Manufacturing method of titanium-steel-titanium two-sided composite plate

A technology for composite plates and titanium plates, applied in the field of preparation of composite steel plates, can solve the problems of harsh vacuum welding conditions, unreasonable process design, high material requirements, etc., and achieves low welding requirements, good mechanical strength and process performance, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

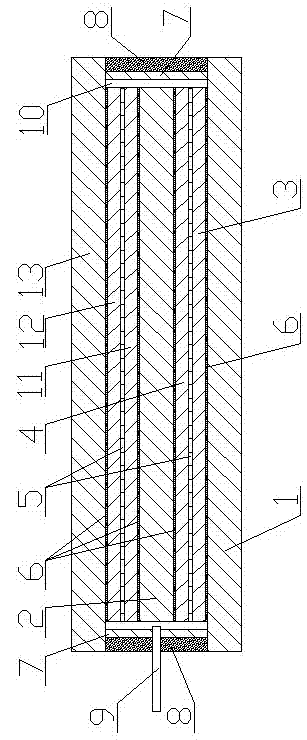

[0019] like figure 1 Shown, a kind of preparation method of titanium-steel-titanium double-sided composite plate, carries out according to the following process steps:

[0020] (1) Four pieces of the first titanium plate 3, the second titanium plate 4, the third titanium plate 11, the fourth titanium plate 12 and three equal-sized first steel plate 1, the second steel plate 2, the Three steel plates 13, the surface of the first titanium plate 3, the second titanium plate 4, the third titanium plate 11, the fourth titanium plate 12 and the first steel plate 1, the second steel plate 2, the third steel plate 13 are derusted and derusted Oxide layer treatment; the length and width of the steel plate are 80-100mm larger than the length and width of the titanium plate;

[0021] (2) Spot-weld the retaining strips 7 around the first steel plate 1 (with a distance of 200-300mm) to form a closed frame, lay the transition layer 6 on the top of the first steel plate 1 (joint surface) in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| shear strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com