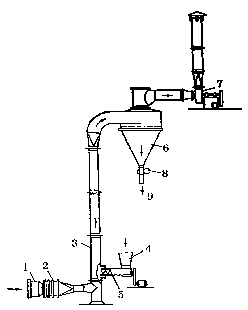

Long-pipe airflow dryer

An air drying and dryer technology, applied in the field of mechanical devices, can solve the problems of long drying pipes, building construction, operation and inconvenience of equipment maintenance and so on.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention will be further described below in conjunction with the accompanying drawings.

[0011]

[0012] A long tube type airflow dryer, the main part of the dryer is a drying tube 3 with a length of several meters to more than ten meters, the material and hot air enter at the lower end of the drying tube 3, and the hot air passes through the air filter before entering 1 and preheater 2, the material is added by the screw feeder 5 through the hopper 4, and the dried material is separated from the hot air and volatilized moisture in the cyclone separator 6, and is discharged by the product outlet 9 through the air locker 8 out.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com