Energy-saving environment protection apparatus for drying and producing chemical gypsum powder by using tail gas

An energy-saving and environment-friendly gypsum powder technology, which is applied in the field of energy-saving and environment-friendly devices for the production of gypsum powder, can solve the problems of high energy consumption for calcination and environmental pollution caused by dust, and achieve the effects of large contact area, energy saving and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

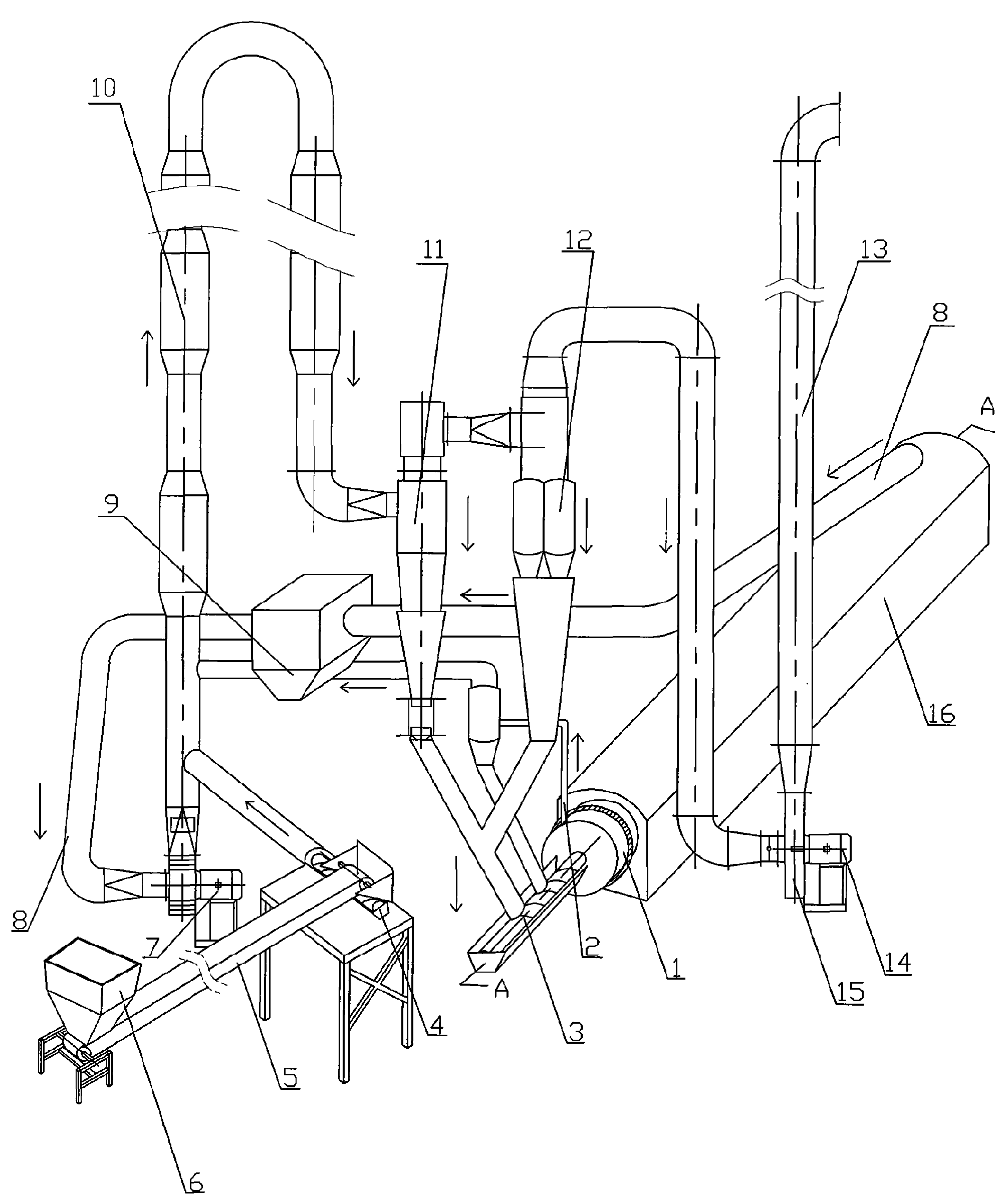

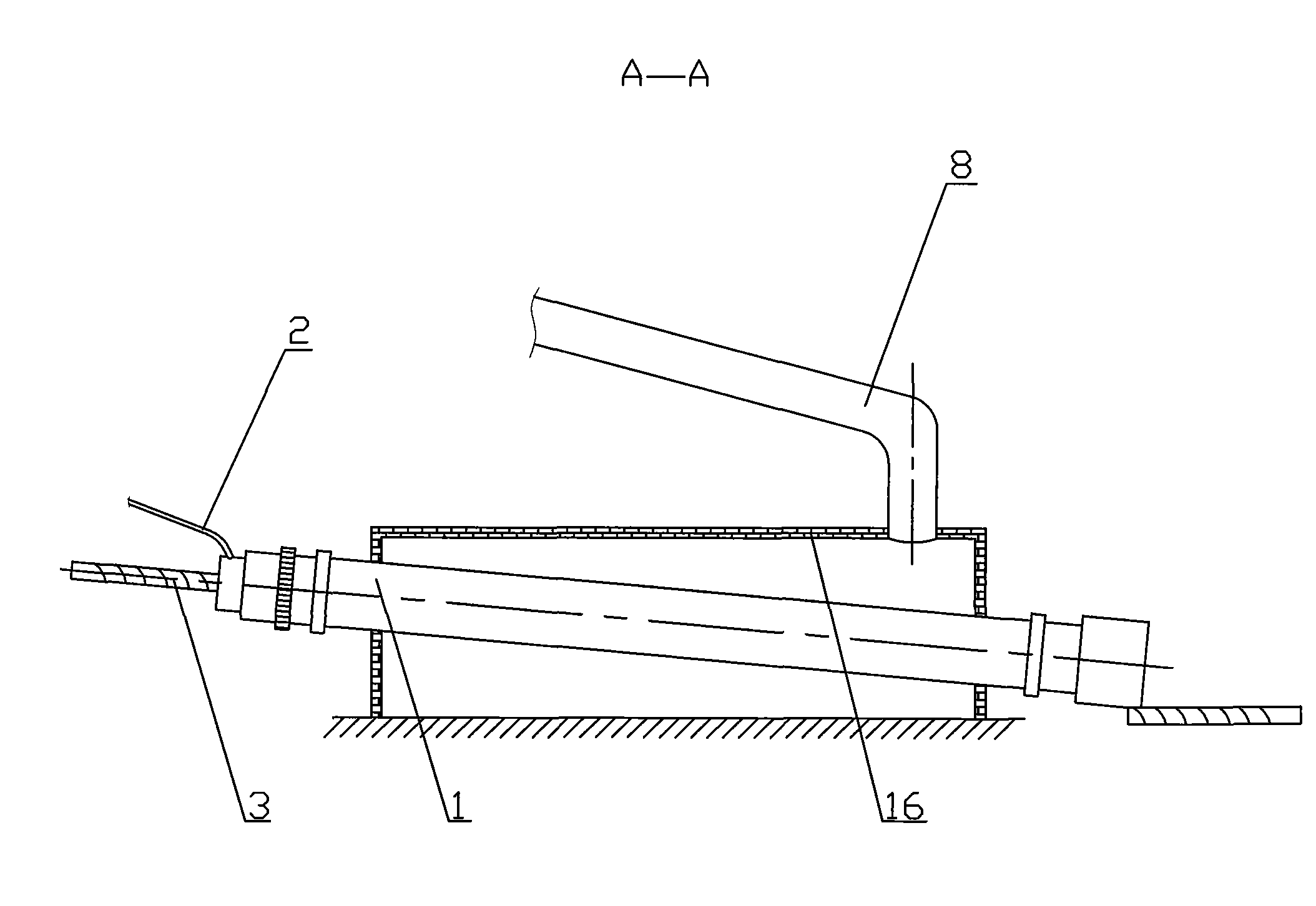

[0018] Such as figure 1 and figure 2 As shown, the gypsum powder drying device includes a rotary frying pan 1 and a furnace 16, the rotary frying pan 1 is provided with an auger conveyor 3, a trough is provided under the auger conveyor, and an exhaust gas collection pipe 8 is provided at the end of the furnace 16 , the tail gas collection pipe 8 is provided with a tail gas dust collector 9, and the front end of the rotary frying pan is provided with a water vapor collection pipe 2, and the tail gas collection pipe 8, the water vapor collection pipe 2 and the feeding mechanism are respectively connected with three interfaces at one end of the pulse drying pipe 10, and the pulse The end of the drying pipe 10 is also provided with an intensifier 7; the other end of the pulse drying pipe 10 is connected to a cyclone dust collector 11, and one end of the cyclone dust collector 11 is provided with a feeding pipe connected to the auger conveyor 3, and the other end is Connect with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com