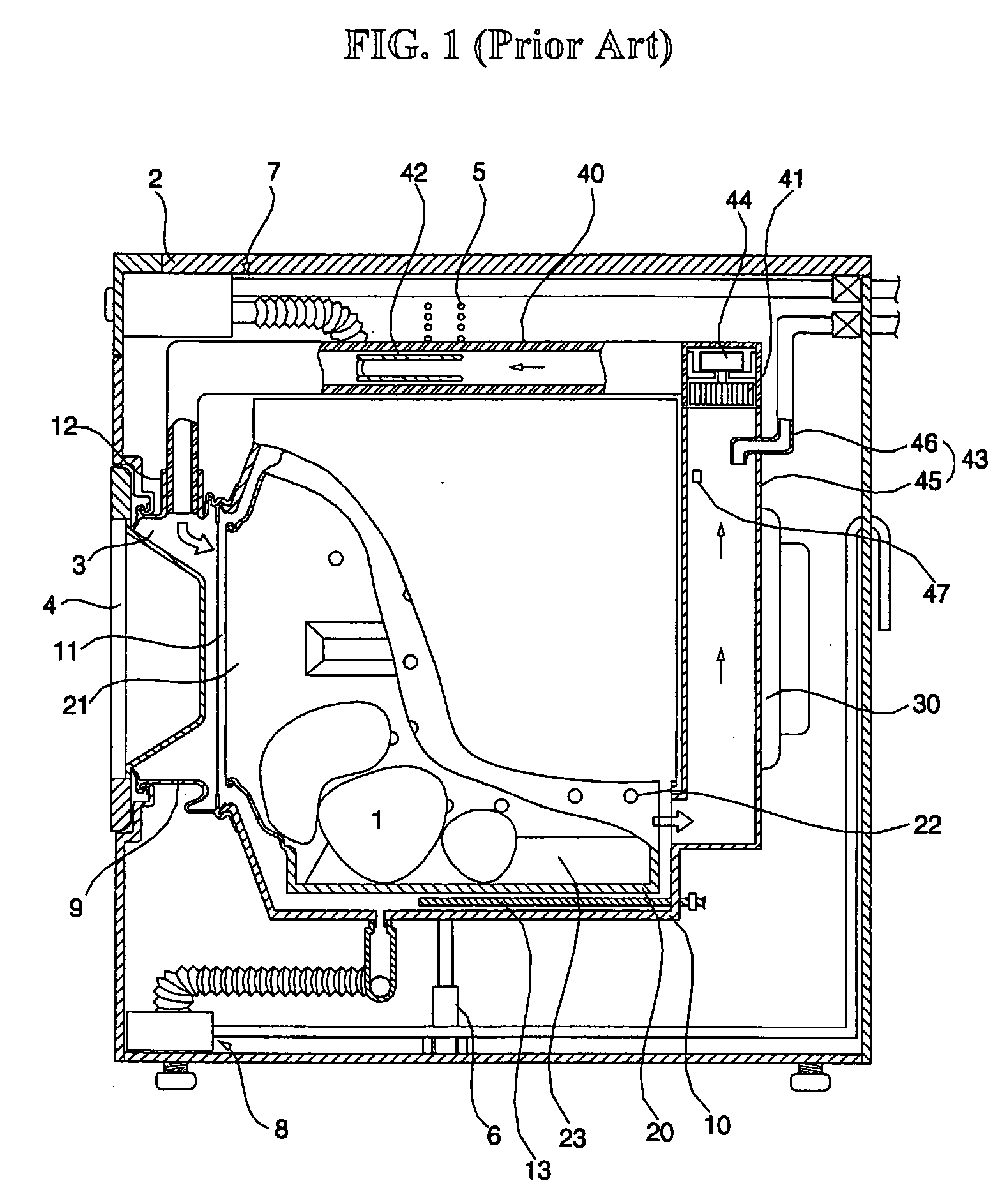

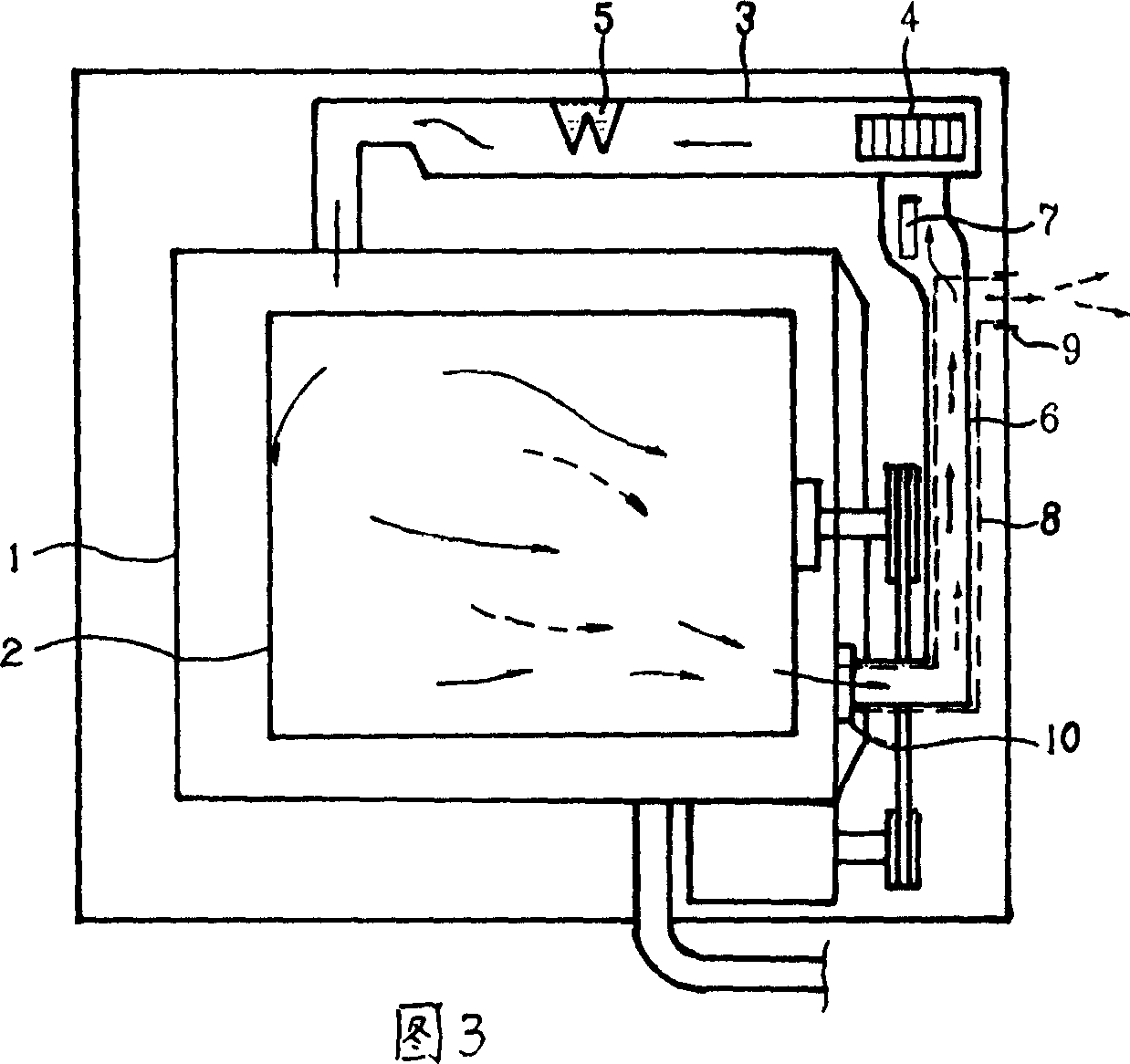

Heat shield fastening structure for drum type washing machine with laundry drying function

InactiveUS20050262885A1Simple structureImprove efficiencyOther washing machinesWashing machine with receptaclesEngineeringLaundry

Provided is a drum type washing machine combined with a dryer and employing an improved air passage structure that can enhance the drying efficiency and drying performance, in particular, that can prevent a tub from being deformed due to heat of a heater of the drying duct. The washing machine includes: a cylindrical plastic tub having a hot air inlet formed at a front upper portion thereof and a hot air outlet formed at a rear lower portion thereof; a drum rotatably installed inside the tub; a drying duct provided with a heater and a blower fan that are mounted on an inner air passage of the drying duct and fixed to an upper predetermined portion of an outer circumference of the tub; a condensation duct for removing moisture contained in hot air exhausted through the hot air outlet of the tub; and a heat shield interposed between the tub and the drying duct, for shielding heat of the drying duct from being transferred directly to the tub.

