Cooling assembly

a cooling assembly and cooling device technology, applied in air humidification systems, heating types, lighting and heating apparatus, etc., can solve the problems of limited water supply, limited use, and insufficient quantities of water, and achieve the effects of convenient transportation, simple, reliable, and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The detailed description of the invention will now be provided with respect to two different preferred embodiments:

[0044] Low Humidity Air Conditioner Embodiment:

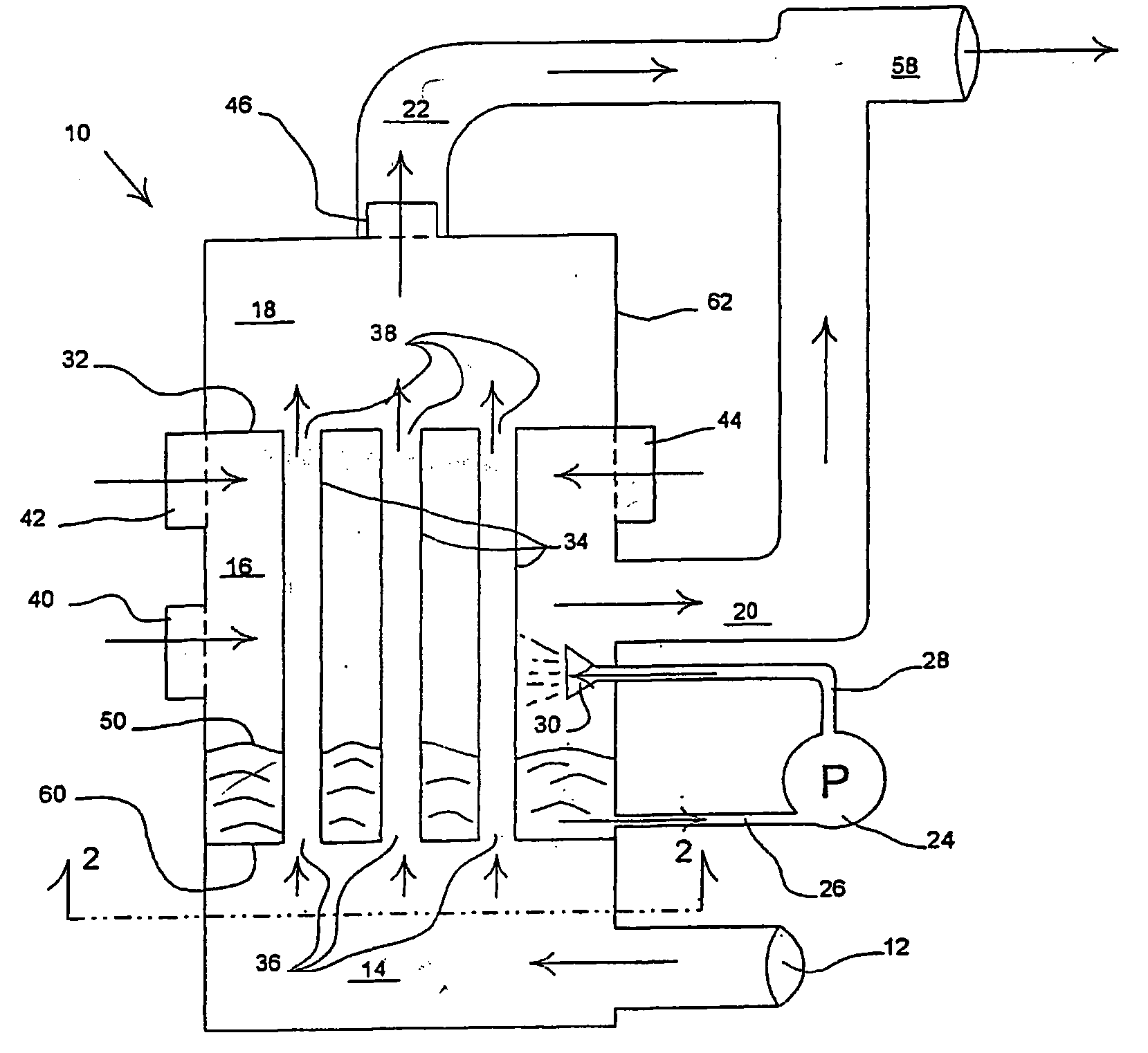

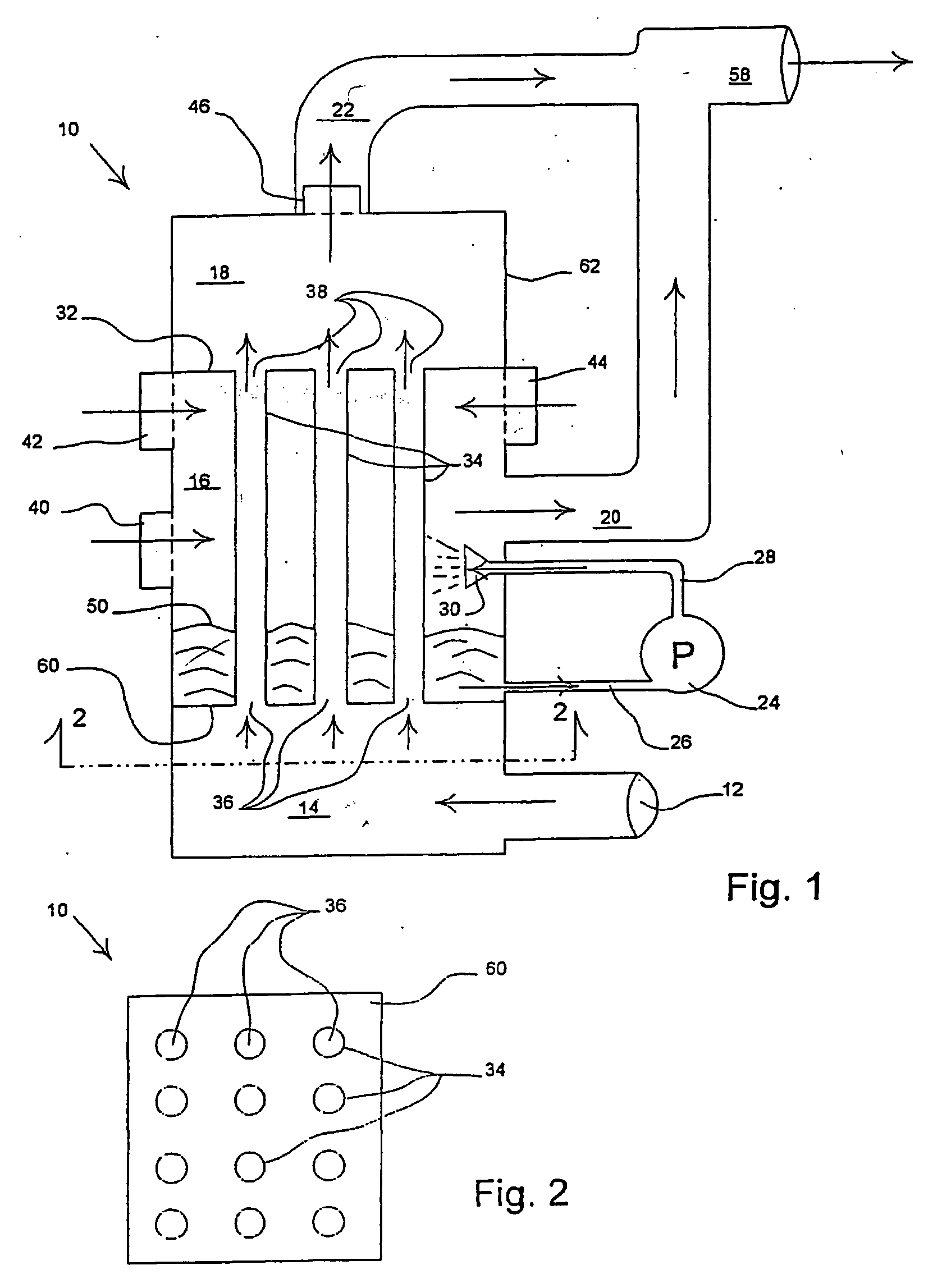

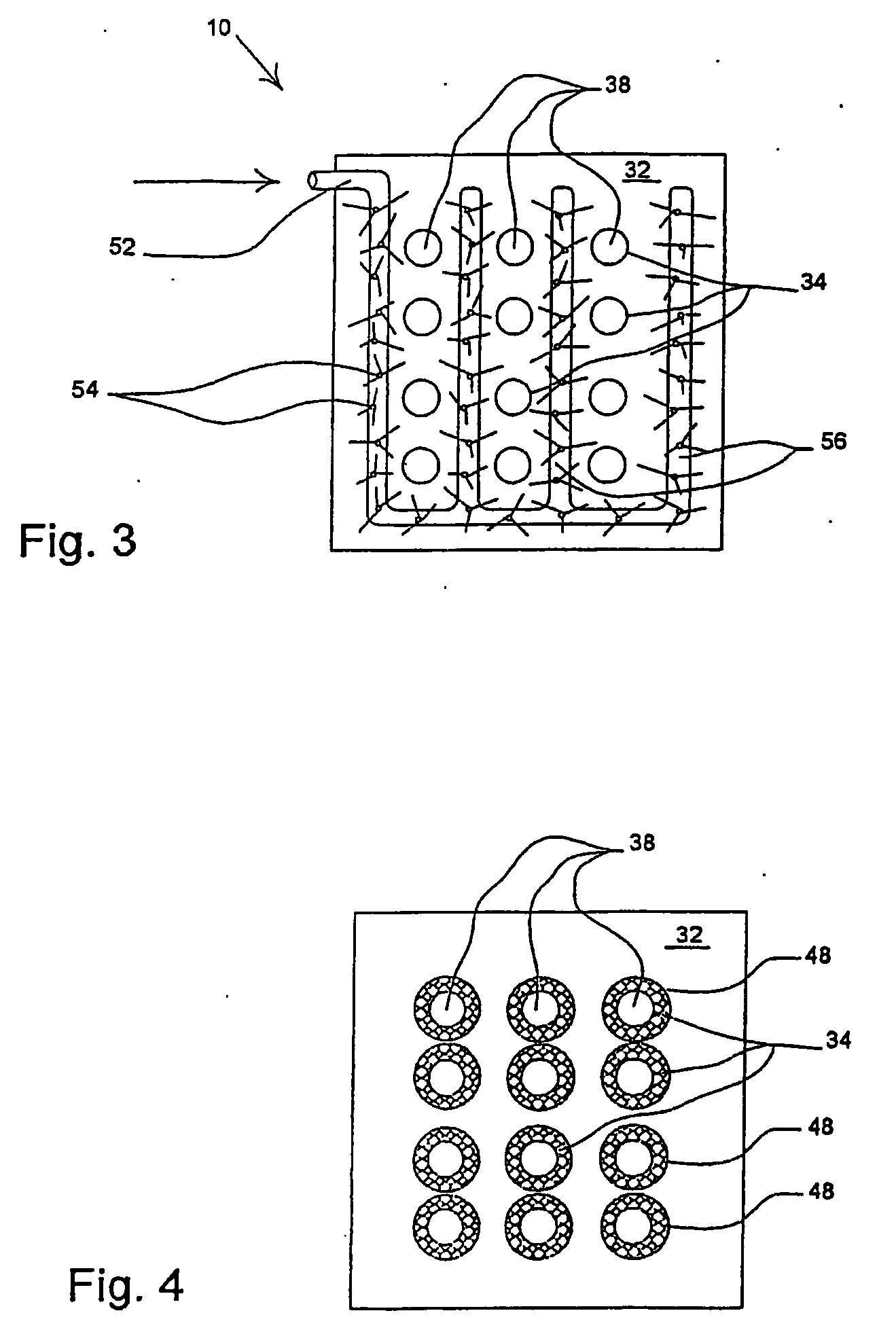

[0045] Referring now to the drawings wherein like reference numerals designate identical or corresponding parts throughout the several views, there is illustrated generally at 10 a tube and shell heat exchanger, which is particularly adapted for use as a low power air conditioning unit in high temperature, low humidity conditions with structures that are not hermetically sealed. The floor plan of such a structure is indicated generally at 64 in FIG. 5.

[0046] Heat exchanger 10 is confined within external case 62. For purposes of illustration, external case 62 is shown as rectangular, but other arcuate, spherical, or cylindrical forms are contemplated within the scope of the present invention.

[0047] Air, preferably internal air from near the ceiling of a structure that is to be cooled, is drawn into the tube side o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com