Manufacturing tooling and efficient production method of large height-diameter ratio circular casting billet

A technology for manufacturing tooling and height-to-diameter ratio, which is applied in the field of manufacturing tooling and high-efficiency preparation of round billets with large height-to-diameter ratio. Effects of secondary oxidation of inclusions and gas entrainment, shortening of production cycle, and improvement of utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

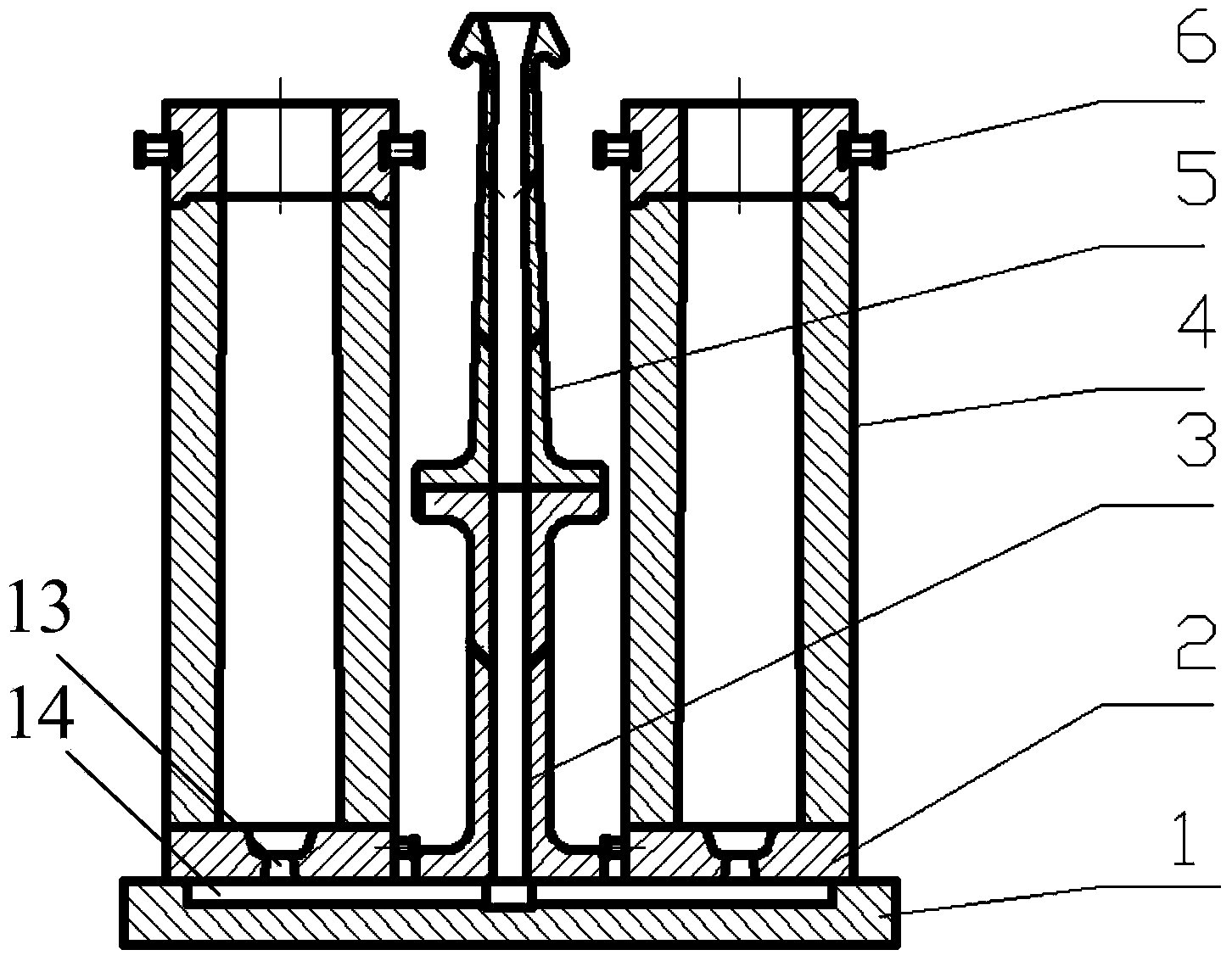

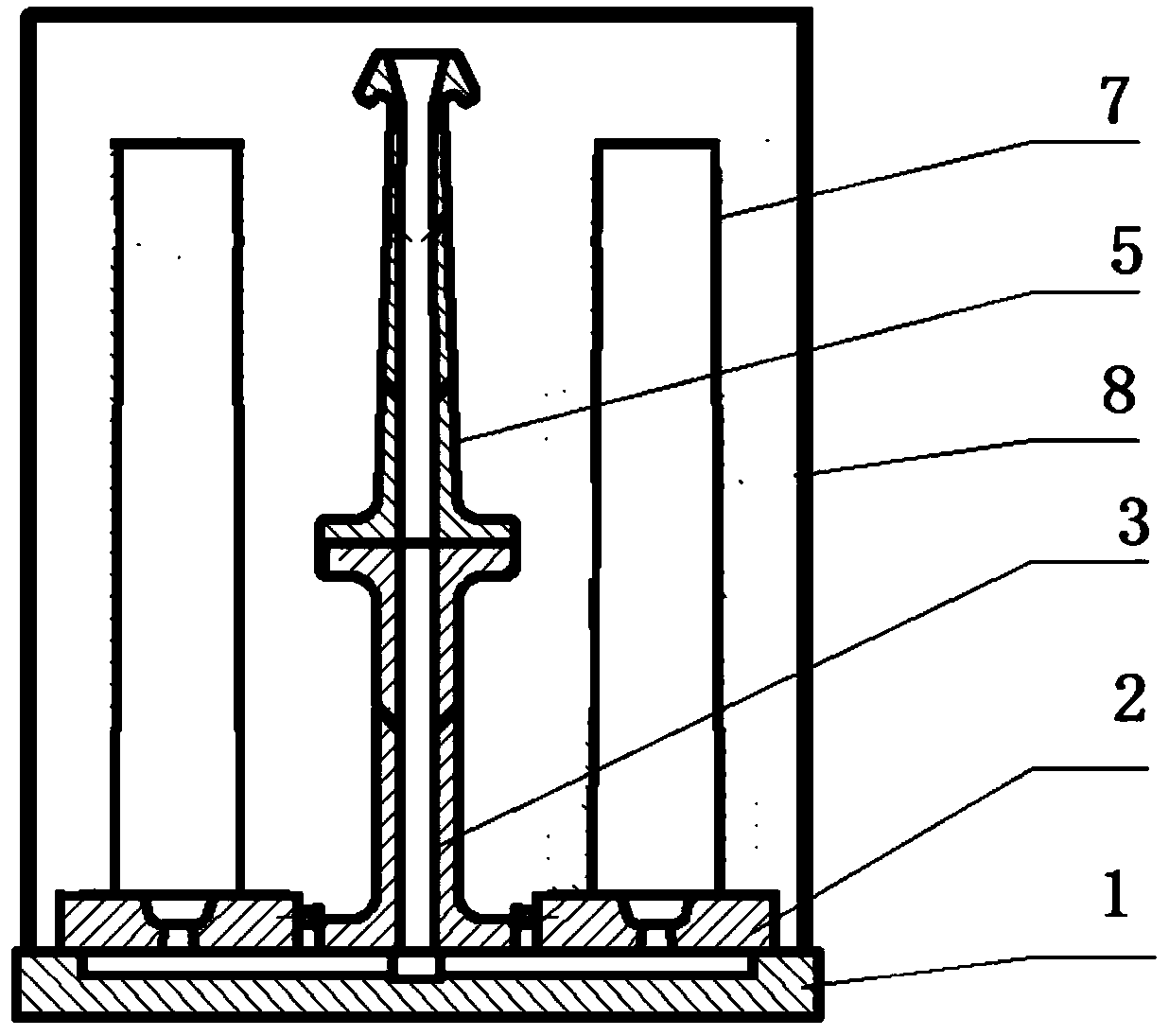

[0059] In this embodiment, the weight of the round billet produced by the present invention is 14.1t, and the ratio of height to diameter is 5. The specific process parameters are as follows:

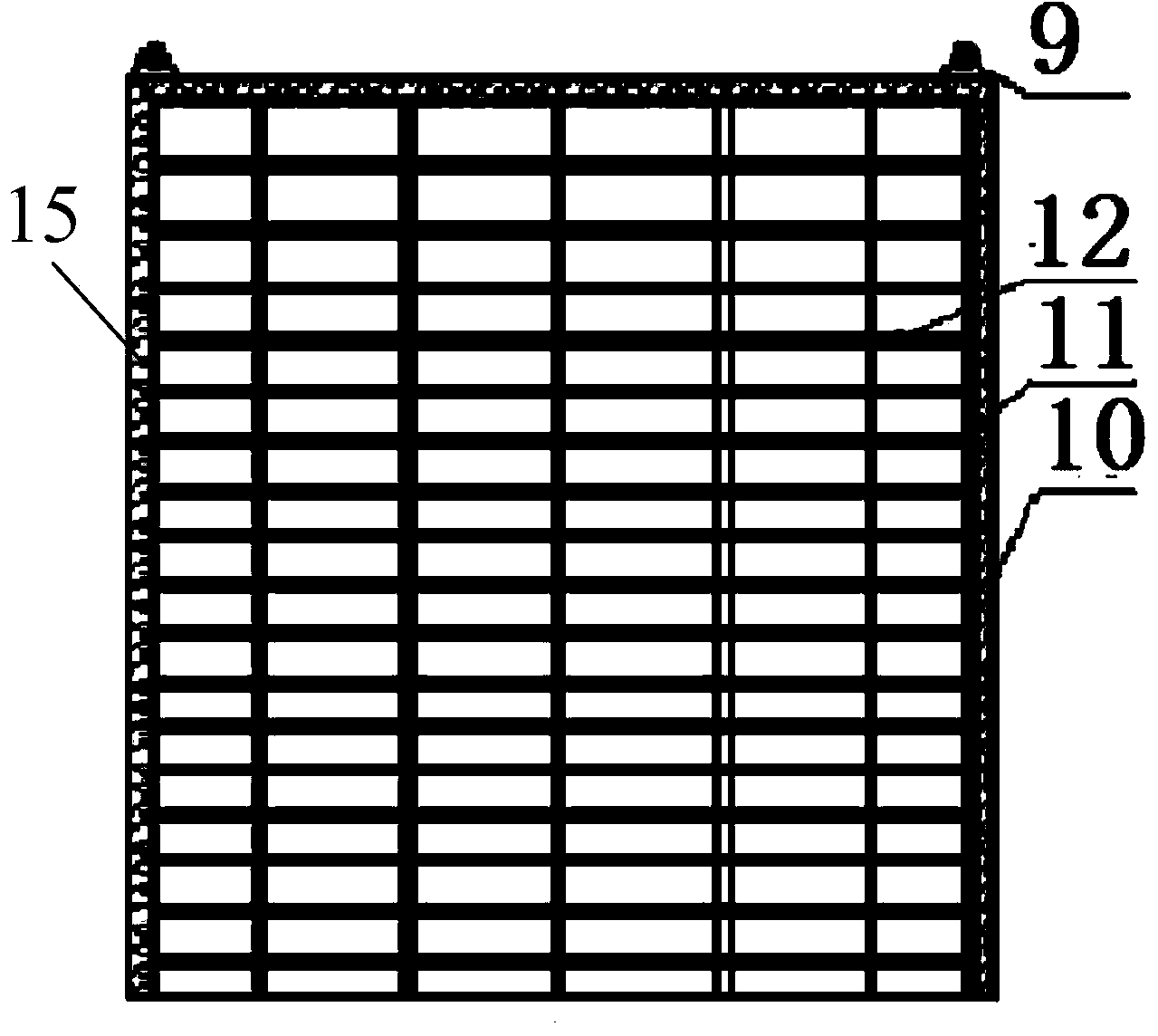

[0060] sprue diameter sprue outlet diameter The wall thickness of the middle injection pipe brick is 35mm; the inner diameter of the runner Drill diameter directly on the runner The inner runner, the upper part of the inner runner is larger and the lower part is smaller, and the difference in diameter is 10mm. The taper of the ingot mold is 2%, and the wall thickness of the ingot mold is 300mm. High-quality thermal insulation riser is used, the height of the riser is 400mm, the taper of the riser is 2%, and the thickness of the riser insulation board is 30mm; before use, the riser preheating temperature is 300°C.

[0061] The preheating temperature of the ingot mold is 80°C, and the interior is sprayed with 1mm thick zircon powder coating. The chassis is placed in the pouring pit...

Embodiment 2

[0065] In this embodiment, the weight of the round billet produced by the present invention is 15t, and the ratio of height to diameter is 5.3. The specific process parameters are as follows:

[0066] sprue diameter sprue outlet diameter The wall thickness of the middle injection pipe brick is 50mm; the inner diameter of the runner Drill diameter directly on the runner The inner runner, the upper part of the inner runner is larger and the lower part is smaller, and the difference in diameter is 15mm. The taper of the ingot mold is 4%, and the wall thickness of the ingot mold is 350mm. High-quality thermal insulation riser is used, the height of the riser is 500mm, the taper of the riser is 4%, and the thickness of the riser insulation board is 40mm; before use, the riser preheating temperature is 300°C.

[0067] The preheating temperature of the ingot mold is 100°C, and the interior is sprayed with 2mm thick zircon powder coating. The chassis is placed in the pouring ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com