Owner:LG ELECTRONICS INC

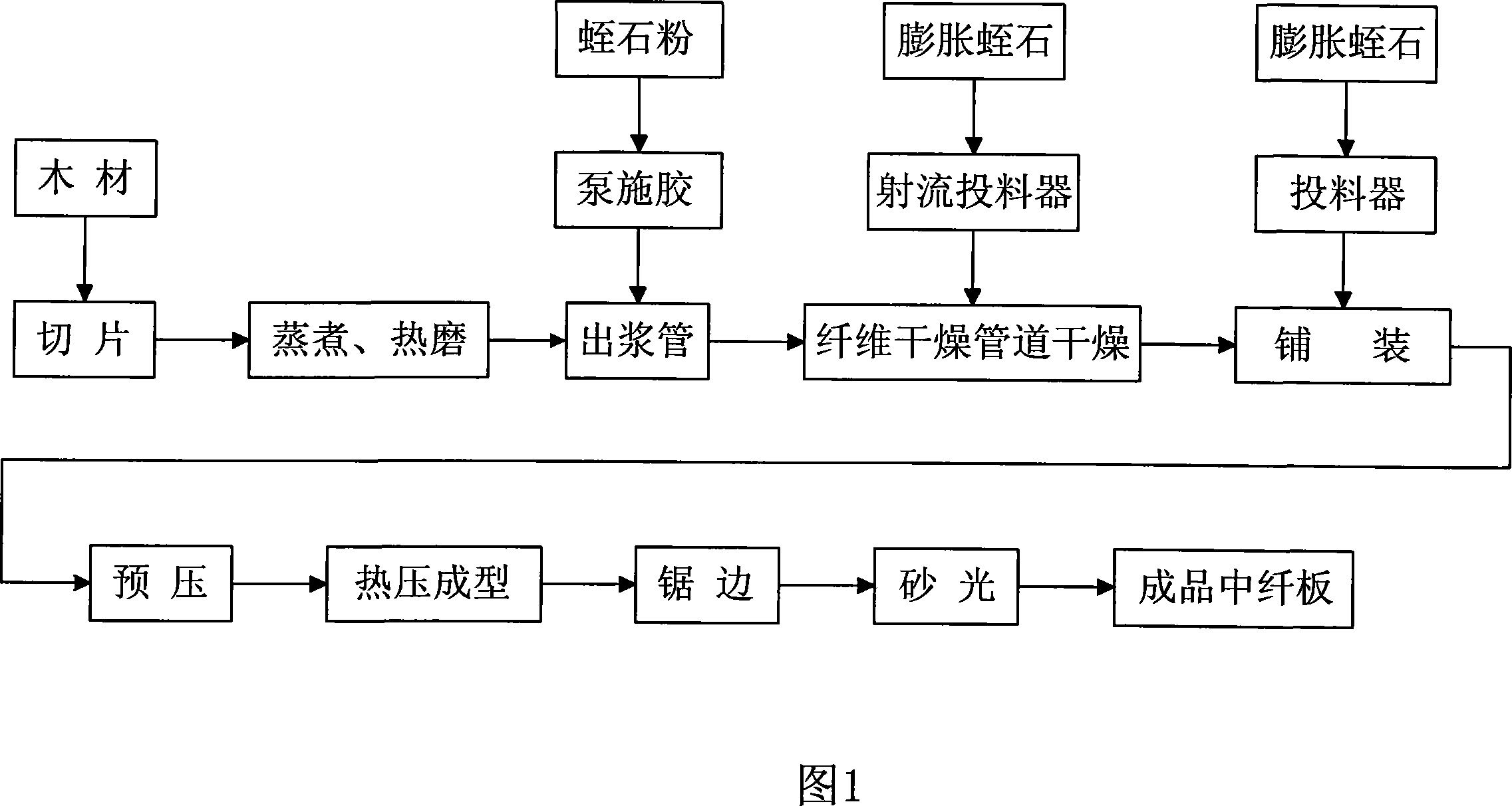

Flame retardant medium density fiberboard and manufacturing method therefor

InactiveCN101108503AReduce pollutionReduce manufacturing costDomestic articlesFlat articlesFiberMedium density fiberboard

The invention relates to a middle intensity fiber board with fire resistance performance, which comprises a wood fiber material, glue agent and fire resistance material. The fire resistance material is swelled vermiculite grain, the adding volume of the swelled vermiculite grain is 20 to 80 per cent of the absolute dry fiber material, the adding volume of the glue agent is 15 to 20 per cent of the absolute dry fiber material. Vermiculite powder is added in the fire resistance material. The method of producing the invention is that: cut the wood material into plate; the breakage material is dissolved into wood pulp by steaming and boiling and heat milling in the heat milling machine; proceed adding and mixing glue to the wood pulp; dry in a fiber drying tube; adopt a performing machine to proceed pressing into board adobe after pavement on a paving machine; the board adobe is pressed rough adobe board; the rough adobe board forms a intensity fiber board after sawing edge and sanding, before the wood fiber enters the pavement procedure, add swelled vermiculite grain or swelled vermiculite grain, vermiculite powder fire resistance material. The invention has the advantages of lightness, little pollution to environment and low manufacturing cost.

Owner:吉发

Cooling assembly

InactiveUS20060032258A1Easy to transportEfficient and reliable and economical and simple and effectiveFree-cooling systemsStationary conduit assembliesShell and tube heat exchangerEngineering

An apparatus for air conditioning the interior of a structure is shown which can be run entirely off a DC power source, such as a storage battery. A shell and tube heat exchanger is combined with a mechanical refrigeration system to provide a wet shell side and a dry tube side of the apparatus. In the operation of the air conditioner, a mass of distributed water is established on the wet shell side, and a flow of ambient air is passed through the wet shell side to form a resulting stream of moist air. A flow of ambient air is passed through the dry tube side and a resulting stream of dry cooled air is recovered. The streams of most and cooled air can either be combined or routed separately depending primarily upon the humidity of the surrounding environment to be cooled.

Owner:GPM INC

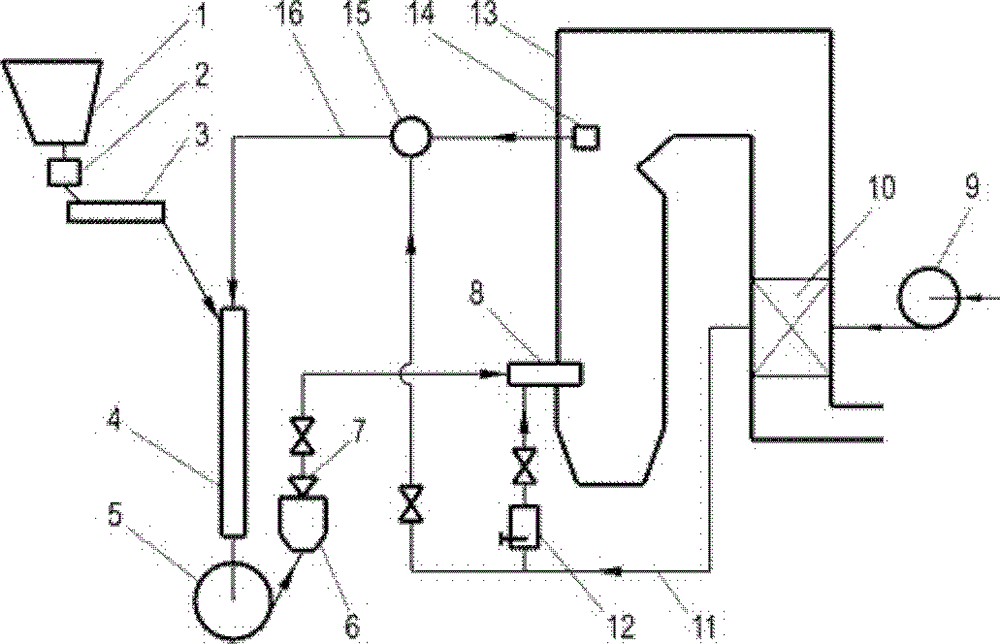

Direct fired pulverizing system of smoke drying lignite coal fan mill

ActiveCN102889607AGuaranteed temperatureReduce ventilationDrying gas arrangementsLump/pulverulent fuel preparationBoiler furnaceProcess engineering

The invention discloses a direct fired pulverizing system of a smoke drying lignite coal fan mill, which comprises a high temperature furnace smoke pipe and a hot wind mixer, wherein the high temperature furnace smoke pipe is formed by arranging a cluster of circular pipes in parallel to form a flue; the circular pipes are located in a vapor-water circulating system of a power plant; an outlet of the high temperature furnace smoke pipe is communicated with a down drying tube; an inlet is communicated with a hot smoke pumping port of a boiler furnace; the hot wind mixer is connected between a classifier and a pulverized coal distributer; the other route of the hot wind device is connected to the hot wind mixer; and a coal inlet of the fan coal mill is further connected with a cool smoke pumping port of the boiler flue. The direct fired pulverizing system of the smoke drying lignite coal fan mill has the advantages of safety in operation, simple structure, low investment and being capable of effectively utilizing heat energy of high-quality smoke.

