Technology for processing floor films

A processing technology and flooring technology, which is applied in the field of floor film processing technology, can solve the problems affecting the apparent transparency, difficulty in coiling, whitening, etc., and achieve the effect of improving the surface friction of hot metal, reducing cohesion, and uniform plasticization degree

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

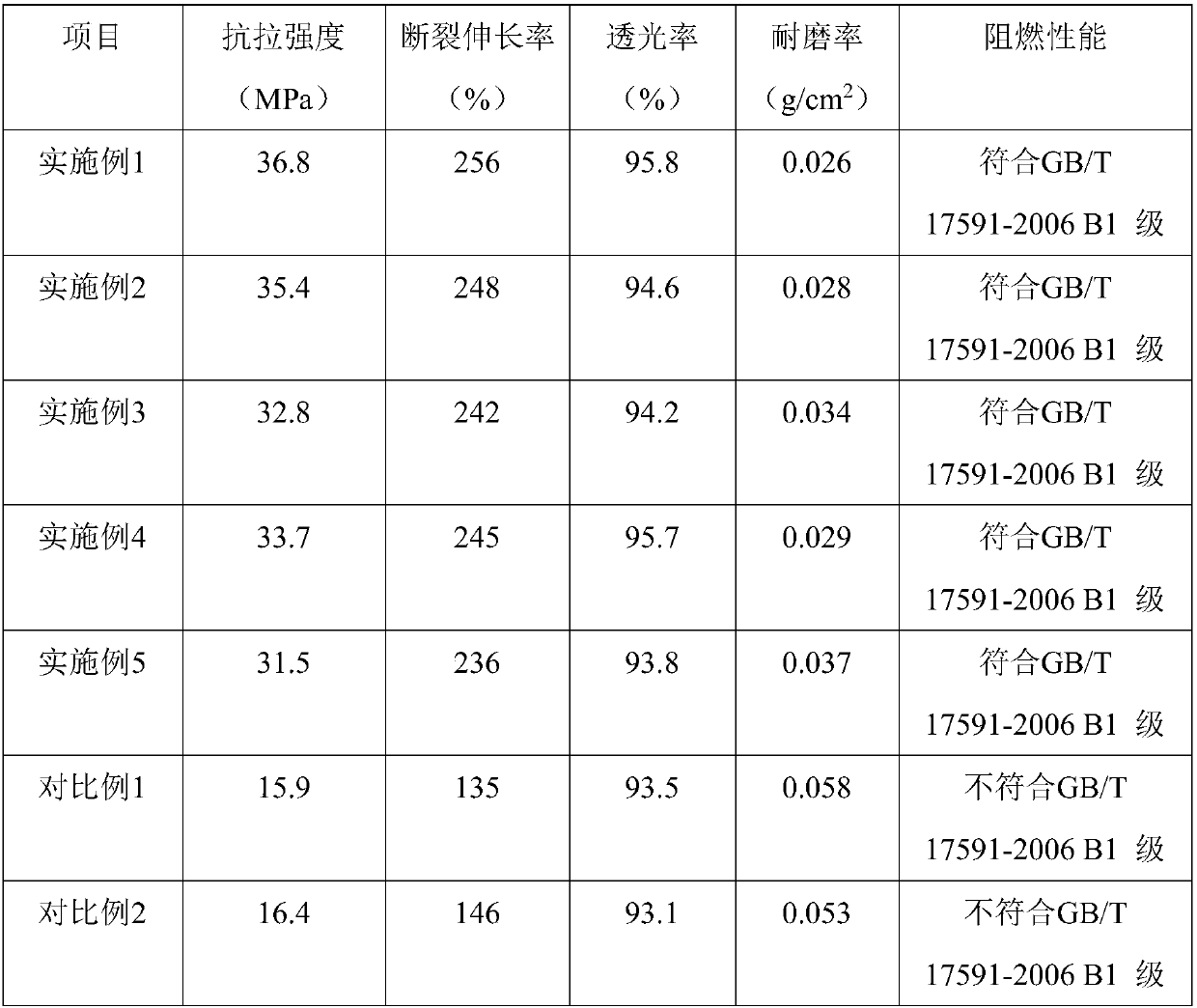

Examples

Embodiment 1

[0020] A processing technology for a floor film, comprising the following steps:

[0021] (1) Batching mixing: take by weighing the PVC resin powder of 135kg, the anti-impact MBS resin of 15kg, the ACR processing aid of 10kg, the diisodecyl phthalate of 9kg, the internal lubricant stearic acid amide of 5kg, 6kg of polyethylene wax as an external lubricant and 2kg of phosphate flame retardant tricumyl phosphate were transported to a high-speed mixer through an automatic feeder, stirred at a speed of 400r / min for 25min, and then cold stirred for 16min to obtain a mixed material.

[0022] (2) Extrusion, plasticization, and calendering: put the mixture in step (1) into a planetary extruder, extrude and granulate at 166 ° C, and then send it to a two-roller open mill for plasticization, and then pass through a five-roller calender The extruder is calendered into a film; among them, the number of screws of the planetary extruder is 12-16, and the residence time of the extruded mater...

Embodiment 2

[0026] A processing technology for a floor film, comprising the following steps:

[0027] (1) Batching mixes: take by weighing the PVC resin powder of 145kg, the anti-impact MBS resin of 22kg, the ACR processing aid of 13kg, the diisodecyl phthalate of 7kg, the internal lubricant calcium stearate of 5kg, 7kg of external lubricant oxidized polyethylene wax, 2kg of phosphate flame retardant cresyl diphenyl phosphate, transported to a high-speed mixer by an automatic feeder, stirred at a speed of 380r / min for 30min, and then cold stirred for 20min to obtain a mixed material .

[0028] (2) Extrusion, plasticization, and calendering: put the mixture in step (1) into a planetary extruder, extrude and granulate at 180°C, and then send it to a two-roll mill for plasticization, and then pass through a five-roll calender The extruder is calendered into a film; among them, the number of screws of the planetary extruder is 12-16, and the residence time of the extruded material is 25-35s....

Embodiment 3

[0032] A processing technology for a floor film, comprising the following steps:

[0033] (1) Ingredients mixing: Weigh 150kg of PVC resin powder, 17kg of impact resistant MBS resin, 11kg of ACR processing aid, 10kg of diisodecyl phthalate, 5kg of internal lubricant butyl stearate , 5kg of external lubricant, 3kg of phosphate flame retardant tricresyl phosphate, transported to a high-speed mixer by an automatic feeder, stirred at a speed of 420r / min for 25min, and then cold stirred for 18min to obtain a mixed material.

[0034] (2) Extrusion, plasticization, and calendering: put the mixed material in step (1) into a planetary extruder, extrude and granulate at 172°C, and then send it to a two-roller open mill for plasticization, and then pass through a five-roller calender The extruder is calendered into a film; among them, the number of screws of the planetary extruder is 12-16, and the residence time of the extruded material is 25-35s. When the five-roll calender is rolling...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com