Process for producing polyoxymethylene dimethyl ether from methanol and paraformaldehyde

A technology of polyoxymethylene dimethyl ether and process methods, applied in chemical instruments and methods, preparation of organic compounds, organic chemistry, etc., can solve the problems of low yield of process products and achieve good technical effects and good selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

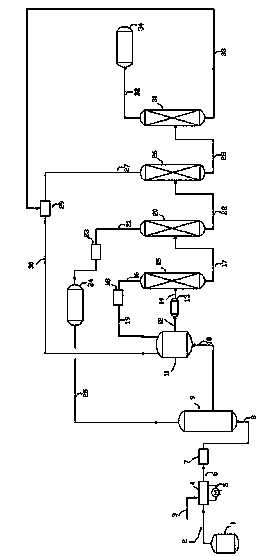

Image

Examples

Embodiment 1

[0029] In the reaction process shown in the accompanying drawings, the volume of the spray tower 9 is 5L, and the volume of the reactor 11 is 2L, equipped with an electric stirring device and heated by an electric heating mantle.

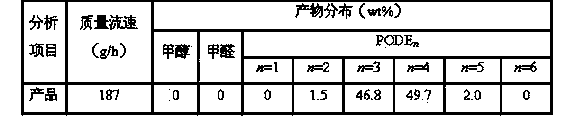

[0030] Fill 300g of HZSM-5 molecular sieve (Si / Al=30) in the liquid phase reaction kettle 11, purge the device with nitrogen, and continuously add 15000g of paraformaldehyde in the mixing tank, the temperature of the mixing tank is 250°C, the formaldehyde generated after heating The gas enters the spray tower 9 after dewatering through the drying tube, and contacts with methanol countercurrently in the spray tower. The feed rate of methanol is 93.75 g / h, the operating pressure of the spray tower is 0.3 MPa, and the operating temperature is 55°C; The formed methanol solution of formaldehyde is fed to the liquid phase reactor 11, and at the same time, a mixed solution of methylal and polyoxymethylene dimethyl ether (n=2, 5, 6) is added to the liquid ph...

Embodiment 2

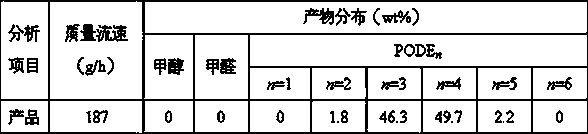

[0033] Fill 300g of ethylenediaminetetraacetic acid in the liquid-phase reaction kettle 11, purge the device with nitrogen, and continuously add 10,000g of paraformaldehyde into the mixing tank. The temperature of the mixing tank is 250°C. Then enter the spray tower 9, contact with methanol countercurrently in the spray tower, the feed rate of methanol is 62.5 g / h, the operating pressure of the spray tower is 0.3 MPa, and the operating temperature is 55 °C; the methanol solution of formaldehyde formed Feed to the liquid phase reactor 11, and simultaneously add the mixed solution of methylal and polyoxymethylene dimethyl ether (n=2,5,6) into the liquid phase reactor 11, the feed rate is 45.5g / h respectively, 46g / h. The operating conditions of the liquid phase reactor 11 are a reaction temperature of 130° C. and a reaction pressure of 1.50 MPa. The reaction output enters the anion exchange resin bed layer.

[0034] Other operations are the same as in Example 1, continuous reac...

Embodiment 3

[0036] Fill the liquid phase reaction kettle 11 with 300g of strong acidic styrene-based cation exchange resin, purge the device with nitrogen, and continuously add 7500g of paraformaldehyde into the mixing tank, the temperature of the mixing tank is 250°C, and the formaldehyde gas generated after heating is dried After removing water, the tube enters the spray tower 9, and contacts with methanol countercurrently in the spray tower. The feed rate of methanol is 93.75 g / h, the operating pressure of the spray tower is 0.3 MPa, and the operating temperature is 55 ° C; the formed formaldehyde The methanol solution is fed into the liquid phase reactor 11, and the mixed solution of methylal and polyoxymethylene dimethyl ether (n=2,5,6) is added to the liquid phase reactor 11 at the same time, and the feeding rate is 44.8g respectively / h, 69.5g / h. The operating conditions of the liquid phase reactor 11 are a reaction temperature of 100° C. and a reaction pressure of 0.50 MPa. The r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com