Owner:SHANGHAI YUANMENG ELECTRIC POWER ENERGY TECH CONSULTING CENT

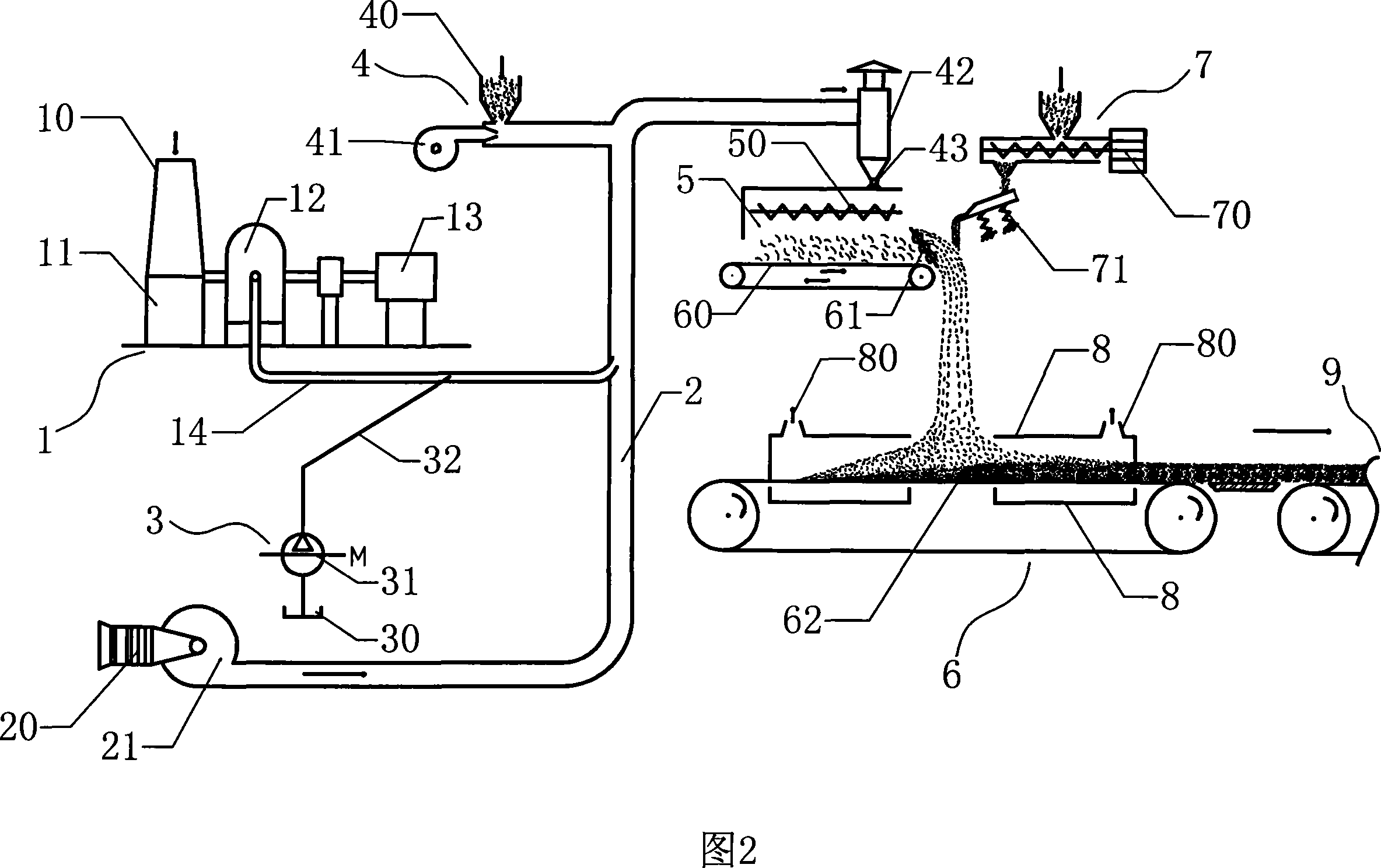

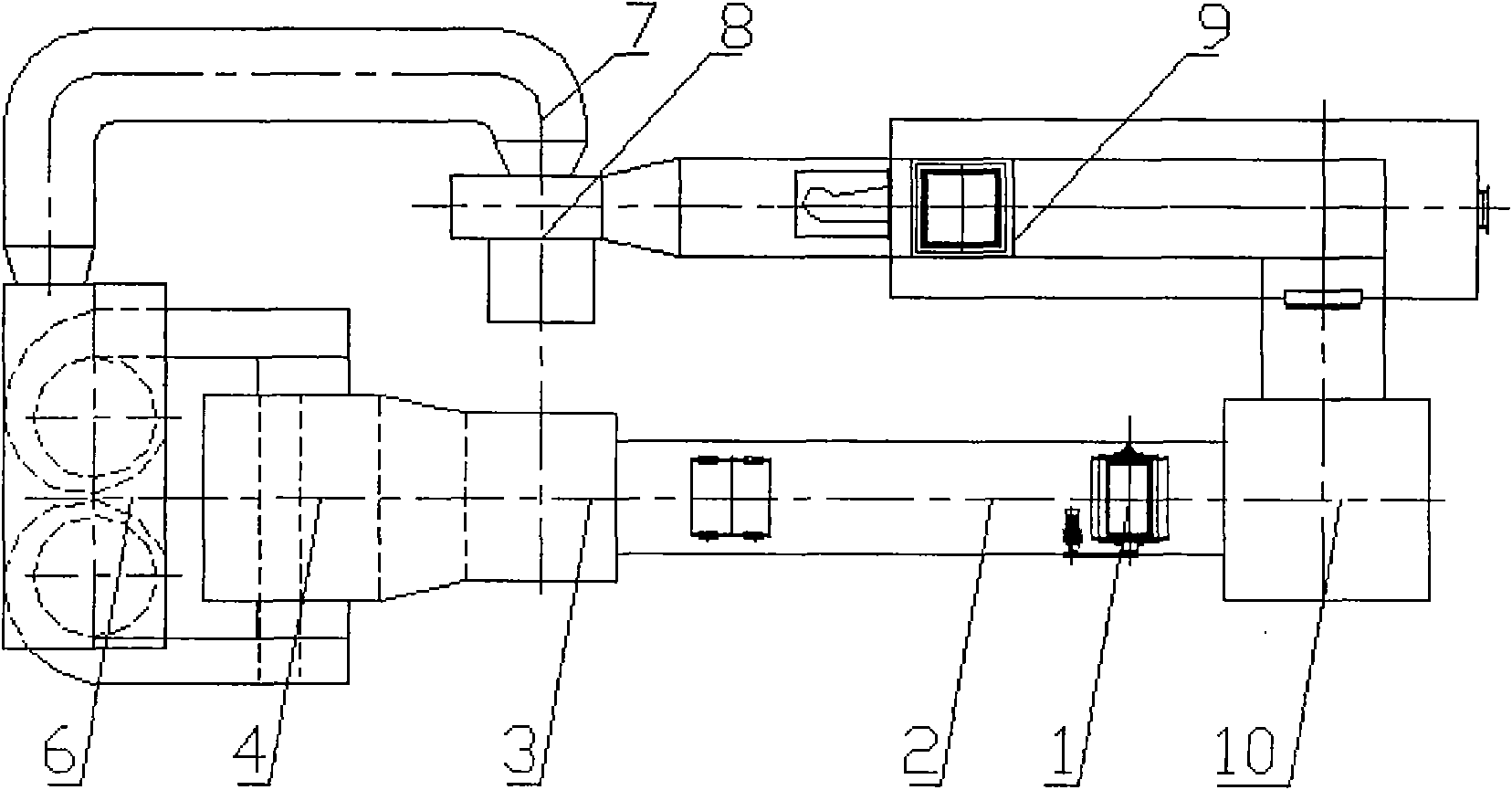

Tobacco material pneumatic drying process and equipment

ActiveCN101601500AShorten speedExtended drying timeTobacco preparationVolumetric Mass DensityEngineering

