Sampling apparatus and method for detecting formaldehyde content of engines tail gas

A sampling device and engine technology, applied in measuring devices, sampling devices, instruments, etc., can solve the problems of formaldehyde detection interference, expensive instruments, and difficulty in preparation, and achieve the effects of low cost, convenient operation, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

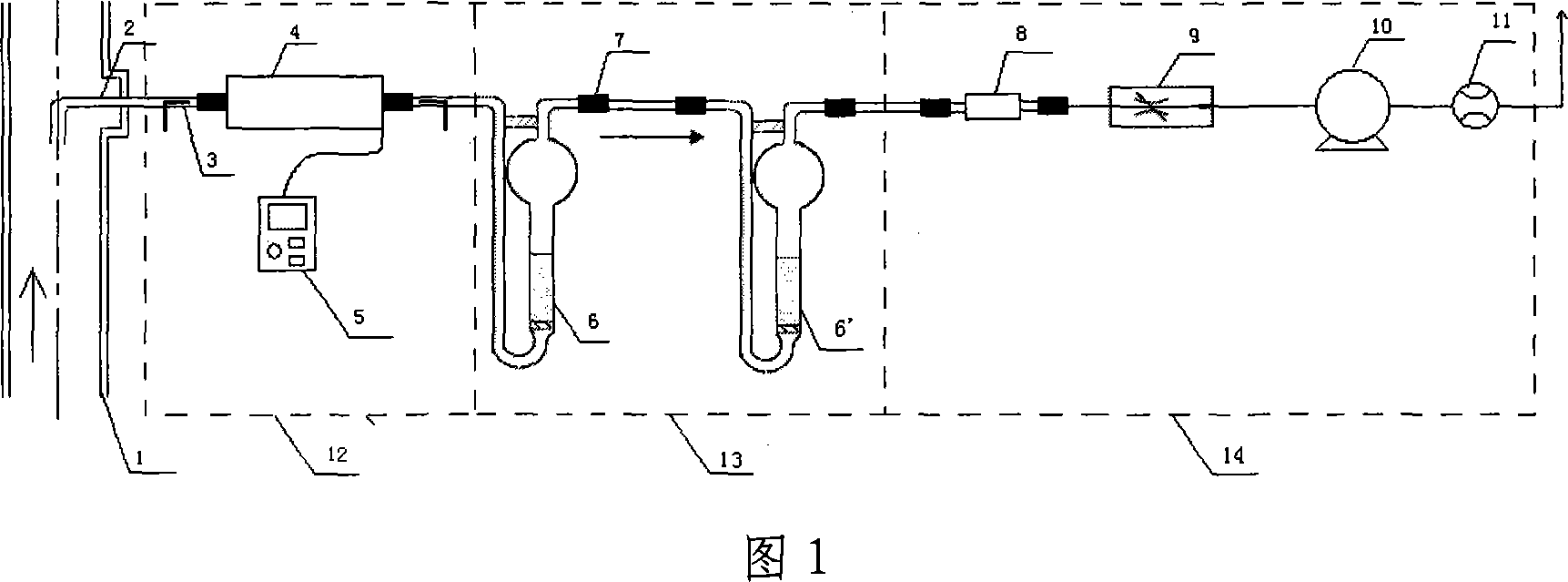

[0037] With reference to Fig. 1, probe 1 is made by stainless steel pipe processing, and air inlet end stretches into exhaust pipe 15 (extends to and exhaust pipe central axis place) in sampling process, and exhaust end is sealed with nylon pipe inlet end;

