Gas/dual-fuel engine intake manifold gas injection device

A dual-fuel engine and intake manifold technology, which is applied to combustion engines, machines/engines, internal combustion piston engines, etc., can solve the problems of engine emission and economical decline, uneven intake of each cylinder, and combustion deterioration. Achieve the effects of improving fuel economy, improving combustion quality, and enhancing mixing degree

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described in detail below in conjunction with the drawings and specific embodiments.

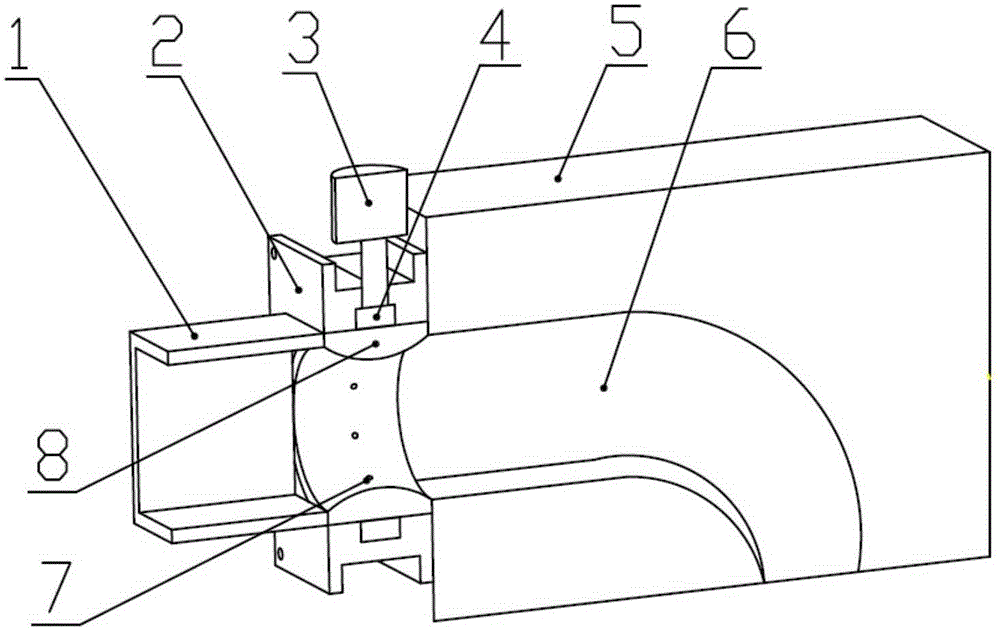

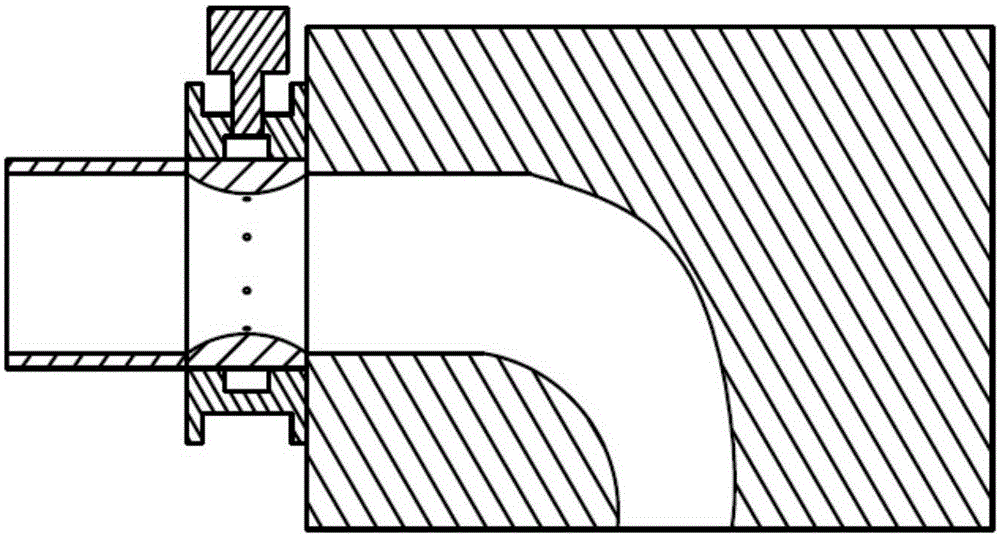

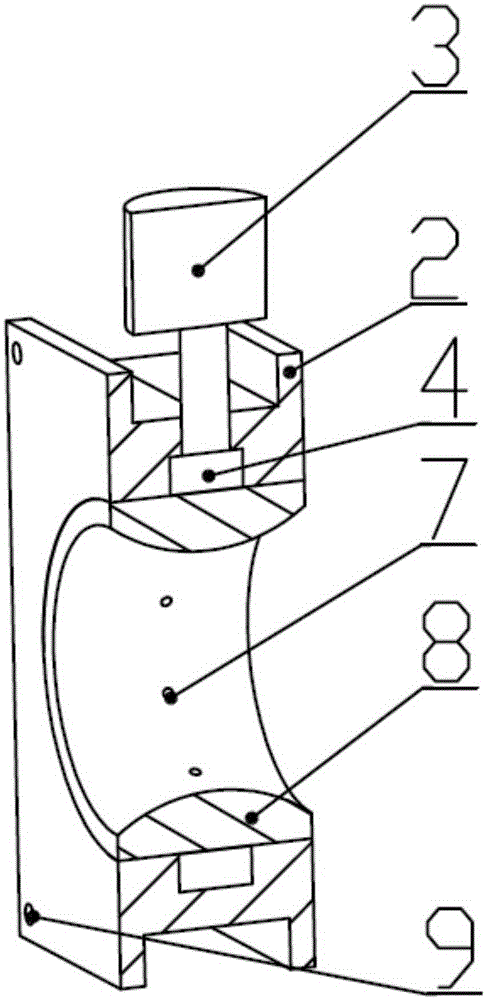

[0014] Combine Figure 1~2 The technical solution of the present invention is realized in this way. A gas / dual fuel engine gas injection device is composed of an intake manifold 1, a cylinder head 5, a gas injection solenoid valve 3, and a gas injection structure. The inside of the gas injection structure is a venturi tube 8, the external frame 2 is machined with a gas supply ring groove 4, the external frame 2 and the internal venturi tube 8 are assembled together by interference fit, and the gas injection structure is installed in the intake manifold 1 and The connection of the intake duct 6 in the cylinder head is fastened by bolts, and a sealing ring is placed between the two contact surfaces to prevent air leakage. A gas injection solenoid valve 3 is installed at the top of the gas injection structure. The upper surface of the outer frame 2 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com