The invention provides a pneumatic drying method and equipment thereof for realizing large-flow tobacco material puffing drying treatment; the method comprises the following steps: puffed tobacco material is conveyed to a drying pipe for being dried by hot air flows, and then the tobacco material is separated from hot sir; the drying pipe is composed of a horizontal drying pipe and a vertical drying pipe of which the cross section is more than the cross section of the horizontal drying pipe; hot air with the temperature at 100-250 DEG C and air flow speed of10-50m / s of is sent in the horizontal drying pipe, wherein the air flow feeding direction is vertical to the material feeding direction; the material driven by hot air flows enters in the vertical drying pipe and is ascended in a suspension way, and the ascending speed of the material is reduced to 0.5-5m / s; meanwhile, sundries such as slivers with large density in the material can not be suspended and are separated pneumatically under the wind speed. By arranging the vertical drying pipe with large caliber, the speed of the material, moving upwards along the air flow direction, is reduced, on the premise of not increasing the drying route, the drying time of the material is prolonged, heat-transferring and mass transferring coefficient is improved, and the drying time of the material is improved.

Owner:ZHISI HLDG GRP

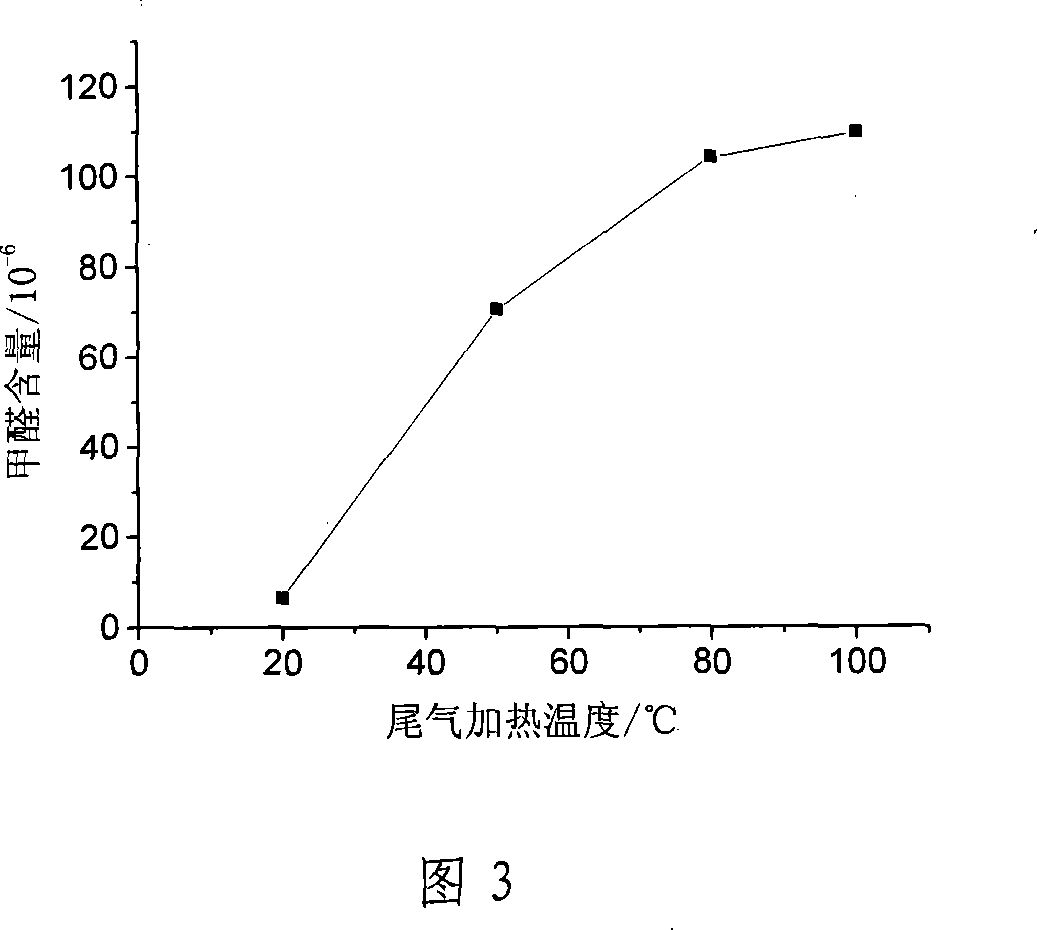

Sampling apparatus and method for detecting formaldehyde content of engines tail gas

InactiveCN101042314ASimple structureEasy to operateComponent separationWithdrawing sample devicesVacuum pumpingTime range

This invention relates to one motor tail gas test sampling method and device, wherein, the device comprises one probe, gas-in constant structure, tail absorptive derive structure and sample gas flow control structure. The invention method comprises the following steps: a, making absorptive liquid; b, injecting it into two series U shape multi-hole board; c, loading proper absorbent cotton into dry tube; d, adjusting the structure temperature as 80+-2deg.C; e, starting micro vacuum pump between 0.12L / min-0.15L / min; f, vacuum pumping for 5 minutes; g, starting continual sampling with time range of 10min-15min; H, after sampling pouring the liquid into one contain bottle to get the sample liquid.

