Drying apparatus for drum washing machine of switching type drying mode

A technology of drum washing machine and drying method, which is applied in the direction of washing device, washing machine with container, textile and paper making, etc. It can solve the problems such as the difficulty of designing drying device, achieve the effect of simplifying manufacturing equipment and manufacturing procedures, and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

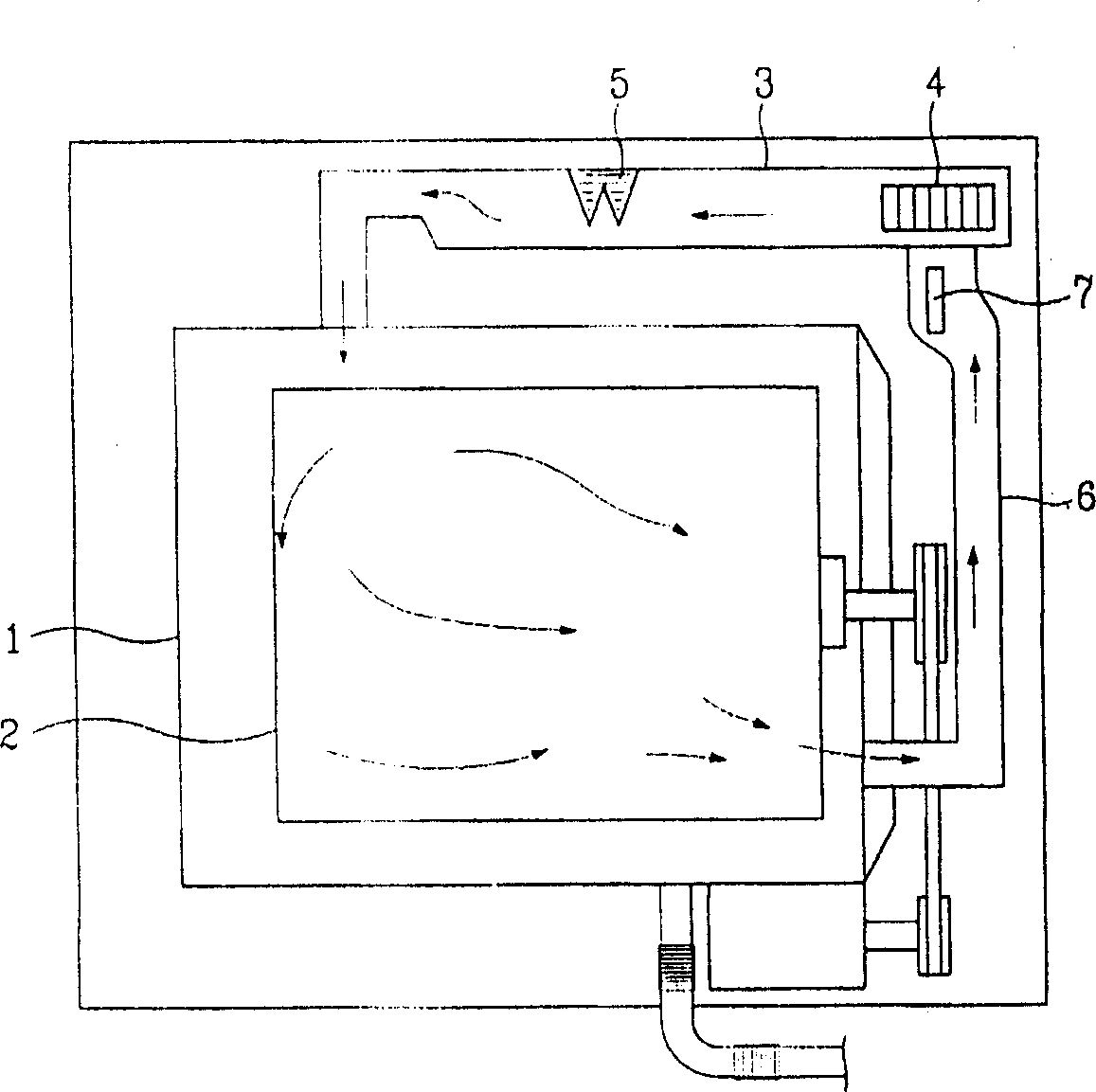

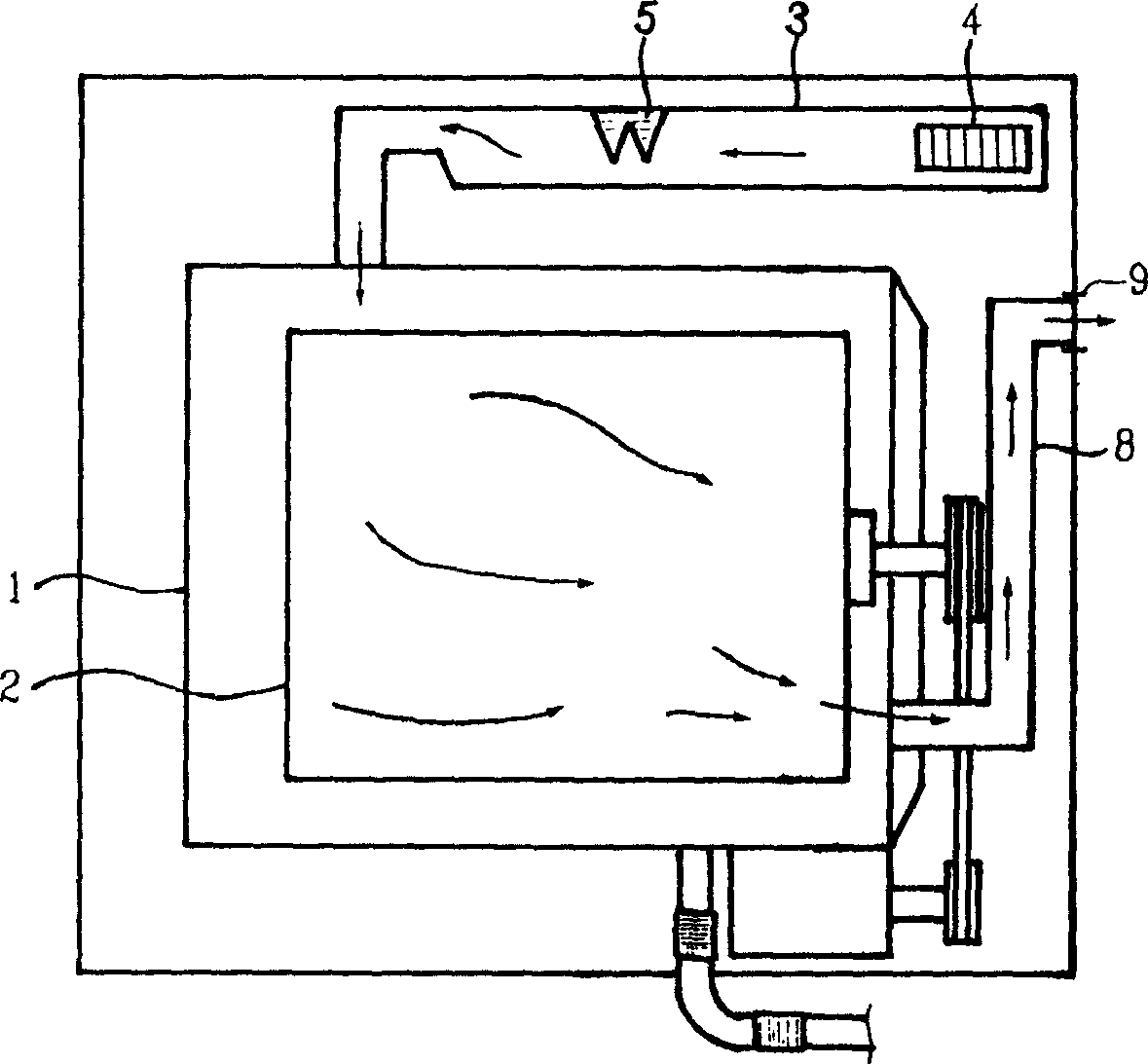

[0025] The drying device of the drum washing machine in the conversion drying mode of the present invention comprises a washing tub 1 and a drying pipe 2 for supplying heated air to the washing tub 1. A fan 4 is arranged in the drying pipe 2. A condensing pipe 6 is arranged on the side, and the humid air discharged to the outside of the washing tub 1 by the blowing fan is dried and returned to the condensing pipe 6 of the washing tub 1 through the drying pipe 2, or in the washing tub 1 One side of the exhaust pipe 8 can replace the condensation pipe 6, and the exhaust pipe 8 can prevent the humid air discharged to the outside from returning to the washing tub 1.