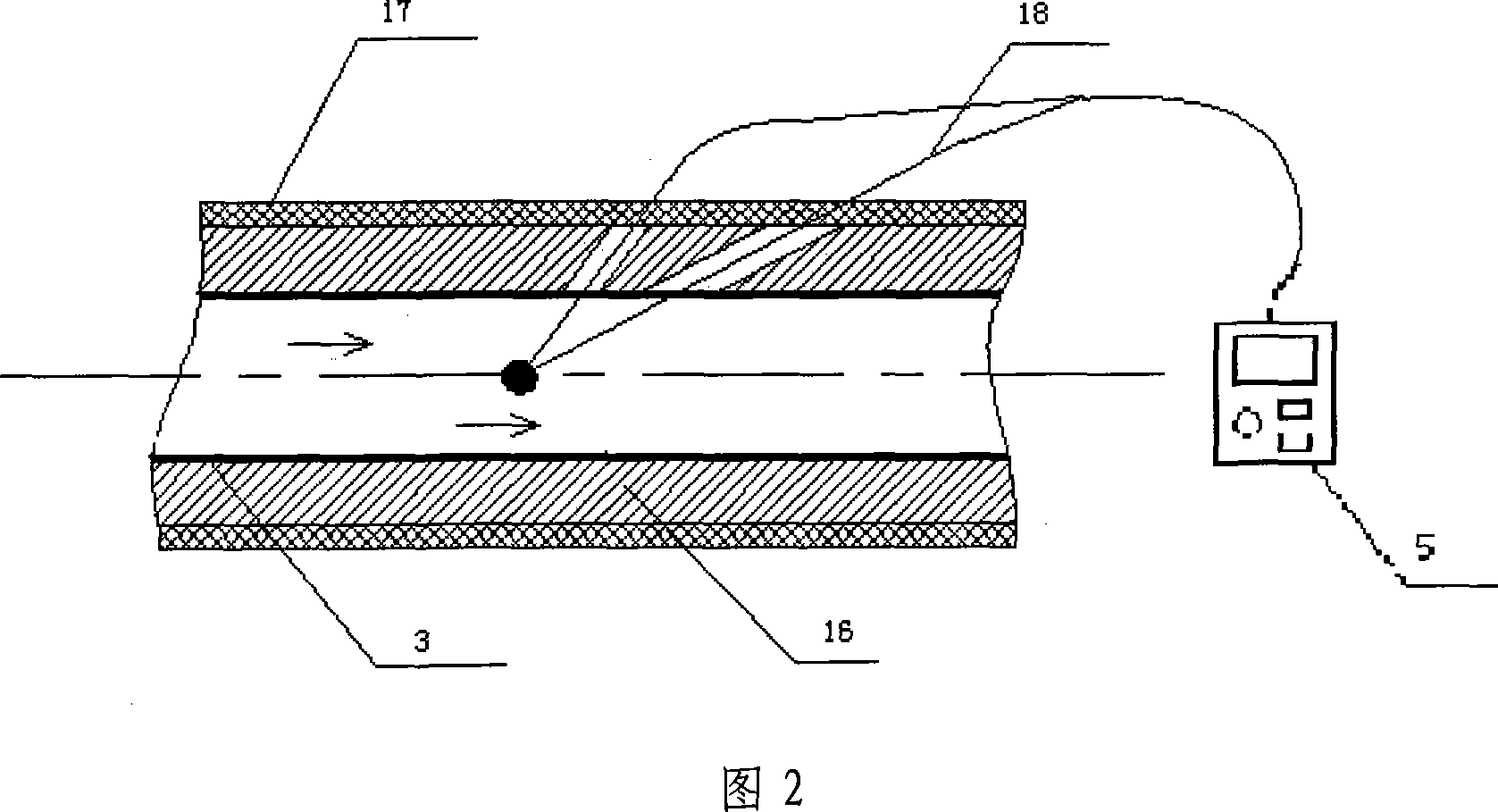

[0038] The inlet constant temperature mechanism 12 is connected with the probe 1, so that the gas can be kept between 78°C and 82°C after passing through the inlet constant temperature mechanism 10; referring to Figure 2, the inlet constant temperature mechanism 12 includes: a pipeline 3 for the gas to pass through, The thermal resistance type heating belt 16 wrapped outside the pipeline, the insulation cotton 17 wrapped outside the heating belt, the K-type thermal couple 18 obliquely buried at the axis of the junction of the pipeline and the exhaust gas absorption derivative mechanism, and the K-type thermocouple The positive and negative pole wires and the temperature control relay 5 connected with the positive and negati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com