Owner:TIANJIN UNIV

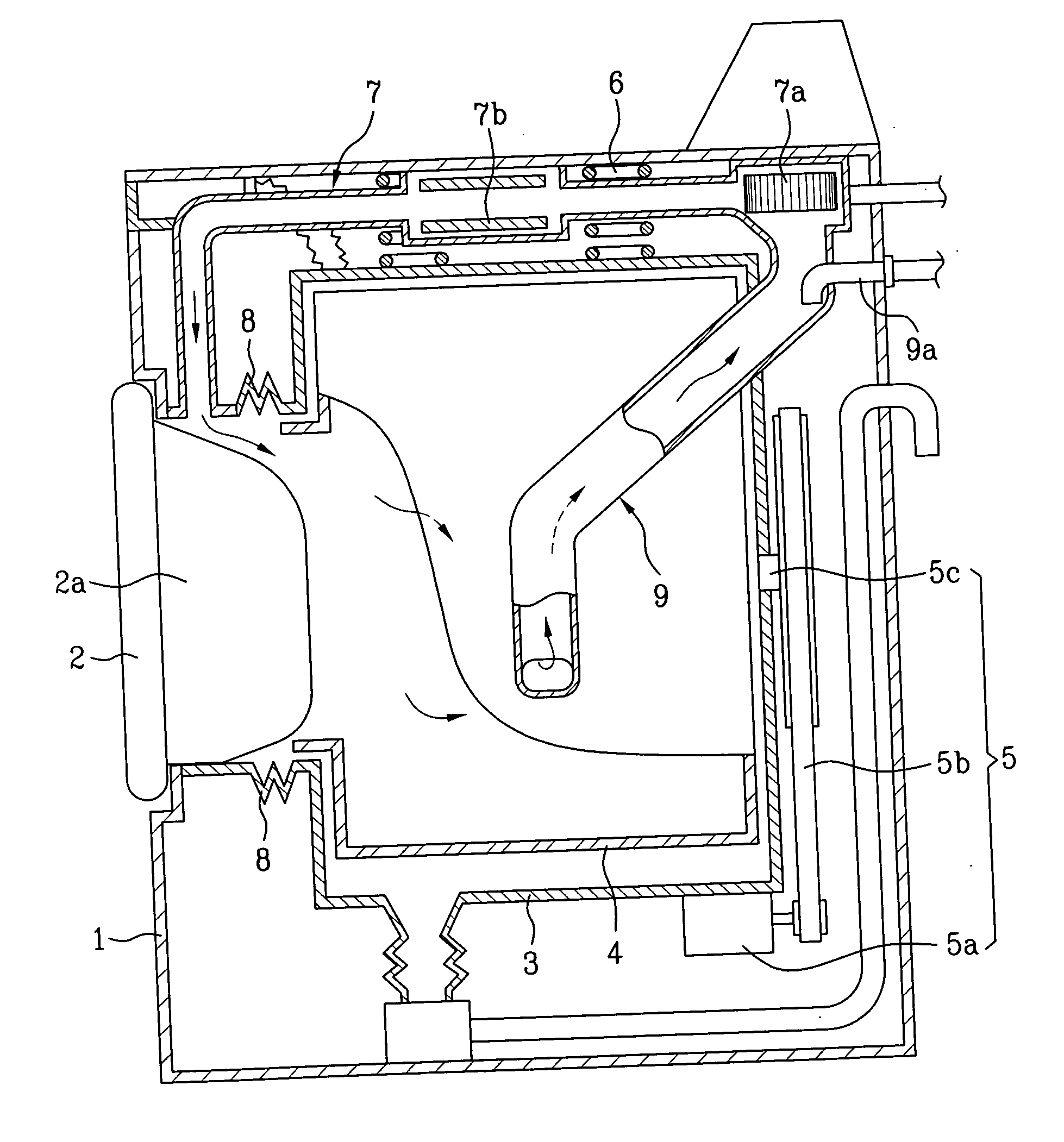

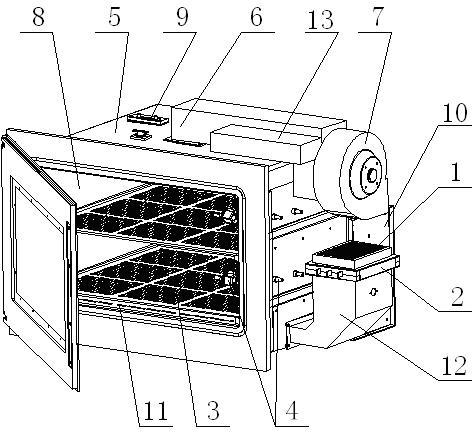

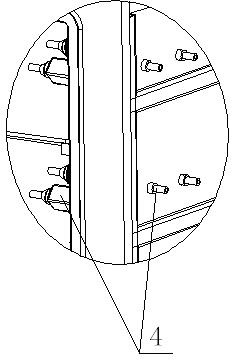

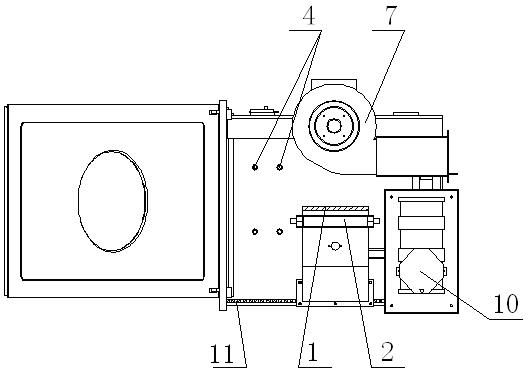

Low-temperature drying cabinet and drying method thereof

ActiveCN102353240AReduce or avoid secondary pollutionStable temperatureDrying gas arrangementsDrying machines with local agitationAir filtrationThermodynamics

The invention discloses a low-temperature drying cabinet and a method for drying medical equipment by using the low-temperature drying cabinet. The low-temperature drying cabinet comprises a cabinet body (5), an air filtering device (1), an air heating device (2), a pumping device (10), an air exhaust pipeline (6), an exhaust fan (7), a heater (9) and a control device (13), wherein a drying chamber (8) is arranged in the cabinet body (5); a grid rack (3) and a pipeline drying connector (4) are arranged in the drying chamber (8); and the pipeline drying connector (4) is connected with the pumping device (10) and used for drying the inner wall of pipeline type medical equipment. The invention has the advantages of good drying effect on the medical equipment, in particular on the pipeline type medical equipment, high drying efficiency, uniformity in air supply, and no dead area; and by the invention, air which enters the drying chamber (8) can be disinfected and sterilized.

Owner:LAOKEN MEDICAL TECH

Method for preparing 1,3 propylene glycol by using glycerol method

InactiveCN101003462AHigh purityGood choiceOrganic compound preparationHydroxy compound preparationHydrogenGlycerol

This invention discloses a method for preparing 1, 3-propylene glycol from glycerol. The method has such advantages as high catalytic activity, mild reaction conditions, high product selectivity, high product purity, simple process. The method comprises: (1) adding 95% glycerol and 30% oxydol into a round bottom flask, setting condensing tube and drying tube, heating to 100 deg.C under stirring, and reacting for 1-3 h to obtain acetone alcohol; (2) adding acetone alcohol into a pressure reaction kettle loaded with transition oxometalate catalyst, introducing hydrogen for 4-6 h at 100-200 deg.C and 10 MPa, reacting, and rectifying to obtain 1,3-propylene glycol.

Owner:INST OF CHEM IND OF FOREST PROD CHINESE ACAD OF FORESTRY +1

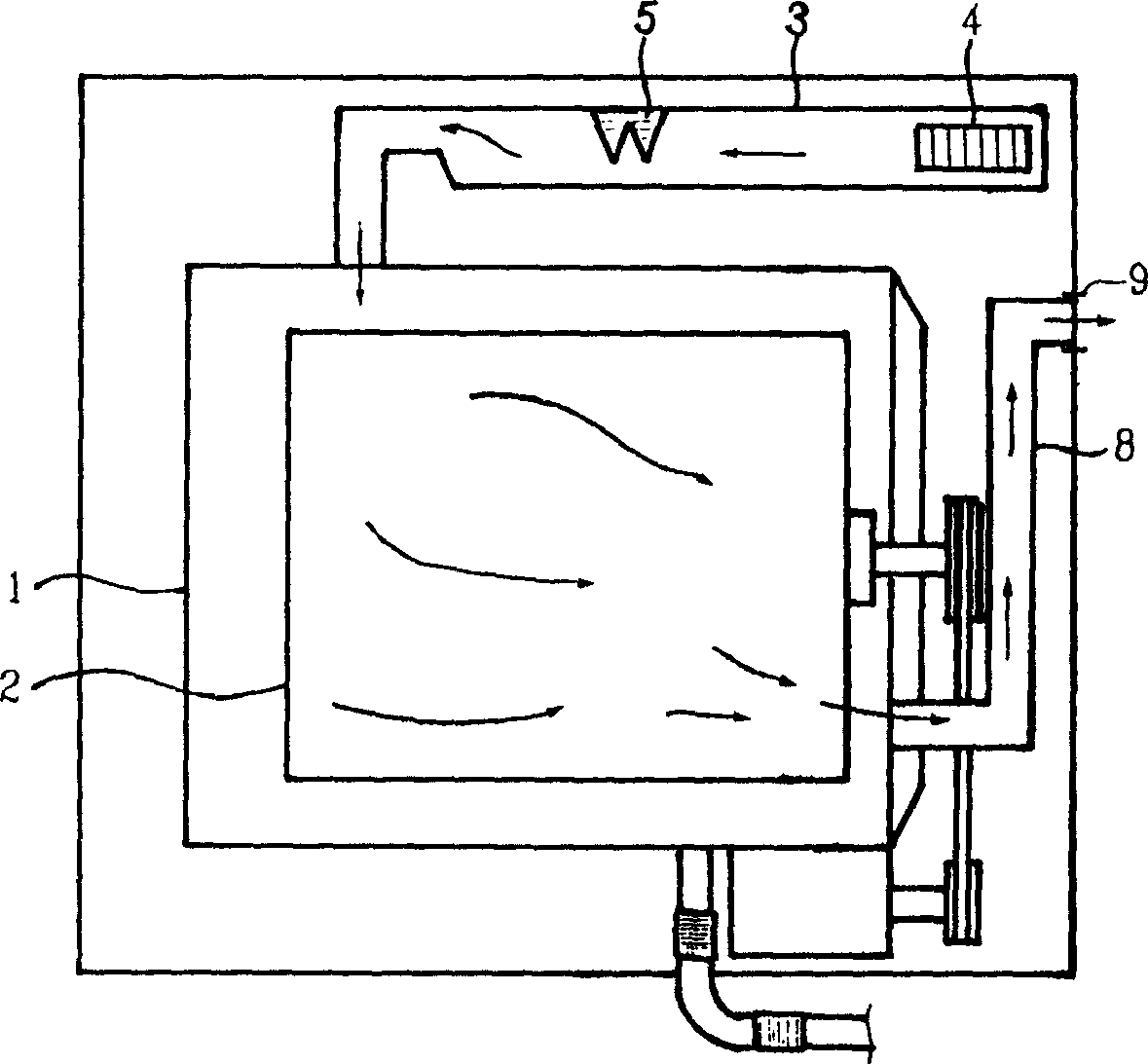

Washing and drying machine

ActiveUS20060225468A1Flow resistance is minimizedReduce power consumptionOther washing machinesWashing machine with receptaclesProcess engineeringLaundry

A washing and drying machine includes a drying duct having at least one inlet end and at least two outlet ends. Consequently, air flow is increased, and drying time and power consumption are reduced. The inlet end is connected to the center portion of the circumferential surface of a tub, and the outlet ends include a front outlet end connected to the front side of the tub and a rear outlet end connected to the rear side of the tub. Consequently, the laundry is uniformly dried even when the laundry is placed in the drum at the front and / or the rear sides of the drum, and therefore, damage to the laundry is prevented. Flow resistance is minimized, and drying time and power consumption are reduced.