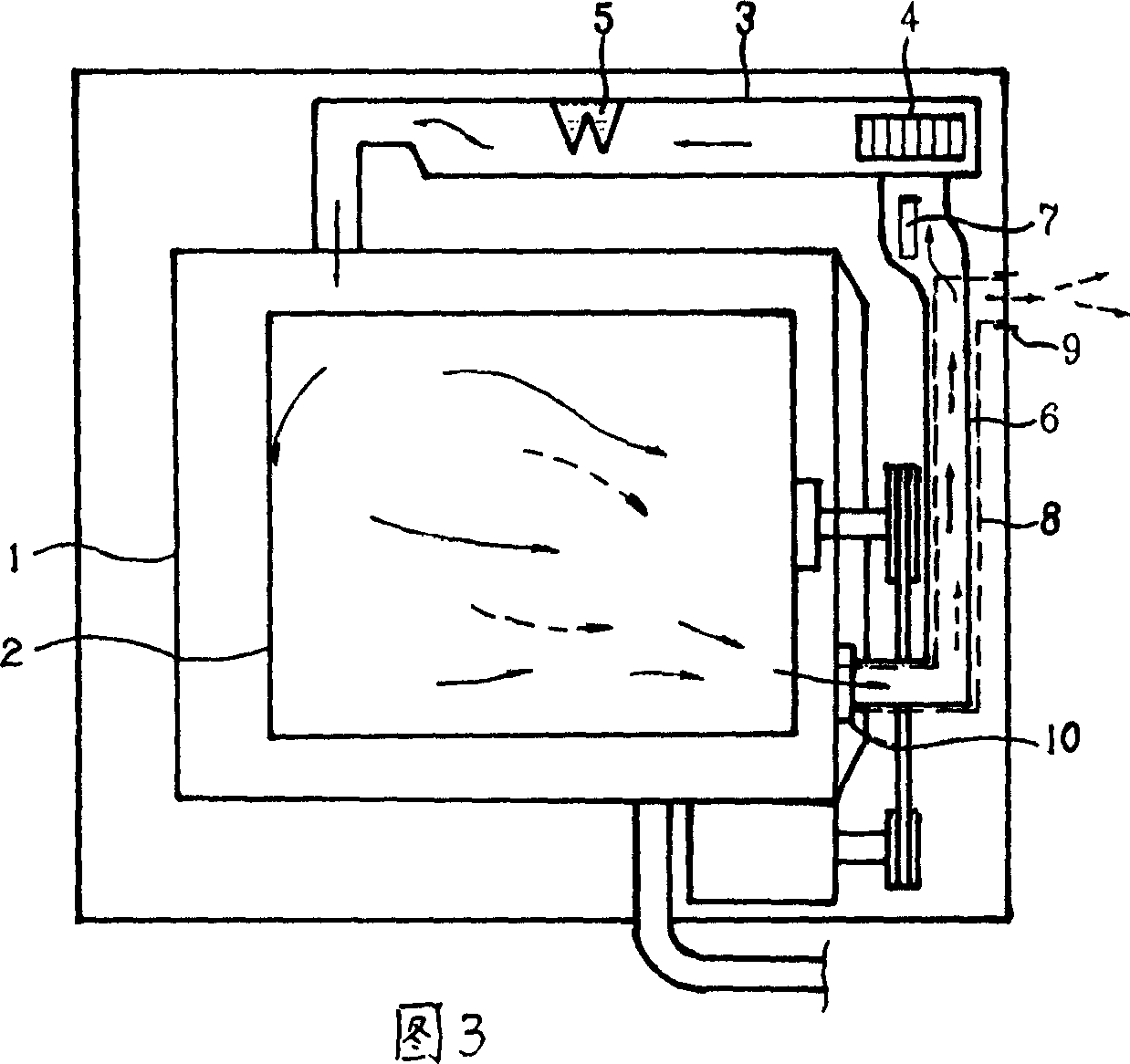

[0026] The drying device of the drum washing machine in the conversion drying mode will be described below with reference to FIG. 3 .

[0027] Figure 3 shows that on one side of the w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com