Fan mill front counter flow type furnace-smoke drying dewatering direct blowing pulverization system

A pulverizing system, counter-flow technology, applied in the preparation of block/powder fuel, supply/distribution of block/powder, petroleum industry, etc., can solve the problem of limited use, huge investment, and high cost of lignite upgrading technology And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

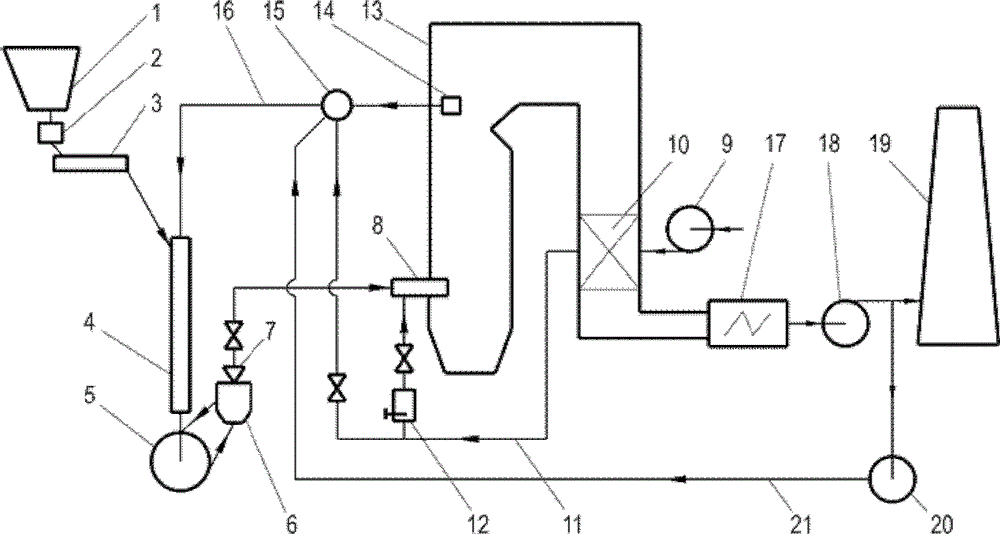

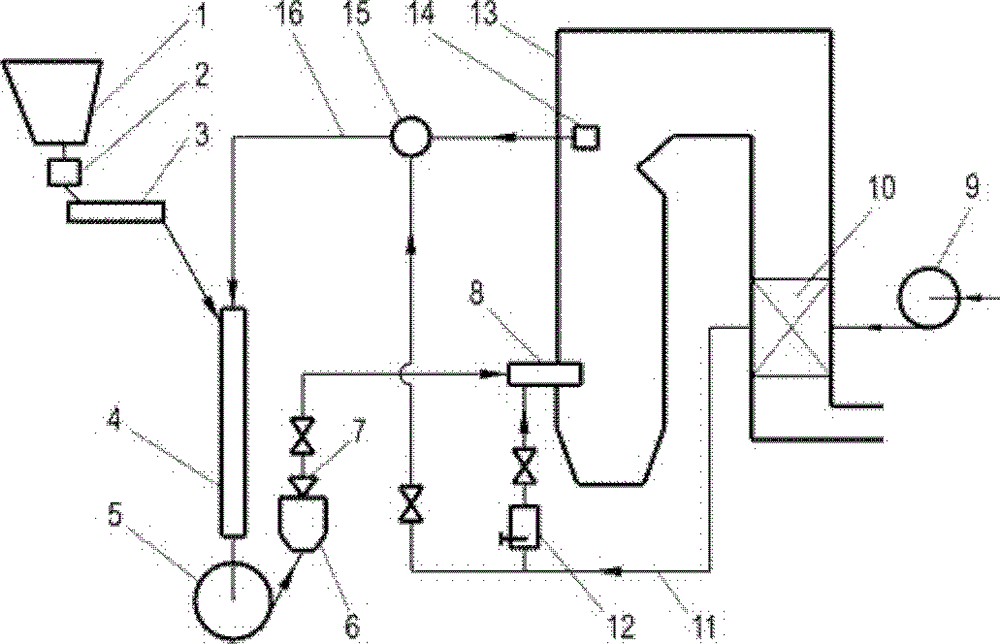

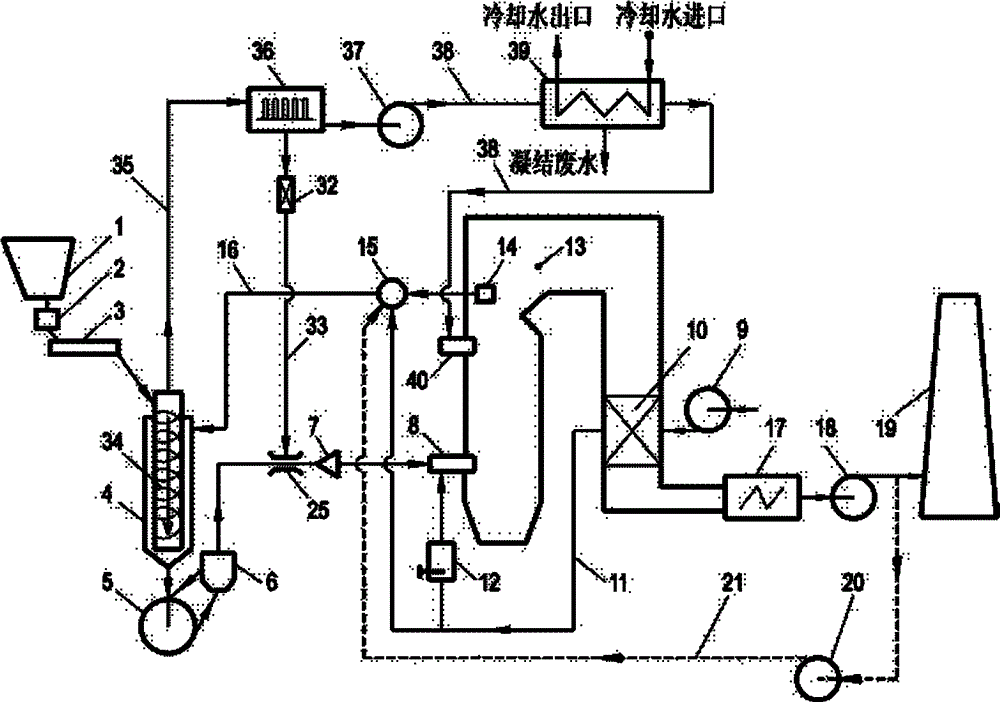

[0026] like image 3 As shown, in the direct-blown pulverizing system of the present invention for the counter-flow furnace smoke drying and dehydration before the three-media fan grinding, the raw coal bunker 1 is connected to the automatic scale 2, and the automatic scale 2 is connected to the coal feeder 3, and the coal feeder 3 is then connected to the coal feeder 3. Connect the descending drying pipe 4, the descending drying pipe 4 is then connected to the fan pulverizer 5, the fan pulverizer 5 is then connected to the coarse powder separator 6, the coarse powder separator 6 is connected to the pulverized coal mixer 25, and the pulverized coal mixer 25 is connected to the coal The pulverized coal distributor 7 is connected to the burner 8 of the boiler 13 , and the downward pipe 4 has a gas generator 34 . The upper part of the furnace of the boiler 13 has a smoke port 14 , and the smoke port 14 is connected to the first air inlet of the mixing chamber 15 . A blower 9 is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| heating value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com