Owner:LG ELECTRONICS INC

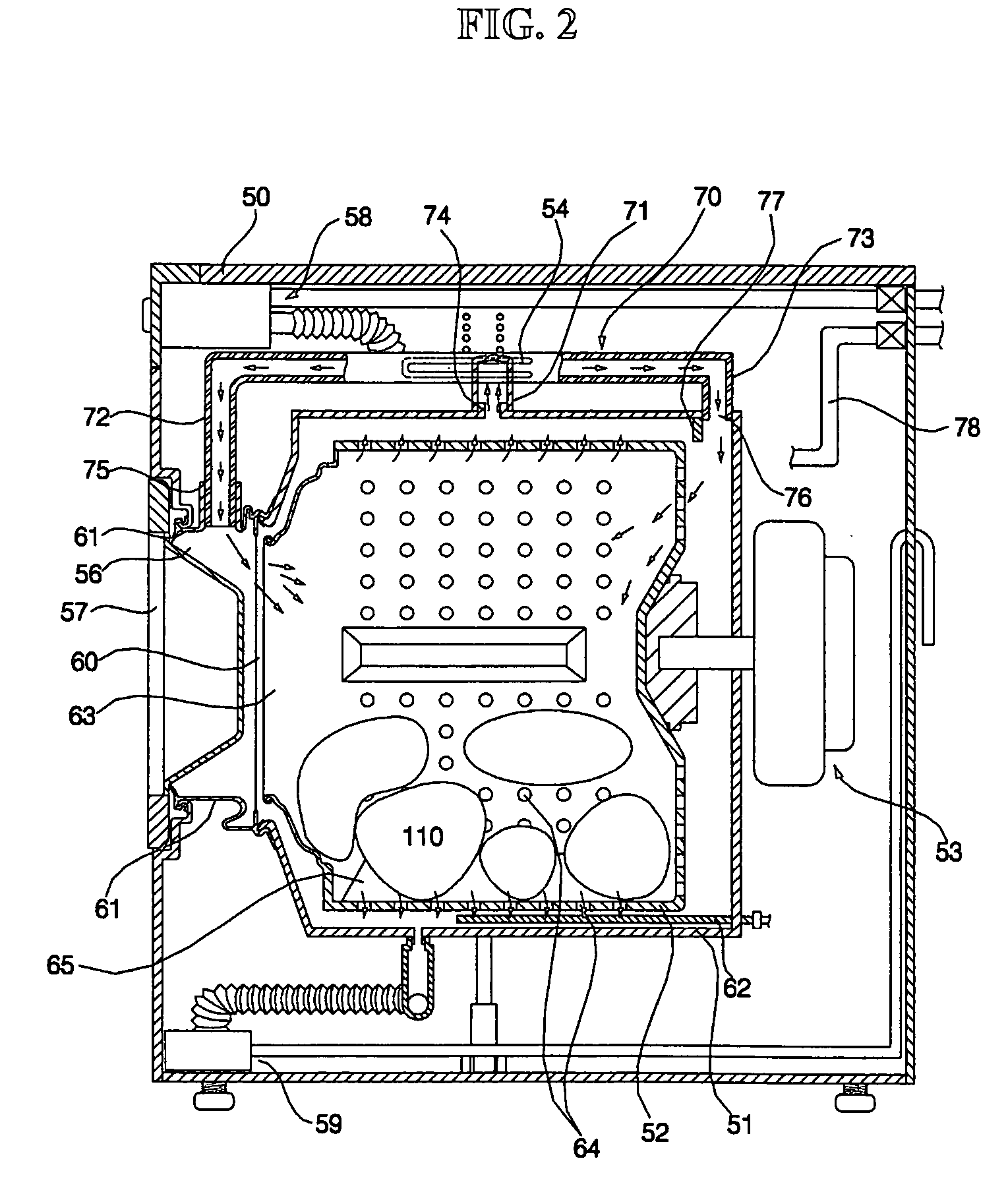

Dry process of dodecyl sodium sulfate

InactiveCN101456829AReasonable process designLower the preheat temperatureDrying using combination processesDrying solid materials with heatOrganic compoundSodium sulfate

The invention provides a process for drying lauryl sodium sulfate, which belongs to the technical field of preparation of a surfactant in an organic compound. The method is carried out in a compound vacuum drier formed by a vacuum tube type spray drying part (A), an adapting tank (B) and a vacuum scraper drying part (C), and comprises the following steps: (1) preheating a lauryl sodium sulfate material in a preheater to the temperature of between 50 and 100 DEG C, and making the material be in a half atomized state and enter a vacuum drying tube with vapor in the vacuum tube type spray drying part (A) at a pressure of between 0.2 and 1.0MPa by a conveying pump, so that the moisture content of the material is reduced to 50 to 10 percent; (2) introducing the material into the vacuum scraper drying part (C) through the adapting tank (B) for secondary drying, so that the moisture content of the dried material is lower than 3 percent; and (3) according to the prior process, granulating the dried materials through a double screw extruder to manufacture an acicular product. The process has reasonable design, and can effectively improve the drying efficiency and product quality.

