Device and method for measuring three-phase permeability of supercritical CO2 emulsion by steady-state flow method

A three-phase permeability and supercritical technology, which is applied in the field of devices for measuring the three-phase permeability of supercritical CO2 emulsion by steady-state flow method, can solve the problem of complex calculation, can not guarantee close to the actual value of the experiment, and does not measure the three-phase permeability. Devices and methods, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

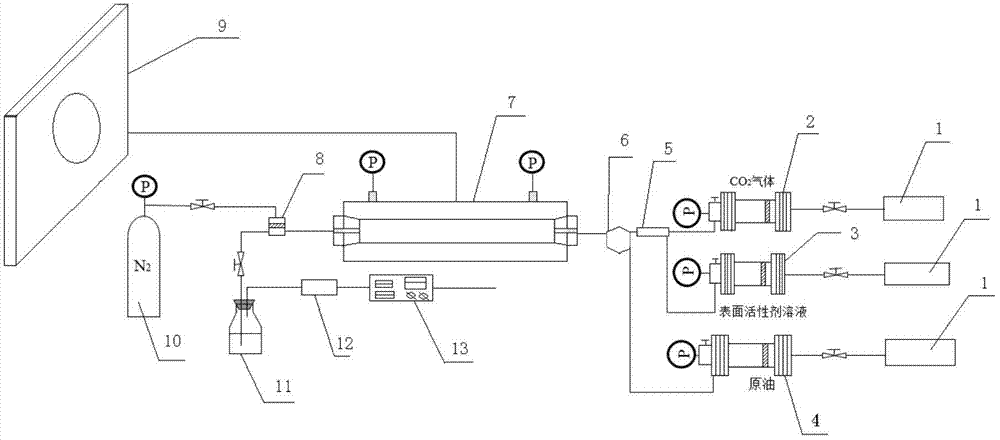

[0036] A steady-state flow method for the determination of supercritical CO 2 The device of emulsion three-phase permeability, the structure is as figure 1 As shown, it includes a transverse cylindrical one-dimensional core model 7 and a CT scanner 9 for scanning the core of the one-dimensional core model 7, and the one-dimensional core model 7 is filled with quartz sandstone cores. Specifically, the one-dimensional core model 7 includes a cylindrical shell, and a cylindrical inner cavity is arranged inside the shell, and the inner cavity is filled with quartz sand with a particle size between 50-200 meshes, and the inlet and outlet ends of the shell are respectively set With threaded interface, the length of the cylindrical lumen is 50cm and the diameter is 5cm. The CT scanner 9 adopts GE's LIGHTSPEED 8-slice spiral CT, which can realize dual-energy simultaneous scanning (DEES), and can perform CT scanning on the core under two different energies at the same time, and obtain...

Embodiment 2

[0040] A steady-state flow method for the determination of supercritical CO 2 The device of emulsion three-phase permeability, structure is shown in embodiment 1, and difference is:

[0041] The one-dimensional core model 7 includes a cylindrical shell, which is provided with a cylindrical inner cavity, and the inner cavity is filled with quartz sand with a particle size between 50-200 mesh, and the inlet and outlet ends of the shell are respectively provided with threaded joints , the cylindrical lumen has a length of 100 cm and a diameter of 10 cm.

Embodiment 3

[0043] A steady-state flow method for the determination of supercritical CO 2 The device of emulsion three-phase permeability, structure is shown in embodiment 1, and difference is:

[0044] The one-dimensional core model 7 includes a cylindrical shell, which is provided with a cylindrical inner cavity, and the inner cavity is filled with quartz sand with a particle size between 50-200 mesh, and the inlet and outlet ends of the shell are respectively provided with threaded joints , the cylindrical lumen has a length of 80 cm and a diameter of 8 cm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com