Dry process of dodecyl sodium sulfate

A sodium lauryl sulfate and drying process technology, which is applied in the direction of sulfuric acid ester preparation, drying solid materials, heating to dry solid materials, etc., can solve the problems of high moisture content in products, affecting product quality, and harsh drying conditions. Achieve the effects of reducing dust pollution and product loss, reducing the amount of tail gas treatment, and not easy to agglomerate and absorb moisture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

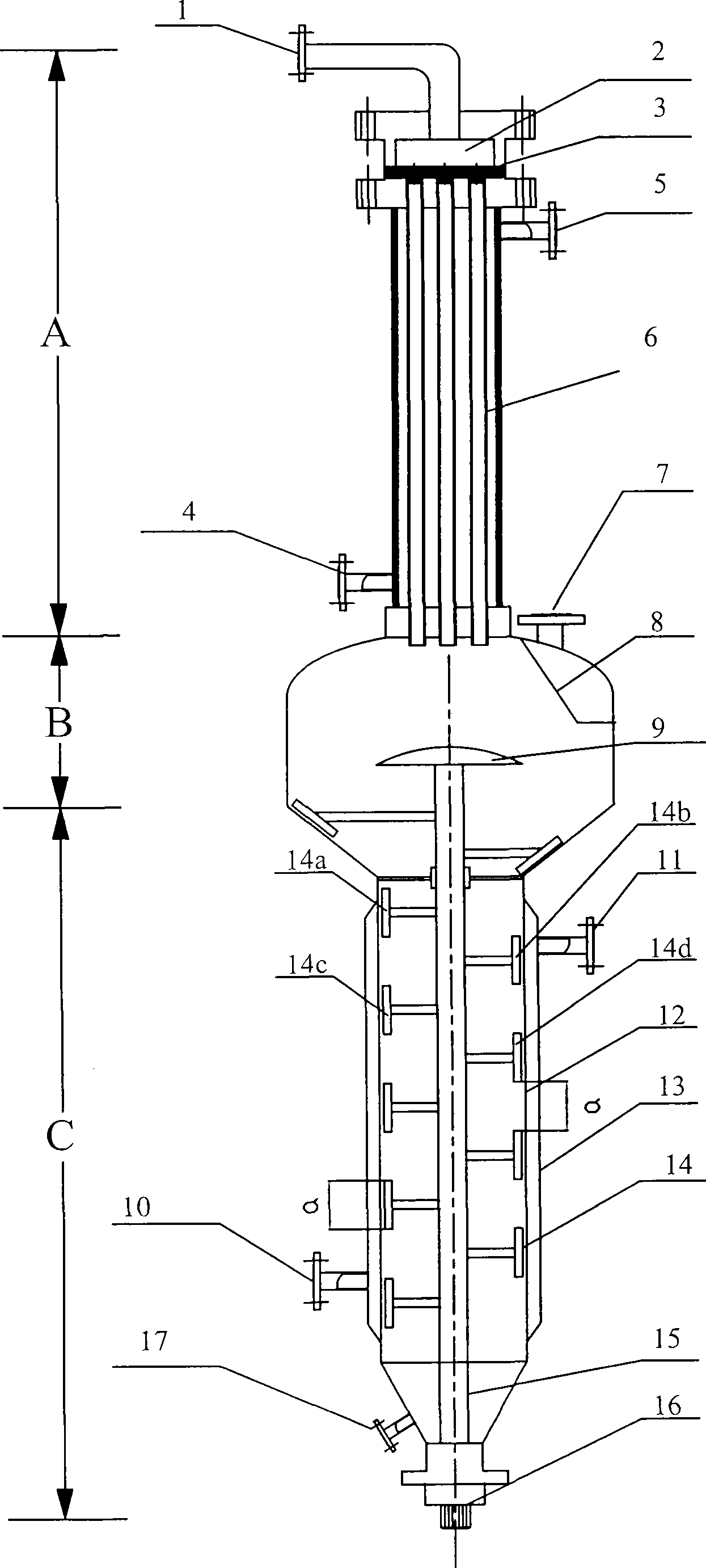

[0026] Example 1: After measuring sodium lauryl sulfate with a water content of 70%, preheat it to 75°C in a preheater, and use a gear pump to enter the material into a vacuum drying with steam in a semi-atomized state under a pressure of 1MPa Then it is thrown to the four walls by the swirl plate, slides along the four walls and enters the vacuum scraper drying part with a vacuum degree of 6.0kPa for secondary drying. The moisture content of the dried material is about 2.5%, and then according to the conventional process , Extruded and granulated by a twin-screw extruder to obtain needle-shaped sodium lauryl sulfate products.

Embodiment 2

[0027] Example 2: After metering sodium lauryl sulfate with a water content of 60%, preheat it to 70°C in the preheater, and use a gear pump to put the material into the vacuum drying tube in a semi-atomized state under a pressure of 1.0MPa , and then throw it to the four walls through the swirl plate, slide down along the four walls and enter the vacuum scraper dryer with a vacuum degree of 6.5kPa for secondary drying. The moisture content of the dried material is about 2.0%, and then according to the conventional process, It is extruded and granulated by a twin-screw extruder to obtain needle-shaped sodium lauryl sulfate products.

Embodiment 3

[0028] Example 3: After metering sodium lauryl sulfate with a water content of 30%, preheat it to 75°C in a preheater, and use a screw pump to enter the material into a vacuum drying tube in a semi-atomized state under a pressure of 0.8MPa , and then throw it to the four walls through the swirl plate, slide down along the four walls and enter the vacuum scraper dryer with a vacuum degree of 7.0kPa for secondary drying. The moisture content of the dried material is about 1.5%, and then according to the conventional process, It is extruded and granulated by a twin-screw extruder to obtain needle-shaped sodium lauryl sulfate products.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com