Owner:ZANYU TECH GRP CO LTD

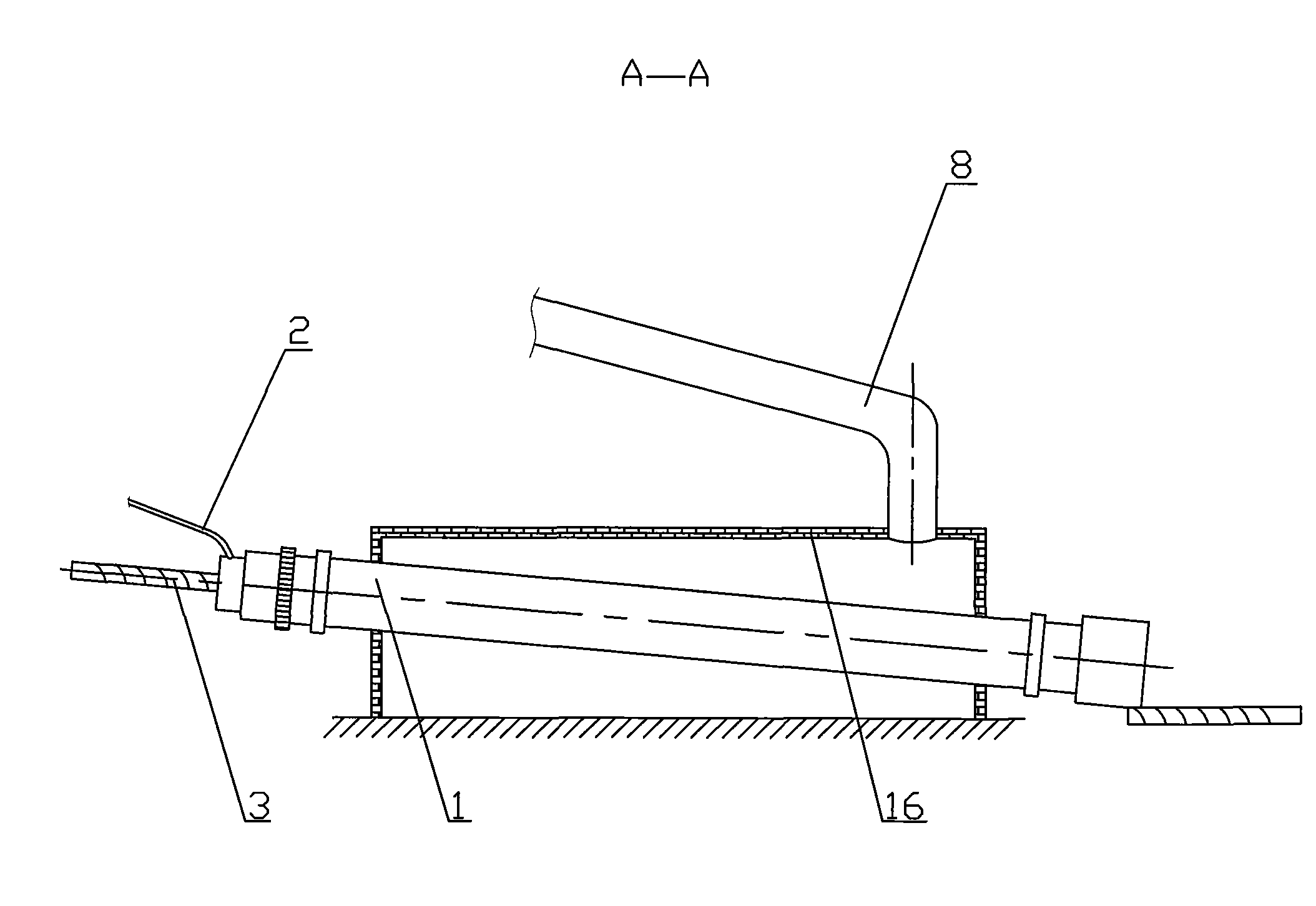

Energy-saving environment protection apparatus for drying and producing chemical gypsum powder by using tail gas

The present invention relates to an energy-saving environment protection apparatus for drying and producing chemical gypsum powder by using tail gas, including a circumversion frying pan (1) and a hearth box (16), wherein the circumversion frying pan is provided with a packing auger feeder (3), characterized in that a tail gas collecting tube (8) is connected with one end of a impulse drying tube (10), the other end of the impulse drying tube (10) is connected with a cyclonic collector (11), a feed end of the cyclonic collector (11) is connected with the packing auger feeder (3), and an exhaust end of the cyclonic collector (11) is connected with a draught fan (14). The beneficial effect of the apparatus is that the gypsum raw material is dried by using the high-temperature tail gas and aqueous vapour generated by the circumversion frying pan. The gas drying contact area is large, and the thermal efficiency is high. The tail gas contains microparticle flue dust which may play a function of the activated carbon to remove yellow, so that the white content of the gypsum powder is improved. The tail gas and the aqueous vapour is purified by a dedusting environment protection apparatus, thus the pollutant will be not discharged outside, and the environment protection effect is good.

Owner:蚌埠百佳新型建材有限公司

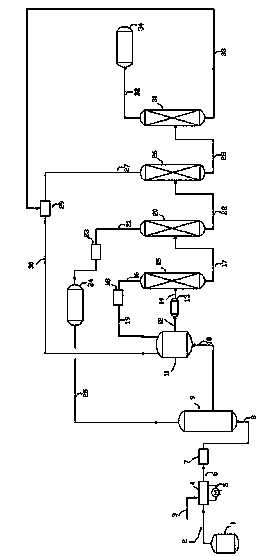

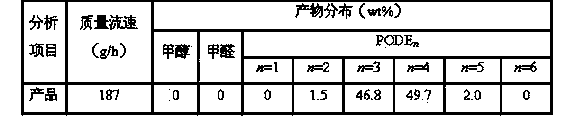

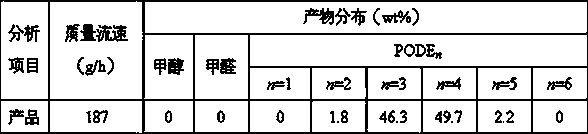

Process for producing polyoxymethylene dimethyl ether from methanol and paraformaldehyde

ActiveCN104230685AGood choiceImprove technical effectOrganic chemistryOrganic compound preparationPtru catalystSolid acid

The invention relates to a process for producing polyoxymethylene dimethyl ether from methanol and paraformaldehyde. The invention mainly solves the problem of low yield of polyoxymethylene dimethyl ether by using the process for producing polyoxymethylene dimethyl ether from methanol and paraformaldehyde. The process is divided into a reaction zone and a separation zone. The reaction zone includes a nitrogen storage tank, a methanol storage tank, a mixing tank with a heater, a drying tube, a spray tower and a liquid phase reaction still. The process steps in the reaction zone are as below: heating paraformaldehyde in the mixing tank into formaldehyde gas; transmitting the formaldehyde gas by nitrogen purging to the drying tube for water removal; introducing the formaldehyde gas into the spray tower from the bottom to the top; conducting countercurrent contact with methanol in the spray tower to form a methanol solution of formaldehyde and sending the solution to a liquid phase reactor; under the effect of a solid acid catalyst, reacting the solution with a mixture recycling to the reactor to generate polyoxymethylene dimethyl ether. The technical scheme well solves the problem, and can be used in industrial production of polyoxymethylene dimethyl ether.

Owner:CHINA PETROLEUM & CHEM CORP +1

Drying apparatus for drum washing machine of switching type drying mode

InactiveCN1464089ASimplify manufacturing equipmentThe production process is simpleWashing machine with receptaclesTextiles and paperPulp and paper industryExhaust pipe

The present invention relates to drying device of washing machine, and is especially conversion drying device of cylindrical washing machine operating in conversion mode. The conversion drying device includes washing cylinder and drying pipe to supply the washing cylinder with hot air, condensating pipe to suck wet air from the drying pipe, fan set on the drying pipe to dry the exhaust wet air and make the dried air return to the condensating pipe via the drying pipe and exhaust pipe to replace the condensating pipe for preventing exhausted wet air from returning to washing cylinder. There are also water supplying unit inside the condensating pipe, nozzle in the condensating pipe, drying device installing part on one side of washing machine casing. The said drying device structure has the identical connection structure suitable for both condensating drying device and exhaust drying device, and this simplifies the production equipment of washing machine.

Owner:LG ELECTRONICS (TIANJIN) APPLIANCES CO LTD

Long-pipe airflow dryer

Disclosed is a long-pipe airflow dryer. The main body of the long-pipe airflow dryer is a drying pipe meters or decameters long; materials and hot air can be fed at the lower end of the drying pipe, wherein the hot air passes through an air filter and a preheater before entering the drying pipe, and the materials is fed via a feeding hopper through a screw feeder; dried materials are separated from the hot air and volatilized moisture in a cyclone separator and discharged from a product outlet through a flap valve.

Owner:HEILONGJIANG DAMING DAIRY MACHINERY

Air dryer system and method employing a jet engine

InactiveUS7178262B2Quality improvementExpensive to operateDrying solid materials with heatBoiling apparatusJet engineAir dryer

An air dryer and process employs a jet engine for producing high quality dried products. A turbofan jet engine in an air-drying system uses both thermal and non-thermal air-drying. The turbofan jet engine is housed within an air distribution chamber for directing exhaust air and bypass air from the jet engine into a product drying tube, where it is dried through a combination of thermal drying from heat content in an engine exhaust, and by the kinetic energy of air flowing past the product traveling through the drying tube, that may include a physical impediment for retarding retard the speed of the product solids flowing in the air stream through the tube.

