Chain coal burning boiler with automatic ash discharging device

A coal-fired boiler, chain-type technology, applied in the boiler field, can solve problems such as pollution, high labor intensity, and influence on boiler combustion, and achieve the effects of reducing pollution, reducing labor intensity, and improving combustion quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

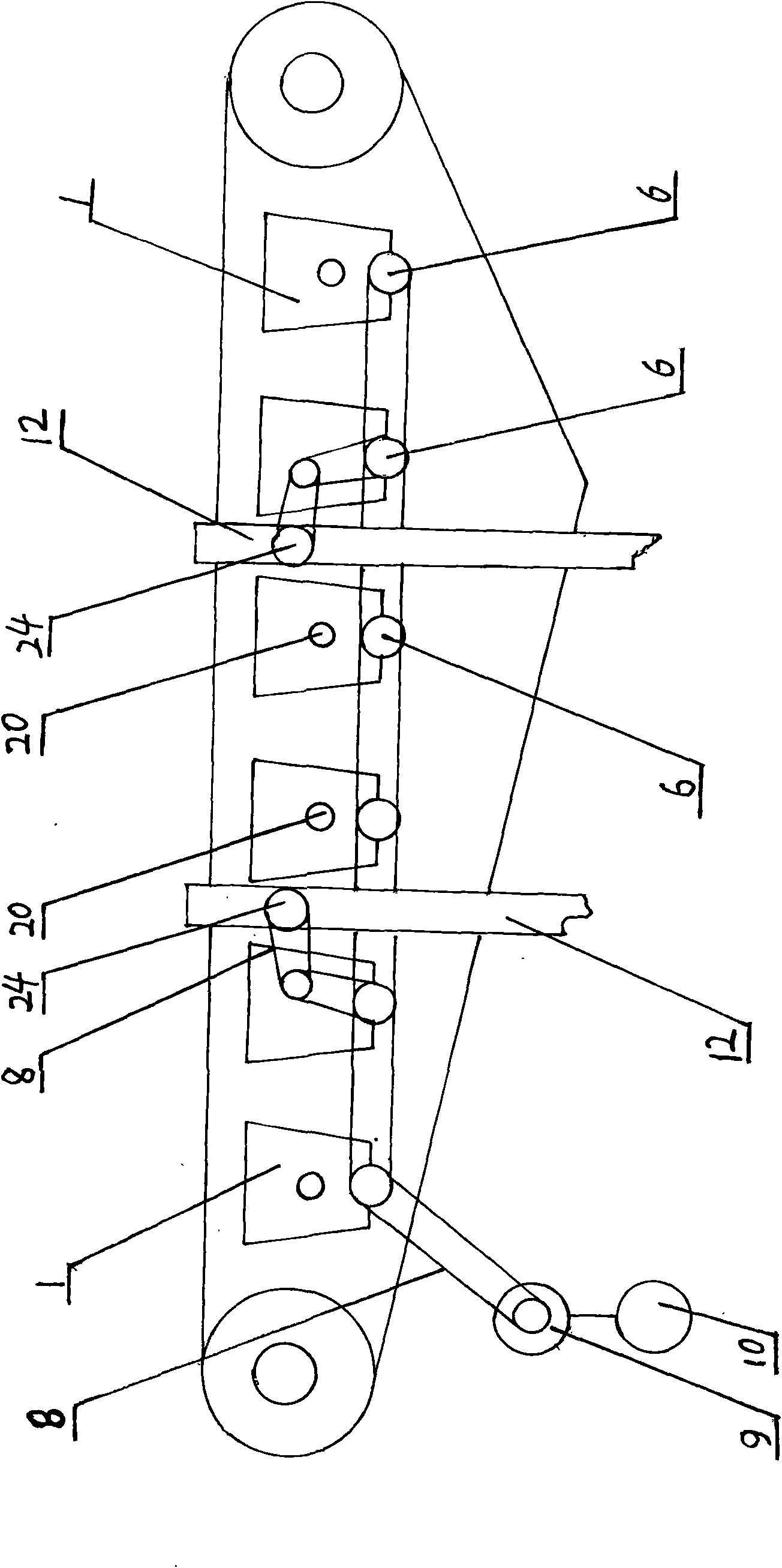

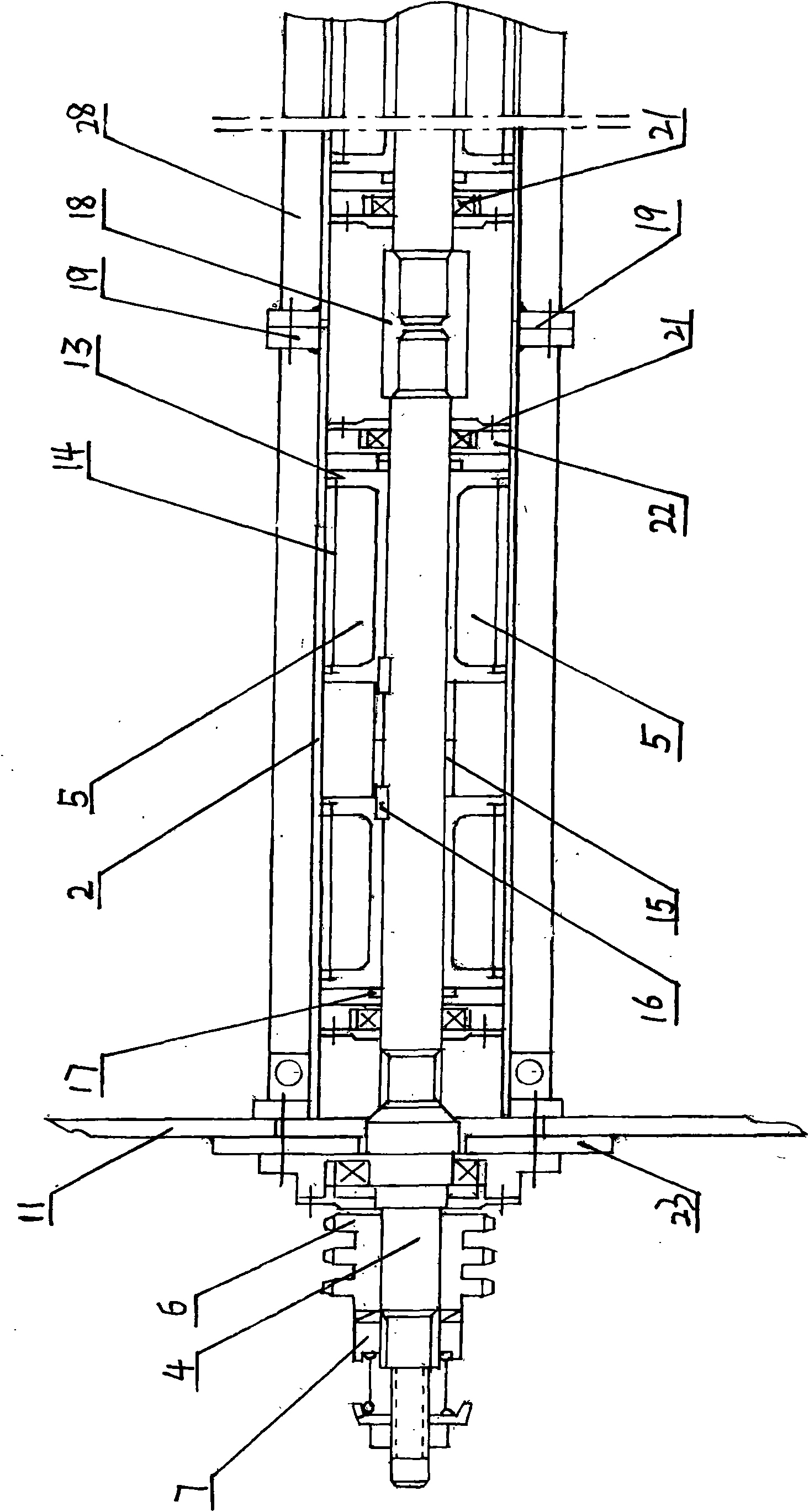

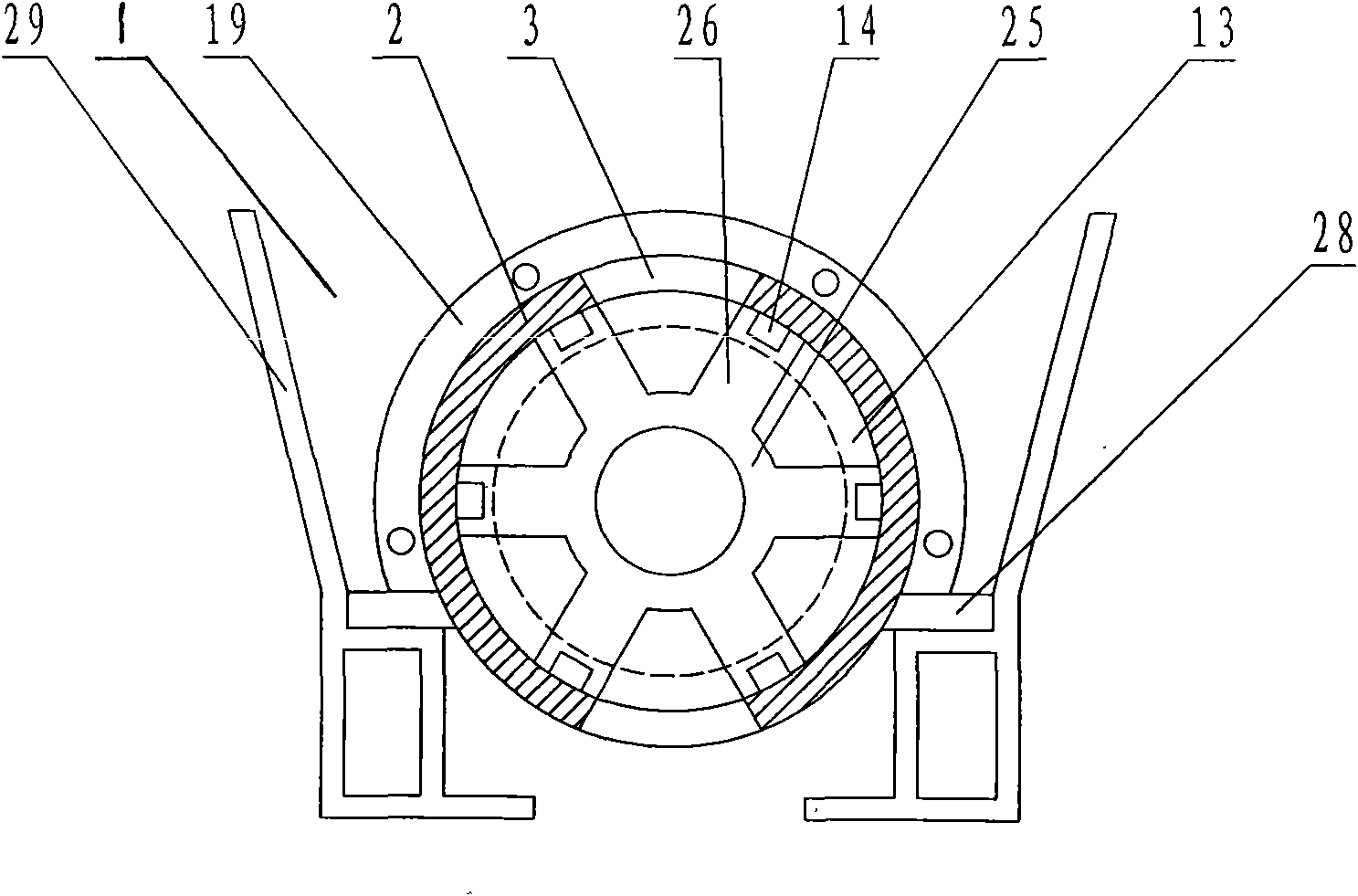

[0017] A chain-type coal-fired boiler with an automatic ash discharge device, including an air chamber 1, the bottom of which is sealed and fixed with a sleeve 2, and the upper and lower sides of the cylindrical surface of the sleeve 2 are provided with exhaust pipes at positions corresponding to each air chamber 2. The ash hole 3, the casing 2 is provided with a shaft 4 passing through the side plate 11 of the wind chamber, and the shaft 4 is fixed with an ash discharge wheel 5 that is equal to the inner diameter of the casing 2 and corresponds to the ash discharge hole 3. The ash discharge wheel 5 It is composed of the hub, the wheel and the partitions at both ends of the wheel. One end of each rotating shaft 4 outside the air chamber side plate 11 is covered with a sprocket 6, and the outer end surface of the sprocket 6 is engaged with a safety clutch 7 fixed to the rotating shaft 4. A chain 8 is set between every adjacent two sprockets 6, and the sprocket 6 on one of the ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com