Flame retardant medium density fiberboard and manufacturing method therefor

A technology of medium density and fiberboard, applied in the field of flame retardant medium density fiberboard and its manufacturing, can solve the problems of limited use, high price, heavy weight of medium density fiberboard, etc., and achieve weight reduction, low cost and good heat insulation The effect of fire resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

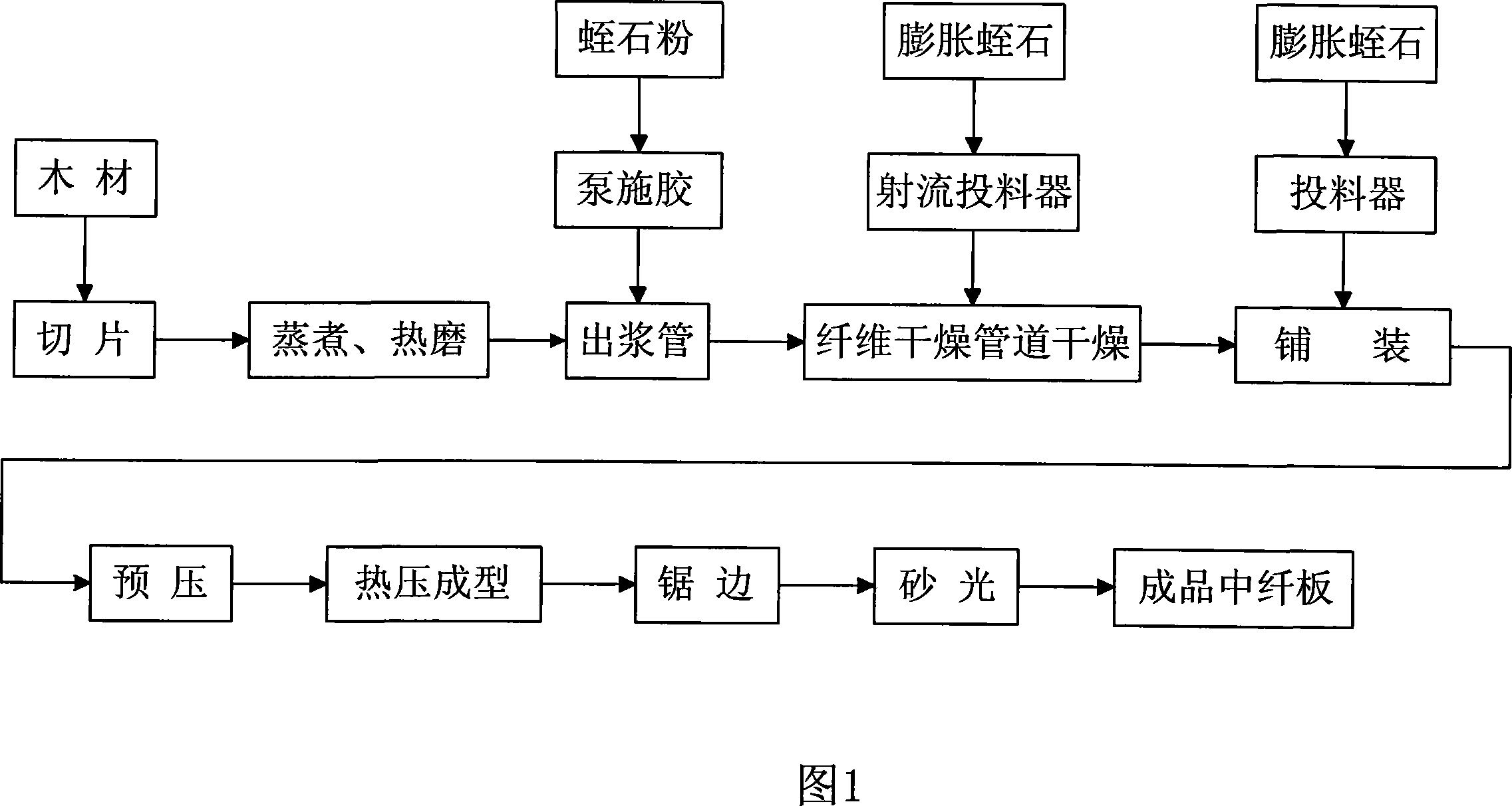

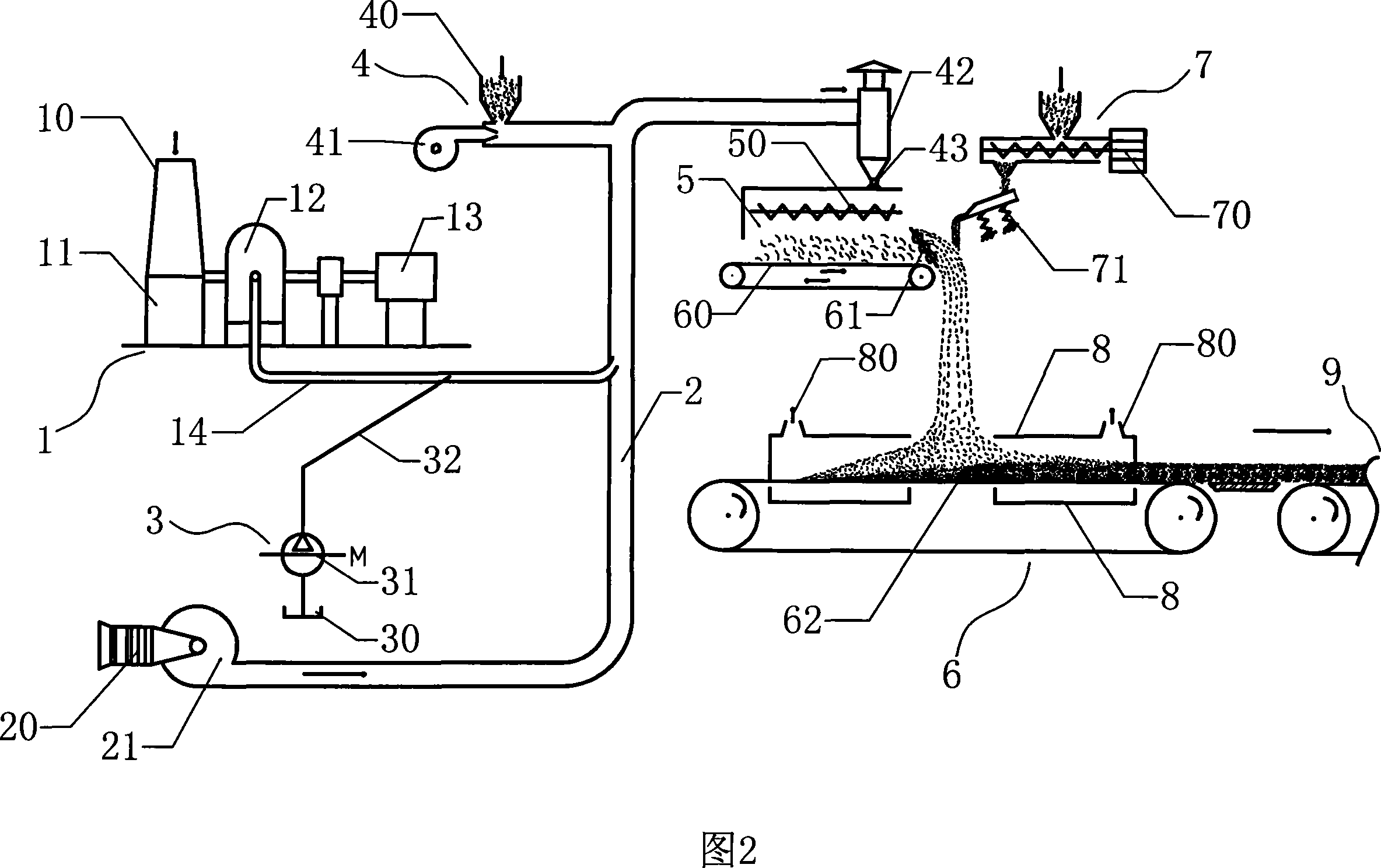

[0019] The specific embodiments of the present invention will be described in further detail below in conjunction with the accompanying drawings.

[0020] The flame retardant medium density fiberboard of the present invention, the main raw material includes wood fiber material, adhesive and expanded vermiculite particle flame retardant material, the addition amount of expanded vermiculite particle is 20%~80% of the dry fiber material weight, the adhesive addition amount It is 15%-20% of the weight of the dry fiber material (the amount of the adhesive added is calculated based on the solid content of the adhesive, taking urea-formaldehyde glue as an example, the solid content is about 60% in the normal use state.). Among them, the particle size of the expanded vermiculite used is generally between 100 and 8000 μm, and the quality of the medium density fiberboard produced between 5 and 50 times the expansion rate is better. Of course, a small amount of vermiculite powder can als...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com