Owner:STAPLES WESLEY A

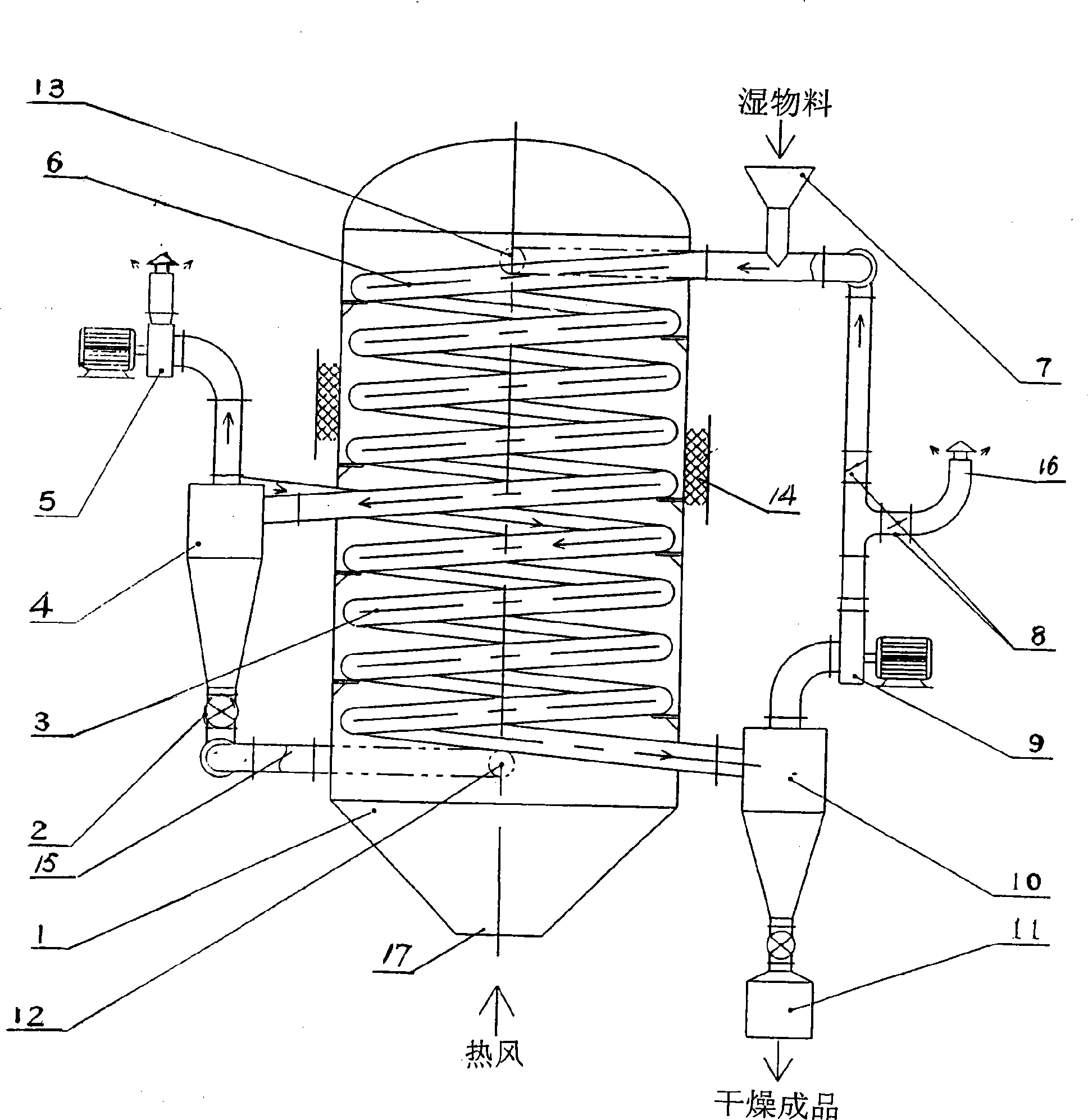

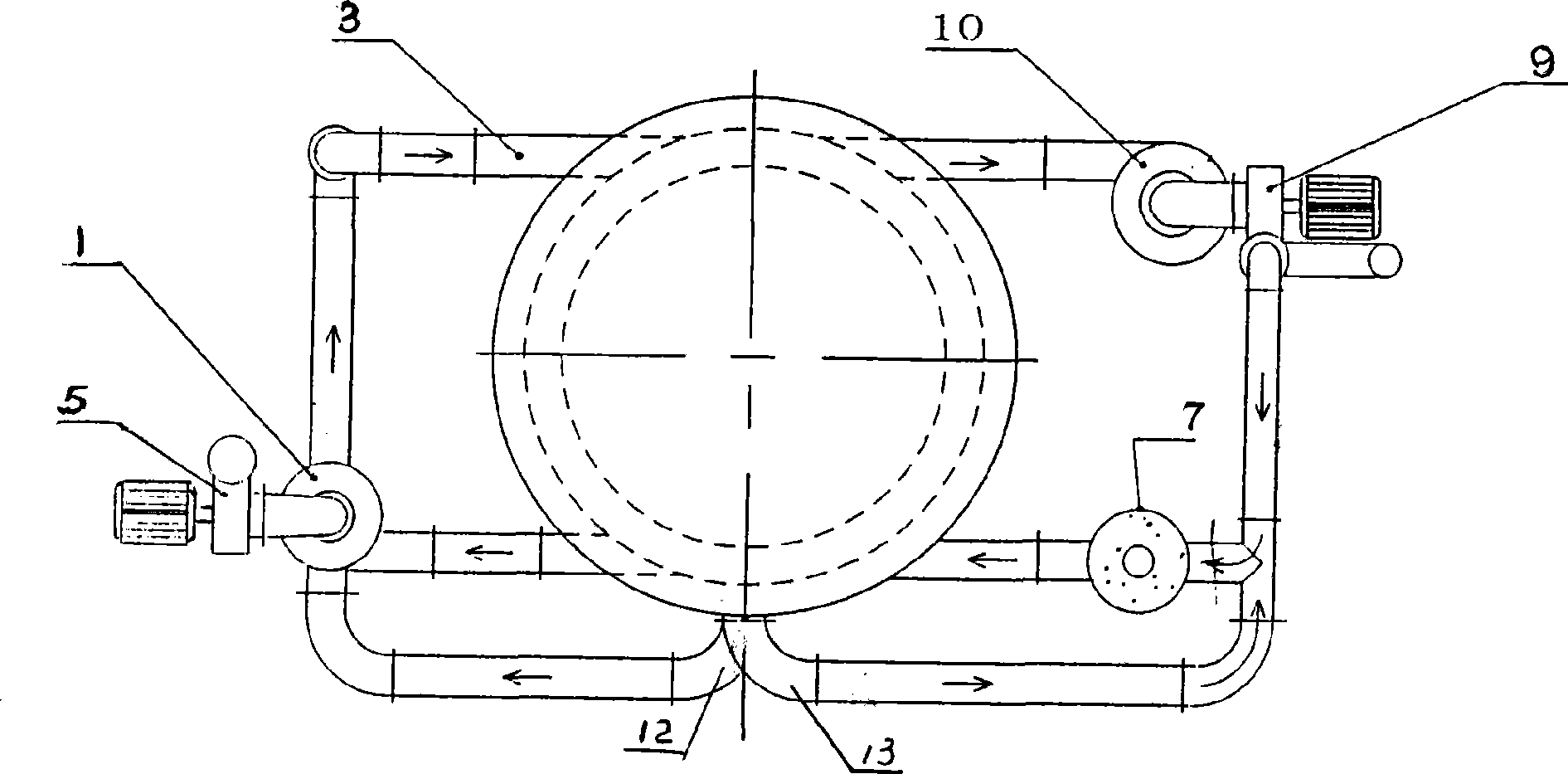

Vent gas circulating type spiral pipe blast drier and its drying method

InactiveCN101464091AReasonable designCompact structureDrying solid materials with heatHearth type furnacesCycloneProcess engineering

The invention relates to an exhaust gas circulating spiral pipe pneumatic dryer and a drying method thereof. A pneumatic drying pipe is made into the spiral pneumatic drying pipe, thereby leading the spiral pneumatic drying pipe to be positioned in a high temperature zone and forming the convection heat transfer in the pipe and the conduction heat transfer out of the pipe, namely the heating of the interior and the exterior of materials is simultaneously carried out, thereby being capable of improving the heat transfer rate and shortening the drying time of the materials. The exhaust gas circulation is further adopted for heating the materials and fully utilizing waste heat in the exhaust gas. The structure comprises a cylindrical container, a first-stage spiral pneumatic drying pipe, a second-stage spiral pneumatic drying pipe, a first-stage drying cyclone separator, a second-stage drying cyclone separator, a first-stage drying induced draft fan, a second-stage induced draft fan and a receiving hopper; the first-stage spiral pneumatic drying pipe and the second-stage spiral pneumatic drying pipe are arranged in the cylindrical container, a hot air inlet is formed at the bottom part of the cylindrical container, a second hot air outlet is formed at the upper part of the cylindrical container, and a first hot air outlet is formed at the lower part of the cylindrical container.

Owner:张文华

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com